iFactory3D One Pro User manual

_97971.01

Assembly instructions - Aufbauanleitung

iFactory3D One Pro

Language

ENG Page 2

DE Page 20

Check for updated versions of the assembly instructions on https://ifactory3d.com/instruction-

manuals/

Die neueste Version der Anleitung kann hier abgerufen werden: https://ifactory3d.com/instruction-

manuals/

V_97971.01

2

ENG

General Information

Read the instructions carefully. By using the machine, you confirm to have

read the assembly instructions as well as safety, maintenance and warranty

advise!

Safety advises

Unintended use and wrong handling can lead to machine fault.

The machine can only be used or cleaned or maintained by instructed persons.

Intended use just includes 3D-Printing (additive manufacturing) of polymer parts with appropriate material (filament).

Outdoor use is not recommended. Use only at own risk.

Avoid contact between the device and any liquid.

Always pull the power plug when the machine is not in use or before cleaning/maintaining.

Power cable is not allowed to touch hot, moving or sharp objects.

Do not use the machine if:

o The power plug or cable are damaged.

o The device might have taken damage from falling or other reasons.

Do not open the electronics case, especially not the power supply unit.

The device must be used on a flat surface, which is large enough for the whole machine to fit on.

This surface must be heat resistant and able to handle vibrations.

Make sure no flammable objects can get in contact with the machine.

Careful!

Printhead and printbed / belt area as well as surrounding parts will be hot during use. Do not touch!

Belts driving the printhead and the main belt will move while printing or operating. Do not touch!

Do not move the device during use.

V_97971.01

3

Maintenance

Check the quality of the produced parts regularly.

Nozzle and belt will wear down while printing.

We recommend changing the nozzle after constant use. The reasonable frequency highly depends on the used materials abrasiveness.

The nozzle should be changed as soon as you notice the extrusion width exceeds its original size by far.

We have been able to still achieve good results after more than one month of constant printing with iFactory3D brass nozzle and

iFactory3D PETG filaments.

Non-hardened brass nozzles wear faster than hardened nozzles especially when using filaments with high abrasiveness, such as plaster or

reinforced filaments.

The belt usually lasts between 6 - 12 months of constant printing if the whole belt width is used. Try varying the placing of objects in the

slicer to use the whole width of the belt evenly to increase its lifetime.

The belt might be stained after printing with some materials but it can still be printed on these areas.

Change the belt when it’s been heavily roughened and fibers stand out clearly or parts of it have melted.

Check the friction of the linear rails holding the printhead regularly.

For relubricating, check the instructions:

https://www.hiwin.us/wp-content/uploads/lubricating_instructions.pdf

for MGN12 linear rails.

Use supported lubricants only.

Warranty

Perform all maintenance instructions regularly. There is no warranty on parts listed in maintenance section caused by skipping

maintenance schedule or normal wear.

If you perform any software changes unauthorized by iFactory3D, we cannot provide any support for software related issues.

Opening the power supply unit or changing parts of the electronics will also lead to a loss of warranty.

Do not use any software which is not officially tested by iFactory3D.

Do not exchange parts of the machine with different parts that have not been tested before by iFactory3D.

Only use genuine iFactory3D parts for this machine.

Changing the machine by exchanging parts or somehow mechanically machining them will lead to a loss of warranty for all changed parts

and all damages caused by these changes.

V_97971.01

4

A testprint has been performed on your machine before shipping.

Any traces of filament on the nozzle/heatblock or marks on the belt are caused by a single short

testprint performed by us to check the quality and settings of the machines.

Note: Some assembly groups are attached to each other via cables.

Remove them from the packaging material carefully to not stress or bend the cables.

The One Pro comes with a unique serial number on the right side next to the power input.

For any support questions or problems with your machine make sure to have the serial number

ready.

V_97971.01

5

Parts included

Please check if all listed parts are included before starting to assemble the machine.

If there are damaged or missing parts, contact [email protected] immediately.

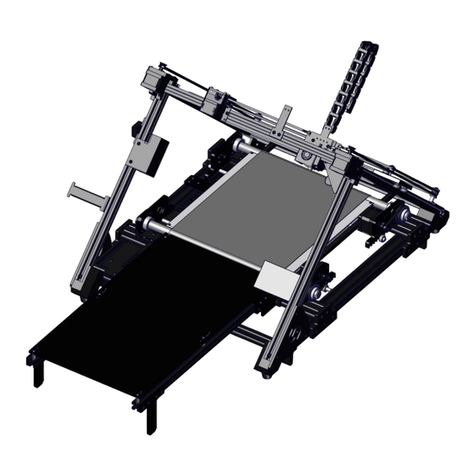

ASM-Group1:

This group contains electronics, display and the belt.

ASM-Group2 and the Raspberry-Pi camera are attached to AMS-Group1 via cable.

V_97971.01

6

ASM-Group2:

This group contains printhead and gantry.

Do not tension gt2-belts before the machine is fully assembled.

ASM-Group3:

This group contains a 2040-Extrusion with the filament runout sensor.

V_97971.01

7

ASM-Group4:

This group only contains one 2040 extrusion.

Other parts:

Cam-clip x3

Allen keys 1.5; 2; 2.5; 3 and 4 [mm]

Wrench 13 mm for M8 nuts (belt rollers)

Wrench 5.5 mm for M3 nuts

Power cable

Clip for coupler

Screws & nuts:

o M5x30 4x

o M5x20 6x

o M5x8 2x

o M4x18 4x

o M4x8 5x

o M4 slot nut 5x (+ one spare)

V_97971.01

8

Assembly

Step 1:

Place AMS-Group1 on a flat surface. Make sure the cable connecting ASM-Group1 and ASM-Group2

is not tensioned.

Now place ASM-Group3 (profile with filament runout sensor) onto the front right foot in a 45° angle.

The filament sensor should point inwards.

Use two M5x20 screws to secure the profile to the foot.

Use two M4x8 screws and two M4 slot nuts to attach the profile to the display.

Note: Slot nuts need to be inserted into the slot of the profile before positioning them:

V_97971.01

9

Step 2:

Mount ASM-Group4 to the front left foot:

Make sure that the sinkings on the top end of the profile are pointing to the outside.

Use two M5x20 screws.

V_97971.01

10

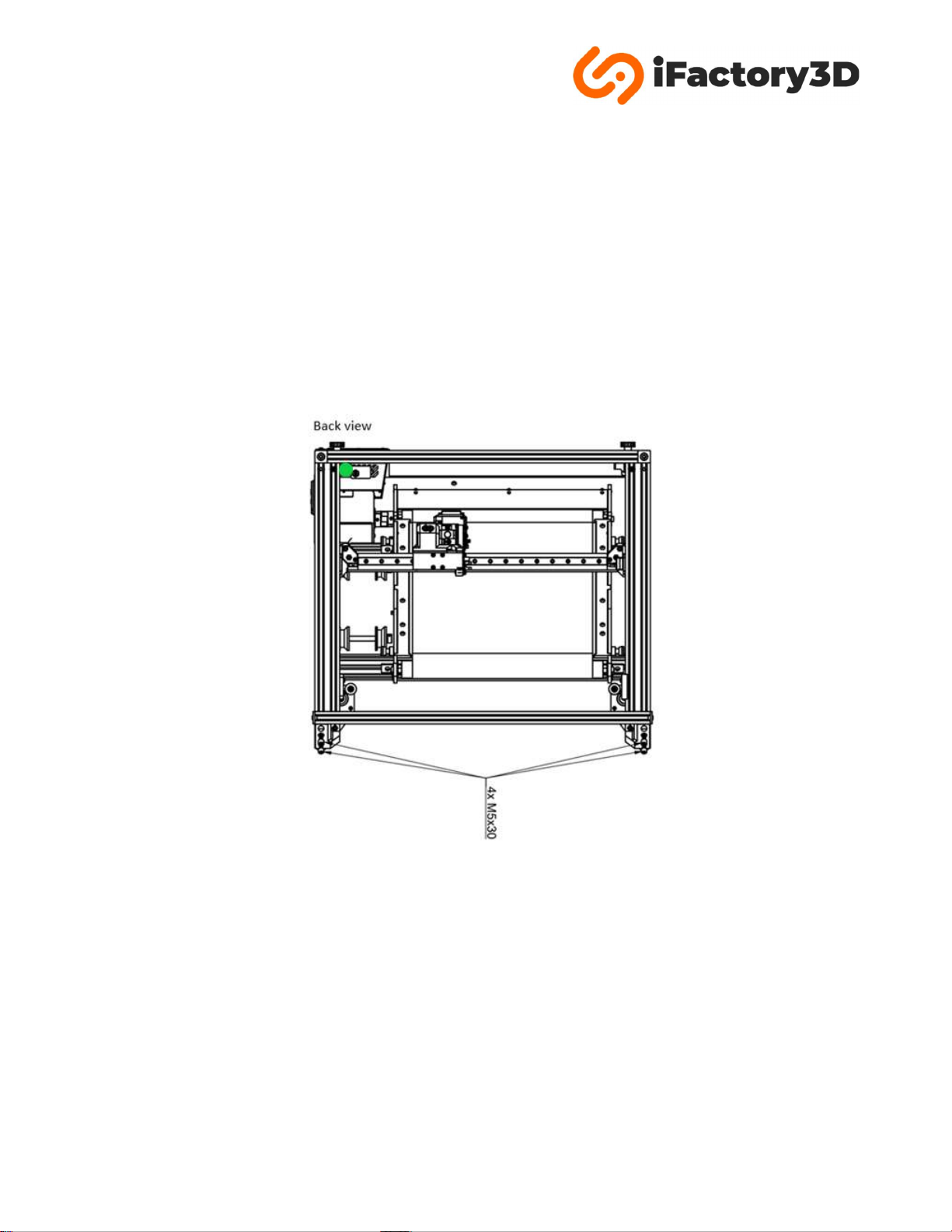

Step 3:

Mount ASM-Group2 on the end of the back profiles of ASM-Group1:

The corner cubes and gt2-tensioning system should point upwards.

Back feet of ASM-Group2 should point downwards.

The cable connecting the printhead with ASM-Group1 must be placed beside the filament runout

bracket from ASM-Group3:

Use four M5x30 screws for the back feet of ASM-Group2.

V_97971.01

11

Use one M4x8 screw and one M4 slot nut on each motor corner to mount them to the bottom

profiles of ASM-Group1.

V_97971.01

12

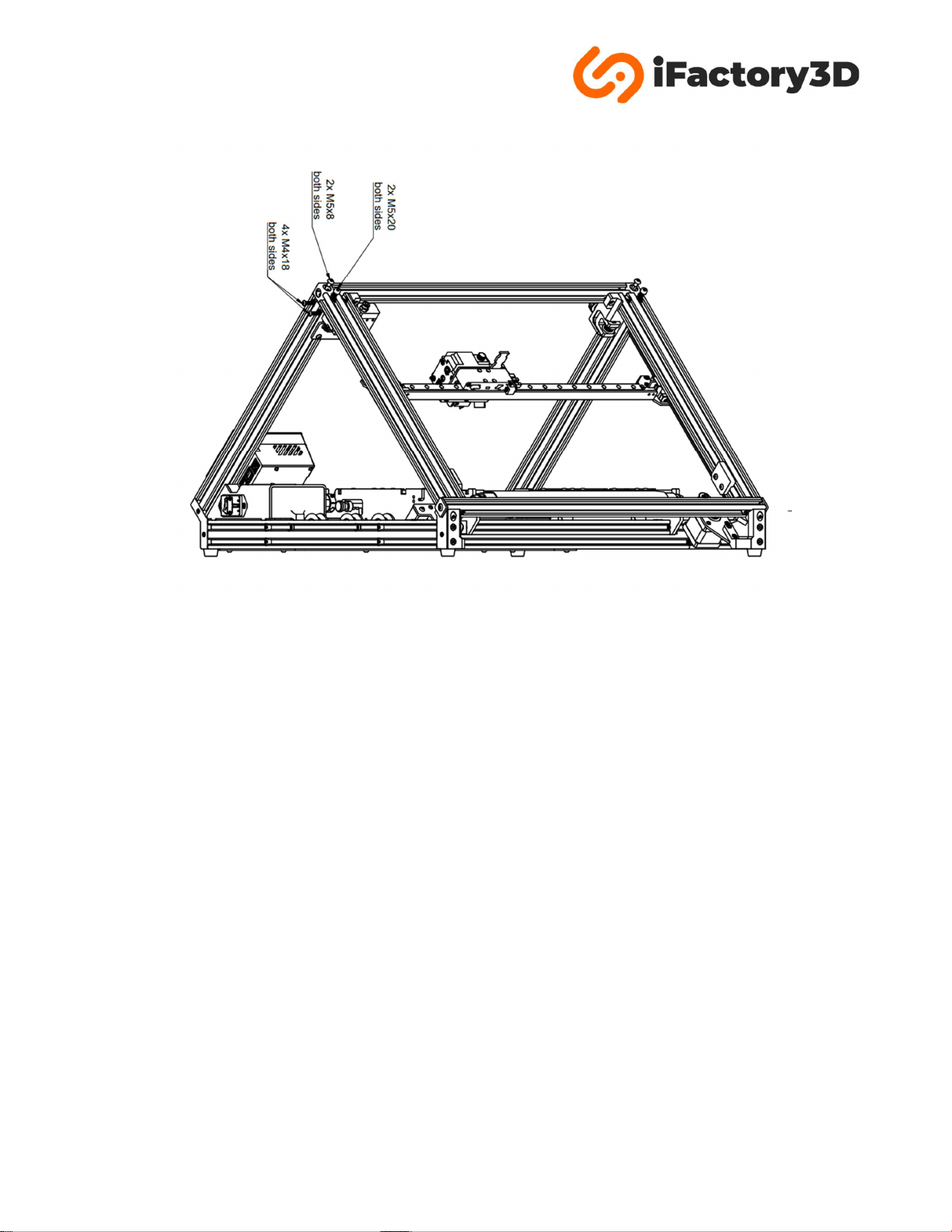

Perform the following steps in both top corners:

Use one M5x20 screw to mount the back profile of ASM-Group2 to ASM-Group 3/4.

Use one M5x8 screw in the corner cube of AMS-Group2 to mount it to the profile of ASM-Group 3/4.

Use two M4x18 screws in the sinkings of the profiles ASM-Group 3/4 to connect them to the GT2-

tensioner (printed parts) of ASM-Group2.

V_97971.01

13

Step 4:

Mount the camera on the top 2020-Profile next to the Filament runout sensor using a M4x8 screw

and a M4 slot nut.

Cam-clips & cable:

Use 3 cam-clip printed parts to guide the camera cable along the profile of ASM-Group3.

The excess length of the cable can be pushed back inside the case on the bottom of the machine.

V_97971.01

14

Cables

Plug all four cables in the nearby parts of the machine.

They can just be plugged in one direction.

X- & Y-Motor:

Filament runout sensor:

Use the cable with 2 strands for the filament runout sensor.

Y-Endstop:

Use the cable with 3 strands for the Y-endstop.

Note: For later versions of the machine an optical endstop will be used as Y-endstop. Parts and colors of the cables might look different.

V_97971.01

15

Bowden tube

Connect the end of the filament bowden tube originating from the printhead to the coupler of the

filament runout sensor.

Push in the bowden tube as far as possible.

Secure the position using the clip on the coupler:

V_97971.01

16

Input voltage

Make sure the selected input voltage is matching the voltage of your local power grid before turning

the machine on.

It can be switched between 110V and 220V.

Note: Labelling can be different for each machine. “110V” supports all voltages from 100V up to 120V

[US standard], while “220V” setting supports all voltages from 220V up to 240V [EU standard].

Both 50Hz and 60Hz are supported.

The Voltage that is visible on the red switch is the selected one.

V_97971.01

17

Tensioning GT2-belts

Check the tension of the belts used in ASM-Group2:

The two thumb screws can be turned clockwise to increase the belts tension.

Each screw is connected to a different GT2-belt, meaning they are not linked. Tension should be

equal on both GT2-belts.

They should be tensioned to a level that they grip onto the motor pulley and do not slip off while

moving.

Make sure the GT2-belts are not tightened too much, the screws holding idler pulleys will bend or

break under high tension. This might cause bad printing quality / wear of the belts / machine stop.

V_97971.01

18

Filament insertion

Choose a spool size you want to use.

1 kg and smaller rolls are supported inside the machine dimensions, for up to 2.2 kg spools the

spoolholder and filament runout sensor can be mounted on the outside by rotating and remounting

them:

Insert the end of the filament into the filament runout sensor.

Make sure that the diameter of the tip of the filament is ≤ 1.75 mm.

Push the filament into the bowden tube until you notice resistance.

Now pull the lever on the printhead to the front:

Push the filament further.

When releasing the lever, the filament must be grabbed by the gear of the extruder.

Heat up the nozzle (see software instructions).

Extrude 50 mm of filament slowly (< 5 mm/s) via touchscreen or web interface.

To remove filament, perform the steps in opposite order. Start with heating the nozzle to the melting

point of your material.

V_97971.01

19

Adjusting the spring tension

The spring tension of the extruder must be adjusted. To adjust the spring tension, turn the thumb

screw on the top of the extruder. Turning it clockwise increases the spring tension and thus exerts

more pressure on the filament.

Recommended spring tension

The spring block should be aligned with the face of the tension lever. Depending on the material

used, further adjustments may be necessary, e.g. additional tension for flexible filaments. The teeth

of the gear should be fully visible in the filament, but should not leave deep notches.

Make sure the temperature of the Nozzle is below 50°C every time you turn off the machine to

prevent clogging or damage to the hotend.

V_97971.01

20

Y-hardstop

Before operating the machine make sure to loosen the screws in two Y-hardstops.

They do not need to be removed completely; just make sure that the printed part can move up and

down the profile smoothly.

Tighten the screws again as soon as the prinhead position is set (see software manual).

Y-hardstops prevent the nozzle from crashing into the printbed if an error occurs during printing.

Make sure they are always tight when the machine is printing.

Also make sure they are always loose when you want to recalibrate the nozzle position.

Other manuals for One Pro

1

Table of contents

Languages:

Other iFactory3D 3D Printer manuals