OSPDN20A-EN

7/8

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

AIR PIPING

• Pneumatic actuator has an air supply ports to operate

piston.

Double-acting type

TAD-040 : Rc 1/8

TAD-050 to 160 : Rc 1/4

Single-acting type

TAO / TAC : Rc 1/4

• Piping of double-acting type is connected by seal tape

on PORT A / B. Piping of single-acting type is put seal

tape only on the air intake port.

• The air supply port may be damaged if over-tightened.

Please lightly tighten by hand.

• Never put anything on the actuator or make it into a

foothold.

OPERATION

AIR SOURCE

• Use the filtered dry air (less than 40 ).

• Extra attention is needed where it's cold climate

(below 5 °C).

• When air pressure is high, reduce it to standard

pressure (0.4 to 0.7 MPa). Air pressure should not

exceed 0.7 MPa during operation test.

• Capacity of compressor and air tank are to be

calculated by capacity of piping and air consumption.

A margin of 30 % is required.

TEST OPERATION

Check the operation of pneumatic actuator before

fluid enters the piping.

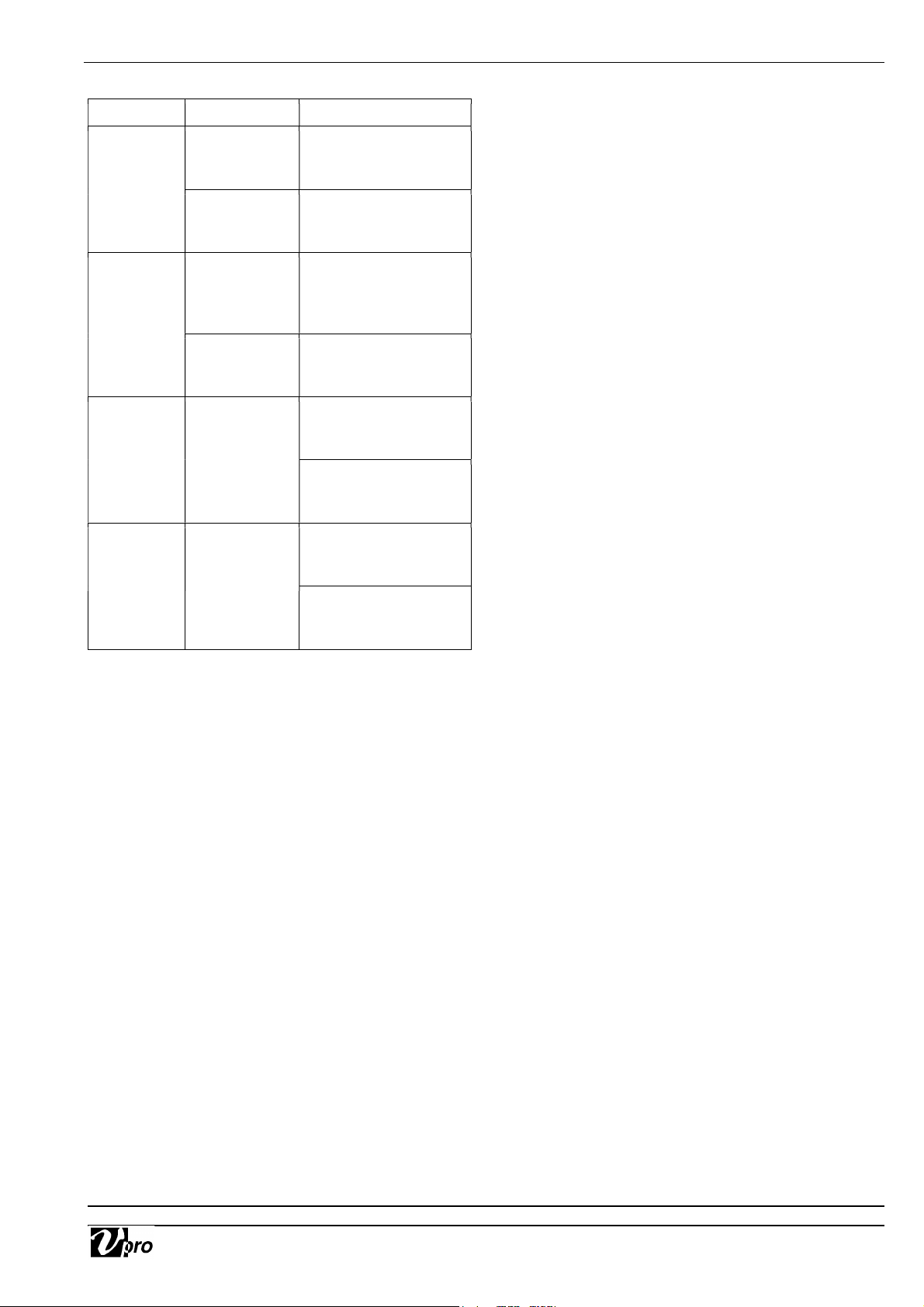

Double-acting

type

Stop the air from the air source.

Release the residual pressure in the

air cylinder. Open the air equalizer.

Move the manual shaft of actuator

with a wrench.

Single-acting

type

Send the standard pressure air.

Confirm the opening / closing

operation by slowly moving the

actuator.

TESTING

After piping, check following points.

• Piping is correct.

• Air or fluid leakage from connection. Flow direction

of air is correct.

• Air pressure is in the range.

• Nothing interferes with operation when limit switch

or solenoid valve is attached.

ATTENTION

The opening and closing operation of the pneumatic

actuator is fast, which may affect the product life.

Please adjust the operation time of pneumatic

actuator using a speed controller.

Valve size Adjustment of operation time.

080 to 300 mm More than 2 seconds.

MANUAL OPERATION

• Double-acting; stop the air supply and do not leave

the air inside of cylinder.

• Single-acting; cannot be operated manually.

Optional code with the handle: TAO-MT / TAC-MT.

• Before automatic operation, be sure to remove

wrench.

OPERATION (TAD)

After turning air pressure to 0, turn manual shaft

slowly with a smooth-jawed wrench to check the

direction of OPEN/SHUT position.

MAINTENANCE

• Do the routine maintenance at least once in half a

year.

• Do not set or take spring unit parts apart after

installing the pneumatic single-acting actuator.

Can be used with no oil supply.

• Confirm the air leakage.

• Confirm the air supply pressure.

• Confirm the dirt or grit inside of cylinder.

Lubrication Procedure (TAD / TAO / TAC)

In case of lubricating, use turbine oil or the

equivalent through a lubricator. (ISO VG 32.46).

Once lubricate, do the regularly.

Inspection items

• Confirm operation of opening and closing.

• Confirm whether screws are loose or not.

• Confirm the fluid temperature or pressure.

• Confirm the leak from valve stem.

• Confirm the bolt tightening torque.

PORT A PORT B

Air intake