Contents

Chapter 1 Introduction .................................................................................1

1.1 Introduction...............................................................................................1

Chapter 2 Specifications ..............................................................................2

Specifications ...................................................................................................2

Label .................................................................................................................4

Chapter 3 Operation ....................................................................................6

3.1 Initial Inspection and Setup ...................................................................... 6

3.2 Connections.............................................................................................. 6

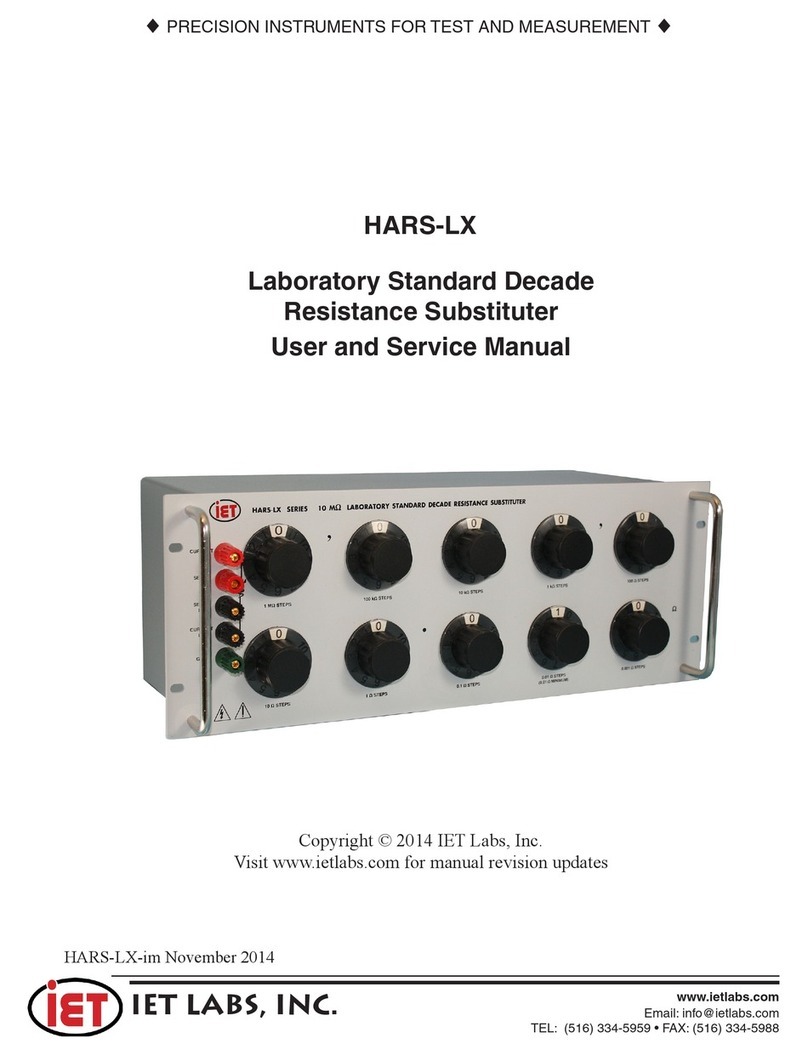

3.2.1 Connections for values ≤190 kΩ.....................................................6

3.2.2 Connections for values > 190 kΩand <100 MΩ.............................6

3.2.3 Connections for values ≥100 MΩ....................................................7

3.3 Thermal emf Considerations.....................................................................7

3.4 Environmental Conditions......................................................................... 7

3.4.1 Operating Temperature ................................................................... 7

3.4.2 Storage Temperature....................................................................... 7

3.5 Shipping and Handling ............................................................................. 7

Chapter 4 Maintenance................................................................................8

4.1 Maintainability and Reliability ...................................................................8

4.2 Preventive Maintenance ........................................................................... 8

4.3 Calibration ................................................................................................8

4.3.1 Calibration Interval ..........................................................................8

4.3.2 General Considerations ..................................................................8

4.3.3 Required Equipment .......................................................................9

4.3.4 Calibration Procedure .....................................................................9

4.4 Replaceable Parts List.............................................................................. 9

v