Ier AUTOMATIC SYSTEM SL930 User manual

The information contained in this document is the property of Automatic Systems and is confidential. The recipient is forbidd en to use it for any purpose other

than for the use of the products or the execution of the project to which they refer or to commu nicate it to third parties without the prior written consent of

Automatic Systems. Document subject to change without advance notification.

SL93x + PPV323 + TBV327-MT-EN p. 1/39

USER MANUAL

Rev 10

(Translated from French original notice)

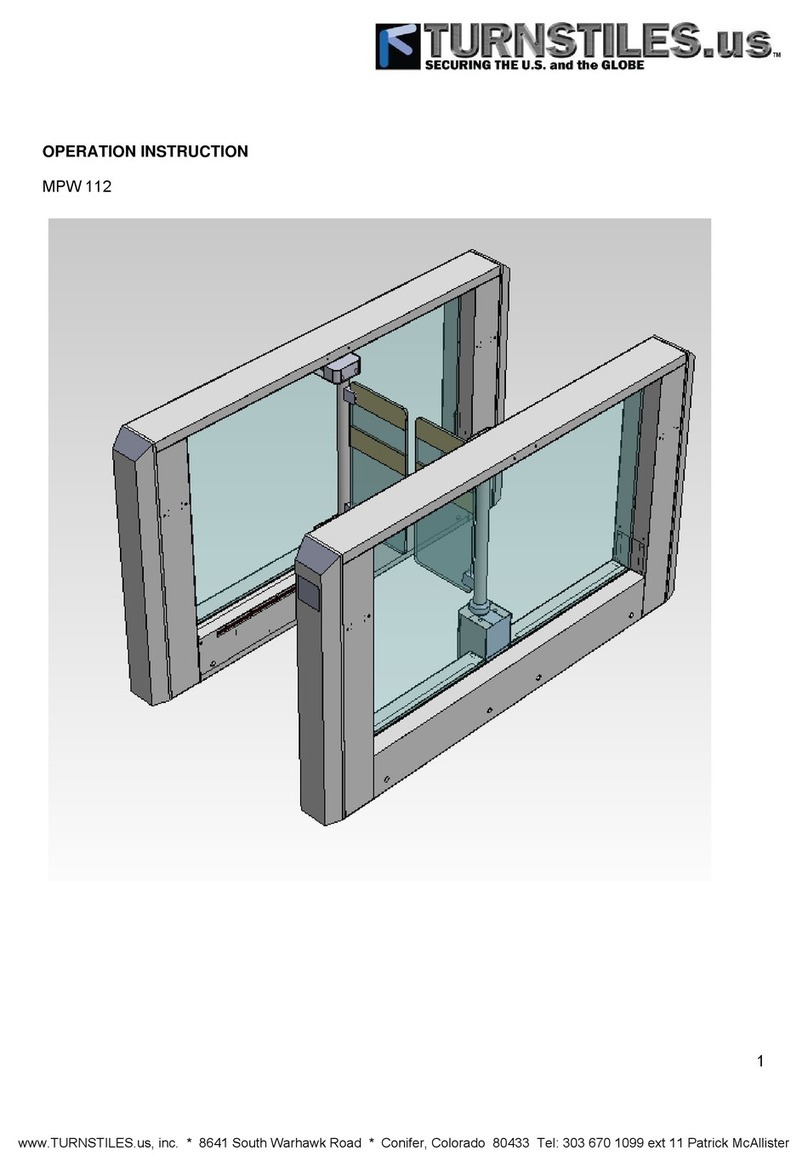

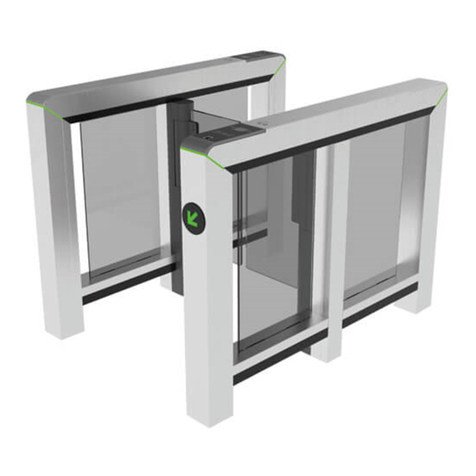

GLASS SWING GATE

SL930 –SL931 –SL932

PPV323

GLASS

LOW-HEIGHT

TURNSTILE

TBV327

The information contained in this document is the property of Automatic Systems and is confidential. The recipient is forbidd en to use it for any purpose other

than for the use of the products or the execution of the project to which they refer or to commu nicate it to third parties without the prior written consent of

Automatic Systems. Document subject to change without advance notification.

SL93x + PPV323 + TBV327-MT-EN p. 2/39

Document changes

Rev.

Date

Written

Checked

Subject

00

2006-12-12

MFy

RWK + JB

Initial version

01

2007-04-23

Mfy

- Page 15 (locking): “locked under voltage”.

- Parameter 60°, 90°, rotating): add range and

default value.

- Input 2: “Pitch of encoder 80”.

- Page 25 (point 3): “remove the screws(31)”.

- Page 5 (1st point): “Folded and soldered

stainless steel plate housing”.

02

2007-06-25

Mfy

- Pages 11, 13, 15, 19: replace the terms “suction

device”and “suction mechanism”by “hold

magnet”.

- Pages 15 & 34: translate electric diagrams in

English.

03

2010-06-11

Mfy

RWK+HB+DL

- Complete revision for adaptation to the

modification realized on the equipment.

04

2010-07-01

Mfy

- Tec. Spec: replace flow by opening time of the

obstacles.

- Non-return lock option for TBV only.

05

2010-07-02

Mfy

RH

- Installation: Last points of the Fixing procedure

transferred to Electrical connections and

Commissioning chapters.

- Preventive maintenance: check power leakage

and evacuation.

06

2011-01-17

Mfy

- SL932 added in:

·Title p1,

·Table ch.2.1,

·Installation plan ch.3.2,

·Spare parts ch.5.4,

·EC certificate ch.7.

07

2012-01-09

Mfy

- Ch. 2.1: MCBF, IP, CE, DAS added.

08

2012-10-03

Mfy

- Parts related to PPV322 & TBV326 removed

from spare parts.

09

2013-04-03

Mfy

YC + RWK

- Spare parts: conical coupling + references to

illustrations added.

- Ch. 5.10. adapted to software version v5.36.

- Ch.5.11. added (Maintenance Interface).

- Electrical diagrams adapted to CPU v16 +

Power board v10.

10

2013-08-28

SLu

- Ch. 5.4. : update spare parts table.

The information contained in this document is the property of Automatic Systems and is confidential. The recipient is forbidd en to use it for any purpose other

than for the use of the products or the execution of the project to which they refer or to commu nicate it to third parties without the prior written consent of

Automatic Systems. Document subject to change without advance notification.

SL93x + PPV323 + TBV327-MT-EN p. 3/39

Table of Contents

1. SAFETY INSTRUCTIONS 4

2. DESCRIPTION 5

2.1. Technical Specifications 5

2.2. Location of the components 6

3. INSTALLATION 7

3.1. Storage 7

3.2. Installation plans 8

3.3. Fixing the equipment to the floor 11

3.4. Electrical connections 12

3.5. Commissioning 13

4. PRINCIPLE OF OPERATION 14

4.1. Locking 15

4.2. Position encoder 16

4.3. Safety 16

5. MAINTENANCE 17

5.1. Removing the housing 17

5.2. Turning the equipment ON/OFF 18

5.3. Preventive maintenance 18

5.4. Spare parts 19

5.5. Adjusting the locking sensor 20

5.6. Adjusting the obstacle closed point 21

5.7. Setting the movement limit stops (5, p6) 21

5.8. Fitting and adjusting the locking mechanism 22

5.9. Replacing an obstacle 25

5.10. Control unit menu (program v5.36) 26

5.11. Maintenance interface 29

5.11.1. Network communication settings 29

5.11.2. Login 29

5.11.3. Status 30

5.11.4. Identification 30

5.11.5. Commands 30

5.11.6. Network 31

5.11.7. Menu Configuration 31

5.12. Trouble shooting 32

5.13. Disposal / Destruction 33

6. ELECTRICAL DIAGRAMS 34

7. DECLARATION OF CONFORMITY 38

The information contained in this document is the property of Automatic Systems and is confidential. The recipient is forbidd en to use it for any purpose other

than for the use of the products or the execution of the project to which they refer or to commu nicate it to third parties without the prior written consent of

Automatic Systems. Document subject to change without advance notification.

SL93x + PPV323 + TBV327-MT-EN p. 4/39

1. SAFETY INSTRUCTIONS

The SL93x, PPV323 and TBV327 gates and turnstiles are intended for the access control of users

and cannot be otherwise used without risk for the user or for the integrity of the equipment.

They are intended for light traffic applications (cf. technical specifications, ch.2.1. )

It is mandatory to let the equipment complete its opening and closing cycles automatically (without

pushing the obstacle) to avoid untimely out of order.

All operations on the equipment must be carried out by qualified personnel. Any unauthorized

operation, or operation carried out by a technician not qualified on this product, voids the

manufacturer’s guarantee automatically.

Access to the mechanism must be limited to personnel aware of the electrical and mechanical risks

that are incurred by negligent action.

If possible, disconnect the electrical supply before opening the enclosure.

Otherwise, turn the power off by means of the circuit breaker located on the power board (ch.5.2. ).

WARNING: In both cases, wait 5 minutes before working inside the equipment (capacitors

discharge)!

Any internal element likely to be put under voltage or to move must be handled with caution.

The equipment is configured in a minimal risk mode for its users. Any changes to the parameters

must be carried out with full knowledge of the facts by qualified personnel and are not the

responsibility of Automatic Systems.

The information contained in this document is the property of Automatic Systems and is confidential. The recipient is forbidd en to use it for any purpose other

than for the use of the products or the execution of the project to which they refer or to commu nicate it to third parties without the prior written consent of

Automatic Systems. Document subject to change without advance notification.

SL93x + PPV323 + TBV327-MT-EN p. 5/39

2. DESCRIPTION

2.1. Technical Specifications

AISI 304 stainless steel sheet housing.

Internal frame protected with epoxy coating.

Passage obstacle in clear toughened glass, thickness: 10 mm.

Electrical supply: single phase, 230 VAC, 50 Hz (not to be connected to a floating network or to high-impedance

earthed industrial distribution network).

Consumption: 0.12 A in closed and locked position,

0.50 A when turning,

0.90 A while locking.

Automatic obstacle unlocking on power failure.

Variable speed controller ensures smooth obstacle movements.

Obstacle position determined by encoder.

Operating temperature: -20(*) to +60°C (*Thanks to the heat generated by the powered internal

equipment).

RH < 95%, without condensation.

Minimum opening time of the obstacle (adjustable): 2.5 seconds.

Net weight (kg):

MCBF (Mean Cycles Between Failures), when respecting recommended maintenance: 1,000,000

cycles

IP 51

EC compliant.

DAS Certified (Powered Security Device) in accordance with Fire Safety NF S 61-937 standard

Gates and turnstiles control pedestrian access in both directions.

By definition, Direction A is the direction in which the controls are located on the right of the user (=>

obstacle opening in the clockwise direction).

PPV323

SL930

1 m

SL930

1.2 m

SL931

1.4 m

SL931

1.7 m

SL931

1.9 m

SL932

0.9m

TBV327

Column

62

62

62

77

77

77

62

77

Panels

17

19

24

29

36

40

17

3 x 8.4

Total

79

81

86

106

113

117

79

102

Direction A = clockwise

The information contained in this document is the property of Automatic Systems and is confidential. The recipient is forbidd en to use it for any purpose other

than for the use of the products or the execution of the project to which they refer or to commu nicate it to third parties without the prior written consent of

Automatic Systems. Document subject to change without advance notification.

SL93x + PPV323 + TBV327-MT-EN p. 6/39

2.2. Location of the components

1. Mounting base (attached to the floor)

2. Main chassis (= equipment without obstacle)

3. Obstacle (= glass panel)

4. Conical coupling of the rotor to the motor

5. Movement limit stop (not on TBV)

6. Variable speed controller

7. Locking system

8. Position encoder

9. Power supply board

10. Control board v16 (CPU)

(illustrated with optional IP module)

IP option

11. Regulated power supply

12. Obstacle support rotor

13. Additional support for high obstacle

(for SL931 only)

14. Motor

15. Serial plate

1

2

3

4

5

6

7

8

9

10

11

(rear)

14

(rear)

12

13

15

The information contained in this document is the property of Automatic Systems and is confidential. The recipient is forbidd en to use it for any purpose other

than for the use of the products or the execution of the project to which they refer or to commu nicate it to third parties without the prior written consent of

Automatic Systems. Document subject to change without advance notification.

SL93x + PPV323 + TBV327-MT-EN p. 7/39

3. INSTALLATION

The installation must be carried out in accordance with the safety instructions (p 4) and the installation

plan (p3.2. ).

3.1. Storage

Before installation, avoid all shocks to the equipment and place it in its original packing in a dry place,

protected from dust, heat and bad weather.

Storage temperature limits: -30 to +80°C

The information contained in this document is the property of Automatic Systems and is confidential. The recipient is forbidd en to use it for any purpose other

than for the use of the products or the execution of the project to which they refer or to commu nicate it to third parties without the prior written consent of

Automatic Systems. Document subject to change without advance notification.

SL93x + PPV323 + TBV327-MT-EN p. 8/39

3.2. Installation plans

The information contained in this document is the property of Automatic Systems and is confidential. The recipient is forbidd en to use it for any purpose other

than for the use of the products or the execution of the project to which they refer or to commu nicate it to third parties without the prior written consent of

Automatic Systems. Document subject to change without advance notification.

SL93x + PPV323 + TBV327-MT-EN p. 9/39

The information contained in this document is the property of Automatic Systems and is confidential. The recipient is forbidd en to use it for any purpose other

than for the use of the products or the execution of the project to which they refer or to commu nicate it to third parties without the prior written consent of

Automatic Systems. Document subject to change without advance notification.

SL93x + PPV323 + TBV327-MT-EN p. 10/39

The information contained in this document is the property of Automatic Systems and is confidential. The recipient is forbidd en to use it for any purpose other

than for the use of the products or the execution of the project to which they refer or to commu nicate it to third parties without the prior written consent of

Automatic Systems. Document subject to change without advance notification.

SL93x + PPV323 + TBV327-MT-EN p. 11/39

3.3. Fixing the equipment to the floor

1. Remove the 2 covers by removing the screws (50, p 25).

2. Unscrew the base (1, p 6) from the main chassis and secure it to the floor with the 3 expanding bolts

supplied (Liebig B15/30 (A)). First drill 3 x 15 mm diameter holes to a depth of 85 mm.

WARNING: It is essential to adapt the fastening hardware and the installation procedure to the

environment and the nature of the floor on which the gate will be positioned.

Installation must be validated by certified civil engineers.

The gate must be fastened to the floor before it is made available to the users!

Automatic Systems cannot be held responsible for any accident or damage to the gate due to the

fact that the gate was not adequately fastened to the floor.

3. Position the main chassis (2, p 6) over the base (1), with the sticker COTE DU PASSAGE

(=Passageway side) aligned as shown below, so that the control board (10, p 6) remains

accessible.

4. Fit the obstacle(s) to the rotor (see ch.5.9. ).

5. Adjust the vertical alignment of the main chassis with the 3 bolts (B).

6. Tighten the 3 locknuts (C) to secure the main chassis to the base (tightening torque: 43 Nm).

7. Cut the cable tie securing the locking mechanism (7, p 6).

A

C

B

A

C

V

B

1

2

The information contained in this document is the property of Automatic Systems and is confidential. The recipient is forbidd en to use it for any purpose other

than for the use of the products or the execution of the project to which they refer or to commu nicate it to third parties without the prior written consent of

Automatic Systems. Document subject to change without advance notification.

SL93x + PPV323 + TBV327-MT-EN p. 12/39

3.4. Electrical connections

WARNING: The operations must be undertaken in accordance with the safety warnings, ch.1.

In particular, the mains must be shut down before any of the work described below is begun.

Connections must be executed in accordance with the wiring diagrams provided inside the equipment,

which remain the reference.

Type of

cable

Connections

3G2.5²

Electrical power supply of

each equipment (230 V

single phase + ground +

differential breaker 30 mA

min for each equipment).

WARNING: High leakage

current.

=> Connection to the

ground imperative with a

1-mm² cable before

connecting the mains.

=> Do not connect

several equipments to the

same differential breaker.

2.5²

If the gates are powered

through long cables,

ensure the equipotential

bonding between the gates

forming a bank by

connecting them with a 1-

mm² ground wire.

0.75²

Connect the Emergency

command (Fire) if

desired.

Refer to the electrical diagrams.

0.75²

Connect the opening

commands and eventual

Inputs/Outputs.

Refer to the electrical diagrams.

Δ 30

mA

Δ 30

mA

230 VAC - 50 Hz

The information contained in this document is the property of Automatic Systems and is confidential. The recipient is forbidd en to use it for any purpose other

than for the use of the products or the execution of the project to which they refer or to commu nicate it to third parties without the prior written consent of

Automatic Systems. Document subject to change without advance notification.

SL93x + PPV323 + TBV327-MT-EN p. 13/39

3.5. Commissioning

1. Adjust the obstacle opening angle in the clockwise and anti-clockwise directions by adjusting the

mechanical stops (ch.5.7. ).

2. Switch ON the equipment.

The obstacle will move, seeking its starting point (closed position), then it locks.

3. Start the CONFIG AUTO menu (Note: the obstacles must be fitted):

Press the Menu button,

Press the > button until CONFIG AUTO is displayed,

Press OK to start the procedure

The equipment seeks the mechanical stops in both directions at slow speed and accelerates.

4. Check the locking by pushing the obstacle.

5. Give a clockwise opening command.

6. Give a counter-clockwise opening command.

7. Trigger a FIRE command (open the Fire contact on the power board, see electric diagrams) and

check if the obstacle opens (the opening direction is adjustable, cf. ch.5.10. ).

8. Turn off the power and check that the obstacle unlocks.

9. Replace the covers.

The information contained in this document is the property of Automatic Systems and is confidential. The recipient is forbidd en to use it for any purpose other

than for the use of the products or the execution of the project to which they refer or to commu nicate it to third parties without the prior written consent of

Automatic Systems. Document subject to change without advance notification.

SL93x + PPV323 + TBV327-MT-EN p. 14/39

Angle parameters

The parameters are the same for clockwise and counter-clockwise

opening directions.

OPENING ANGLE AWAY

Closed

(= 0°)

STOP TIME DELAY

Opening angle B way

Dir. B

Braking angle

for opening

opening angle A way

Dir. A

Braking angle

for closing

4. PRINCIPLE OF OPERATION

The references in this chapter refer to the illustrations on ch.2.2.

The Swing Gates and Turnstiles (named hereafter "Gates") are bidirectional pivoting access control units

that allow passage in both directions.

They have a steel central column (2) fixed to the floor containing the control board (10) and the drive

unit. The central column is equipped with 1 or 3 glass obstacles (3).

The gate is unlocked by an external command (pushbutton, card readers, etc.). According to the selected

mode, the obstacle then starts to turn automatically (in the authorized direction of passage) or on light

pressure.

The movement of the obstacle is transmitted by a geared motor driven by a variable speed controller (6),

which allows the opening and closing speed to be adjusted.

The opening angle can be adjusted in both directions and 2 mechanical stops maintain the obstacles open.

The direction of rotation and the position of the obstacle are determined by a position encoder (8).

The obstacle stays open for a period set by a parameter and then closes again automatically.

Movement sequence:

The obstacle opens from the starting point (= passage closed) at the selected speed.

From the BRAKING ANGLE (set by the program according to the selected speed and the

obstacle inertia), the obstacle decelerates to complete its movement against the mechanical

stop.

The obstacle registers a stopping time (set by parameter) in the open position.

The obstacle is maintained at low power against the limit stop.

The obstacle closes at the selected speed.

From the BRAKING ANGLE, the obstacle decelerates to complete its movement.

When the obstacle reaches its closed position, the lock is engaged.

The information contained in this document is the property of Automatic Systems and is confidential. The recipient is forbidd en to use it for any purpose other

than for the use of the products or the execution of the project to which they refer or to commu nicate it to third parties without the prior written consent of

Automatic Systems. Document subject to change without advance notification.

SL93x + PPV323 + TBV327-MT-EN p. 15/39

4.1. Locking

The locking mechanism (70) is activated by an electromagnet (71) with positive security (locked under

voltage).

When the obstacle approaches its closed position, the locking sensor (75) is activated by detection of a

vane (76). The electromagnet then moves the lock into hole (77a) of plate (77), locking the rotor (12).

Locking is maintained by the electrical circuit between the hold magnet (72) and the contact plate (73).

The Fire Detection signal on the power board (see wiring diagrams) opens the obstacle in the selected

direction and allows free passage.

NON-RETURN OPTION (for TBV model only*): During the opening in one direction, if the obstacle is

forced to open in the other direction, the electromagnet (68) moves the non-return lock (69) into hole

(77b) of plate (77), locking the rotor (12).

The correct movement continues as soon as this reverse force is removed (without putting the equipment

out of service).

(*) This option is not available on SL93x because the flow direction is not controlled.

70

71

72

73

75

76

77

77a

77b

77

69

68

69

The information contained in this document is the property of Automatic Systems and is confidential. The recipient is forbidd en to use it for any purpose other

than for the use of the products or the execution of the project to which they refer or to commu nicate it to third parties without the prior written consent of

Automatic Systems. Document subject to change without advance notification.

SL93x + PPV323 + TBV327-MT-EN p. 16/39

4.2. Position encoder

The direction of rotation and the position of the obstacle are determined by a position encoder (80),

consisting of a vaned disk that turns with the motor shaft and passes through 2 sensors (81 and 82).

This encoder does not need any adjustment.

4.3. Safety

During rotation, if the obstacle encounters an obstruction limiting its movement, it will make

several attempts to complete the current movement, after which the motor will be powered off

automatically if the resistance is still present (see parameter NUMBER OF WARNINGS, ch.5.10. ).

As long as the opening command is maintained, the obstacle will not close.

When a second opening command is received in the same direction while the obstacle is closing,

it will re-open immediately.

When an Emergency command (FIRE) is received, the gate opens automatically (the direction of

opening is set by parameter DIR.EMERGE.OPENING, ch.5.10. ).

When there is a power failure, the gate is unlocked automatically and can then be opened

manually.

80

81

82

The information contained in this document is the property of Automatic Systems and is confidential. The recipient is forbidd en to use it for any purpose other

than for the use of the products or the execution of the project to which they refer or to commu nicate it to third parties without the prior written consent of

Automatic Systems. Document subject to change without advance notification.

SL93x + PPV323 + TBV327-MT-EN p. 17/39

5. MAINTENANCE

WARNING: The adjustment operations must be carried out in accordance with the safety instructions (p

4).

5.1. Removing the housing

1. Remove all the screws (50).

2. Remove both elements of the housing.

50

The information contained in this document is the property of Automatic Systems and is confidential. The recipient is forbidd en to use it for any purpose other

than for the use of the products or the execution of the project to which they refer or to commu nicate it to third parties without the prior written consent of

Automatic Systems. Document subject to change without advance notification.

SL93x + PPV323 + TBV327-MT-EN p. 18/39

5.2. Turning the equipment ON/OFF

5.3. Preventive maintenance

Every 100,000 operations, or every 6 months, whichever comes first, check the following points:

The security of all components (attachment to the floor, obstacle, motor, conical coupling (4, p 6),

etc.).

The state of the ground cable on the rotor (Fig. A).

The control signals.

The opening and closing speeds.

The obstacle opening and closing angles and positions.

The activation of the locking mechanism in the closed position.

The unlocking in case of a power outage.

The obstacle opening in case of an emergency command (opening of the Fire contact on the power

board, see electric diagrams).

Any output signals to optional peripheral equipment.

Clean the stainless steel surfaces and glasses by means of an appropriate product.

Every 800,000 operations, replace the locking mechanism (ch.5.8. ).

Fig. A: connection of the rotor to the ground

ON

OFF

The information contained in this document is the property of Automatic Systems and is confidential. The recipient is forbidd en to use it for any purpose other

than for the use of the products or the execution of the project to which they refer or to commu nicate it to third parties without the prior written consent of

Automatic Systems. Document subject to change without advance notification.

SL93x + PPV323 + TBV327-MT-EN p. 19/39

5.4. Spare parts

DESIGNATION

CODE

VALIDITY

PPV323

SL930

SL931

SL932

TBV327

Conical coupling (4, p6)

0/6980/816

> 01/2007

x

x

x

x

x

Contact plate (73, p 15)

0/6982/071

> 01/2007

x

x

x

x

x

CPU board (10, p6)

E/6980/530

> 01/2007

x

x

x

x

x

Electromagnet (71, p 15)

E/6980/540

> 01/2007

x

x

x

x

x

Frequency inverter 230V

0/6982/066

> 12/2008

x

x

x

x

x

Frequency inverter 230V (6, p 6)

E/6980/538

< 12/2008

x

x

x

x

x

Hall-effect sensor (75, p15 & 82, p16)

E/6980/531

> 01/2007

x

x

x

x

x

Holder electromagnet (72, p 15)

E/6980/520

> 01/2007

x

x

x

x

x

Locking assembly (p 22)

E/6980/542

> 01/2007

x

x

x

x

x

Locking disc (77, p 15)

0/6980/583

> 01/2007

x

x

x

x

x

Long lock in aluminum (21, p22)

0/6982/068

< 08/2008

x

x

x

x

x

Mobile obstacle 1030 x 850 mm

OBV-E07047

> 01/2007

x

Mobile obstacle 1230 x 850 mm

OBV-E07050

> 01/2007

x

Mobile obstacle 1530 x 850 mm

OBV-E07030

> 01/2007

x

Mobile obstacle 1730 x 850 mm

OBV-E07049

> 01/2007

x

Mobile obstacle 480 x 640 mm

OBV-E07054

> 01/2007

x

Mobile obstacle 640 x 950 mm

OBV-E07052

> 01/2007

x

Mobile obstacle 830 x 850 mm

OBV-E07014

> 01/2007

x

Motor assembly with encoder (14 + 8, p6)

0/6982/065

> 12/2008

x

x

x

x

x

Motor assembly with encoder (14 + 8, p6)

E/6980/541

< 12/2008

x

x

x

x

x

Non-return lock (69, p15)

0/6980/658

> 01/2007

x

Obstacle mobile 740 x 850 mm

E/0875/023

>01/2007

x

Optocoupler on CPU board

E/6980/539

> 01/2007

x

x

x

x

x

Power supply board V3 (9, p 6)

E/6980/537

< 10/2009

x

x

x

x

x

Power supply board V5 (9, p 6)

0/6982/064

> 10/2009

x

x

x

x

x

Short lock in stainless steel (21, p22)

0/6982/069

> 08/2008

x

x

x

x

x

Stabilized Power supply (11, p 6)

E/6980/536

> 01/2007

x

x

x

x

x

Stainless steel cover

0/6980/542

> 01/2007

x

Stainless steel cover (cut-out)

0/6980/545

< 01/2007

x

x

x

Stainless steel cover (cut-out)

CRA-E01122

> 01/2007

x

x

x

Stainless steel cover (cut-out)

0/6980/547

> 01/2007

x

Stainless steel cover (straight)

0/6980/546

< 01/2007

x

x

x

Stainless steel cover (straight)

CRA-E01124

> 01/2007

x

x

x

Stainless steel cover (straight)

0/6980/548

> 01/2007

x

Stainless steel top cover

0/6980/549

< 01/2007

x

x

x

x

x

Stainless steel top cover

CRA-E01107

> 01/2007

x

x

x

x

x

The information contained in this document is the property of Automatic Systems and is confidential. The recipient is forbidd en to use it for any purpose other

than for the use of the products or the execution of the project to which they refer or to commu nicate it to third parties without the prior written consent of

Automatic Systems. Document subject to change without advance notification.

SL93x + PPV323 + TBV327-MT-EN p. 20/39

5.5. Adjusting the locking sensor

1. Unlock the obstacle by switching off the power or selecting programming mode.

2. Turn rotor (12) until one of the 3 locking holes is in front of lock (70).

3. In that position, the sensor (75) must detect one of the vanes (76).

If necessary, adjust the vane and/or the vane support ring (79).

4. For the TBV327, repeat the procedure for the 2 remaining locking holes.

12

Locking

holes

70

78

79

76

75

This manual suits for next models

4

Table of contents

Other Ier Turnstile manuals