IEPC EPC9126 User manual

Development Board

EPC9126/EPC9126HC

Quick Start Guide

EPC2212/EPC2001C

100 V High Current Pulsed Laser Diode Driver

Revision 3.0

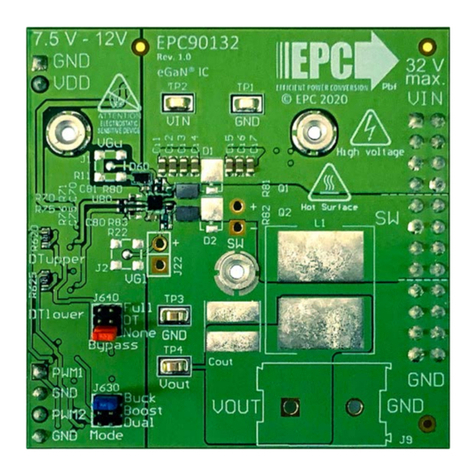

QUICK START GUIDE Demonstration System EPC9126xx

EPC – THE LEADER IN GaN TECHNOLOGY | WWW.EPC-CO.COM | COPYRIGHT 2019 | | 2

DESCRIPTION

The EPC9126 and EPC9126HC development boards are primarily intended

to drive laser diodes with high current pulses with total pulse widths < 3 ns

(half amplitude pulse width). The board is shipped with an EPC2212 or

EPC2001C (HC version) enhancement mode (eGaN®) eld eect transistor

(FET). The EPC2212 is an AEC-Q101 automotive qualied 100 V FET capable

of current pulses up to 75 A, and the EPC2001C is a 100 V FET capable

of current pulses up to 150 A. The development boards used the same

printed circuit board with minor component changes in addition to the

dierent FETs. Due to the fact that the basic design and behavior of the

boards is nearly the same, the term EPC9126xx will be used to refer to either

board, and only when necessary will one or the other board be called

attention to. The EPC9126xx ships with the EPC9989 interposer board.

The EPC9989 has a collection of break-away 5 mm square interposer PCBs

with footprints for dierent lasers and a collection of other footprints. The

use of the interposers allows many dierent lasers or other loads to be

mounted while still being able to use the EPC9126xx. The boards do not

include a laser diode, which must be supplied by the user.

The EPC9126xx comprises a ground-referenced eGaN FET driven by a

Texas Instruments LMG1020 gate driver. The EPC9989 interposer provides

multiple options for mounting laser diodes. The printed circuit board is

designed to minimize the power loop inductance while maintaining

mounting exibility for the laser diode or other load. It includes multiple

on-board passive probes for voltages and discharge capacitor current,

and is equipped with SMA connections for input and sensing designed for

50 ohm measurement systems. In addition, the board includes a narrow

pulse generator capable of sub-nanosecond precision, or the user can

simply send the input to the gate drive directly. Finally, the board can also

be used for other applications requiring a ground-referenced eGaN FET,

e.g. Class E ampliers or similar. A complete block diagram of the circuit is

given in gure 1, and a detailed schematic in gure 4.

For more information on the EPC2212C or EPC2001C eGaN FETs,

please refer to the datasheets available from EPC at www.epc-co.com.

The datasheet should be read in conjunction with this quick start guide.

In addition, there is an application note, AN027 eGaN FETs for Lidar –

Getting the Most Out of the EPC9126 Laser Driver. While the note discusses

Rev. 2 of the EPC9126xx, most of the information is applicable to Rev. 3.

SETUP AND OPERATION

Development board EPC9126xx is easy to set up to evaluate the

performance of the EPC2212 or EPC2001C(HC version) eGaN FET. Refer

to Figure 2 for proper connect and measurement setup and follow the

procedure below:

1. Review laser safety considerations. Observe all necessary laser

safety requirements including the use of personal protection

equipment (PPE) as required. Refer to qualied safety personnel

as necessary.

2. With power o, install laser diode U2 or other load. The use of one

of the interposers from the included EPC9989 be used to mount the

laser or other load, and this is discussed in the section Laser Diode and

Load Considerations for further information.

Table 1: Performance Summary (TA= 25°C) EPC9126 and EPC9126HC

Symbol Parameter Conditions Min Nom Max Units

VLogic

Gate drive and

logic supply 6 12 V

VBUS

Bus Input

Voltage Range 0

80

V

ZIN Input impedance 50 Ω

VINPUT Input pulse range 0

5

V

TPin Input pulse width 1 ns

3. With power o, connect the input power supply bus to +VBUS (J2)

and ground / return to –VBUS (J2) or GND.

4. With power o, connect the logic supply (7-12 V VDC) to +VLogic or

GND.

5. With power o, connect the signal pulse generator to the input

J5. J5 is terminated with 50 Ω on the EPC9126, and is designed

for a 5 V logic input. The signal input can handle up to 0.25 W

RMS (3.5 V RMS), which corresponds to a 50% duty cycle at 5 V.

This pulse specication is for the input only, and the user will have

to make informed choices regarding the rest of the circuit.

6. Connect the remaining measurement SMA outputs to an

oscilloscope, using 50 Ω cables and with the scope inputs set

to 50 Ω impedance. See section Measurement Considerations

for more information, including the attenuation values for each

output.

7. Turn on the logic supply voltage to a value within the

specications.

8. Turn on the bus voltage to a value within the specication.

9. Turn on the pulse source and observe switching operation via the

outputs and any additional desired probing. Laser diode output

may be observed with an appropriate electro-optical receiver.

10. Once operational, adjust the bus voltage, input pulse width, and

pulse repletion frequency (PRF) as desired within the operating

range and observe the system behavior.

11. For shutdown, please follow steps in reverse.

NOTE: When measuring the high frequency content switch node, care must be taken

to avoid long ground leads. Measure the switch node by placing the oscilloscope

probe tip through the large via on the switch node (designed for this purpose) and

grounding the probe directly across the GND terminal provided. See Figure 3 for

proper scope probe technique.

SAFETY WARNING: This board is capable of driving laser diodes to

generate high peak power optical pulses. Such pulses are capable of

creating PERMANENT VISION DAMAGE. Laser diodes may emit infrared

(IR) light that is invisible, but which can still cause PERMANENT VISION

DAMAGE. User is fully responsible for following proper laser safety

procedures to prevent vision damage.

QUICK START GUIDE Demonstration System EPC9126xx

EPC – THE LEADER IN GaN TECHNOLOGY | WWW.EPC-CO.COM | COPYRIGHT 2019 | | 3

OPERATING PRINCIPLE

The EPC9126xx is shipped as a capacitive discharge laser diode driver.

Please refer to the block diagram (gure 2) and the schematic (gure 4).

It has several possible modications (section MODIFICATIONS), but only

the basic operation will be covered in this section. The EPC9126xx basic

operating principle is to discharge energy storage capacitance {C10,

C11, C12, C13, C14} through the laser diode, and then recharge {C10,

C11, C12, C13, C14} through the resistor bank {R2, R3, R5, R6}.

The discharge is controlled via an input pulse that is delivered to SMA

connector J5, which is terminated on the demo board with 50 Ω. As

shipped, SW1_6 is turned on, and this pulse is delivered to gate driver

U5. When the input goes high, the gate driver turns on Q1, allowing {C10,

C11, C12, C13, C14} to discharge through the laser diode U2. When the

input goes low, Q1 turns o. If there is current remaining in the power

loop, diodes D1, D2 (if added by user) can conduct and help prevent

overvoltage of the laser and FET.

Measurements of many of the main waveforms can be made through

the SMA test points provided. These test points can provide waveform

measurements with equivalent bandwidths > 3 GHz. As a result, they

have requirements and properties that dier from most conventional

oscilloscope probes. More details on the usage of these test points is

provided in section MEASUREMENT CONSIDERATIONS.

For further details on lidar driver circuits, it is recommended to read

the application note Getting the Most out of eGaN FETs and Your

EPC9126 Laser Driver (AN027), available at www.epc-co.com. While this

application note refers to V2.5 of the EPC9126xx, the basic principles

and design methods are still applicable.

LASER DIODE OR LOAD CONSIDERATIONS

The EPC9126xx can be used as is to mount a laser diode or other

load. Figure 3 highlights the output pad locations. However, many

laser suppliers have dierent mounting footprints, making it dicult

to optimize the performance of the driver and still maintain the

desired exibility. The use of an interposer PCB provides a solution

to this problem with only a small added performance penalty.

The EPC9126xx Rev. 3 ships with the EPC9989 interposer PCB,

shown in gure 4. The EPC9989 has an assortment of 5 mm square

interposer PCBs that can be snapped o the board. These interposers

have various footprints on the top side that can accommodate

several surface mount laser diodes, an MMCX connector, and several

patterns designed to accommodate a wide variety of possible loads.

These interposers mount between the EPC9126xx and the laser diode

or other load. Figure 5 shows an example of an Excelitas SMD laser

diode mounted with one of the interposers.

Figure 1: Block diagram of EPC9126xx development board

C10, 11, C12, C13, C14

R14, R15, R16, R17, R18

Shunt (J6)

VBUS

D1,D2

VOUT (J7)

S1_1 – S1_5

S1_6

Cap (J3)

Input (J5) Narrow pulse

generator VGS (J9)VGDIN

VLogic

U2

Q1

+

+

–

–

Figure 2: Connection and measurement setup

Figure 3: Output terminals of EPC9126xx

Figure 4: EPC9989 interposer PCB

Top

Bottom

SMD lasers MMCX Alternate loads

Breakaway

V-grooves

Laser cathode

(FET drain)

Laser anode

(FET drain)

GND (for alternate

applications)

V7

IN

Laser

diode

or load

Signal generator

V

BUS

+– +–

Oscilloscope

(50 Ωinputs)

QUICK START GUIDE Demonstration System EPC9126xx

EPC – THE LEADER IN GaN TECHNOLOGY | WWW.EPC-CO.COM | COPYRIGHT 2019 | | 4

The recommended use of the interposer is the following:

1. Apply solder paste to the U2 pads on the EPC9126xx PCB.

2. Apply solder paste to the appropriate pads on the top side of the

interposer.

3. Carefully position the desired interposer with the bottom side facing

the top side of the EPC9126xx on the U2 footprint.

4. Position the laser diode or desired load on the interposer.

5. Reow with the recommended temperature prole for the solder

used. The use of a reow oven that can meet the recommended

soldering specications is highly recommended. Other reow

methods may also be used based on the experience of the user.

The power loop inductance, including that of the laser diode, is a primary

factor that determines the shape of the laser pulse. Considerable eort

has been made to minimize power loop inductance while maximizing

the choice of laser diode and its orientation. The discharge caps,

current sense resistors, and the eGaN FET must all be mounted in close

proximity to minimize inductance. As a result, the user must take care

not to damage any components when mounting the laser or changing

other components in the power loop.

Laser diode current pulses can result in peak powers of several hundred

watts to over 1 kW. Laser diodes for lidar applications are designed with

this in mind, but thermal limitations of the laser package mean that

pulse widths, duty cycles, and pulse repetition frequency limitations

must be observed. Read laser diode data sheets carefully and follow any

manufacturers’ recommendations.

This board has been tested with the following laser diodes:

TPGAD1S09H from Excelitas (http://www.excelitas.com).

MEASUREMENT CONSIDERATIONS

SMA jacks are provided to measure several voltages in the circuit, including

gate drive input, Q1 gate voltage, Q1 drain voltage, charge voltage of

the energy storage cap, and the sense voltage of the discharge cap

current measurement shunt. All measurement points are designed to be

terminated in 50 Ω, hence when viewing waveforms, the oscilloscope

inputs should be set to a 50 Ω input. Ideally, unused inputs should be

also terminated with a 50 Ω load to prevent the probes from creating

additional resonances. The Q1 drain voltage and the discharge cap sense

voltage have on-board terminations to greatly reduce this eect, and in

practice, the remaining resonances may be small or otherwise tolerable.

It is recommended that the user verify this for their own requirements.

All sense measurement SMAs, except for the shunt measurement, use the

transmission line probe principle to obtain waveform delity at sub-ns

time scales. They have been veried to produce near-identical results to a

Tektronix P9158 3 GHz transmission line probe. As a result of their design,

they have a built-in attenuation factor. In addition, the impedance of the

probes is relatively small, and as a result, the test points for high voltage

measurements include a DC blocking capacitor. If long pulse widths are

used, these test points may yield erroneous results, and an external probe

should be used.

The current shunt is designed to estimate the discharge capacitor current.

Substantial eort has been made to reduce the inductive eects of the

current shunt, both through the use of carefully selected resistors and a

compensation network to help compensate for the shunt equivalent

series resistance. However, the shunt is a compromise between current

measurement accuracy and minimizing the impact on the laser driver

performance. If a more accurate shunt waveform measurement is desired,

the shunt resistors may be replaced with ones that provide higher accuracy.

This is likely to require higher resistor values, which can contribute to errors

in the capacitor voltage measurement and in increased power dissipation.

Finally, note that the capacitor current also includes the current due to D1

and D2 (if included), and PCB capacitance.

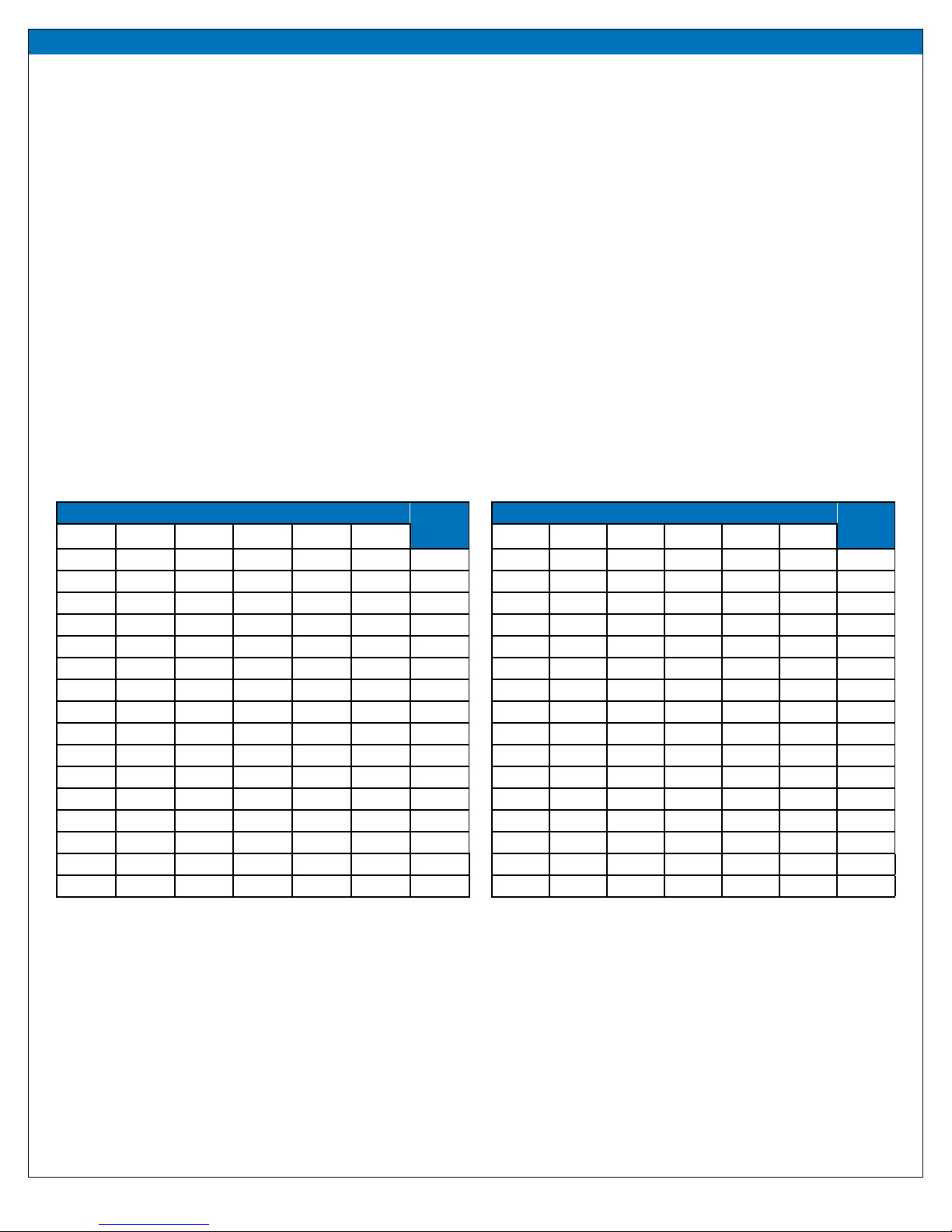

Table 2 summarizes the properties of the SMA test points for ease of

reference.

Table 2: Properties of SMA test points

Designator PCB label Description Attenuation factor DC blocking cap LF time constant Internal 50 Ω

termination

J3 CAP Discharge capacitor voltage

(VCHARGE on schematic) 41 V/V 10 nF 10 μs YES

J6 SHUNT Discharge shunt voltage 21.2 A/V (EPC9126)

45.5 A/V (EPC9126HC) NO N/A NO

J7 VOUT Q1 drain voltage

41 V/V

10 nF 10 μs YES

J9 VGDIN Gate drive input 20 NO N/A NO

J10 VGS Q1 gate voltage 20 NO N/A NO

Laser diode

or load

EPC9989

interposer

EPC9126

eGaN FET

Gate driver

Current

shunt

Discharge

capacitors

Recharging

resistors

Figure 5: Laser mounted to EPC9126xx using interposer

QUICK START GUIDE Demonstration System EPC9126xx

EPC – THE LEADER IN GaN TECHNOLOGY | WWW.EPC-CO.COM | COPYRIGHT 2019 | | 5

OTHER FEATURES

Narrow pulse generator:

Many signal generators cannot produce an accurate, short pulse.

The EPC9126xx includes a function to obtain narrow output pulses, following

a method given in Section 8.2.2.2 of the Texas Instruments LMG1020 data

sheet.This is controlled through DIP switch S1. For normal operation, position

6 should be ON, and the positions 1 through 5 should be OFF. In this case, the

input pulse to J5 will be passed to the gate drive unmodied.

To operation the narrow pulse generator, move position 6 to OFF. The pulse

input to J5 is now a trigger pulse and must be set to at least 60 ns, with at

least 300ns o time between pulses. The pulse width can now be adjusted

via S1 switch positions 1 through 5. For best results, keep position 1 in the

OFF state. For very narrow pulses, the position 1 switch may be turned ON,

but reliable operation cannot be expected. Approximate pulse width values

are summarized in Table 3. Since these values are approximate, user must

verify as necessary.

Switch setting (Pos 1 = OFF) Pulse

width

(ns)

654321

0 0 0 0 0 0 60.4

0 1 0 0 0 0 38.1

0 0 1 0 0 0 18.5

0 1 1 0 0 0 11.5

0001009.3

0101006.6

0011005.5

0111005.1

0000104.9

0100103.4

0010102.9

0110102.4

0001102.1

0101101.9

0011101.7

0111101.2

Switch setting (Pos 1 = ON) Pulse

width

(ns)

654321

0000011.6

0 1 0 0 0 1 1.46

0 0 1 0 0 1 1.32

0 1 1 0 0 1 1.17

0 0 0 1 0 1 0.96

0 1 0 1 0 1 0.65

0 0 1 1 0 1 0.45

0 1 1 1 0 1 0.32

0000110.3

0100110

0010110

0110110

0001110

0101110

0011110

0111110

Table 3: Narrow pulse generator switch settings with S1 Pos 6 = OFF. (a): POS 1 = OFF (recommended). (b) POS 1 = ON (not recommended for reliable operation).

(a) (b)

Modications:

While diodes D1 and D2 can provide some protection to FET Q1 and

laser D3, they have parasitic inductance and capacitance that can reduce

performance at the very fastest speeds. Hence, they are not populated,

and it is left to the user to determine whether they are necessary for a

particular application.

The value of the shunt resistors can be increased up to a point to improve

the discharge cap current sense accuracy. Note that accurate measure-

ment of current while inserting extremely low inductance into the power

loop is extremely challenging, and many factors must be considered.

For the lowest possible inductance, the resistors can be replaced with

copper foil if no sensing is needed.

The value of the energy storage cap {C11, C12, C13, C14, C15} can be

modied as desired, as well as the recharge resistor {R2, R3, R5, R6}.

In the extreme case, the resistor may be reduced to 0 Ω for cases where a

capacitive discharge pulse is not desired.

QUICK START GUIDE Demonstration System EPC9126xx

EPC – THE LEADER IN GaN TECHNOLOGY | WWW.EPC-CO.COM | COPYRIGHT 2019 | | 6

Figure 6: Lidar Pulse Demonstration Board schematic

V5V

6VDC - 12VDC

Logic Supply Regulator

MCP1703T-5002E/MC

5.0 V 250 mA DFN

OUT

GN D

IN

GN D

U1

Logic Suppl

y

Main Supply Input

FD1

Local Fiducials

FD2 FD3

Vlogic

PULSE_IN

SMA SM

D

J5

SMA SMD

J7

100

12

R10

0.47

12

R14

100

12

R22

Vout

V5V

1 μF, 50 V

C2

1 μF, 50 V

C3

1 μF, 50 V

C4

VBUS

100

12

R11

100

12

R23

100 nF, 25 V

C20

0

1 2

R1

Vdrain

Vgate

SMD probe loop

1

TP2

1

TP4

SMD probe loop

1

TP1

VBUS

VCHARGE

SMD probe loo

p SMD probe loop SMD probe loop SMD probe loop

1

TP3

5 pF, 50 V

C15

10

1 2

R9

100 nF, 25 V

C18

100 nF, 25 V

C22

PLS_IN1

100 V 25A 7 mΩ

EPC9126: Q1 = EPC2212

EPC9126HC: Q1= EPC2001C

220 pF, 100 V

C10

220 pF, 100 V

C11

220 pF, 100 V

C12

220 pF, 100 V

C13

220 pF, 100 V

C14

3.9k

1 2

R2

3.9k

1 2

R3

3.9k

1 2

R5

3.9k

1 2

R6

VSHUNT

1μF, 100 V

C5

1μF, 100 V

C6

1μF, 100 V

C7

1μF, 100 V

C8

330 Ω, 700 mA

12

FB2

10 nF, 100 V

C19

953

12

R34

VGDIN VGS

1k

1 2

R19

Gate drive input sense

SMA SMD

J3

100

12

R7

100

12

R8

10 nF, 100 V

C9

1k

1 2

R4

SMA SMD

J6

SMA SMD

J9

SMA SMD

J8 953

12

R33

Gate voltage sense

Shunt voltage sense

Discharge cap voltage sens

e

4.7 μF, 25 V

C1

4-40

HOLE1

4-40

HOLE2

4-40

HOLE3

4-40

HOLE4

1

2

J1

1776113-2

330 Ω, 700 mA

1

2

FB3

CAP

SHUNT

i

Z 50 single core

i

Z 50 single core i

Z 50 single core

i

Z 50 single core

i

Z 50 single core

i

Z 50 single core

i

GD prop delay i

GD prop delay

1

TP6

1

TP5

3x1 0.1" Male Vert

.

1

2

3

J4

Vlogic

VBUS

i

Z 50 single core

i

Z 50 single core

0.47

12

R15

0.47

12

R16

0.47

12

R17

0.47

12

R18

i

High voltage

V5V

1

2

J2

1776113-2

MB1

MB3

MB5

MB7

MB2

MB4

MB6

MB8

Drain voltage sense

100 V 200 mA

D1

EMPTY

100 V 200 mA

D2

EMPTY

100 nF, 16V

C21

1

6

54

3

2

VDD

GND

OUTH

OUTL

IN-

IN+

U4

XLMG1020

1 6

5

43

2

VCCGND

U5

NC7WZ16L6X

1 6

5

43

2

VCCGND

U3

NC7WZ16L6X

0

1

2

R30

EMPTY

8 pF, 50 V

C26

402, 1%

1 2

R25

820, 1%

1 2

R27

1.60k, 1%

1 2

R29

8 pF, 50 V

C24

PLS_IN1

14

3 2

23

1

4

U2

DNP

1

2

3

4

5

6 7

8

9

10

11

12

S1

100

12

R20

EMPTY

100

12

R21

5 pF, 50 V

C23

5 pF, 50 V

C25

10

1 2

R26

10

1 2

R28

200, 1%

1 2

R24

3.24k, 1%

1 2

R31

10

1 2

R32

5 pF, 50 V

C16

EMPTY

5 pF, 50 V

C17

EMPTY

i

Z 50 single core

330 Ω, 700 mA

12 FB1

V5V

49.9

1 2

R12

Capacitor Recharge

Discharge capacitor

Pulse current shunt

Laser (or alternate load)

Optional drainclamp

Gate drive

Input pulse processing

0

1 2

R13

HC: C10-C14 = 560 pF

HC: R14-R18 = 0.22

QUICK START GUIDE Demonstration System EPC9126xx

EPC – THE LEADER IN GaN TECHNOLOGY | WWW.EPC-CO.COM | COPYRIGHT 2019 | | 7

Table 4: Bill of Materials - EPC9126xx

Item Quantity Reference Part Description Manufacturer Part Number

1 1 C1 Capacitor, 4.7 μF, 25 V, X5R

TDK

C1608X5R1E475K080AC

2 5 C10, C11, C12, C13, C14 Capacitor, 220 pf, 100 V, NP0 (EPC9126)

Capacitor, 560 pf, 100 V, NP0 (EPC9126HC)

TDK

C1005C0G2A221J050BA (EPC9126)

C1005C0G2A221J050BA (EPC9126HC)

3 3 C15, C23, C25 Capacitor, 5 pf, 50 V, NP0

TDK

C1005C0G1H050C050BA

4 2 C16, C17 Capacitor, 5 pf, 50 V, NP0

TDK

C1005C0G1H050C050BA

5 3 C18, C20, C22 Capacitor, 100 nf, 25 V, X7R

TDK

C1005X7R1E104K050BB

6 3 C2, C3, C4 Capacitor, 1 μF, 50 V, X7R

Taiyo Yuden

UMK107AB7105KA-T

7 1 C21 Capacitor, 100 nf, 16 V, X5R

TDK

C0510X5R1C104M030BC

8 2 C24, C26 Capacitor, 8 pf, 50 V, NP0

Murata

GRM1885C1H8R0BA01D

9 4 C5, C6, C7, C8 Capacitor, 1 μF, 100 V, X7R

TDK

CGA4J3X7S2A105K125AE

10 2 C9, C19 Capacitor, 10 nf, 100 V, NP0

TDK

C1608C0G2A103J080AC

11 3 FB1, FB2, FB3 Ferrite bead, 330 Ω, 700 mA

TDK

MPZ1005S331ET000

12 2 J1, J2 Board to wire connector, 2 position

Tyco Electronics

1776113-2

13 6 J3, J5, J6, J7, J8, J9 Female SMA SMD

Molex

0732511350

14 1 J4 Header, 3x1 0.1 Male Vert.

Tyco

68001-236HLF

15 1 Q1 100 V 18A 13.5 mΩ (EPC9126)

100 V 25A 7 mΩ (EPC9126HC)

EPC

EPC2212 (EPC9126)

EPC2001C (EPC9126HC)

16 1 R1 Resistor, 0, 0402

Panasonic

ERJ-2GE0R00X

17 2 R10, R11 Resistor, 100, 1%, 0603

Vishay

MCT0603MC1000FP500

18 1 R12 Resistor, 49.9, 1% 0402

Panasonic

ERJ-2RKF49R9X

19 1 R13 Resistor, 0, 0402

Panasonic

ERJ-2GE0R00X

20

5

R14, R15, R16, R17, R18 Resistor, 0.47, 1%, 0402 (EPC9126)

Resistor, 0.22, 1%, 0402 (EPC9126HC)

Rohm UCR01MVPFLR470 (EPC9126)

UCR01MVPFLR220 (EPC9126HC)

21

4

R2, R3, R5, R6 Resistor 3.9 k, 1% 0402

Panasonic ERJ-P08J392V

22 1 R24 Resistor 200, 1%, 0402

Stackpole RMCF0402FT200R

23

1

R25 Resistor 402, 1% 0402

Stackpole RMCF0402FT412R

24

1

R27 Resistor 820, 1% 0402

Stackpole RMCF0402FT806R

25

1

R29 Resistor 1.60 k, 1% 0402

Stackpole RMCF0402FT1K60

26

1

R31 Resistor 3.24 k, 1% 0402

Stackpole RMCF0402FT3K24

27

2

R33, R34 Resistor 953 1% 0402

Panasonic ERJ-2RKF9530X

28

2

R4, R19 Resistor, 1 k, 1%, 0603

Vishay PHP00603E1001BST1

29

5

R7, R8, R21, R22, R23 100 1% 0402

Panasonic ERJ-2RKF1000X

30

4

R9, R26, R28, R32 10 1% 0402

Panasonic ERJ-2RKF10R0X

31 1 S1

DIP switch, 6 pos SPST, SOIC

Nidec Copal Electronics CHS-06TA

32 6 TP1, TP2, TP3, TP4, TP5, TP6

SMD probe loop

Keystone 5015

33 1 U1

LDO, 5.0 V 250mA DFN

Microchip MCP1703T-5002E/MC

34 1 U2

Laser

User supplied User Supplied

35 2 U3, U5

UHS dual buer

Fairchild NC7WZ16L6X

36 1 U4

Gate driver

Texas Instrument LMG1020

Table 5: Optional Components

Item Quantity Reference Part Description Manufacturer Part Number

1 2 D1, D2 User selected

User selected

User selected

2 1 R20 Resistor 100 1% 0402

Panasonic

ERJ-2RKF1000X

3 1 R30 Resistor 0 1% 0402

Panasonic

ERJ-2GE0R00X

Demonstration Board Notication

The EPC9126xx board is intended for product evaluation purposes only and is not intended for commercial use. Replace components on the Evaluation Board only with those parts shown on the

parts list (or Bill of Materials) in the Quick Start Guide. Contact an authorized EPC representative with any questions.

This board is intended to be used by certied professionals, in a lab environment, following proper safety procedures. Use at your own risk.

As an evaluation tool, this board is not designed for compliance with the European Union directive on electromagnetic compatibility or any other such directives or regulations. As board builds

are at times subject to product availability, it is possible that boards may contain components or assembly materials that are not RoHS compliant. Ecient Power Conversion Corporation (EPC)

makes no guarantee that the purchased board is 100% RoHS compliant.

The Evaluation board (or kit) is for demonstration purposes only and neither the Board nor this Quick Start Guide constitute a sales contract or create any kind of warranty, whether express or

implied, as to the applications or products involved.

Disclaimer: EPC reserves the right at any time, without notice, to make changes to any products described herein to improve reliability, function, or design. EPC does not assume any liability arising out of

the application or use of any product or circuit described herein; neither does it convey any license under its patent rights, or other intellectual property whatsoever, nor the rights of others.

EPC Products are distributed through Digi-Key.

www.digikey.com

For More Information:

Please contact info@epc-co.com

or your local sales representative

Visit our website:

www.epc-co.com

Sign-up to receive

EPC updates at

bit.ly/EPCupdates

or text EPC to 22828

This manual suits for next models

1

Table of contents

Other IEPC Motherboard manuals