10

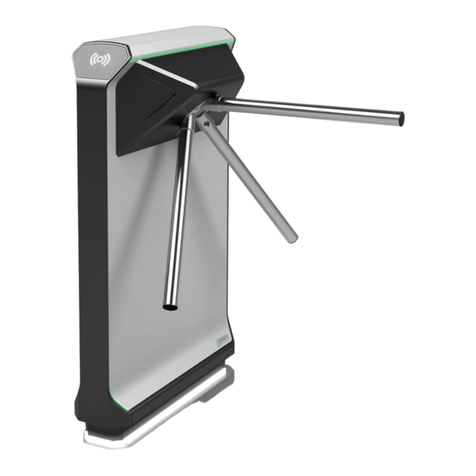

MPB-311

Safety

2 Safety

2.1 Intended use

The MAGNETIC pedestrian gate MPB is made of a full height turnsle and a bicycle

access. The pedestrian gate MPB is intended only for access control of persons from

a zone not controlled (ZNC) to a zone controlled (ZC). The separate bicycle access

makes it possible to move a bicycle into the zone controlled. Riding the bicycle is

contrary to provisions.

In general, the pedestrian gate is integrated in the fence and gate systems.

The pedestrian gate is intended for passage of persons who can pass the pedestrian

gate safely, quickly and without any help. Separate means of access must be

provided for persons who cannot pass through the pedestrian gate safely, quickly or

without assistance, such as small children, elderly people or people with disabilies.

Children under 14 years of age may only pass through the pedestrian gate under the

supervision of an adult.

The pedestrian gate may only be mounted on non-ammable oors.

The pedestrian gate may only be operated within the temperature range indicated

on the type plate.

Misuse

Any use diering from or beyond this is considered improper use. Magnec is not

liable for any resulng personal injury or damage to property.

For example, the following applicaons are regarded as improper use:

› Use of the pedestrian gate by unaccompanied children under 14 years of age.

› Use of the pedestrian gate by persons who cannot pass the pedestrian gate safely,

quickly or without assistance.

› Use of the pedestrian gate without released passage. This means that the centre

pillar is forced to rotate.

› Mounng of the pedestrian gate on ammable ground.

2.2 Changes and modicaons

Modicaons and conversions to the product, to an aachment or to one of the

components can lead to unforeseen dangers. Magnec's wrien approval must be

obtained before any technical modicaons or alteraons are made to the product

or any of its components.