Tiso Gate-GS User manual

Operation Manual 2

CONTENTS

INTRODUCTION.........................................................................................................................................................3

1. DESCRIPTION AND OPERATION ...............................................................................................................5

1.1 General Information and Purpose...................................................................................................................5

1.2 Specifications.................................................................................................................................................7

1.3 Configuration and Scope of Delivery .............................................................................................................7

1.4 Design and operation......................................................................................................................................9

1.5 Instrumentation, tools and accessories..........................................................................................................11

1.6 Description and operation of controllers as a component of the turnstile.....................................................11

2 INTENDED USE .....................................................................................................................................................14

2.1 Operation restrictions....................................................................................................................................14

2.2 Layout and installation..................................................................................................................................15

2.3 Preparation for use........................................................................................................................................20

2.4 Contingency actions......................................................................................................................................22

3 MAINTENANCE.....................................................................................................................................................22

3.1 General guidelines ........................................................................................................................................22

3.2 Safety Measures............................................................................................................................................23

3.3 Maintenance procedure.................................................................................................................................23

4 ROUTINE MAINTENANCE ..................................................................................................................................24

4.1 General guidelines ........................................................................................................................................24

4.2 Possible malfunctions ...................................................................................................................................24

4.3 Postrepair checkout......................................................................................................................................24

5 TRANSPORTATION AND STORAGE .................................................................................................................24

5.1 Turnstile storage ...........................................................................................................................................24

5.2 Turnstile transportation.................................................................................................................................24

6 DISPOSAL...............................................................................................................................................................25

Annex А.1(mandatory) Overall and installation dimensions of “Gate-GS” type turnstile.........................................26

Annex А.2(mandatory) Overall and installation dimensions of “Gate-GSH”type turnstile......................................27

Annex А.3(mandatory) Overall and installation dimensions of “Gate-TS”type turnstile .........................................28

Annex А.4(mandatory) Overall and installation dimensions of “Gate-TTS” type turnstile.......................................29

Annex B (mandatory) Control desk and connection diagram .....................................................................................30

Annex C (mandatory) Wiring diagram of Swing Gate type turnstile..........................................................................32

Annex D.1(mandatory) Wiring diagram of turnstile connection to access control system (ACS)..............................33

Annex D.2(mandatory) Wiring diagram of one turnstile connection to fire alarm system (FAS)...............................34

Annex D.3(mandatory) Wiring diagram of two turnstiles connection to fire alarm system (FAS).............................35

Annex D.4(mandatory) Wiring diagram of two turnstiles connection to fire alarm system (FAS).............................36

Annex D.5(mandatory) Wiring diagram of turnstile connection to control panel.......................................................37

Operation Manual 3

INTRODUCTION

This Operation Manual (hereinafter referred to as OM) covers the servo-operated waist-high

turnstile of swing gate type (hereinafter referred to as the "turnstile"). The Operation Manual

contains information about design, specifications, installation for proper operation and

maintenance of the turnstile.

This Operation Manual is prepared in compliance with the specification requirements of ТU

U 28.9-32421280-005:2018.

The turnstile shall be serviced only by the qualified staff having the relevant class of permit

to work with electrical facilities with voltage up to 1000V and scrutinizing this Operation Manual,

obtaining safety instructions and trained for operation and maintenance of the turnstile.

Reliability and durability of the turnstile operation is provided with observation of modes

and conditions of transportation, storage, installation and operation. So, fulfillment of all

requirements specified in this document is mandatory.

Due to regular improvement of the product its design can be modified without degradation

of the product features and quality not covered by this Operation Manual.

Depending on the purpose and design features of the turnstile, the following pattern of

reference designation is accepted:

T3.КХХ.X D

Waist-high turnstile

Swing Gate

K

D

with leaf rotation

to both sides

Servo-operated,

with stainless

steel leaf

СН

K

Painted housing

P

Polished stainless steel

Servo-operated,

with glass

leaf

СС

S

Brushed stainless steel

Example of reference designation of the servo-operated waist-high turnstile of swing gate

type made of brushed stainless steel when the turnstile T3.КСС.PD TU U 28.9-32421280-

005:2018 is ordered.

Operation Manual 4

WARNINGS TO THE CUSTOMER

ON SAFE OPERATION OF THE TURNSTILE

These warnings are designed for ensuring of safety during operation of the turnstile to prevent

violation of safety characteristics by improper installation or operation. These warnings are aimed at

drawing attention of the customer to safety problems

.

GENERAL WARNINGS

The Operation Manual is an integral part of the product and it shall be handed over to the

customer. The OM shall be kept for later use and consulted for clarifications if required. If the

turnstile is resold, handed over to another owner or transported to another place, make sure that

the OM is enclosed to the turnstile to be used by new owner and/or maintenance staff during

installation and/or operation.

Safety measures and requirements specified in this in this OM must be observed:

–the turnstile must be connected to ground loop prior to operation;

–the turnstile should be connected to AC network with parameters specified in paragraph

1.2 "Specifications";

–іnspection, adjustment and repair should be performed only after the turnstile is

deenergized.

After purchasing of the turnstile it should be unpacked and its integrity should be checked.

In case of doubt in integrity of the turnstile it should not be used and the customer should refer to

the supplier or to the manufacturer.

Packing accessories (wooden pallet, nails, clips, polyethylene bags, cardboard etc.) as

potential sources of hazard must be removed to unacceptable place prior to proper use of the

turnstile.

As electric shock protection device the turnstile is related to 01 protection class according to

GOST (State Standard) 12.2.007.0-75 and is not intended for operation in explosive and fire

hazardous areas by the "Rules for design of electrical installations".

Using of the turnstile for unintended purpose, improper installation, nonobservance of

conditions of transportation, storage, installation and operation, specified by this OM, may result

in damage to people, animals or property for which the manufacturer is not responsible.

Operation Manual 5

1. DESCRIPTION AND OPERATION

1.1 General Information and Purpose

1.1.1 Purpose:

The turnstile is designed for pedestrian movement control at access points of industrial

enterprises, banks, stadiums, administrative facilities etc. controlled by access control system

(from proximity card readers) or manually (from manual control panel).

The turnstile traffic flow capacity without personal identification is at least 20 persons per

minute in one direction.

1.1.2 The turnstile dimensions and weight correspond to the values specified in Table 1

Table 1

Model

Designation

Designation

of

modification

Access way

width

Dimensions, mm

Max.

weigh, kg

Height

Length

Width

Gate-TS

AUIA.203-01

Т3.KСН.SD

Т3.KСН.PD

Т3.KСН.KD

650

1000

225

815

41

900

1065

42

Gate-TTS

AUIA.203-02

700 -1050

1000

225

865-1215

42

Gate-GS

AUIA.203

Т3.KСC.SD

Т3.KСC.PD

Т3.KСC.KD

650

1000

225

815

45

900

1065

48

Gate-GSH

AUIA.203-03

650

1500

225

815

52

900

1065

58

Operation Manual 6

1.1.3 The operation condition parameters according to GOST 15150-69 for climatic

modification NF4 are specified in Table 2.

Operation conditions

Parameter value

Ambient temperature

+ 1 to + 40 °С

Relative humidity

80 % at 20 ºС (non-condensing)

Ambient temperature

allowable pressure

84 to 106,7kPa

Transportation temperature

range

- 40 to + 50 °С

Storage temperature range

- 5 to + 40 °С

Group of mechanical

application

L3

Altitude above sea level

up to 2000m

Environment

Explosion-proof, does not contain current-conducting dust,

aggressive gases and vapours in concentration destroying

isolation and metals, disturbing normal operation of the

equipment installed in turnstiles

Installation site

In enclosed spaces in the absence of direct impact of

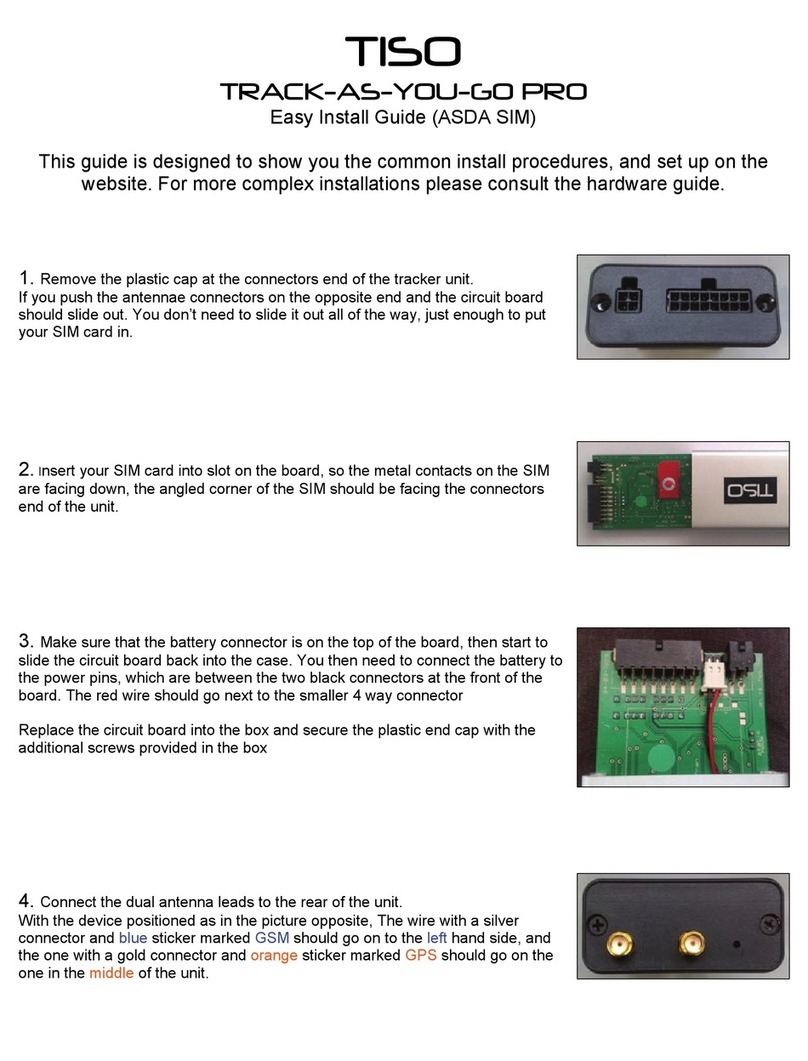

Fig. 1–Installation dimensions of the Swing Gate

type turnstile

Operation Manual 7

precipitations and solar radiation

Operating position

Vertical, deviation from vertical position no more than 1º to any

side is tolerated

1.1.5 Reliability indices:

mean time to repair (without delivery time of spare parts, tools and accessories) – at most

6 hours;

mean time to failure – at least 5 000 000 accesses;

mean service life between overhauls – at least 10 years.

1.2 Specifications

The key parameters of the turnstile are specified in Table 3. Table 3

Parameter description

Parameter

Minimum traffic flow capacity in free access mode

60 man/min.

Opening time

2-5 s

Maximum access way width

- narrow leaf

- wide leaf

- telescopic leaf

650 mm

900 mm

700-1050 mm

Maximum access way width

100 240V

~ 50/60Hz

–AC power supply (primary)

–DC power supply (secondary)

12W

Maximum power consumption

55W

Index of protection according to EN 60529

IP41

1.3 Configuration and Scope of Delivery

1.3.1 The swing gate type waist-high turnstile design includes the following key devices

and components:

–housing;

–leaf;

–actuator;

–control unit;

The turnstile also includes control panel.

Design, overall and installation dimensions of the turnstile are shown in Annex A.

The turnstile modification is based on the leaf material

1) stainless steel leaf (reference designation T3.КCН.XD);

2) glass leaf (reference designation T3.КСС.XD).

The turnstile modifications are manufactured from:

– brushed stainless steel (reference designation T3.КXХ.SD).

– polished stainless steel (reference designation T3.КXХ.РD).

– carbon steel subject to painting (reference designation T3.КXХ.КD);

Operation Manual 8

“Gate-GS”* “Gate-TS”*

* The design of the turnstiles “Gate-GSH” and “Gate TTS” is the same as the design of the turnstiles

“Gate-GS” and “Gate-TS”

Legend:

1,2. - Base and assembly mechanism;

3. - Housing;

4. - Lid;

5. - Glass leaf or Stainless steel tubular leaf;

6. - Actuator and control unit;

7. –Glass holder or place for leaf fixation

Fig.2 - Design of the single turnstile “Gate-GS” and “Gate-TS”

Leaf options for gates АUIA.203:

«Gate GS»

Glass leaf

«Gate GSH»

High glass leaf

«Gate TS»

Stainless steel tubular

leaf

«Gate TTS»

Telescopic stainless

steel tubular leaf

Fig. 3–Leaf options “Gate” АUIA.203

1.3.2 Scope of Delivery

The turnstile is delivered by one package.

1.3.3 Design, overall and installation dimensions of the turnstile are shown in Annex А.

Operation Manual 9

1.3.4 The turnstile material of manufacture is carbon steel subject to painting, brushed

stainless steel or polished stainless steel.

1.4 Design and operation

1.4.1 General appearance of the turnstile

1.4.1.1 The swing gate consists of assembly mechanism 2 with fixed base 1. (Fig.4).

Housing 3 with leaf 5 from glass or tube is installed on the top of assembly mechanism 2.

1.4.1.2 On top of the turnstile housing 3, a lid 4 is installed with a welded screw, which is

screwed into the turnstile assembly mechanism 2, fixing the main elements of the gate.

1.4.1.3 Control unit and actuator 6 are located at the bottom of the turnstile housing.

Leaf is automatically brought to initial position by means of servomotor after each turnstile access.

Housing is connected with control unit and actuator 6 by means of screw with washers, providing

rotation of leaf to both sides at the angle of 90°.

1.4.1.4 Control unit 6 is a metal box installed on assembly mechanism 2. Power supply unit

and card, on which controllers with electronic components and connectors for peripheral

connections are fixed inside control unit.

Control unit is designed for the turnstile energization and latching control.

1.4.1.5 Control panel is a small desktop device in plastic case and is designed for setting and

indication of operating modes when the turnstile is operated manually. Control panel and its

connection diagram are shown in Annex В.

1.4.2 Principle of operation

1.4.2.1 Turnstile operating modes:

1) to be opened in the direction “A” or “B”;

2) free access in the direction “A” or “B”

Switching of the turnstile operating modes is performed either by control panel or as part of

automated access control system (ACS) (by means of cards, badges etc.).

1.4.2.2 In the initial state, when the turnstile is energized, leaf is locked from rotation in both

directions by actuator.

After access permission command in one of directions is received:

–leaf is unlocked;

–servo drive rotates leaf to the angle of 90° in the appropriate direction;

–after access permission command is cancelled, servomotor brings leaf back to initial

position and it is locked from rotation in both directions.

More detailed description of the turnstile operating modes is given in section 1.8

"Description and operation of controller as a component of the turnstile”

1.4.2.3 12V DC power voltage is provided by power supply unit.

1.4.2.4 The turnstile wiring diagram is shown in Annex C.

Operation Manual 10

a) “ Gate TS” b) “Gate GS”

Legend:

1 –Base;

2 –Assembly mechanism;

3 –Housing;

4 –Lid with screw М12;

5 –Glass leaf or stainless steel tubular

leaf;

6 –Actuator and control unit;

7 –Screws М16х22 -2 pcs.(for stainless steel tubular leaf)

or countersunk screws А2 М6х16-4pcs. with spring and

flat washer (for glass leaf)

8 –Anchor М12;

9 –Shaft of top support;

10 –Protective case of control unit;

11 –Screws of protective case;

Fig. 4 –Design of swing gate AUIA.203

Operation Manual 11

1.5 Instrumentation, tools and accessories

Dedicated tools are not required for installation of the turnstile (multi-purpose measurement

instrumentation and installation tools are sufficient (Fig. 6).

1.6 Description and operation of controllers as a component of the turnstile

1.6.1 Purpose of the turnstile controller РСВ.201.01.00.00

The controller is designed for acquisition of commands from external control devices

(control panel, access control system etc.) and generation of control signals for swing gate

motorized mechanism.

The controller is assembled on the (85 х 70mm) board, on which electronic components and

connectors for external connections are mounted.

13 light emitting diodes are installed on the controller board. Their purpose is as follows:

• 8 LEDs indicate condition of inputs “IN1» «IN8”.

• «POWER» LED indicates availability of supply voltage 5V.

• 4 LEDs indicate condition of outputs for connection of motor.

24 terminals are installed on board: 2 of them are designed for external connections, the

rest are designed for connection to the turnstile units or are standby.

1.6.2 Technical features

The controller technical features are shown in Table 4. Table 4

Parameter description

Parameter value

Number of inputs

2

Number of outputs

4

Type of input

logical

Type of output GRN1, RED1, GRN2, RED2

open collector

Logical «1» voltage

(3,7 5) V

Logical «0» voltage

(0 1,7) V

Peak voltage applied to inputs «IN1»÷ « IN8»

15 V

Peak voltage switched by outputs «GRN1», «RED1», «GRN2»,

«RED2»

30 V

Peak current switched by outputs «GRN1», «RED1», «GRN2»,

«RED2»

2 А

Peak voltage switched by outputs «-MG1», «-MG2»

50 V

Peak current switched by outputs «-MG1», «-MG2»

5 A

Peak voltage switched by outputs «MOT1», «MOT2»

27 V

Peak current switched by outputs «MOT1», «MOT2»

≤ 4 А

Controller supply voltage

(10 27) V

Consumption current when outputs «MOT1» and « MOT2» are OFF

≤0,15 А

Climatic modification and location category according to GOST 15150-69

NF4

1.6.3 Description of operation

The controller operates according to the program entered into memory of microprocessor.

Swing. The swing gate mechanism is controlled based on commands coming from external

devices (control panel, access control system etc.) and position of leaf based on the logic

downloaded into program. Control commands are generated to controller via logical inputs

«IN1», «IN2» and «IN3», «IN4» by means of closing them on «GND». Inputs «IN1» and

«IN3» are designed for opening of the turnstile in the direction “A” and Inputs «IN2» and

«IN4» are designed for opening of the turnstile in the direction “B”. The difference is that 4 sec.

closing delay is counted via inputs «IN1» and «IN2». That is in case of short time short-circuit of

Operation Manual 12

«IN1» or «IN2» on «GND», the turnstile will open completely and only after a lapse of time it will

start closing. There is no such delay via inputs «IN3» and «IN4», and the turnstile will start

closing at once from the moment of disappearance of input signal, even if the turnstile is not fully

opened. Normally opened contacts of buttons, relay contacts or outputs of open collector type can

be used for generation of control commands.

That is, in order to generate the command “TO BE OPENED IN THE DIRECTION “A” it is

necessary to connect input «IN1» (X1/1) to one of terminals "GND" (X1/9 X1/11), accordingly

for generation of command “TO BE OPENED IN THE DIRECTION “B” it is necessary to

connect input «IN2» (X1/2) to terminal "GND". After obtaining opening command the controller

deenergizes winding of solenoid, fixing leaf, connected to output “-MG2” (X2/7).

It results in that leaf will be unlock and can be freely rotated in any direction. After that

controller feeds current to motor winding via outputs “MOT1” and “MOT2” (X2/9 and X2/10). It

results in that leaf starts to rotate opening the access. During rotation of leaf controller reads actual

angle of rotation from position sensor rigidly connected to the swing gate leaf. Sensor signals

come to inputs «IN5», «IN6», «IN8» (X1/5, X1/6, X1/8). Rotation speed signal from the relevant

sensor come to the controller input «IN7» (X1/7).

Besides motor current is constantly measured and is limited, if necessary. After leaf reaches

the definite angle, the controller switches motor to braking mode to prevent impact of leaf about

rotation limiter. As soon as leaf rests against limiter, controller feeds little current to motor to hold

leaf in open position. Now access opening procedure is finished.

In this state the swing gate will remain until the relevant “TO BE OPENED” command is

active.

The controller appearance is shown in Figure 5.

Fig. 5 – Appearance, overall and connection dimensions of controller РСВ.201.01.00.00

Operation Manual 13

Closing procedure begins upon expiration of 4 sec. after connection of input “IN1” or “IN2”

with “GND” is open. In order to close the turnstile the controller actuates motor, having changed

current polarity via it, that leads to rotation of leaf in opposite direction. In this case angle of leaf

rotation and motor speed are controlled. When leaf approaches to fixation point in closed position,

the controller reduces revolutions of motor. Then when leaf reached initial position, it feeds

current to the solenoid, which fixes leaf, via input «-MG2» (X2/7). It results in complete stopping

and locking of leaf in initial position. Now access closing procedure is completed.

The controller’s contacts designed for connection of peripherals are specified in Table 5.

Table 5

Conne

ctor /

Conta

ct No

Design

ation

Direction

Purpose

Signal parameters and

description

1

2

3

4

5

X1/1

IN1

ENTRY

Command “ TO BE OPENED

IN THE DIRECTION А” (with

4 sec. closing delay)

1) logical «0»

(0 1,7) V;

2) logical «1» (3,7 5)V;

3) active level of signal –

logical «0»;

4) voltage on open input

≤ 5 V

X1/2

IN2

ENTRY

Command “ TO BE OPENED

IN THE DIRECTION B”

(with 4 sec. closing delay)

X1/3

IN3

ENTRY

Not applicable

X1/4

IN4

ENTRY

Not applicable

X1/5

IN5

ENTRY

To be connected to position

sensor

X1/6

IN6

ENTRY

X1/7

IN7

ENTRY

To be connected to speed sensor

X1/8

IN8

ENTRY

To be connected to position

sensor

X1/9

GND

“-” power supply (common

wire)

X1/10

GND

X1/11

GND

X1/12

+5 В

EXIT

Not applicable

X2/1

GRN1

EXIT

To be connected to green LED

display of the direction “А”

X2/2

RED1

EXIT

To be connected to red LED

display of the direction “А”

X2/3

GRN2

EXIT

To be connected to green LED

display of the direction “B”

X2/4

RED2

EXIT

To be connected to red LED

display of the direction “B”

X2/5

-MG1

EXIT

Connection of solenoid forcing

winding

1) type of output –open

collector;

2) peak voltage on

privacy key –50 V;

3) peak current of public

key –5 A

X2/6

+MG1

EXIT

Connection of solenoid forcing

winding (cathode of protective

diode)

Operation Manual 14

Continued table 5

1

2

3

4

5

X2/7

-MG2

EXIT

Not applicable

1) type of output –open

collector;

2) peak voltage on

privacy key –50 V;

3) peak current of public

key –5 A

X2/8

+MG2

EXIT

X2/9

MOT1

EXIT

Motor connection

1) voltage

(10 ÷ 27) V;

2) current ≤ 4 А

X2/10

MOT2

EXIT

X2/11

GND

«-» power supply (common

wire)

X2/12

+24 В

ENTRY

«+» power supply

(controller energization)

1) voltage

(10 27)V;

2) current ≤ 4 А.

2 INTENDED USE

2.1 Operation restrictions

2.1.1 The turnstile must be used in the environment specified in p. 1.1.5 of this

document subject to the specifications listed in section 1.2.

IT IS FORBIDDEN:

1) TO MISUSE THE TURNSTILE (See section 1 "DESCRIPTION AND

OPERATION");

2) TO USE THE TURNSTILE UNEARTHED;

3) TO USE HEATING PIPES AND RADIATIONS AS WELL AS PIPES OF

CENTRAL WATER SUPPLY FOR EARTHING;

4) TO REPAIR AND ADJUST WITHOUT DEENERGIZATION;

5) TO RELOCATE THE OBJECTS EXCEEDING THE PASSAGEWAY

WIDTH THROUGH THE TURNSTILE ACCESS AREA;

6) TO JERK AND IMPACT BARRIER RODS, LED DISPLAY OR OTHER

PARTS THE PRODUCT, WHICH MAY CAUSE THEIR MECHANICAL

DAMAGE;

7) APPLY FORCE ON LEAVES MORE THAN 400 Н (40 KG) IN “LOCK OF

ACCESS" MODE.

2.1.2 It is forbidden to use the turnstile:

–at the presence of mechanical rattle in movable parts of the turnstile;

–when metalwork of the turnstile and its components and accessories are mechanically

damaged.

2.1.3 List of special operation conditions

Mean time of the turnstile access (in single access mode) equals to 2-5 sec.

The turnstile’s mechanism allows emergency access by means of antipanic device.

The force applied by accessory to barrier rod should not exceed 400 N.

Escape door, portal or pedestrian gate can be installed near the turnstile to increase the

turnstile traffic flow capacity in case of emergency.

Operation Manual 15

IMPORTANT: MANUFACTURER WARNS OF THE NECESSITY TO

KEEP SEALS OF THE MANUFACTURER ON THE TURNSTILE’S

COMPONENTS!

2.2 Layout and installation

2.2.1 The turnstile and components of scope of supply to be delivered to installation site in

factory packing. The turnstile to be unpacked only on installation site.

2.2.2 Preparation of the turnstile for installation (dismounting) and commissioning to be

performed according to this OM with mandatory observation of safety measures specified in p. 2.1

and general electrical safety code.

WARNING:

The turnstile damages occurred during transportation are not covered by the

manufacturer's warranty liabilities.

2.2.3 Safety Measures:

Installation to be performed only by the persons briefed on safety and studied this

manual;

Only serviceable tools to be used during installation of the turnstile;

Connection of all cables to be performed only when power supply is OFF;

Cables to be laid in compliance with electric code;

The turnstile to be installed by at least 2 installers.

2.2.4 Tools and accessories to be used (Fig.6):

puncher;

concrete drills;

(according to diameter of anchors included in the turnstile scope of delivery;

extension cord;

kit of end;

and pin wrenches;

kit of hexagons;

kit of screwdrivers;

hammer;

multimeter (tester);

measuring tape;

marker;

pliers, side cutters;

builder's level.

2.2.5 Turnstile layout options

Fig. 6- Tools and accessories for layout and installation

Operation Manual 16

Fig. 7 –Turnstile layout options

Operation Manual 17

2.2.6 Installation procedure

The turnstile installation procedure is as follows:

1) The package integrity to be checked prior to unpacking. If package is damaged, then

damages to be fixed (picture to be taken, damage report to be made).

2) The turnstile to be unpacked and inspected for defects and damages as well as

completeness to be checked according to the turnstile technical passport;

WARNING:

When the turnstile damages are detected or in case of shortage of delivery,

installation work to be stopped and the turnstile supplier to be referred to.

3) Make sure that the turnstile installation area is ready as follows:

The installation site surface to be flat, hard and without defects (potholes, unevenness

etc.) and upright installation plus minus 1° to be provided;

Thickness of concrete blinding coat under site to be at least 150 mm.

4) The turnstile fixation holes to be marked on the area surface according to Figure 8. The

turnstile itself can be used as a template.

6) The relevant holes to be drilled on the surface according to the marking due to diameter

of anchors (12×120М10) for the turnstile fixation.

7) Anchor jackets to be inserted into the prepared holes.

Fig. 8 –Swing gate type turnstile installation marking

WARNING:

The turnstile is fixed by means of Redibolt (with jacket and screw) included in

the scope of delivery.

The turnstile installation and fixation to be performed only after all electric

cables are pulled.

8) The following cables to be run to the turnstile installation site:

Power supply cable 220 V ~;

Control panel connection cable;

Access Control System connection cables, if available

9) The length of cable free ends to be at least 1 m to provide their entry, termination and

connection to the relevant terminals in the turnstile post.

10) The cable outlet point to be aligned with the hole on the turnstile mounting plate.

11) The turnstile to be installed upright at the prepared location (Fig.9):

Operation Manual 18

1

3

4

5

2

4

Anchor M12

Cableinput

1

2

4

3

5

-Cables to be pulled through available

access holes in the turnstile post bottom

end part by tilting gate.

- Fixation holes at the turnstile bottom

plate to be aligned with prepared surface

holes.

- The turnstile to be fixed by means of

anchors included in the scope of

delivery.

- Install protective case of the control

unit on gate post assembly;

- Swing gate body to be joined with leaf:

а) The swing gate with glass leaf

to be attached by means of four countersunk

screws А2 М6х16 and and washers to glass

holder, that welded to the swing gate body.

b) The swing gate with stainless steel

tubular leaf to be attached by two screws

М16 х22 tightening them from inside.

- The swing gate with leaf to be installed

on assembly mechanism.

* The turnstile to be connected prior to

installation (See p.12 of section 2.2.6)

- Lid to be installed on housing of

assembled gate and screw it into the

assembly mechanism with a force of no

more than 2N×m, check the turnstile

operation.

* In case of difficult moving (rotation) of

the swing gate, the lid to be a little

loosened.

WARNING:

Leaf zero position marks to be taken into account on each assembly part for

correct installation of the gate and leaf direction.

Fig. 9 –Installation of swing gate type turnstile

Operation Manual 19

12) Turnstile connection:

a) Power supply cable

~220 V to be connected:

- Phase L to be connected

to the circuit breaker;

- Neutral (N) to be

connected to terminal

~220V (N);

- Earth (РЕ) to be

connected to earthing

terminal (РЕ).

b) Control panel cable to

be connected to terminals:

1- LED “Closed A”

2 - LED “Opened A”

3 –“Open A”

4 - +12 V

5 - GND - common wire of

control panel;

6 –“Open B”

7 - LED “Open B”

8 - LED “Closed B”

Fig. 10–Connection of gate

Connection diagram of the turnstile and control panel is shown Annex D6

WARNING:

During the turnstile installation it is necessary to take into account that leaf

to be located at a distance not more than 50-100 mm (fig.11) from passage way

creator (any surface perpendicular to leaf: enclosure module, wall etc.)

Terminals for connection of

communication cable and control

panel

Connection of power supply cable

Gate mechanism controller

Operation Manual 20

2.2.7 Leaf initial position setting

1. The initial position setting

button on the magnetic sensor board to

be pushed (2);

2. Leaf to be set in the required

initial position (mark on flange 1);

3. The button to be released (2);

4. After releasing the button on the

magnetic sensor board, the initial

position indication LED should light up

(see Fig.15);

5. The presence of signals for

changing rotation angle, speed and initial

position on controller PCB 201 to be

checked (Fig.14) –terminals: IN5, IN6,

IN7, IN8. When the leaf is turned:

- IN5, IN6 - should blink;

- IN7 - is lit brightly when leaf is

not turned or turned slowly. If leaf is

turned quickly then brightness will be

reduced;

- IN8 - to be lit only in the set

initial position;

6. The new initial position setting

is completed.

Fig. 12 –Leaf in initial position

*WARNING:

Please note that turnstile may have a tolerance for leaf positioning of ±3

Fig. 11 –Leaf in initial position

This manual suits for next models

3

Table of contents

Other Tiso Turnstile manuals