iFactory3D One User manual

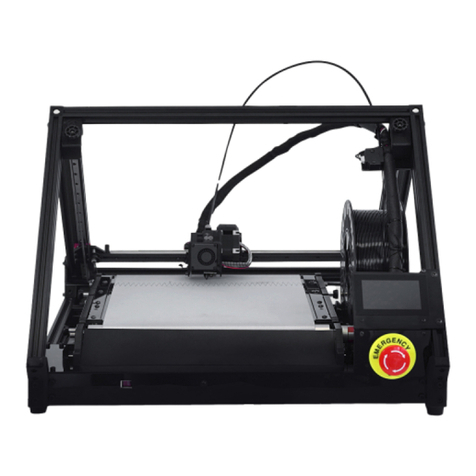

iFactory One Semi

Disclaimer: This is an early version of this manual. For the newest version visit: https://ifactory3d.com/support/#manual

General advice

For the assembly of many components of the iFactory

One, so-called T-nuts are used. The T-nuts need to be

pushed into the profiles groove. This only works if the

T-nut is in the correct position, as shown in the

picture.

General advice

Once the T-nut is in the groove and the component is

in place, the screw can be tightened. To create the

desired clamping, the T-nut must be turned 90° as

shown in the picture.

There might be the case that the T-nut does not turn

in the groove when the screw gets tightened. If this

happens, you should turn the screw back a little (do

not turn the screw all the way out because then you

will lose the nut!) and then tighten it again until the

T-nut produces the desired clamping.

In general, screws in plastic components should not

be tightened too much, otherwise those might break

(as soon as you hear noises, do not continue turning).

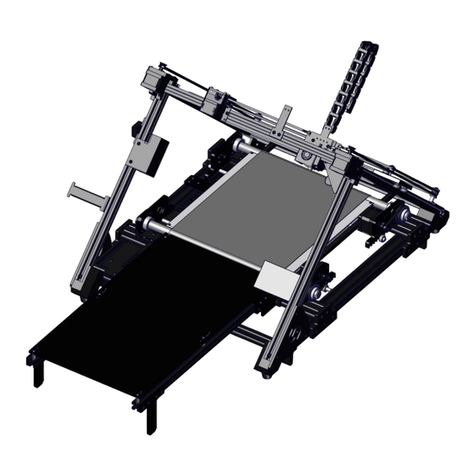

Step1

Mounting of the back feet

Belt group

First, the feet must be attached to the pre-

assembled belt assembly. The rear feet are

already attached

to an aluminium profile and will be mounted on

the back of the belt assembly as shown in the

picture.

The easiest way to mount the feet is to lay the

belt assembly on its side and tighten the pre-

assembled

M4x14 screws in the feet from below. The rear

feet must be placed so that they touch the

underside of the rear tensioning guides.

Back feet

Step 2

Mounting of the front feet

The front feet will be mounted on the front 20x20

profile and are attached in the same way as the back

feet.

The 45°chamfer is pointing inwards.

Foot LF Foot RF

Step 3

Mounting the guide rails

The guide profiles are mounted with the small roller

holders to the aluminium profile of the back feet.

For this purpose, the T-nuts of the roller holders are

used.

Guide rails

Step 4

Printhead

The guide profile of the print head is pushed over the

metal rails with the pre-assembled large roller

holders. The print head must be aligned so that the

nozzle of the printhead points in the direction of

the belt. If the printhead guide rail has been pushed

correctly, [roller holder large R] is now on the same

rail as the [roller holder small L].

Printhead

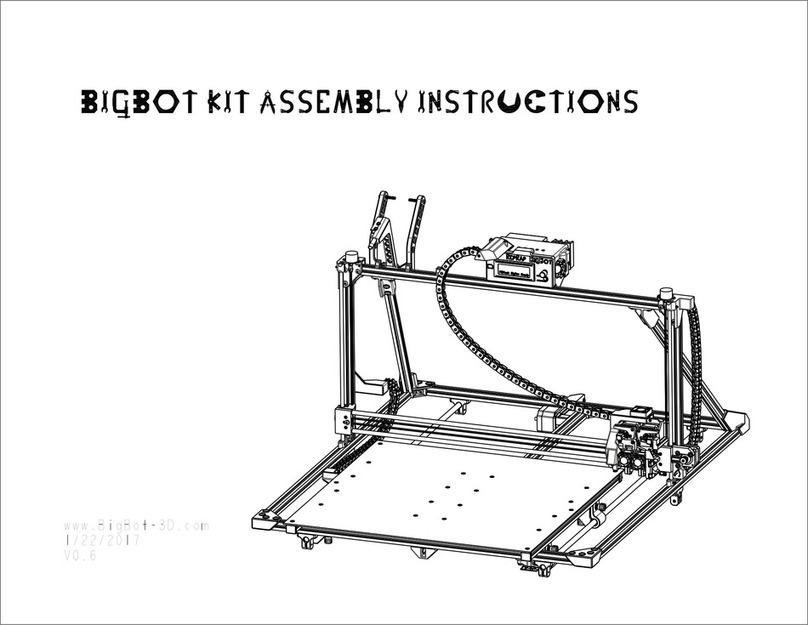

Step 5

Attaching the 20x20x460 profiles

Now the 20x20x460 profile with the pre-

assembled angles must be mounted to the

front

feet (attention: angles are attached to the

profile and are not used to attach the profiles

to the feet).

Mount the profiles on the 45° side of the feet

so that the angles on the profiles point

upwards. Attach the other side of the

20x20x460 profile to the guide rail.

Use M5x25 screws for this step.

20x20x460 Profile

Step 6

Mounting of the motor profile

Please note the orientation of the motors as shown

in the picture. Mount the profile on the angles from

the previous step.

Motors with profile

Step 7

Adjusting the motors

Now loosen the M4 (lower) screws in the X- and Y-

plates.

Then slide the plates inwards as shown in the

illustration until the side T-nuts are in the recesses of

the 20x20x460 profile (mounted in Step 5).

Step 8

Securing the motors

After the motors are placed, tighten the circled screws and

screw in a M5x25 screw as indicated in the picture.

Do this step for the Y- as well as for the X-motor.

Step 8.5

Aligning the wheels

Check, if the printhead moves smoothly upwards and

downwards. If it does, go to Step 9.

If the printhead rail does not move smoothly, do the

following steps:

The wheels that should be adjusted are the eccentric

wheels - indicated with arrows in the picture.

Step 8.5

Aligning the wheels

First, loosen the set screws (no need to do it as far as

in the picture but just a little bit).

Try loosening the bolt on the other side of the wheel.

Step 8.5

Aligning the wheels

You can fasten the bolt again, when you have placed

the X-rail onto the frame. Fastening the bolt

automatically realigns the wheel (it rotates along

with the bolt until the wheel hits the rail). Then

fasten the set screws.

If the bolt does not really want to come loose, you

can try to turn the disc with the eccentric bore. This

may require some force if the bolt is firmly fastened.

Step 9

Placing the Y-belt

The next step is best done from the back of the

printer. Place the gt2 belt over the Y-stepper

motor pulley and then along all the other pulleys

on the back - as shown in the picture - to build a

core XY-motion system. Mount the belt to the

printhead with a cable tie. Do not tension the belt

too much, just avoid any sagging.

Step 10

Placing the X-belt

Place the gt2 belt over the X-stepper motor pulley

and then along all the other top pulleys on the back

as shown in the picture to build a core XY motion

system. Mount the belt to the printhead with a cable

tie.

Do not tension the belt too much, just prevent any

sagging.

Step 11

Tightening the X- and Y-belts

Release the four M3 screws in each motorplate.

Pull the motors upwards as shown in the picture and

tighten the M3 screws again.

If the belt is not tensioned enough, release the four

M3 screws again and repeat Step 20 and 21, but this

time with more tension applied to the belts.

If the belts are tight enough, you can cut off the

remaining gt2 belt at the printhead.

Step 12

Side bracket

Side bracket

Mount the corner brackets with the logo on the front

outer corners.

Step 13

Belt and tightening

Pull the two back belt tightening sliders as far as

possible to the back and tighten the M4 screws.

Pull the two front belt tightening sliders in the

direction of the side plates with the iFactory3D logo

and fasten the sliders as soon as they hit the side

plates*.

* For all early versions of the printers, there are still smaller side plates, so an equal air gap of around 7mm between side plate and sliders

is needed.

Step 14

Rods and tightening

8mm rod

Now place the two 8mm rods through the belt and

the underside of the square bar and clip it into the

fitting of the bearing brackets.

The fittings are numbered, and the rods need to be

at the same number to apply the tension evenly to

the belt.

The higher the number of the fitting, the more

tension is applied to the belt.

This manual suits for next models

1

Table of contents

Other iFactory3D 3D Printer manuals