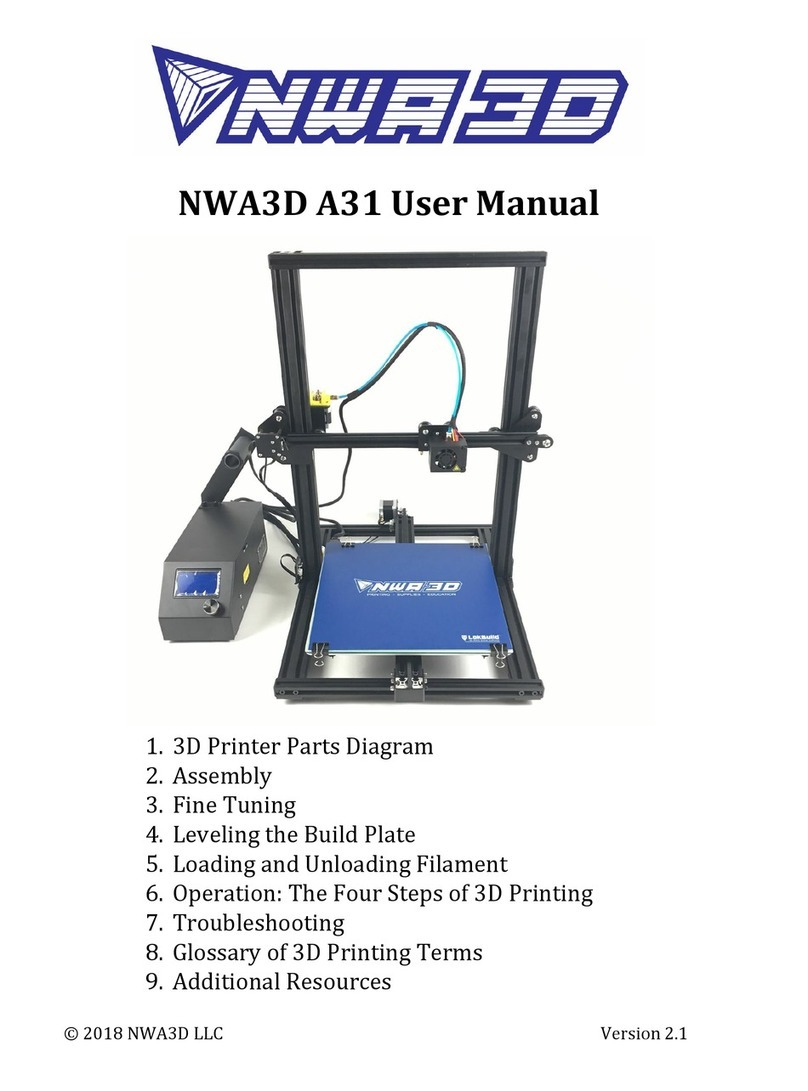

NWA3D A31 User Manual

f. To operate the controls, rotate the button to scroll and push the button to

select.

3. Fine-Tuning

1. Adjust the tension of the build plate assembly on the Y-axis on the base

frame.

a. Check the tension of the build plate assembly. Hold the build plate

carriage under the build plate and try to wiggle it left and right. If the

build plate assembly wiggles back and forth on the Y-axis frame, it is too

loose.

b. To tighten the build plate assembly, rotate the three eccentric nuts that

connect the three wheels to the right side of the build plate assembly. Use

the open-end wrench to rotate the nuts slightly—a quarter turn is usually

enough—until each of the three wheels is tight against the Y-axis frame

and the carriage no longer rotates.

c. Re-check the tension of the build plate assembly. The assembly and the

belt should move forward and backward without much effort, but there

should have no side-to-side wiggle or play.

2. Adjust the tension of the gantry on the right pillar of the gantry frame.

a. Check the tension of the gantry assembly at the right pillar of the frame.

Hold the gantry and try to wiggle it up and down. If the gantry wobbles on

the right pillar frame, it is too loose.

b. To tighten the gantry, rotate the one eccentric nut that connects the

wheel to the inside of the gantry. Use the open-end wrench to rotate the

nut slightly—a quarter turn is usually enough—until the wheel is snug

against the frame pillar and the gantry no longer wobbles.

10

© 2017 NWA3D LLC