IEPC EPC90132 User manual

Development Board

EPC90132

Quick Start Guide

40 V Half-bridge with Gate Drive, Using EPC2055

Revision 1.0

QUICK START GUIDE EPC90132

EPC – POWER CONVERSION TECHNOLOGY LEADER | EPC-CO.COM | ©2021 | | 2

DESCRIPTION

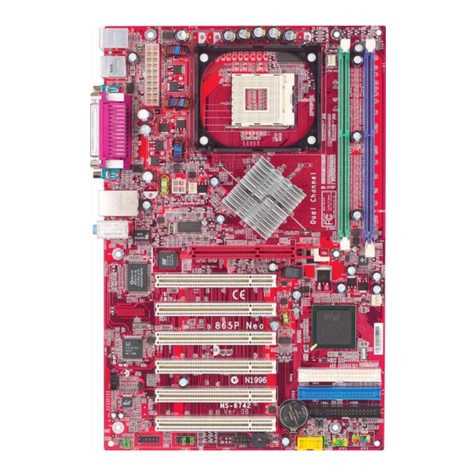

The EPC90132 is a half bridge development board with onboard gate

drives, featuring the 40 V rated EPC2055 GaN eld eect transistor (FET).

The purpose of this development board is to simplify the evaluation

process of the EPC2055 by including all the critical components on a

single board that can be easily connected into the majority of existing

converter topologies.

The EPC90132 development board measures 2” x 2” and contains two

EPC2055 GaN FET in a half bridge conguration and one EPC2038 GaN

FET used to augment the bootstrap supply. The EPC90132 features the uPI

Semiconductor uP1966A gate driver. The board also contains all critical

components and the layout supports optimal switching performance.

There are also various probe points to facilitate simple waveform

measurement and eciency calculation. A block diagram of the circuit

is given in gure 1.

For more information on EPC2055 please refer to their datasheets

available from EPC at www.epc-co.com. The datasheet should be read in

conjunction with this quick start guide.

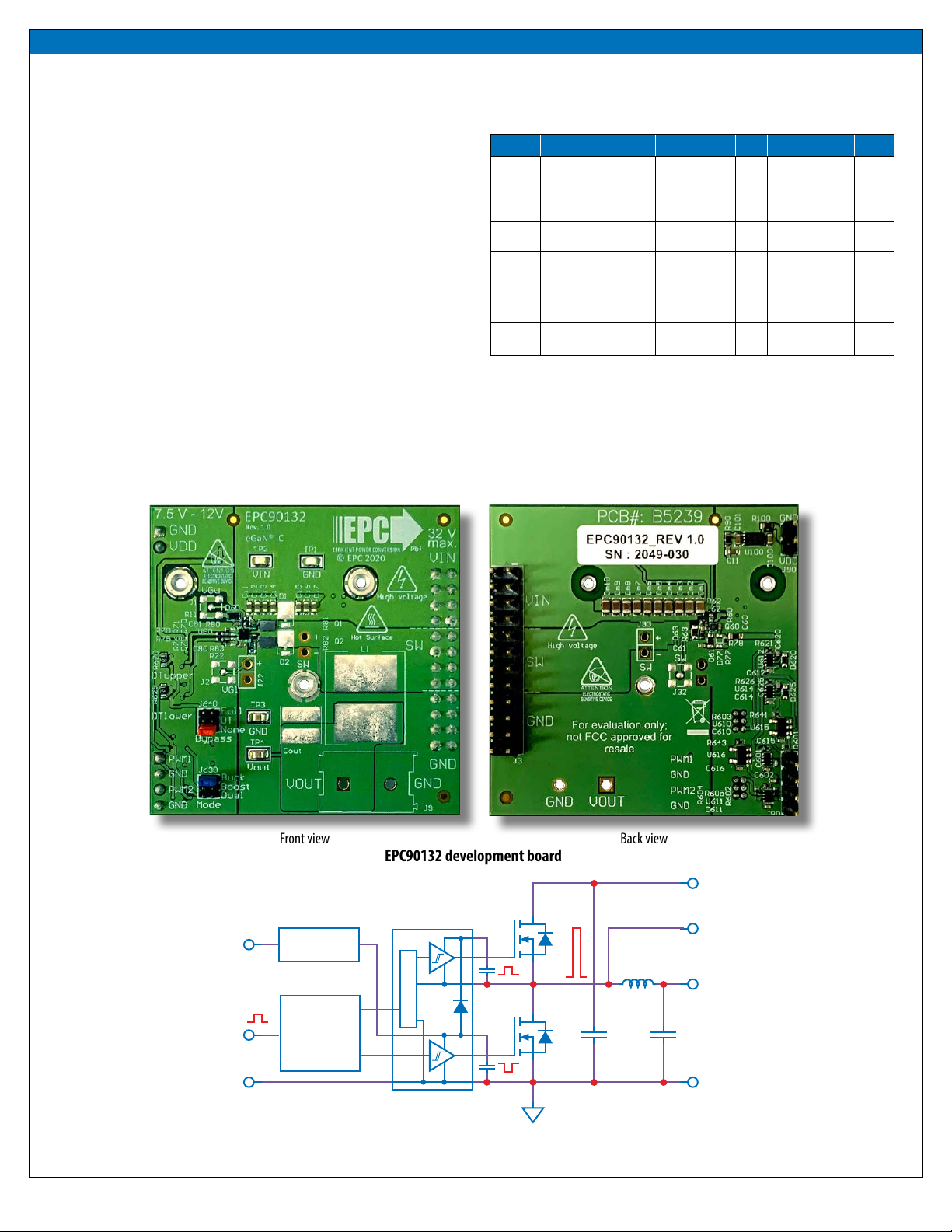

Table 1: Performance Summary (TA= 25°C) EPC90132

Symbol Parameter Conditions Min Nominal Max Units

VDD

Gate Drive Regulator

Supply Range 7.5 12 V

VIN

Bus Input Voltage

Range(1) 32 V

IOUT

Switch Node Output

Current (2) 25 A

VPWM

PWM Logic Input

Voltage Threshold (3)

Input ‘High’ 3.5 5.5 V

Input ‘Low’ 0 1.5 V

PWM ‘High’State Input

Pulse Width

VPWM rise and

fall time < 10ns 50 ns

PWM ‘Low’ State Input

Pulse Width (4)

VPWM rise and

fall time < 10ns 200 ns

(1) Maximum input voltage depends on inductive loading, maximum switch node ringing

must be kept under 40 V for EPC2055.

(2) Maximum current depends on die temperature – actual maximum current is aected by

switching frequency, bus voltage and thermal cooling.

(3) When using the on board logic buers, refer to the uP1966A datasheet when bypassing

the logic buers.

(4) Limited by time needed to ‘refresh’ high side bootstrap supply voltage.

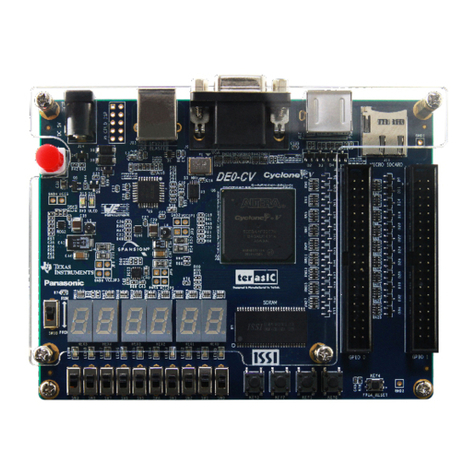

EPC90132 development board

Back viewFront view

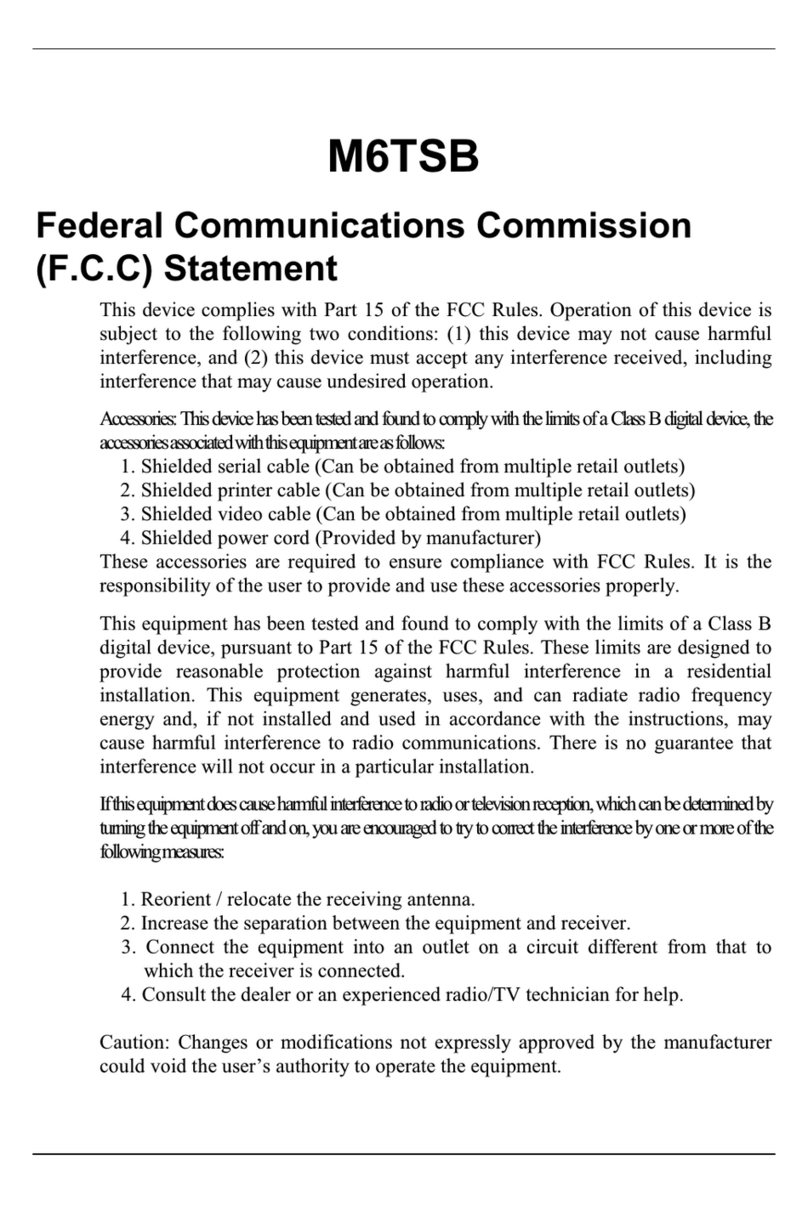

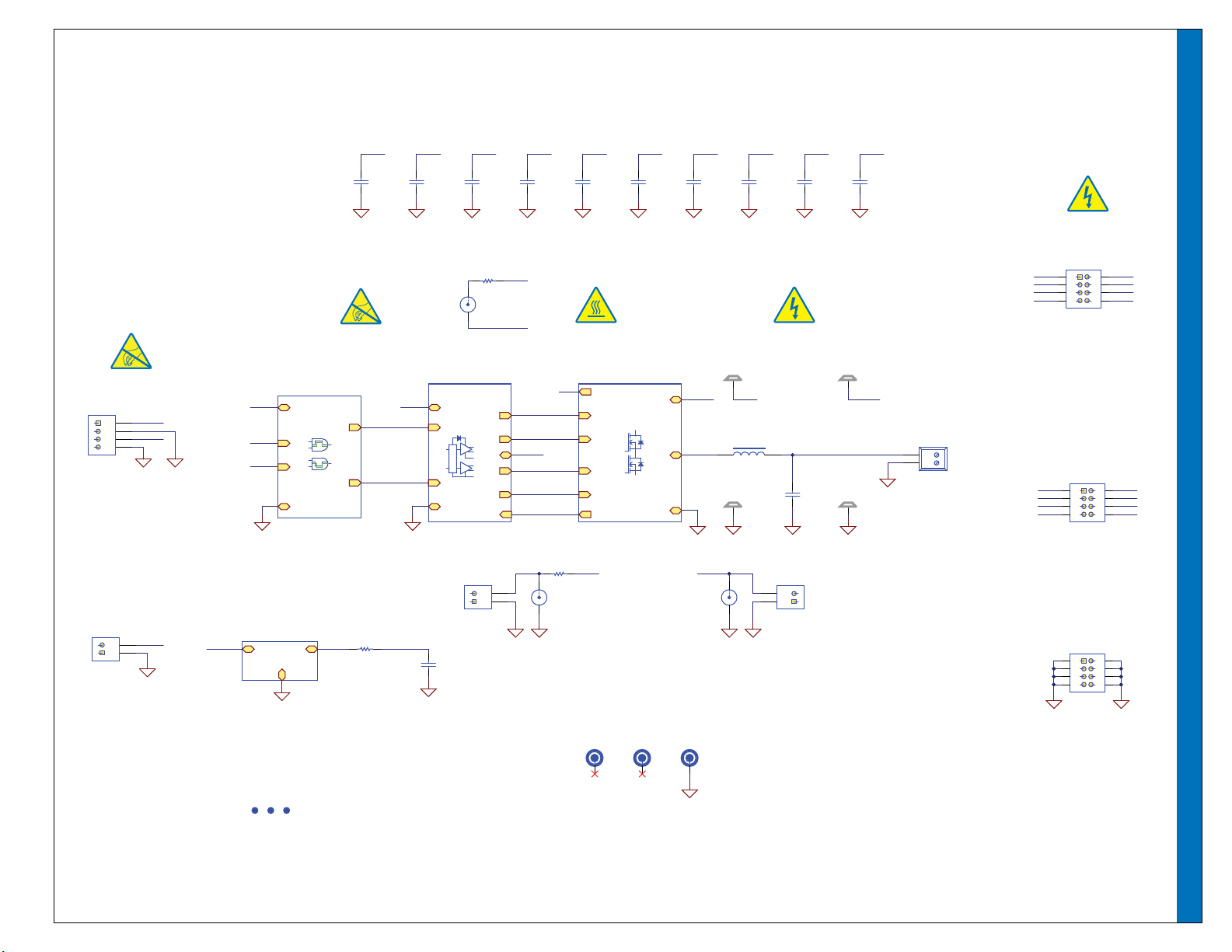

Figure 1: Block diagram of EPC90132 development board default conguration

Level shift

VDD

VIN

Switch node

Q1

Q2

CBypass

PWM

GND

Cout

Gate drive

regulator

Gate driver

DC Output

PGND

Logic and

dead-time

adjust

L1

QUICK START GUIDE EPC90132

EPC – POWER CONVERSION TECHNOLOGY LEADER | EPC-CO.COM | ©2021 | | 3

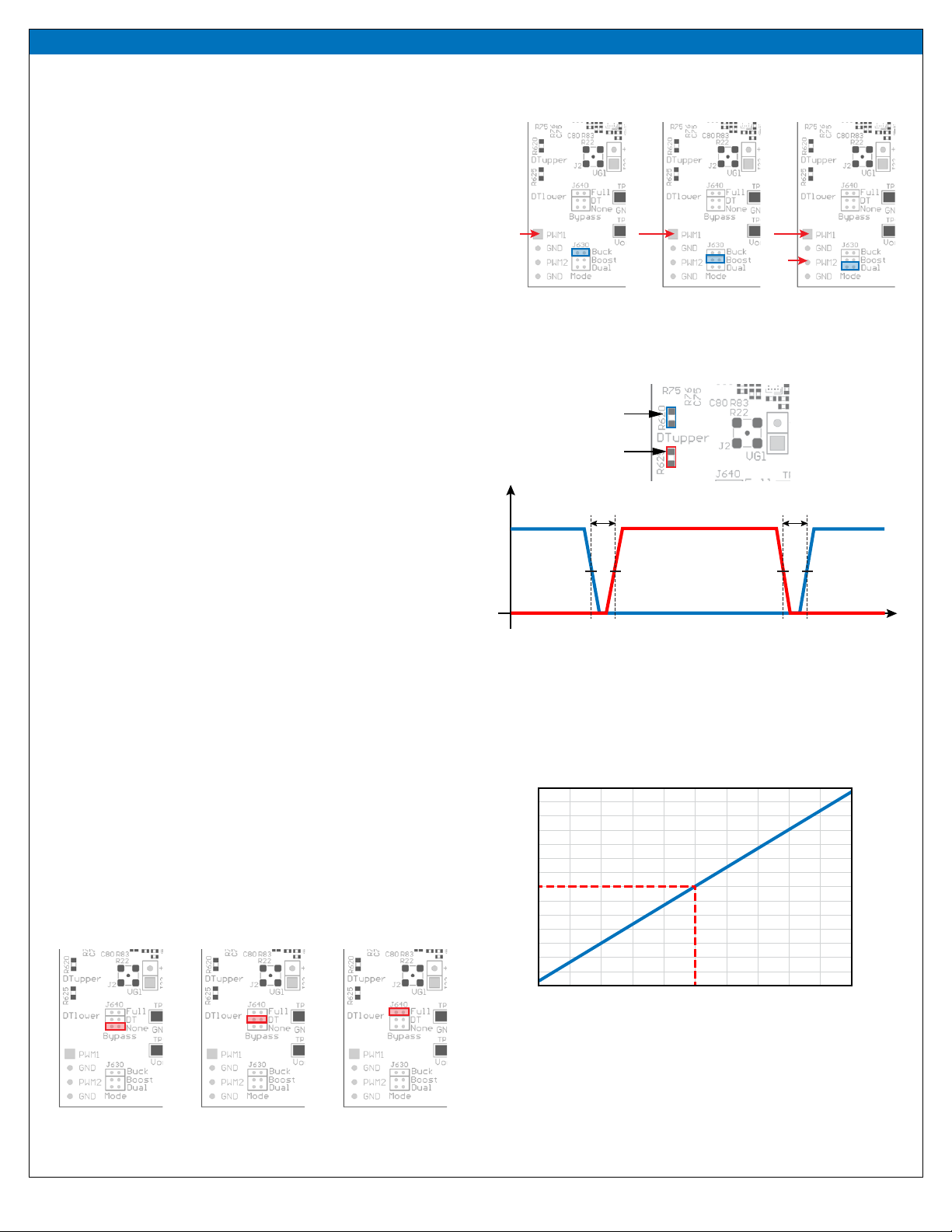

Figure 3: Denition of dead-time between the upper-FET gate signal (DTQup)

and the lower-FET gate signal (DTQlow)

Figure 4: The required resistance values for R620 or R625 as a

function of desired dead-time

Figure 2: Input mode selection on J630

(a) (c)(b)

QUICK START PROCEDURE

The EPC90132 development board is easy to set up as a buck or boost

converter to evaluate the performance of two EPC2055 eGaN FETs.

This board includes a logic PWM input signal polarity changer used to ensure

positive PWM polarity for the switching device when congured in either

the buck or boost modes, and can accommodate both single and dual PWM

inputs. Furthermore, the board includes a dead-time generating circuit that

adds a delay from when the gate signal of one FET is commanded to turn

o, to when the gate signal of the other FET is commanded to turn on. In the

default conguration, this dead time circuit ensures that both the high and

low side FETs will not be turned on at the same time thus preventing a shoot-

through condition. The dead-time and/or polarity changing circuits can be

utilized or bypassed for added versatility.

Single/dual PWM signal input settings

There are two PWM signal input ports on the board, PWM1 and PWM2. Both

input ports are used as inputs in dual-input mode where PWM1 connects to

the upper FET and PWM2 connects to the lower FET. The PWM1 input port

is used as the input in single-input mode where the circuit will generate

the required complementary PWM for the FETs. The input mode is set by

choosing the appropriate jumper positions for J630 (mode selection) as

shown in gure 2(a) for a single-input buck converter (blue jumper across

pins 1 & 2 of J630), (b) for a single-input boost converter (blue jumpers

across pins 3 & 4 of J630), and (c) for a dual-input operation (blue jumpers

across pins 5 & 6 of J630).

Note: In dual mode there is no shoot-through protection as both gate

signals can be set high at the same time.

Dead-time settings

Dead-time is dened as the time between when one FET turns o and the

other FET turns on, and for this board is referenced to the input of the gate

driver. The dead-time can be set to a specic value where resistor R620

delays the turn on of the upper FET and resistor R625 delays the turn on of

the lower FET as illustrated in gure 3.

The required resistance for the desired dead-time setting can be read o

the graph in gure 4. An example for 10 ns dead-time setting shows that

a 120 Ω resistor is needed.

Note: This is the default deadtime and resistor value installed. A minimum

dead-time of is 5 ns and maximum of 15 ns is recommended.

Bypass settings

Both the polarity changer and the deadtime circuits can be bypassed using

the jumper settings on J640 (Bypass), for direct access to the gate driver

input. There are three bypass options: 1) No bypass, 2) Dead-time bypass,

3) Full bypass. The jumper positions for J640 for all three bypass options are

shown in gure 5.

PWM1

Single input

Buck

Single input

Boost Dual input

PWM2

R(Ω) = 13.5 ∙ DT(ns) − 14

Resistance (Ω)

Dead-time (ns)

190

180

170

160

150

140

130

120

110

100

90

80

70

60

505 6 7 8 9 10 11 12 13 14 15

Figure 5: Bypass mode Jumper settings for J640

(a) (c)(b)

Deadtime

v

t

0

50% 50% 50% 50%

DTQup

DTQlow

Deadtime

Lower FET

turn on delay

Lower FET turn on delay

Upper FET

turn on delay

Upper FET turn on delay

No bypass Bypass deadtime Full Bypass

QUICK START GUIDE EPC90132

EPC – POWER CONVERSION TECHNOLOGY LEADER | EPC-CO.COM | ©2021 | | 4

In no-bypass mode, gure 5(a) (red jumper across pins 5 & 6 of

J640), both the on-board polarity and dead-time circuits are fully

utilized. In dead-time bypass mode, gure 5(b) (red jumpers

across pins 3 & 4 of J640), only the on-board polarity changer

circuit is utilized, eectively bypassing the dead-time circuit.

In full bypass mode, Figure 5(c) (red jumper across pins 1 & 2 of

J640), the inputs to the gate driver are directly connected to the

PWM1 and PWM2 pins and the on-board polarity and dead-time

circuits are not utilized.

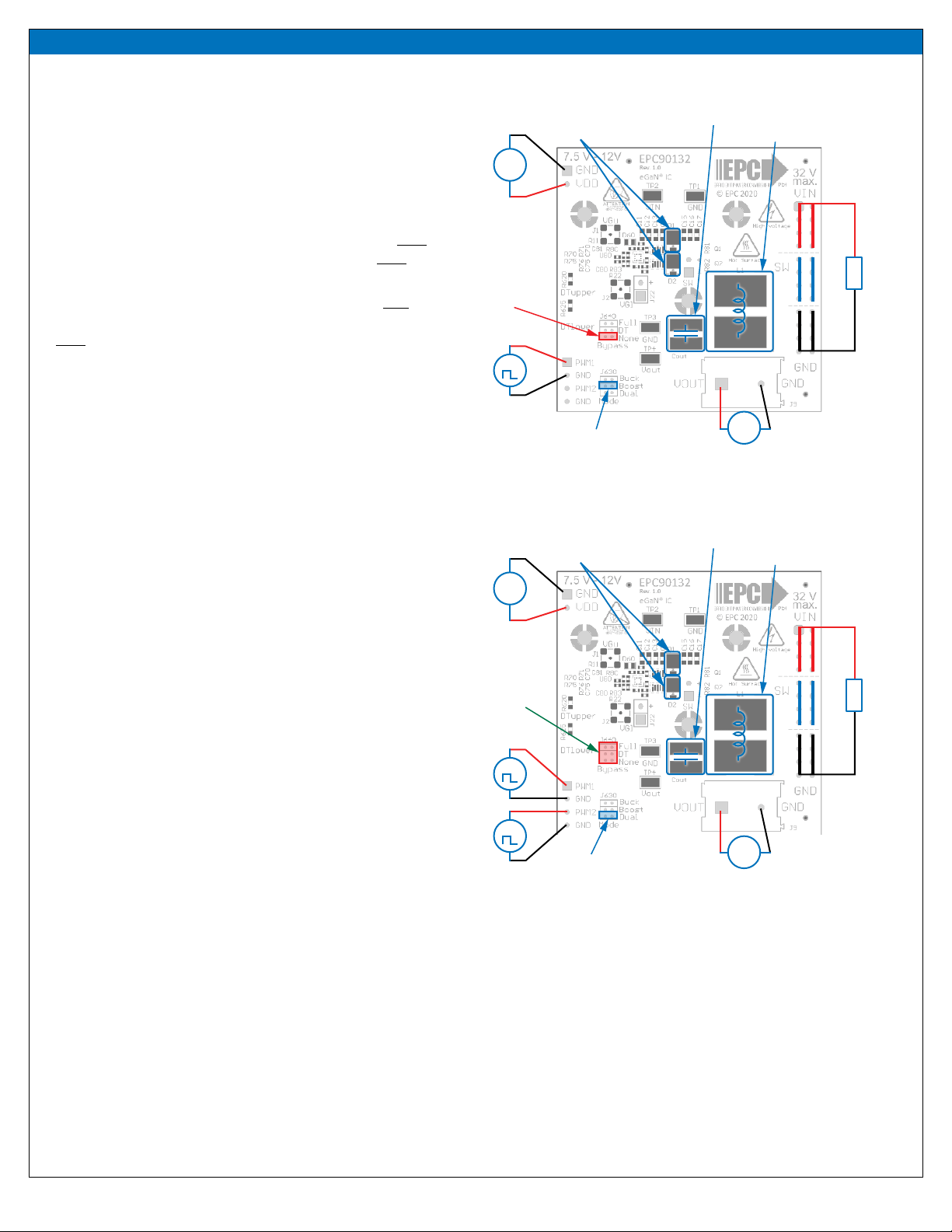

Buck converter conguration

To operate the board as a buck converter, either a single or dual

PWM inputs can be chosen using the appropriate jumper settings

on J630 (mode).

To select Single Input Buck Mode, the bypass jumper J640 must be

set to the no-bypass mode, the buck mode J630 must be selected

as shown in gure 6(a).

To select Dual Input Buck Mode, the bypass jumper J640 may be

congured to any of the valid settings, the dual-input mode J630

must be selected as shown in gure 6(b).

Note: It is important to provide the correct PWM signals that

includes dead-time and polarity when operating in bypass mode.

Once the input source, dead-time settings and bypass cong-

urations have be chosen and set, then the boards can be operated.

1. With power o, connect the input power supply bus to VIN and

ground / return to GND.

2. With power o, connect the switch node (SW) of the half bridge

to your circuit as required (half bridge conguration). Or use the

provided pads for inductor (L1) and output capacitors (Cout), as

shown in gure 6.

3. With power o, connect the gate drive supply to VDD (J1, Pin-1)

and ground return to GND (J1, Pin-2 indicated on the bottom

side of the board).

4. With power o, connect the input PWM control signal to PWM1

and/or PWM2 according to the input mode setting chosen and

ground return to any of GND J2 pins indicated on the bottom

side of the board.

5. Turn on the gate drive supply – make sure the supply is set

between 7.5 V and 12 V.

6. Turn on the controller / PWM input source.

7. Making sure the initial input supply voltage is 0 V, turn on the

power and slowly increase the voltage to the required value

(do not exceed the absolute maximum voltage). Probe switch-

node to see switching operation.

8. Once operational, adjust the PWM control, bus voltage, and load

within the operating range and observe the output switching

behavior, eciency, and other parameters.

9. For shutdown, please follow steps in reverse.

Bypass mode warnings

• It is important to provide the correct PWM signals that includes dead-

time and polarity for either buck or boost operation when making use

of bypass modes.

• When operating in full bypass mode, the input signal specications

revert to that of the uP1966A gate driver IC. Refer to the uP1966A

datasheet for details.

32 VDCmax

VDD supply

(Note polarity)

Output Capacitor

Output Inductor

PWM1

(default)

Jumper positions for

single-input buck

Optional anti-

parallel diodes

DC load

Switch-node

output

Must be in

No-bypass

position

+

+

+

Output Capacitor

Output Inductor

Optional anti-

parallel diodes

7.5 –12 VDC

32 VDCmax

VDD supply

(Note polarity)

VMain

supply

(Note

polarity)

VMain

supply

(Note

polarity)

PWM1

Upper

FET

PWM2

Lower

FET DC load

All valid

positions

permitted

+

+

+

+

7.5 –12 VDC

Jumper positions for

dual-input buck

(a)

(b)

Figure 6: (a) Single-PWM input buck converter (b) Dual-PWM input buck converter

congurations showing the supply, anti-parallel diodes, output capacitor,

inductor, PWM, and load connections with corresponding jumper positions.

QUICK START GUIDE EPC90132

EPC – POWER CONVERSION TECHNOLOGY LEADER | EPC-CO.COM | ©2021 | | 5

Boost Converter conguration

Warning: Never operate the boost converter mode without a

load, as the output voltage can increase beyond the maximum

ratings.

To operate the board as a boost converter, either a single or dual

PWM inputs can be chosen using the appropriate jumper settings

on J630 (mode).

To select Single Input Boost Mode, the bypass jumper J640 must

be set to the no-bypass mode, the boost mode J630 must be

selected as shown in gure.7(a).

To select Dual Input Boost Mode, the bypass jumper J640 may be

congured to any of the valid settings, the dual-input mode J630

must be selected as shown in gure 7(b).

Note: It is important to provide the correct PWM signals that

includes dead-time and polarity when operating in bypass mode.

Once the input source, dead-time settings and bypass congura-

tions have be chosen and set, then the boards can be operated.

1. The inductor (L1) and input capacitors (labeled as Cout) can

either be soldered onto the board, as shown in gure 7, or

provided o board. Anti-parallel diodes can also be installed

using the additional pads on the right side of the EPC2055 FETs.

2. With power o, connect the input power supply bus to VOUT

and ground / return to GND, or externally across the capacitor

if the inductor L1 and Cout are provided externally. Connect the

output voltage (labeled as VIN) to your circuit as required, e.g.,

resistive load.

3. With power o, connect the gate drive supply to VDD (J1, Pin-1)

and ground return to GND (J1, Pin-2 indicated on the bottom

side of the board).

4. With power o, connect the input PWM control signal to PWM1

and/or PWM2 according to the input mode setting chosen and

ground return to any of GND J2 pins indicated on the bottom

side of the board.

5. Turn on the gate drive supply – make sure the supply is between

7.5 V and 12 V.

6. Turn on the controller / PWM input source.

7. Making sure the output is not open circuit, and the input

supply voltage is initially 0 V, turn on the power and slowly

increase the voltage to the required value (do not exceed

the absolute maximum voltage). Probe switch-node to see

switching operation.

8. Once operational, adjust the PWM control, bus voltage, and load

within the operating range and observe the output switching

behavior, eciency, and other parameters. Observe device

temperature for operational limits.

9. For shutdown, please follow steps in reverse.

VDD supply

(Note polarity)

Output Capacitor

Output Inductor

PWM1

(default)

Optional anti-

parallel diodes

Must be in

No-bypass

position

+

+

7.5 –12 VDC

32 VDCmax

DC load

+

VMain supply

(Note polarity)

32 VDCmax

DC load

Output Capacitor

Output Inductor

Optional anti-

parallel diodes

7.5 –12 VDC

VDD supply

(Note polarity)

PWM1

Upper

FET

PWM2

Lower

FET

All valid

positions

permitted

+

+

+

+

VMain supply

(Note polarity)

Jumper positions for

single-input boost

Jumper positions for

dual-input boost

(a)

(b)

Figure 7: (a) Single-PWM input boost converter (b) Dual-PWM input boost

converter congurations showing the supply, inductor, anti-parallel diodes, output

capacitor, PWM, and load connections with corresponding jumper settings.

QUICK START GUIDE EPC90132

EPC – POWER CONVERSION TECHNOLOGY LEADER | EPC-CO.COM | ©2021 | | 6

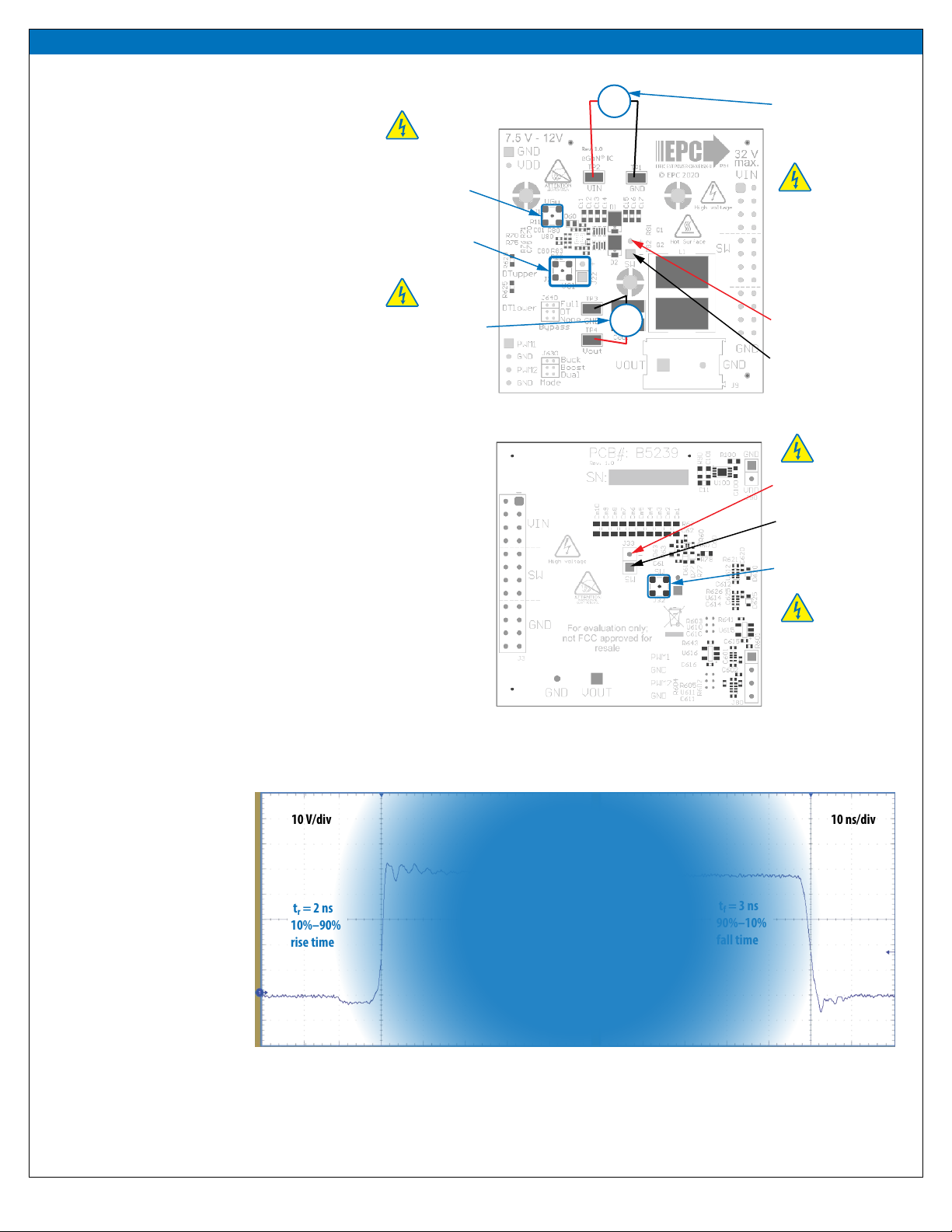

Ground oscilloscope probe

Switch-node oscilloscope

probe (HIGH VOLTAGE!)

Switch-node MMCX

(HIGH VOLTAGE!)

HIGH VOLTAGE

HIGH VOLTAGE

(a)

(b)

Figure 8: Measurement points (a) top side, (b) bottom side

Figure 9: Typical switch-node waveform when operated as a buck converter

MEASUREMENT CONSIDERATIONS

Measurement connections are shown in gure 8.

Figure 9 shows an actual switch-node voltage

measurement when operating the board as a buck

converter.

When measuring the switch node voltage containing

high-frequency content,caremustbe takentoprovide

an accurate high-speed measurement. An optional

two pin header (J33) and an MMCX connector (J32)

are provided for switch-node measurement.

A dierential probe is recommended for measuring

the high-side bootstrap voltage. IsoVu probes from

Tektronix has a mating MMCX connector.

For regular passive voltage probes (e.g. TPP1000)

measuring switch node using MMCX connector,

probe adaptor is available. PN: 206-0663-xx.

NOTE. For information about measurement techniques,

the EPC website oers: “AN023 Accurately Measuring

High Speed GaN Transistors” and the How to GaN

educational video series,including: HTG09- Measurement

EPC90132

Lower FET

Gate Voltage

Ground oscilloscope probe

Switch-node

oscilloscope probe

V

V

+

+

Upper FET Gate

Voltage MMCX

(HIGH VOLTAGE!)

Voltage measurement:

Input voltage for Buck,

Output voltage for Boost

(HIGH VOLTAGE!)

Voltage measurement:

Input voltage for Boost,

Output voltage for Buck

(HIGH VOLTAGE!)

HIGH VOLTAGE

HIGH VOLTAGE

HIGH VOLTAGE

V

IN

= 48 V, V

OUT

= 12 V, I

OUT

= 20 A, f

sw

= 1 MHz, L = 2.2 μH

10 V/div 10 ns/div

t

f

= 3 ns

90%–10%

fall time

t

r

= 2 ns

10%–90%

rise time

Waiting on update

QUICK START GUIDE EPC90132

EPC – POWER CONVERSION TECHNOLOGY LEADER | EPC-CO.COM | ©2021 | | 7

Components to remove prior

to Heat-spreader attach

Spacers for heat-spreader

attach

M2 screws (x3)

20 mm 9.2 mm

16.7 mm

Heat-spreader

Insulator

PCB

assembly

SMD spacer (x3)

eGaN FETs (x2)

TIM

Figure 10: Details for attaching a heatsink to the EPC90132 board.

(a) 3D perspective, (b) top view details.

THERMAL CONSIDERATIONS

The EPC90132 is intended for bench evaluation

with low ambient temperature and convection

cooling. The addition of a heat-spreader or heatsink

and forced air cooling can signicantly increase

the current rating of these devices, but care must

be taken to not exceed the absolute maximum die

temperature of 150°C.

The EPC90132 board is equipped with three

mechanical spacers that can be used to easily

attach a heat-spreader or heatsink as shown in

gure 10 (a), and only requires a thermal interface

material (TIM), a custom shape heat-spreader/

heatsink, and screws. Prior to attaching a heat-

spreader, any component exceeding 1 mm in

thickness under the heat-spreader area will need

to be removed from the board as shown in gure

10 (b). When assembling the heatsink, it may

be necessary add a thin insulation layer for

components with expose conductors such as

capacitors and resistors.

The choice of TIM needs to consider the following

characteristics:

• Mechanical compliance – The TIM becomes

compressed during heatsink attached and exerts

a force on the FETs. A maximum compression of

2:1 is recommended for maximum thermal perfor-

mance and to constrain the mechanical force that

maximizes thermal mechanical reliability.

• Electrical insulation – The backside of the eGaN

FETs are substrate that are connected to source

and the upper FET will thus be connected to the

switch-node. The TIM must therefore provide

insulation to prevent short-circuiting the upper

FET to the ground.

• Thermal performance – The choice of thermal

material will aect the thermal performance.

Higher thermal conductivity materials will result in

higher thermal performance.

EPC recommends t-Global P/N: TG-X 500 µm for

the thermal interface material.

The mechanical spacers will accept M2 x 0.4 mm

thread screws.

NOTE. The EPC90132 development board does not have

any current or thermal protection on board. For more

information regarding the thermal performance of EPC

eGaN FETs, please consult:

D. Reusch and J. Glaser, DC-DC Converter Handbook,

a supplement to GaN Transistors for Ecient

Power Conversion, First Edition, Power Conversion

Publications, 2015.

(a)

(b)

QUICK START GUIDE EPC90132

EPC – POWER CONVERSION TECHNOLOGY LEADER | EPC-CO.COM | ©2021 | | 8

QUICK START GUIDE EPC90132

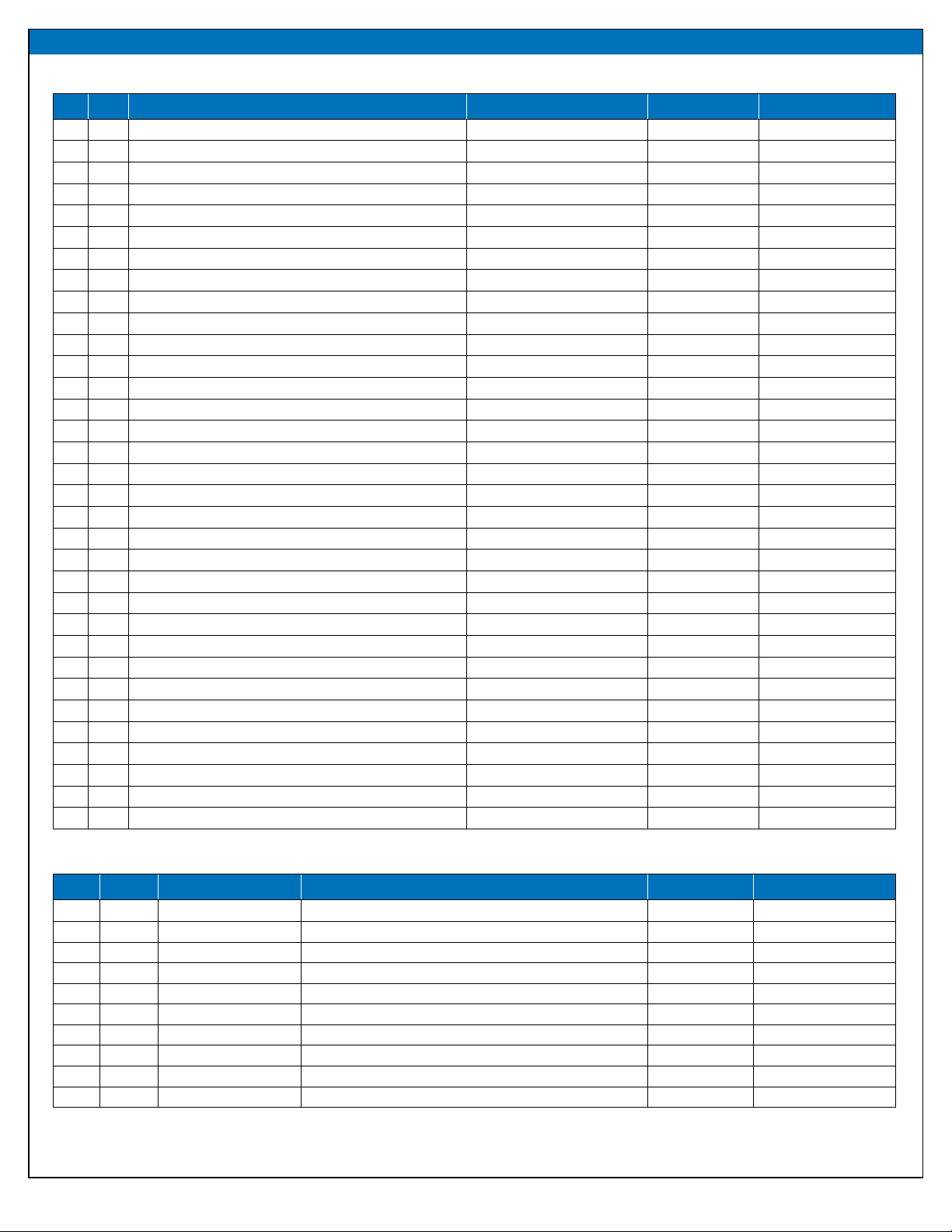

Table 2: Bill of Materials

Item Qty Reference Part Description Manufacturer Part Number

1 1 C11 1 μF TDK C1608X7R1E105K080AB

2 9 C60, C61, C81, C610, C611, C612, C614, C615, C616 0.1 μF, 25 V Yageo CC0402KRX7R8BB104

3 1 C62 22 nF, 25 V TDK C1005X7R1E223K050BB

4 1 C80 4.7 μF, 10 V TDK C1005X5R1A475K050BC

5 2 C100, C101 1 μF, 25 V TDK C1608X7R1E105K

6 2 C601, C602 47 pF, 50 V Yegeo CC0402JRNPO9BN470

7 2 C620, C625 100 pF, 50 V Yegeo CC0402KRX7R9BB101

8 7 Ci1, Ci2, Ci3, Ci4, Ci5, Ci6, Ci7 1 μF, 50 V Taiyo Yuden UMK107AB7105KA-T

910 Cm1, Cm2, Cm3, Cm4, Cm5, Cm6, Cm7, Cm8, Cm9, Cm10 4.7 μF, 50 V TDK C2012X7R1H475K125AC

10 1D60 5 V1, 150 mW Bournes CD0603-Z5V1

11 4D61, D63, D620, D625 40 V 30 mA Diodes Inc. SDM03U40

12 1J3 100 mil 2x12 male header Amphenol 68602-224HLF

13 1J80 100 mil 1x4 male header Tyco 4-103185-0-04

14 1 J90 100 mil 1x2 male header Tyco 4-103185-0-02

15 2J630, J640 .05" Dual Row Male 3-Pos Vert. Sullins GRPB032VWVN-RC

16 1JP630 50 mil +Handle Blue Harwin Inc M50-2030005

17 1JP640 50 mil +Handle Red Harwin Inc M50-2020005

18 2Q1, Q2 40 V 32 A 3.5 mΩ EPC EPC2055

19 1Q60 100 V 2800 mΩ EPC EPC2038

20 1R62 27 k Panasonic ERJ-2GEJ273X

21 1R63 20 Ω Stackpole RMCF0402JT20R0

22 2 R70, R75 2.2 Ω Panasonic ERJ-2GEJ2R2X

23 11 R71, R76, R601, R602, R603, R604, R605, R621, R626, R641, R643 10 k Yageo RC0402FR-0710KL

24 3 R77, R81, R83 0 Ω Stackpole RMCF0402ZT0R00

25 3 R78, R90, R100 0 Ω Panasonic ERJ-3GEY0R00V

26 2R80, R82 1 Ω Yageo RC0402FR-071RL

27 2R620, R625 120 Ω 1% Yageo RC0603FR- 07120RL

28 3 SO1, SO2, SO3 M2 SMD spacer Wurth 9774010243R

29 4 TP1, TP2, TP3, TP4 Test point Keystone 5015

30 1U80 100 V eGaN Driver uPI uP1966A

31 1U100 5.0 V 250 mA DFN Microchip MCP1703T-5002E/MC

32 4U610, U611, U612, U614 Recong Logic Nexperia 74LVC1G99G

33 2U615, U616 Bilateral Analog Switch Texas Instruments SN74LVC1G66DBV

Optional Components

Item Qty Reference Part Description Manufacturer Part Number

1 2 C70, C75 100 pF, 50 V Yegeo CC0402KRX7R9BB101

2 1 Cout GenericOutputCap TBD TBD

3 2 D1, D2 100 V, 2A Vishay SS2PH10-M3

4 1 D77 40 V 300 mA ST BAT54KFILM

5 3 J1, J2, J32 MMCX Molex 734152063

6 1 J9 2 port Euro Block connector Wurth 691216410002

7 2 J22, J33 100 mil 1x2 male header Tyco 4-103185-0-02

8 1 L1 GenericOutputInductor TBD TBD

9 2 R11, R22 0 Ω Stackpole RMCF0402ZT0R00

10 1R60 4.7 Ω Panasonic ERJ-2GEJ4R7X

QUICK START GUIDE EPC90132

EPC – POWER CONVERSION TECHNOLOGY LEADER | EPC-CO.COM | ©2021 | | 9

Figure 11: EPC90132 main schematic

FD1

PCB Fiducial

GND

12 VDC

V dd12

Logic Supply

GND

V dd12

1 μF, 25 V

C11

5 V Logic Regulator

PWM1

PWM2

GND SW Output

Main Supply Input

GND

Sync Buck Output

V CC

GND

FD2

PCB Fiducial

FD3

PCB Fiducial

V OUT

GND

VCC

In1

In2

Qup

Qlow

DT

AP1010_Rev2_1_GeneralDeadtime.SCHDOC

5V

GND

V CC

V 1

AP1006_Rev1_0_12Vto5VlinPSU.SCHDOC

GND

PWM1

PWM2

L I N

HI N

Dead-time and buers

TP2

SMD Probe loop

TP1

TP4

SMD Probe loop

SMD Probe loop SMD Probe loop

TP3

Power StageGate Driver

GND GND

V SW

GND GND

V I N V I N

GND GND

V SW

V SW

Upper Gate

0 Ω

R11

E MPT Y VGu

0 Ω

R22

E MPT Y V Gl

Lower Gate

GND GND

V SW

Switch-node

GNDGND

SO1

Stando M2

9774010243R

SO2

Stando M2

9774010243R

SO3

Stando M2

9774010243R

Heatspreader Mount GND

V GuH

V GlH

V GlL

V GuL

GND

PWMH

PWML

V SW

V GuH

V GlH

V GuL

V GlL

V Gl

GD

AP1017_Rev1_2_100VBGA_GateDriverWboot.SCHDOC

VCC VCC

VCC

GND

GND

V I N

V GuH

V GlH

SW

V GuL

V GlL

V Gu

V Gl

PS

EPC2055_Rev1_0_PhaseLeg.SCHDOC

V OUT

V Gu

V Gl

Signal Inputs

Intermediate Capacitors

Cm7 Cm8 Cm9 Cm10

GNDGND

Cm1

4.7 uF, 50 V 4.7 uF, 50 V 4.7 uF, 50 V 4.7 uF, 50 V 4.7 uF, 50 V 4.7 uF, 50 V 4.7 uF, 50 V 4.7 uF, 50 V 4.7 uF, 50 V4.7 uF, 50 V

Cm2

GND

Cm3

GND

Cm4

GND

Cm5

GND

Cm6

GND GND GND GND

VINVINVINVINVINVINVINVINVINVIN

1 2

3

5

7

4

6

8

J3A

9 10

11

13

15

12

14

16

J3B

17 18

19

21

23

20

22

24

J3C

V I N

V SW

GND

V I N

V I NV I N

V I NV I N

V I NV I N

V SW

V SWV SW

V SWV SW

V SWV SW

GND

TB D

Cout

E MPT Y

TB D

L 1

E MPT Y

.1" Male Vert.

1

2

J90

.1" M ale Vert.

1

2

3

4

J80

.1" M ale Vert.

1

2

J22

E MPT Y

Vert. M MC X

J1

Vert. M MC X

J2

E MPT Y

.1" M ale Vert.

1

2

J33

E MPT Y

Vert. M MCX

J32

E MPT Y

7.62 mm Euro Term

1

2

J9

E MPT Y

0 Ω

R90

ATTENTION

ELECTROSTATIC

SENSITIVE DEVICE

ATTENTION

ELECTROSTATIC

SENSITIVE DEVICE

HIGH VOLTAGE

HIGH VOLTAGE

ATTENTION

HOT SURFACE

QUICK START GUIDE EPC90132

EPC – POWER CONVERSION TECHNOLOGY LEADER | EPC-CO.COM | ©2021 | | 10

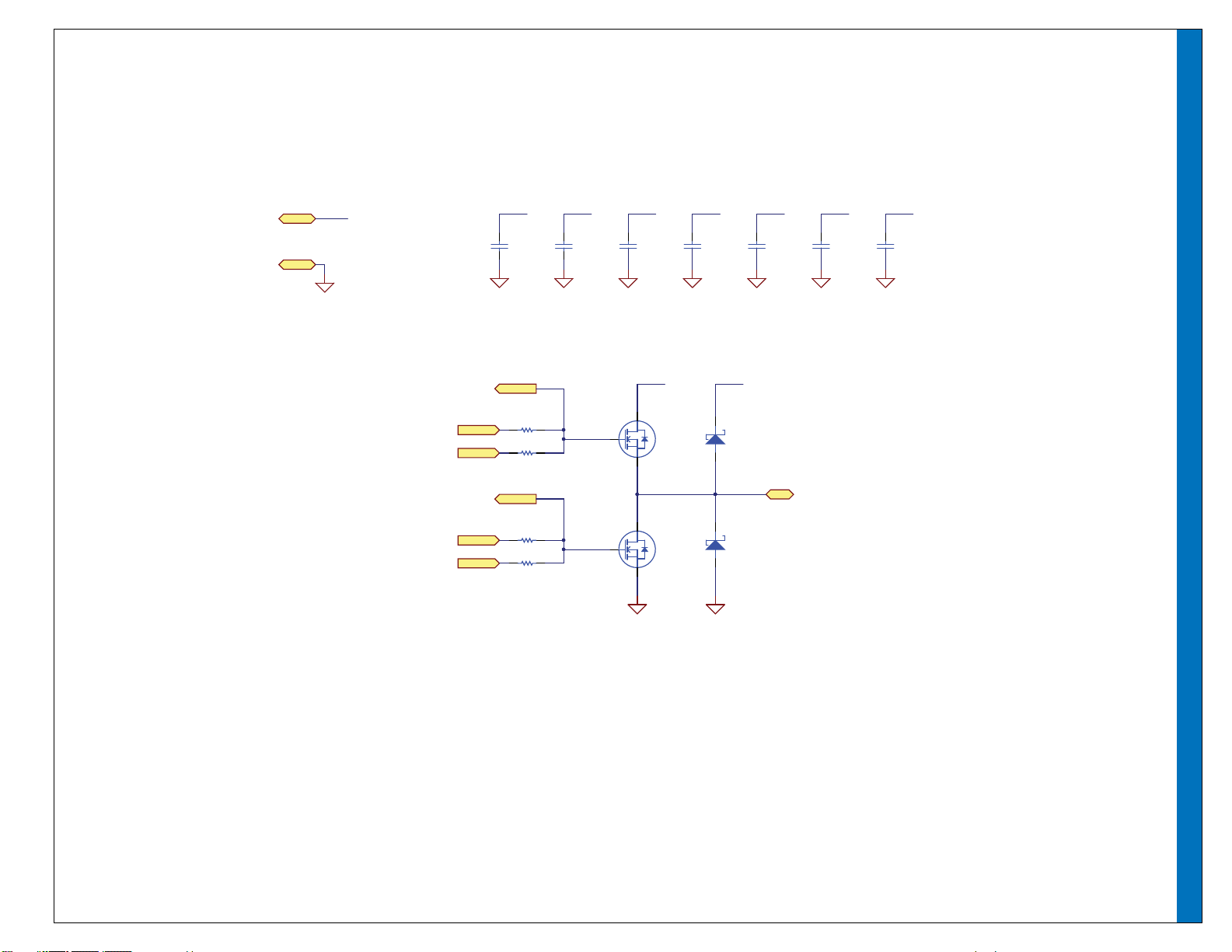

Figure 12: Power Stage schematic using the EPC2055

Vin

GND

GND

DC Input

32 Vmax.

VIN VIN

VIN VIN

VIN VIN VIN VIN VIN VIN

HF Loop Capacitors

Power Stage

SW

SS2PH 10-M3

100 V, 2 A

D1

E MPT Y

GND

SS2PH 10-M3

100 V, 2 A

D2

E MPT Y

Optional Diodes

SW

Ci3 Ci4 Ci5 Ci6 Ci7

1 μF, 50 V 1 μF, 50 V 1 μF, 50 V 1 μF, 50 V 1 μF, 50 V 1 μF, 50 V 1 μF, 50 V

Ci1 Ci2

GND GND GND GND GND GND GND

GND

V GlH

V GuH V Gu

V Gl

0 ΩR81

1 ΩR80

0 ΩR83

1 ΩR82

V GlL

V GuL

V Gl

V Gu

40 V, 32 A, 3.5 mΩ

Q1

EPC2055

40 V, 32 A, 3.5 mΩ

EPC2055

Q2

QUICK START GUIDE EPC90132

EPC – POWER CONVERSION TECHNOLOGY LEADER | EPC-CO.COM | ©2021 | | 11

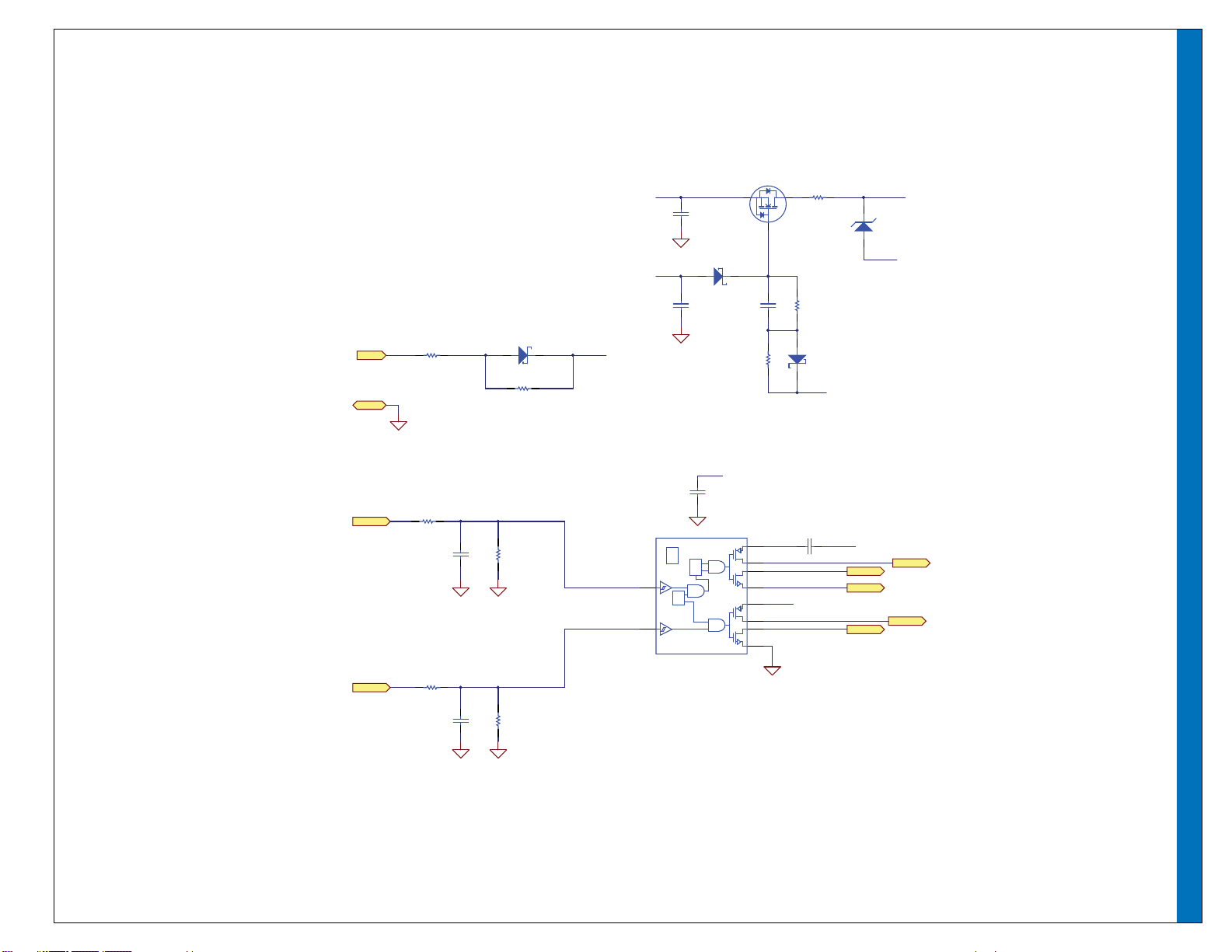

Figure 13: Gate Driver schematic

VCC

PWML Gate Driver

GND

GND

PWMH

0 Ω

R78

2.2 Ω

2.2 Ω

R70

R75

4.7 V

VGlow

Gbtst

5V 1, 150 mW

D60

CD0603-Z5V 1

VBSin 5VHS1

VSWN

0.1 μF, 25 V

C81

4.7 μF, 10 V

C80

4.7 V

0 ΩR77

5VHS1

VSWN

Synchronous Boostrap Power Supply

40 V 30 mA

D63

SDM03U40

27 k

R62

40 V 30 mA

D61

SDM03U40

GND

20 Ω

R63

4.7 Ω

R60

E MPT Y

0.1 μF, 25 V

C61

22 nF, 25 V

C62

0.1 μF, 25 V

C60

GND

40 V300 mA

D77

E MPT Y

GND

GND

10 k

R71

10 k

R76

100 pF, 50 V

100 pF, 50 V

C70

E MPT Y

C75

E MPT Y

GND

GND

4.7 V

4.7 VVCC

GND

GND

100 V2800 mΩ

Q60

EPC2038

U80

uP1966A

Default = No Sync Boot

Sync Boot = Install R60 and D77, remove R77

No Sync Boot = Install R77, remove R60 and D77

VBSin

V SW N

V SW

V Glow

V GuL

V GlL

V GuH

V GlH

QUICK START GUIDE EPC90132

EPC – POWER CONVERSION TECHNOLOGY LEADER | EPC-CO.COM | ©2021 | | 12

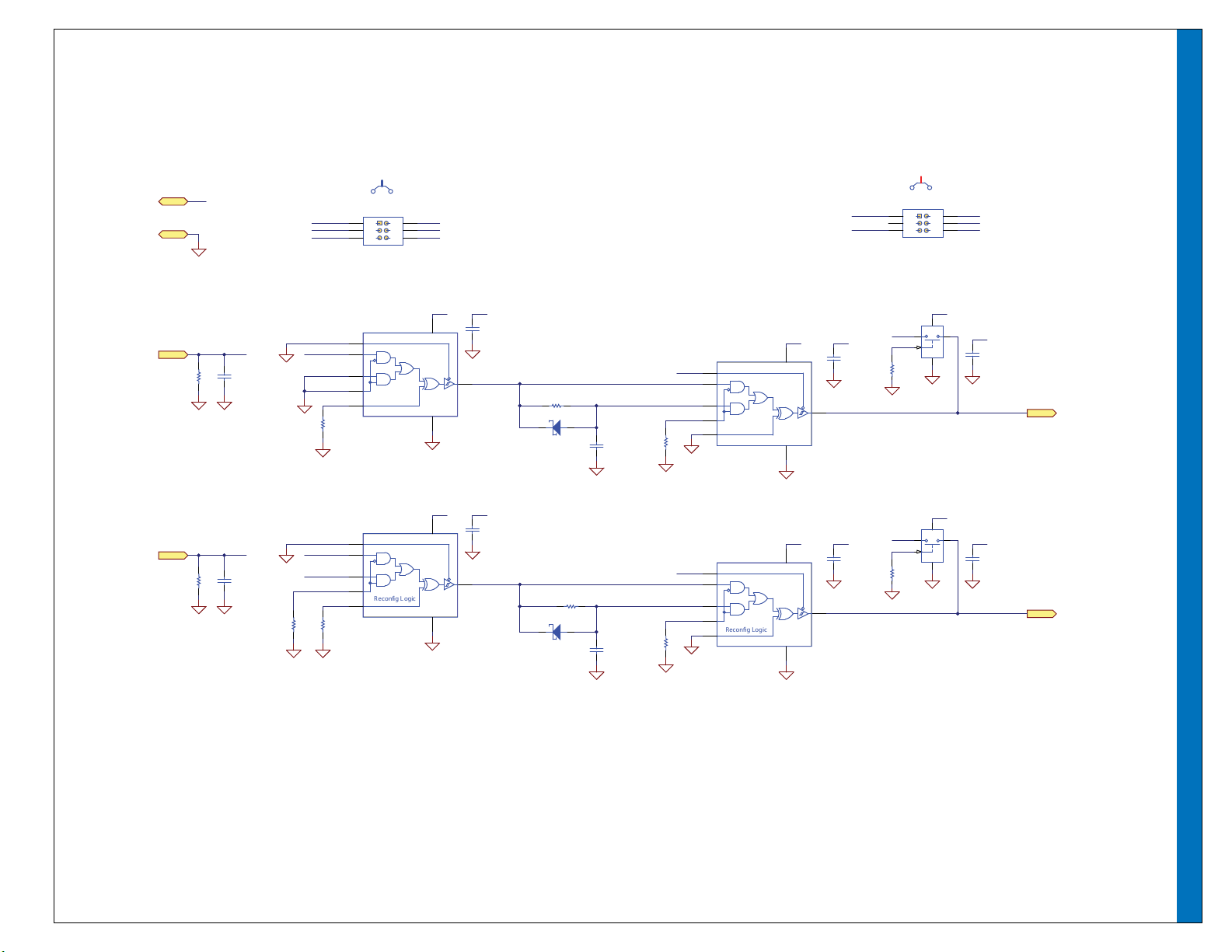

Figure 14: Dead-time and Bypass schematic

GND

GND

V CC

GND

V CC

GND

0.1 μF, 25 V

C610

V CCV CC

GND

GND

GND

0.1 μF, 25 V

C612

V CC

0.1 μF, 25 V

C614

Qlow

Qup

10 k

R602

47 pF, 50 V

C602

GND GND

10 k

R601

47 pF, 50 V

C601

GND GND

In1

In2

100 pF, 50 V

C620

40 V 30 mA

D620

SDM03U40

120 Ω1%

R620

GND

10 k

R604

GND

10 k

R603

GND

0.1 μF, 25 V

C611

Deadti me Lower

Deadti me Upper

Signal Polarity and Input Buers

Bypass Mode Select

Polarity 0=Non-invert, 1= Invert

Polarity 0=Non-invert, 1= Invert

PolQup

PolQlow

DT Qlow

Dual/Single PWM, Buck, and Boost Mode Selector

JP630

50 mil +Handle Blue

Dual Single

Buck Single Signal

Boost Single Signal

V CC

V CC

V CC

F ull By pass

No By pass

DT By pass

In1

In2

InBufQup

InBufQlow

100 pF, 50 V

C625

40 V 30 mA

D625

SDM03U40

120 Ω1%

R625

GND

Default = 10 ns

Default = 10 ns

DT Qup

74LV C 1G99G

Recong Logic

Recong Logic

Recong Logic

G ND

4

2

3

7

V C C

8

5

1

6

U610

GND

GND

74LV C 1G99G

Reconfig Logic

G ND

4

2

3

7

VCC

8

5

1

6

U611

Dual

In1

In1

In2

1 2

3

5

4

6

J630

Con3x2.05M

10 k

R605

GND

GND

V CC

74LVC1G99G

G ND

4

2

3

7

V C C

8

5

1

6

U612

GND

V C C

G ND

U615

Bilateral Analog Switch

GND

0.1μF, 25 V

C615

V CC

GND

V CC

In1

V CC

V CC

V CC

1 2

3

5

4

6

J640

Con3x2.05M

GND

VCCVCC

VCCVCC

74LVC1G99G

G ND

4

2

3

7

VCC

8

5

1

6

U614

GND

GND

10 k

R621

GND

SW byp

SW byp

10 k

R641

GND

V C C

G ND

U616

Bilateral Analog Switch

GND

0.1μF, 25 V

C616

V CC

GND

V CC

In2

SW byp

10 k

R643

GND

UseDT

GND

10 k

R626

GND

UseDT

SW byp

SW byp

UseDT

Output Buers and Signal Select

PolQlow

PolQup

Dual

JP640

50mil +Handle Red

Demonstration Board Notication

The EPC90132 board is intended for product evaluation purposes only. It is not intended for commercial use nor is it FCC approved for resale. Replace components on

the Evaluation Board only with those parts shown on the parts list (or Bill of Materials) in the Quick Start Guide. Contact an authorized EPC representative with any questions.This board is

intended to be used by certied professionals, in a lab environment, following proper safety procedures. Use at your own risk.

As an evaluation tool, this board is not designed for compliance with the European Union directive on electromagnetic compatibility or any other such directives or regulations. As board

buildsare attimes subject to product availability,it ispossible that boards maycontain componentsor assemblymaterialsthat are notRoHScompliant.EcientPower ConversionCorpora-

tion (EPC) makes no guarantee that the purchased board is 100% RoHS compliant.

The Evaluation board (or kit) is for demonstration purposes only and neither the Board nor this Quick Start Guide constitute a sales contract or create any kind of warranty, whether express

or implied, as to the applications or products involved.

Disclaimer: EPC reserves theright atany time, without notice, tomakechanges toany products described herein to improve reliability, function, or design.EPC does notassume anyliability

arising out of the application or use of any product or circuit described herein; neither does it convey any license under its patent rights, or other intellectual property whatsoever, nor the

rights of others.

EPC Products are distributed through Digi-Key.

www.digikey.com

For More Information:

or your local sales representative

Visit our website:

www.epc-co.com

Sign-up to receive

EPC updates at

bit.ly/EPCupdates

or text“EPC”to 22828

Table of contents

Other IEPC Motherboard manuals