IEPC EPC9179 User manual

Evaluation Boards

EPC9179, EPC9180, and EPC9181

Quick Start Guide

Using EPC2252, EPC2218A, and EPC2204A

Revision 2.0

QUICK START GUIDE Evaluation Boards EPC9179/80/81

EPC – POWER CONVERSION TECHNOLOGY LEADER | EPC-CO.COM | ©2023 | For more information: info@epc-co.com | 2

DESCRIPTION

The EPC9179, EPC9180, and EPC9181 are a set of evaluation boards primarily

intended to drive laser diodes with high current pulses with pulse widths

in the single digit nanosecond range, from tens to hundreds of amps.

The high performance is enabled by EPC’s gallium nitride enhancement

mode (eGaN®) FET technology. The boards use the fully automotive

qualied EPC2252 (80 V 75 A), EPC2218A (80 V, 231 A), or EPC2204A

(80 V, 125 A). The boards are accompanied by the EPC9989 interposer

board to provide the user with a simple means of mounting a small set of

commercially available lasers. The EPC9989 has a collection of breakaway

5 mm square interposer PCBs with footprints for dierent lasers and various

alternative loads. The use of the interposers allows many dierent lasers or

other loads to be mounted on the evaluation boards. The boards do not

include a laser diode or load, which must be supplied by the user.

All three boards have the same function and operation, diering only

in peak current and pulse width. Hence, this Quick Start Guide (QSG) will

refer to them collectively by EPC9179/80/81 unless otherwise specied.

The key part of the EPC9179/80/81 is the resonant discharge power stage,

comprising a ground-referenced eGaN FET driven by a Texas Instruments

LMG1020 gate driver. The FET is used to discharge a charged capacitor

through the stray inductance of the load. The eGaN FET enables the use

of a high charging voltage and can turn on in ~1 ns or less, which allows

peak discharge currents to be reached in a few nanoseconds or less.

The printed circuit board is designed to minimize the power loop

inductance and common source inductance while maintaining mounting

exibility for a laser diode or other load. It includes multiple PCB-integrated

high bandwidth passive probes for the simplied measurement of key

circuit voltage and current values, and is equipped with SMA connectors

to provide a high speed connection to instrumentation. In addition, the

user can enable an easily adjustable narrow pulse generator (NPG) capable

of sub-nanosecond precision. As shipped, the board is designed to be

triggered from 3.3 V logic, but is equipped with both a logic level translator

and a dierential receiver (LVDS, CML, LVPECL, etc.) which can be modied

to accommodate dierent use cases. Finally, the board can also be used for

other applications requiring a ground-referenced eGaN FET with ultrafast

switching capability, e.g. Class E ampliers or similar. In addition, footprints

are included on the PCB to simplify the use of some common alternative

laser driving techniques. A simplied block diagram of the circuit is given

in Figure 1.

Additional information on the EPC9179/80/81 is available from EPC at

www.epc-co.com. The full schematics, bill of materials (BOM), and PCB

layout les, along with links to information and datasheets on the EPC2252,

EPC2218A, and EPC2204A AEC-Q101 automotive qualied eGaN FETs can

be found at the following links to the evaluation board product pages:

EPC9179, EPC9180, EPC9181. The datasheets and schematics should

be read in conjunction with this quick start guide (QSG). In addition, EPC

provides an application note: AN027 eGaN FETs for Lidar – Getting the

Most Out of the EPC9126 Laser Driver. While the note discusses the

EPC9126 laser driver, the methods and analysis are directly applicable to the

EPC9179/80/81.

Table 1: Performance Summary (TA= 25°C) EPC9179/80/81

Symbol Parameter Min Nom Max Units

VLogic

Gate drive and

logic supply 5.5 12

VVBUS Pulse charging supply 0

70

VIN Input voltage range

0

5

tPIN Input pulse width 2 ns

FPIN

Pulse input frequency

(does not account for

thermal limitations)

0

Please see Table 2

for maximum

recommended

pulse frequency.

kHz

LASER SAFETY WARNING: This board is capable of driving

laser diodes to generate high power optical pulses. Such pulses

are capable of causing PERMANENT VISION DAMAGE AND

BLINDNESS as well as additional injury or property damage.

Laser diodes may emit infrared (IR) light that is invisible to the

user, but which can still cause PERMANENT VISION DAMAGE

AND BLINDNESS as well as additional injury or property

damage. User is fully responsible for following proper laser

safety procedures to prevent injury or damage.

Figure 1. Block diagram of EPC9179/80/81 development board

RSHUNT

Shunt (J2)

VBUS D1,D2, D3

Optional

VOUT (J3)

PW ADJ (P1)

Cap (J1)

Input select

(J10)

Laser diode or

other load

V3V3

V3V3

V5V0

5V supply

V5V0

VGS

(J6)

RCHRG LSTRAY

CRES

(J4)

VGDIN

(J5)

VLogic (J9)

U1

Q1

+

–

+

–

Narrow pulse

generator

LDO

Enable

Disable

Single-ended (SE)

Input (J9)

Dierential (DIFF)

Input (J11)

3.3V supply

LDO

Table 1 provides the recommended operating conditions for the

EPC9179/80/81. These conditions consider the electrical characteristics of

the unmodied board, and do not take into account thermal limitations,

since the latter depend on the load and use case.

QUICK START GUIDE Evaluation Boards EPC9179/80/81

EPC – POWER CONVERSION TECHNOLOGY LEADER | EPC-CO.COM | ©2023 | For more information: [email protected] | 3

MAIN FEATURES

• High current pulse generation with nanosecond pulse width

• Integrated high bandwidth measurements for key waveforms

• Optional narrow pulse generator to simplify operation with typical pulse

and function generators

• Single-ended or dierential logic inputs

OPERATING PRINCIPLE

The EPC9179/80/81 is intended as both a evaluation board and a exible

development platform. It is functional out of the box, but is designed to

be modied to accommodate a broad range of applications. It is highly

recommended that the user read the entire guide, especially the section

ADDITIONAL FEATURES, in order to get maximum value from the

EPC9179/80/81.

The EPC9179/80/81 is shipped as a resonant capacitive discharge

laser diode driver. Please refer to the block diagram (Figure 1) and the

schematic corresponding to the board of interest. It has several possible

modications (section ADDITIONAL FEATURES), but only the basic

operation will be covered in this section. The EPC9179/80/81 operating

principle is to charge the energy storage capacitance CRES comprised of

{C2, C3, C4, C5, C6 } through the resistor RCHRG comprised of {R4, R5, R6,

R7}, and when triggered, discharge CRES through inductance LSTRAY and

the laser diode or load U1. The stray inductance LSTRAY is a simplied

representation of the total parasitic inductance of the power loop, and

it is not a component mounted to the PCB. The capacitance CRES and the

inductance LSTRAY form the resonant network. Please see AN027 eGaN

FETs for Lidar – Getting the Most Out of the EPC9126 Laser Driver for

a complete description of resonant discharge laser driver operation.

The trigger pulse can be controlled from two dierent inputs. As shipped,

it is controlled via an input pulse that is delivered to SMA connector

J9, which is terminated on the demo board with 50 Ω. Input J9 feeds a

level translator U7, and the output of the level translator is passed to an

input select jumper J10. This pulse PLS_IN is passed to the input of the

narrow pulse generator (NPG). When the input goes high, the output of

the NPG follows, feeding the gate driver U3 which turns on Q1, allowing

CRES to discharge through the laser diode U2. If the NPG is disabled, then

when the input goes low, Q1 turns o. If the NPG is enabled, the user can

get a short gate drive output pulse to the lower limit of the gate drive

IC U3’s capability. This allows the use of lower cost signal generators

while working with the EPC9179/80/81. Details are given in Section

ADDITIONAL FEATURES.

Once CRES is discharged, Q1 should be turned o. Now, CRES will recharge

through RCHRG. Once it is fully charged, the circuit can be red again.

DIFFERENCES BETWEEN THE EPC9179, EPC9180,

and EPC9181

The EPC9179, EPC9180, and EPC9181 evaluation boards are nearly

identical in function, design, and layout. The key dierence between

the boards is the eGaN FET used for Q1. The FETs are selected to

cover a wide range of peak pulse currents, with the larger FETs

enabling higher peak currents. The primary tradeo for the ability to

reach higher peak currents is increased minimum pulse width. The

combination of higher peak current and increased pulse width results

in the need for increased resonant capacitor values and a reduced

current measurement shunt value, along with a change to the latter’s

ESL compensation capacitor. Table 2 gives a comparison of the three

evaluation boards in order to highlight the dierences.

It is recommended that the user choose the smallest FET that will

meet the peak current needs. This will give the shortest possible pulse

while still meeting the peak current requirements. The pulse width

can be increased by increasing the value of the resonant capacitor.

Table 2. Comparison of the EPC9179, EPC9180, and EPC9181

evaluation boards

Parameter

Description EPC9179 EPC9180 EPC9181 Units

Q1FET part number EPC2252 EPC2218A EPC2204A n/a

CRES

(C2-C6)

Eective total

resonant

capacitance

1.1

10.8 3.4 nF

RSHUNT

(R12-R16)

Eective total

resonant current

shunt resistance

102 30

60

mΩ

C7

Shunt

compensation

capacitance

12

36 18

pF

IPeak

Nominal peak

current for ideal

diode load

75 230 125 A

TPW

Nominal pulse

width for high

performance SMT

laser diode

2-3 5-6 3-4 ns

TCHRG

CRES charge time to

0.98 VBUS with ideal

diode load

1.7 17 5.3 μs

FMAX

Max pulse rate

based on 1/TCHRG

(does not account

for any thermal

limitations)

590 59 190 kHz

QUICK START GUIDE Evaluation Boards EPC9179/80/81

EPC – POWER CONVERSION TECHNOLOGY LEADER | EPC-CO.COM | ©2023 | For more information: [email protected] | 4

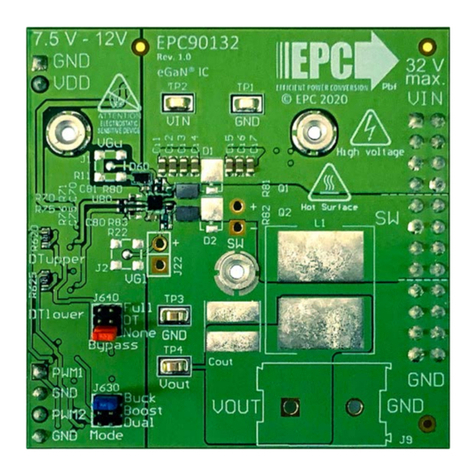

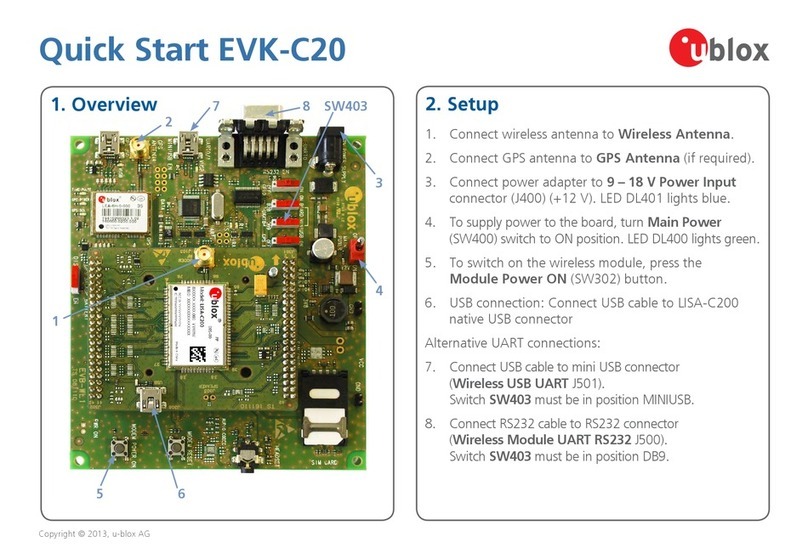

Figure 2. Output terminals of the EPC9179/80/81

Figure 3. EPC9989 interposer PCB for mounting dierent lasers and loads

Top

Bottom

SMD lasers MMCX Alternate loads

Breakaway

V-grooves

Laser cathode

(FET drain)

Laser anode

(FET drain)

GND (for alternate

applications)

LASER DIODE OR LOAD CONSIDERATIONS

The EPC9179/80/81 has a set of pads which can be used as is to mount a

laser diode or alternative load. Figure 2 highlights the output pad locations.

However, many laser suppliers have dierent mounting footprints, making

it dicult to optimize the performance of the driver and still maintain the

desired exibility. The use of an interposer PCB provides a solution to this

problem with only a small impact to performance.

The EPC9179/80/81 ships with the EPC9989 interposer PCB, shown in

Figure 3. The EPC9989 has an assortment of 5 x 5 mm square interposer PCBs

that can be snapped o the board. These interposers have various footprints

on thetopside that can accommodateseveral surfacemount laser diodes, RF

connectors, and several patterns designed to accommodate a wide variety

of possible loads. These interposers mount between the EPC9179/80/81

and the laser diode or other load. Figure 4 shows an example of a laser in an

SMD package mounted with one of the interposers.

The following procedure can be used to hand mount a laser diode or other

load using the interposer. It is recommended that the person doing this

work be experienced in hand rework of SMT components.

1. Prepare the EPC9179/80/81 by removing the jumpers on J4 and J10 so

that they do not deform during reow soldering. Use best practice to

avoid electrostatic discharge (ESD) damage to the laser diode or other

load, or to the EPC9179/80/81, during the following steps. Laser diodes

are often extremely sensitive to ESD damage.

2. Select the interposer with the top side that ts the desired load.

3. Apply solder paste to the appropriate pads on the top side of the

interposer.

4. Place the laser diode or desired load on the interposer such that the pads

of the load line up with the matching pads on the interposer. Set this

assembly gently aside, taking care not to bump it or displace the load

since the solder paste is still soft.

5. Apply solder paste to the U1 pads on the EPC9179/80/81 PCB.

6. Using tweezers or other means, pick up the assembly of the interposer

and laser or alternative load that was set aside in Step 4. Carefully position

the assembly with the bottom side of the interposer facing the top side

of the EPC9179/80/81 on the U1 footprints and set in place.

7. Reow the EPC9179/80/81 together with the interposer-load assembly

using the laser or load manufacturer’s recommended temperature

prole for the selected solder. The use of a reow oven that can meet the

recommended soldering specications is highly recommended. Other

reow methods may also be used based on the experience of the user,

but it should be noted that many lasers have a polymer optical assembly

that is sensitive to overheating.

8. Replace jumpers on J4 and J10.

The power loop inductance, including that of the laser diode, is a primary

factor that determines the shape of the laser pulse. Considerable eort

has been made to minimize power loop inductance while maximizing

the choice of laser diode and its orientation. Maxwell’s Laws dictate that

the discharge capacitors, current sense resistors, and the eGaN FET must

all be mounted in close proximity to minimize inductance. The resulting

proximity of all these components to the laser or other load means that the

user must take extra care not to damage any components when mounting

the laser or changing other components in the power loop.

The schematic and layout les for the EPC9989 interposer can be found

on the main information pages for the EPC9179/80/81. In addition, a

PCB footprint is available so that the user may design their own custom

interposer.

Laser diode current pulses can result in peak powers of several hundred

watts to over 1 kW. Laser diodes for lidar applications are designed with this

in mind, but thermal limitations of the laser package mean that pulse widths,

duty cycles, and pulse repetition frequency limitations must be observed.

Read laser diode data sheets carefully and follow any manufacturers’

recommendations.

Laser diode

or load

EPC9989

interposer

eGaN FETGate driver

Current shunt

Resonant

capacitors

Recharging

resistors

L

Figure 4. Laser diode mounted with EPC9989 interposer

QUICK START GUIDE Evaluation Boards EPC9179/80/81

EPC – POWER CONVERSION TECHNOLOGY LEADER | EPC-CO.COM | ©2023 | For more information: [email protected] | 5

MEASUREMENT CONSIDERATIONS

SMA jacks are provided to measure key signals in the circuit, including

gate drive IC input, Q1 gate voltage, Q1 drain voltage, resonant capacitor

CRES voltage, and the sense voltage of the current measurement shunt

(see Figure 5). All measurement points are designed to be terminated in

50 Ω, hence when viewing waveforms, the oscilloscope inputs should

be set to a 50 Ω input. Ideally, unused outputs should be also terminated

with a 50 Ω load to prevent the probes from creating additional

resonances. However, the Q1 drain voltage VOUT, the discharge capacitor

sense voltage CAP, and the current shunt output SHUNT also have

impedance values relatively close to 50 Ωs as seen from the SMA

connector. Thus, the reection coecient is small and in practice, the

subsequent resonances are small if these are left unterminated. It is

recommended that the user verify that this is suitable for their own

requirements.

All sense measurement SMA connectors except for the shunt

measurement use the transmission line voltage probe principle

to obtain waveform delity at sub-ns time scales. They have been

veried to produce near-identical results to a Tektronix P9158 3 GHz

transmission line probe. As a result of their design, they have a built-in

attenuation factor. These factors are given in Table 3. The impedance of

the probes at the measurement node is relatively small (~1 kΩ). In order

to minimize the eects of the low probe impedance on the operation of

the demo board and prevent overheating of the probe input resistors,

the output voltage (J3) and capacitor voltage (J1) probes have DC

blocking capacitors on the PCB. As a result, measured pulse waveforms

will not have any DC component and will exhibit droop as pulse widths

and other waveform features approach the RC time constant of the

probe. The user should keep these factors in mind if accustomed to

more conventional oscilloscope probes. If long pulse widths are used,

the droop will become substantial, and an external probe may be used

to measure these slower waveforms more accurately.

The current shunt is designed to estimate the discharge capacitorcurrent.

Substantial eort has been made to reduce the inductive eects of the

current shunt, both through the use of carefully selected resistors and

a compensation network to help compensate for the shunt equivalent

series inductance. However, the shunt is a compromise between current

measurement accuracy and minimizing the impact on the laser driver

performance. If a more accurate shunt waveform measurement is

desired, the shunt resistors may be replaced with ones that provide

higher accuracy at the bandwidth required. This will require higher

resistor values which will contribute to errors in the capacitor voltage

measurement, increase power dissipation, and reduce the available

peak current for a given bus voltage VBUS. Additionally, note that the

measured capacitor current also includes the current due to D1, D2, and

D3 (if included), and PCB capacitance, in addition to the load current.

Finally, when one wishes to understand detailed switching behavior, it

is important to consider the timing mismatch of the probe point. The

approximate delay times have been calculated based on the assumption

that a 50 Ω transmission line connects the SMA to the test point of

interest, neglecting the eects of passive component pads. They are

listed in Table 3.

Table 3: Key properties of SMA measurement outputs assuming 50 Ω terminations on measurement instruments

Designator PC label Description Attenuation

factor

PCB propagation

delay (calculated)

DC blocking

cap

DC blocking LF

time constant

On-PCB

termination

J1 CAP Resonant capacitor voltage 41 V/V 119 ps 10 nF 10 ms YES

J2 SHUNT Resonant capacitor current

measurement

19.6 A/V (EPC9179)

66.7 A/V (EPC9180)

33.3 A/V (EPC9181)

116 ps none

n/a YES

J3 VOUT Q1 drain voltage

41 V/V 118 ps 10 nF 10 μs

YES

J5 VGDIN Gate drive IC (U3) input voltage

20 V/V 163 ps none n/a

NO

J6 VGS Q1 gate voltage

20 V/V 171 ps none n/a

NO

QUICK START GUIDE Evaluation Boards EPC9179/80/81

EPC – POWER CONVERSION TECHNOLOGY LEADER | EPC-CO.COM | ©2023 | For more information: [email protected] | 6

QUICK START PROCEDURE

The EPC9179/80/81 evaluation board is simple to set up for evaluation of

the performance of the EPC2252, EPC2218A, and EPC2204A eGaN FETs.

NARROW PULSE GENERATOR

Many signal generators cannot produce an accurate, short pulse with

sub-ns edges. The EPC9179/80/81 includes a narrow pulse generator

(NPG) function to obtain narrow output pulses of adjustable width,

following a method given in Section 8.2.2.2 of the Texas Instruments

LMG1020 data sheet. The pulse width is controlled through

Potentiometer P1. When adjusting P1, the use of a non-conductive

tool is recommended due to the sensitivity of the adjustment to stray

capacitance.

The NPG is enabled by moving the jumper on J4 to the leftmost

position (see Figure 6). With the NPG enabled, the input pulse signal is

split into separate turn-on and turn-o paths. The turn-on path goes

through buer U2, a xed RC delay {R23, C14} and buer U4 on to the

IN+ (non-inverting) input of gate driver U3, which turns output Q1 on.

The turn-o path is similar, but has an adjustable RC delay {P1, R27,

C16}. This delayed pulse is sent to the IN- (inverting) input of U3. The

longer delay of the second path means that after some interval, the IN-

input of U3 goes high, and Q1 is turned o, ending the output pulse.

The procedure in this section provides basic instructions to operate the

boards in the default (as shipped) conguration. Refer to Figure 2 for proper

connection and measurement setup and follow the procedure below:

1. Review laser safety considerations when using a laser load.

Observe all necessary laser safety requirements including the use

of personal protection equipment (PPE) as required. Review high

voltage safety considerations since the evaluation boards may

operate with voltage levels that may present a safety hazard. Refer

to qualied safety personnel as necessary.

2. With power o, install laser diode U1 or alternative suitable load.

The use of one of the interposers from the included EPC9989 can be

used to mount the laser or alternative load. This is discussed in the

section LASER DIODE OR LOAD CONSIDERATIONS.

3. With power o, connect the main power supply to VBUS (J8), taking care

to observe the correct polarity.

4. With power o, connect the logic supply (5.5-12 VDC) VLogic (J7), taking

care to observe the correct polarity.

5. With power o, connect the signal pulse generator to the input J9. J9 is

terminated with 50 Ω, and is designed for a 3.3 V logic input as shipped.

Ensure that the pulse repetition frequency is within the recommended

range.

6. Connect the remaining measurement SMA outputs to an oscilloscope,

using 50 Ω cables and with the scope inputs set to 50 Ω impedance.

See section MEASUREMENT CONSIDERATIONS for more information,

including the attenuation values for each output.

7. Verify that the logic supply voltage is set to a value within the

specications and turn on the logic supply voltage.

8. Verify that the bus supply voltage is set to a value within the specica-

tions and turn on the bus supply voltage.

9. Turn on the pulse source and observe switching operation via the

outputs and any additional desired probing. Laser diode output may be

observed with an appropriate opto-electronic receiver.

Laser diode

or load

VLogic VBUS

Note polarity

Signal generator

Oscilloscope

(50 Ω inputs)

– +

+ –

Figure 5. Connection and measurement setup

10. Once operational, adjust the bus voltage, input pulse width, and

pulse repletion frequency (PRF) as desired within the operating

range and observe the system behavior.

11. For shutdown, please follow steps in reverse.

ADDITIONAL FEATURES

The EPC9179/80/81 is designed to accommodate a range of use

scenarios. Some of these are available with no modications to the

PCB. The locations of key adjustments are indicated in Figure 6.

Advanced features require the ability to remove and replace SMT chip

components. It is recommended that these are done by qualied

personnel with experience in SMT rework.

When reading this section, please have the full schematic available for

reference.

LVDS input

from J11

Single-ended

input from J9

(default)

NPG pulse width

adjustment

NPG enabled

Dierential input Single-ended input

NPG disabled (default)

Figure 6. Location of key features and adjustments

QUICK START GUIDE Evaluation Boards EPC9179/80/81

EPC – POWER CONVERSION TECHNOLOGY LEADER | EPC-CO.COM | ©2023 | For more information: [email protected] | 7

Potentiometer P1 is used to adjust this turn-o delay and the resulting

output pulse width, with clockwise rotation increasing the pulse width

applied to the gate of Q1. Note that the minimum delay setting causes

both turn-on and turn-o paths to have an approximately equal delay,

which would result in a zero-width pulse. Since the gate driver U3 has a

minimum pulse width specication of > 1 ns, it is U3 that determines the

minimum attainable output pulse width. Small errors in the delay path

do not signicantly impact the output. The maximum pulse width that

can be obtained with the NPG is approximately 60 ns, so if longer pulses

are needed, the NPG should be disabled.

When using the NPG, it is recommended that the input pulse should be

at least 10 ns longer than the desired output pulse to guarantee reliable

operation under all ambient conditions.

ADVANCED FEATURES

The EPC9179/80/81 has the option to be controlled from a dierential

input. As shipped, this input is congured for standard LVDS signals.

It input is available to the user through the 8-pin header J11. Table 4

shows the pinout for J11, which also provides alternate access to some

of the power supply voltages on the board. In order to enable the LVDS

or other dierential input, move the jumper on J10 to the upper position

(Figure 6).

LVDS AND ALTERNATE INPUTS

The following features require modications to the board.

Load Clamping diodes

Empty component footprints are present on the EPC9179/80/81 to allow

the user to mount up to 3 clamp diodes (D1, D2, D3). While such diodes

can provide some protection to FET Q1 and laser or load U1, they have

parasitic inductance and capacitance that can reduce performance.

In addition, they clamp the laser or load reverse voltage and this can

reduce turn-o speed. Hence, they are not populated, and it is left to the

user to determine whether they are useful for a particular application.

Eye safe operation

In some applications, it is required that the driver remain eye-safe in

the event of a failure causing Q1 to be on in an uncontrolled manner,

e.g. an erroneous gate drive signal or FET short. While the charging

resistance provides some current limiting, it may not be enough. In

such a case, R8 can be removed, and at least one of the clamp diodes

D1, D2, or D3 populated. Once this is done, the capacitor bank will

be charged through the charging resistance and the clamp diode(s).

However, if Q1 is on, the charging current will now ow through Q1

and not the laser diode, preventing any light output.

Fast Refresh

The value of the energy storage cap {C2, C3, C4, C5, C6} can be modied

as desired, as well as the recharge resistor {R4, R5, R6, R7}. In the extreme

case, the resistor may be reduced to 0 Ω for cases where a capacitive

discharge pulse is not desired. The latter can also be accomplished

by populating R1. If this approach is taken, it is recommended that R1

have some small value of resistance (5 Ω to 20 Ω) to damp possible

resonances in the power bus.

Logic input level and type

The input specication of the demo board may also be modied. For

single-ended inputs, the input logic level can be reduced from 3.3 V

logic to 2.5 V or 1.8 V by changing R37. Please see the U7 datasheet for

further details. If a dierential input dierent than LVDS is desired, the

dierential receiver U8 can accommodate sub-LVDS, CML or LVPECL

signals by changing the values of U8’s input termination network.

Please see the U8 datasheet for further details.

Improving laser cooling

Some pulse laser applications are thermally limited by laser power

dissipation. Usually, the laser die substrate forms the cathode, which is

attached to the drain of Q1. Since this terminal is the most electrically

active terminal in the whole circuit, it must be kept small and electrically

isolated from anything else in the circuit. This makes it dicult for heat

to ow out of the laser. This terminal is connected to a small copper

land on the bottom of the PCB with a thermally conductive via array.

Hence, the thermal resistance from the laser cathode to the bottom

thermally conductive ground plane of the PCB can be reduced by

populating R17, R18, R19, and R20. The high electrical resistance of these

parts means they have negligible electrical eect, but the thermal

resistance of the chip resistors is much lower than the PCB substrate.

Note that thermal performance can be further improved with the use

of thermal bridges, which are essentially a blank resistor chip made

with an aluminum nitride body for enhanced thermal performance.

Table 4. J11 Pin Description

J11 Pin Description Schematic Net Name

1Not connected N/A

2Internal 5 V supply V5V0

3Logic supply Vlogic

4Internal 3.3 V supply V3V3

5Ground GND

6Non-inverting dierential input IN_D+

7Ground GND

8Inverting dierential input IN_D-

QUICK START GUIDE Evaluation Boards EPC9179/80/81

EPC – POWER CONVERSION TECHNOLOGY LEADER | EPC-CO.COM | ©2023 | For more information: [email protected] | 8

PERFORMANCE EXAMPLES

Figures 7, 8, and 9 show typical waveforms for the EPC9179, EPC9180, and EPC9181 demo boards, respectively. In all cases, the waveforms were

obtained with VBUS = 70 V at room temperature.

Figure 7. Waveforms for the EPC9179 demo board using an ams OSRAM SPL S1L90A_3 A01 single channel triple junction laser diode mounted with the EPC9989 interposer.

Figure 8. Waveforms for the EPC9180 demo board using an ams OSRAM SPL S4L90A_3 A01 four channel triple laser diode mounted with the EPC9989 interposer.

All channels are connected in parallel.

Figure 9. Waveforms for the EPC9181 demo board using an ams OSRAM SPL S4L90A_3 A01 four channel triple laser diode mounted with the EPC9989 interposer.

All channels are connected in parallel.

VOUT (vDS),

10 V/div

VCAP,

20 V/div

SHUNT (iLASER)

19.4 A/div

2 ns/div

VGS, 1 V/div

Pulse width: 1.96 ns

Peak current: 63.1 A

5 ns/div

Pulse width: 5.59 ns

Peak current: 223 A

VOUT (vDS),

10 V/div

VCAP,

20 V/div

SHUNT (iLASER)

50 A/div

VGS, 1 V/div

2 ns/div

Pulse width: 3.16 ns

Pulse width: 3.16ns

Peak current: 135A

SHUNT (iLASER)

19.4 A/div

VGS, 1 V/div

VOUT (vDS),

10 V/div

VCAP,

20 V/div

Evaluation Board Notication

The EPC9179/80/81 boards are intended for product evaluation purposes only. They are not intended for commercial use nor is it FCC approved for resale. Replace

components on the Evaluation Board only with those parts shown on the parts list (or Bill of Materials) in the Quick Start Guide. Contact an authorized EPC representative with any questions.

This board is intended to be used by certied professionals, in a lab environment, following proper safety procedures. Use at your own risk.

As an evaluation tool, this board is not designed for compliance with the European Union directive on electromagnetic compatibility or any other such directives or regulations. As board builds

are at times subject to product availability, it is possible that boards may contain components or assembly materials that are not RoHS compliant. Ecient Power Conversion Corporation (EPC)

makes no guarantee that the purchased board is 100% RoHS compliant.

The Evaluation board (or kit) is for demonstration purposes only and neither the Board nor this Quick Start Guide constitute a sales contract or create any kind of warranty, whether express or

implied, as to the applications or products involved.

Disclaimer: EPC reserves the right at any time, without notice, to make changes to any products described herein to improve reliability, function, or design. EPC does not assume any liability

arising out of the application or use of any product or circuit described herein; neither does it convey any license under its patent rights, or other intellectual property whatsoever, nor the rights

of others.

EPC Products are distributed through Digi-Key.

www.digikey.com

For More Information:

or your local sales representative

Visit our website:

www.epc-co.com

Sign-up to receive

EPC updates at

bit.ly/EPCupdates

or text EPC to 22828

This manual suits for next models

2

Table of contents

Other IEPC Motherboard manuals