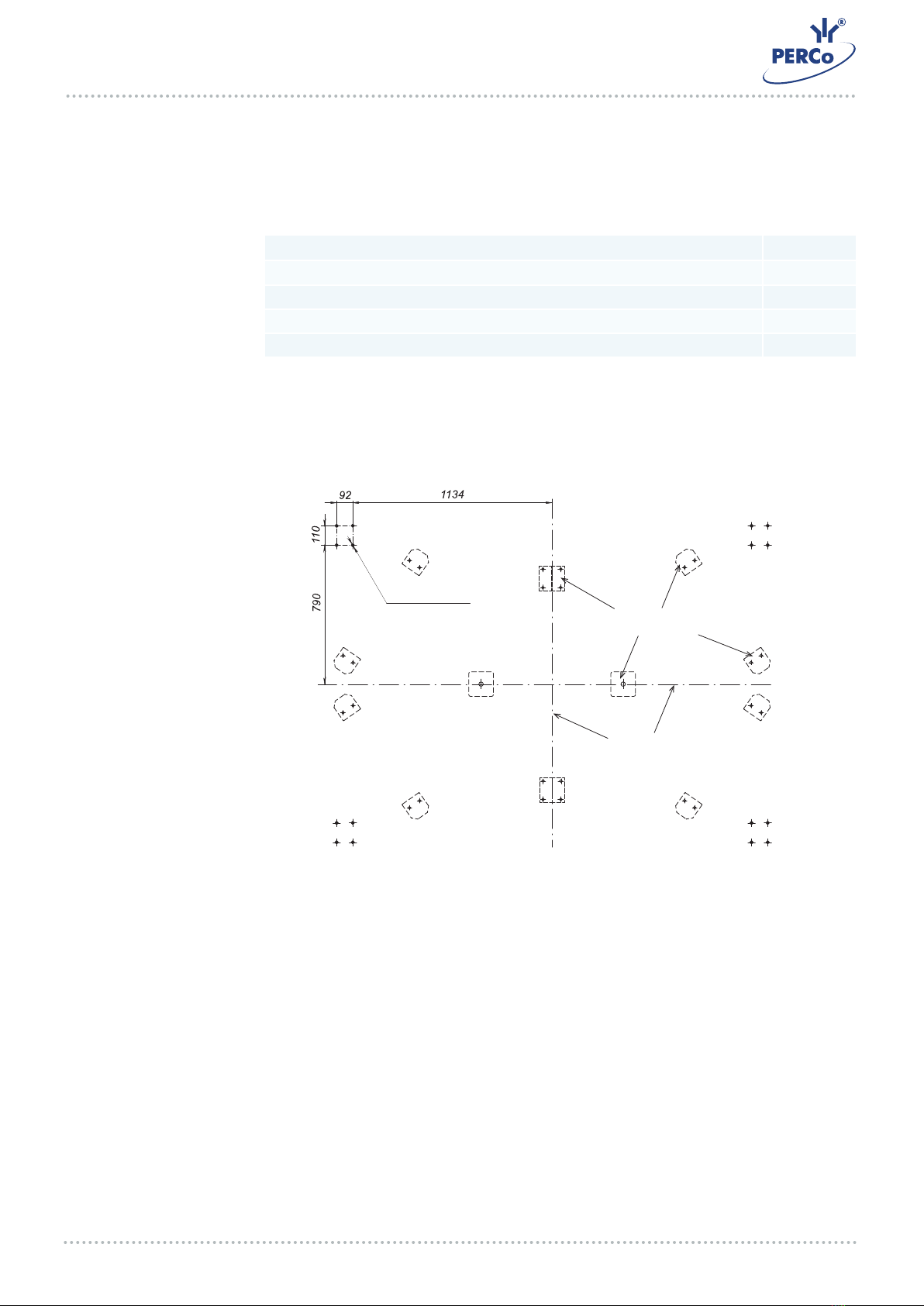

A 13 Walkway downlights power supply (+12 V / 3 A)

Walkway downlights

LED Indication blocks of passage directions A and B

RA, RB ACS readers

1, 2 Indication cables

3 Passage zones power cables

4 External cable for powering walkway downlights

5 Jumpers for switching "IMP/POT" mode

6 Fire Alarm jumpers are connected if there is no Fire Alarm device (A7)

DIN-rail description

Contact Electrical circuit Designation

1, 2 +24 V, GND Power supply connection

3-5 +12 V, Detector, GND Intrusion detector connection

6, 7 Fire Alarm, GND Emergency unlocking input

8 RC Sound RC-panel sound indication output

9-11 UnlockA, Stop,

UnlockB Turnstile control inputs

12-14

RS LedA,

RS LedStop,

RS LedB

RC-panel indication outputs

15, 16 IMP / POT Turnstile control mode setting

17 +12 V Output for powering additional devices

18, 19 Alarm 1, Alarm 2 Siren connection outputs

20 Common Common contact for PASS A, PASS B, Ready, Det Out signals

21 PASS A PASS A relay contact (passage in the direction A)

22 PASS B PASS B relay contact (passage in the direction B)

23 Ready Ready relay contact

24 Det Out Det Out relay contact

25-30 NO, Light, NC Relay contacts for connecting remote indicators

31-36 +12 V, LED, GND Contacts for connecting indication blocks located on the guide

barrier set

37, 38 U1, U2 Connection of the walkway downlights power supply

Operation

algorithm

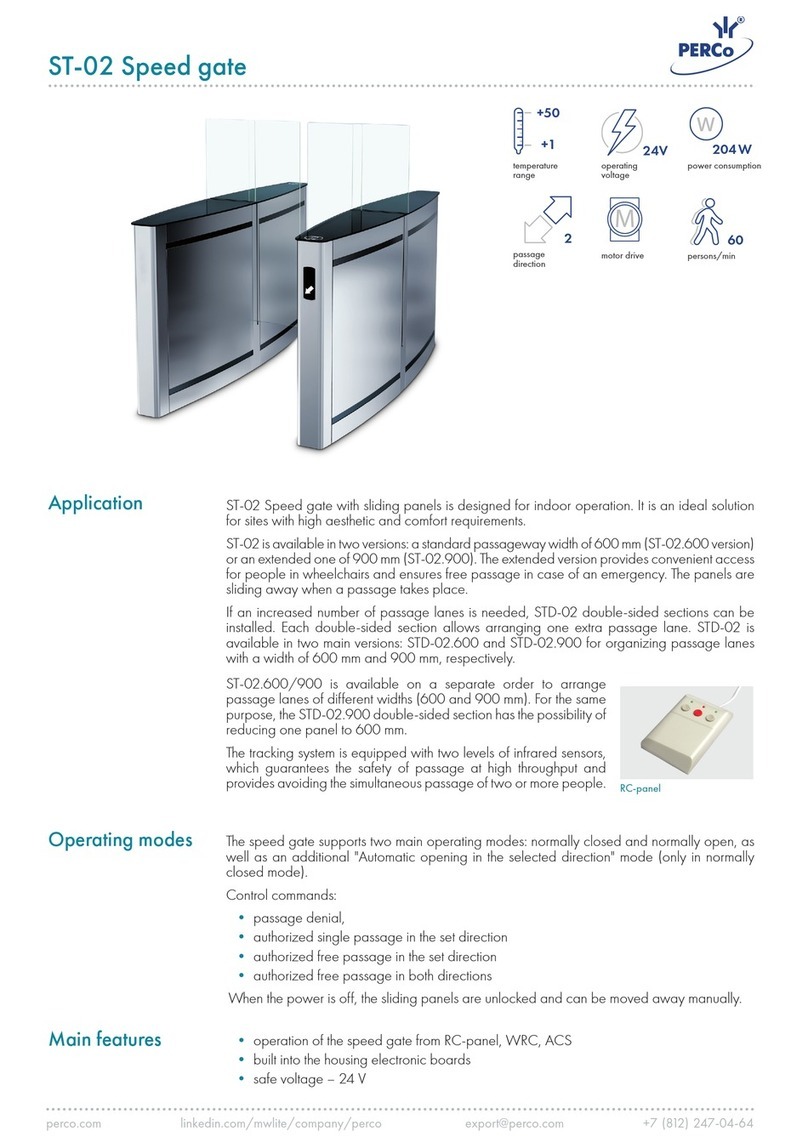

Each passage zone can operate from the RC-panel (included in the delivery set), WRC or

ACS controller. Operation is performed by applying a low-level signal to unlock A, Stop and

Unlock B contacts relative to the GND contact. Response to these signals depends on the

control mode the user has selected (specified by if the IMP/POT jumper wire is installed /

removed on the DIN-rail of the passage zone).

Pulse control mode is when a pulse is applied to the Unlock A (B) input, the passage zone

rotor will automatically unlock for a single passage in the direction A (B). The waiting time for

the passage being completed does not depend on the duration of the control pulse and lasts

5 seconds. Sending a pulse to the Stop input locks the rotor in both passage directions.

Simultaneous sending of pulses to the Unlock A (B) and Stop inputs places the passage zone

in the "Free passage" mode in the selected direction.

It is recommended to use pulse mode during operation from RC-panel or WRC. The

orientation of RC-panel buttons can be changed by swapping the wires from the RC-panel

that are connected to the unlock A and Unlock B contacts, as well as Led A and Led B,

respectively.

Potential control mode is when the control signal is applied to the Unlock A (B) input, the

passage zone rotor unlocks in the selected direction during the entire holding signal time.

RTD-20 Full height rotor turnstile