General Information » Read and keep the operation instructions

Version 1.0 2 von 25

TABLE OF CONTENTS

GENERAL INFORMATION ............................................................................................................................ 4

1. Read and keep the operation instructions ........................................................................................... 4

2. Legend of Symbols ................................................................................................................................. 4

SECURITY ...................................................................................................................................................... 5

1. Intended Use ............................................................................................................................................ 5

PREPARATION 3D-PRINTER ....................................................................................................................... 6

1. Disconnect Power Supply ...................................................................................................................... 6

2. Unplug PTFE Tube ................................................................................................................................. 6

3. Remove Extruder .................................................................................................................................... 7

4. Remove Drive Gear ................................................................................................................................ 7

5. Remove Extruder Drive Motor ............................................................................................................... 8

PREPARATION 3DFEEDY ............................................................................................................................ 9

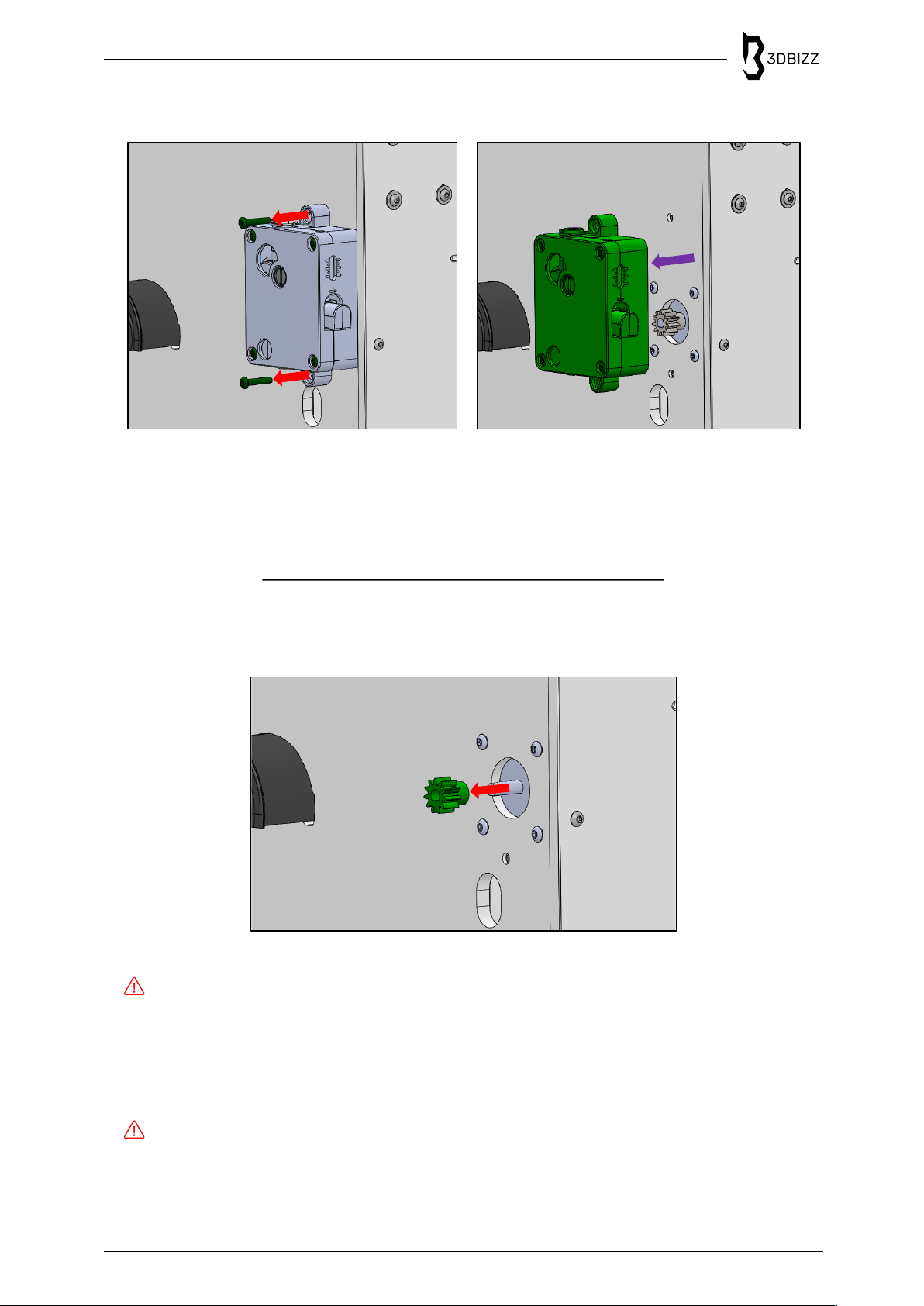

1. Remove Manual Adjustment Fixture .................................................................................................... 9

2. Remove First Selector Cover .............................................................................................................. 10

3. Remove Second Selector Cover ......................................................................................................... 10

4. Remove Third Selector Cover ............................................................................................................. 11

5. Remove Fourth Selector Cover ........................................................................................................... 11

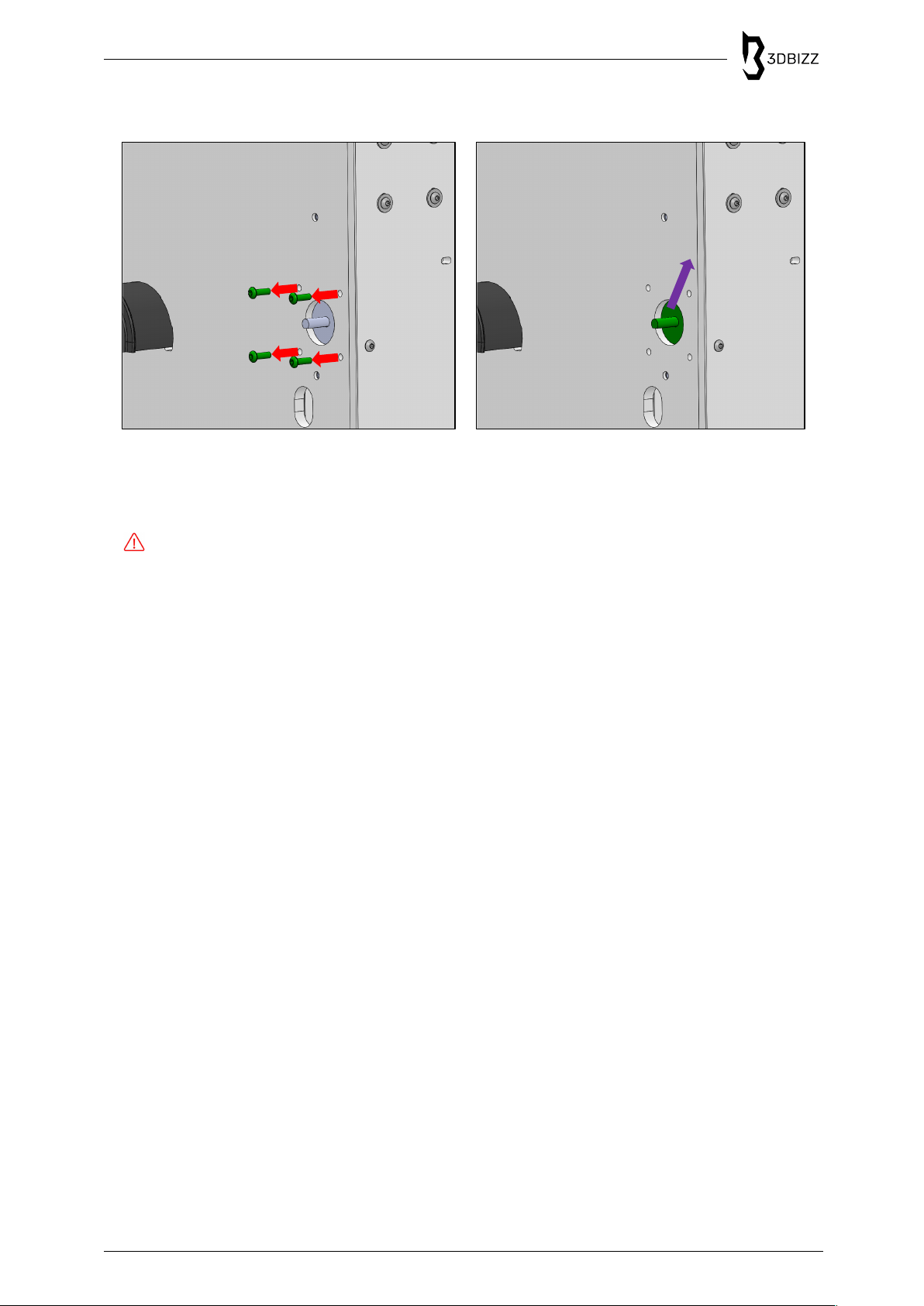

6. Remove Selector Shaft ......................................................................................................................... 12

7. Remove Drive Gear Cover ................................................................................................................... 12

ASSEMBLY 3DFEEDY ................................................................................................................................ 14

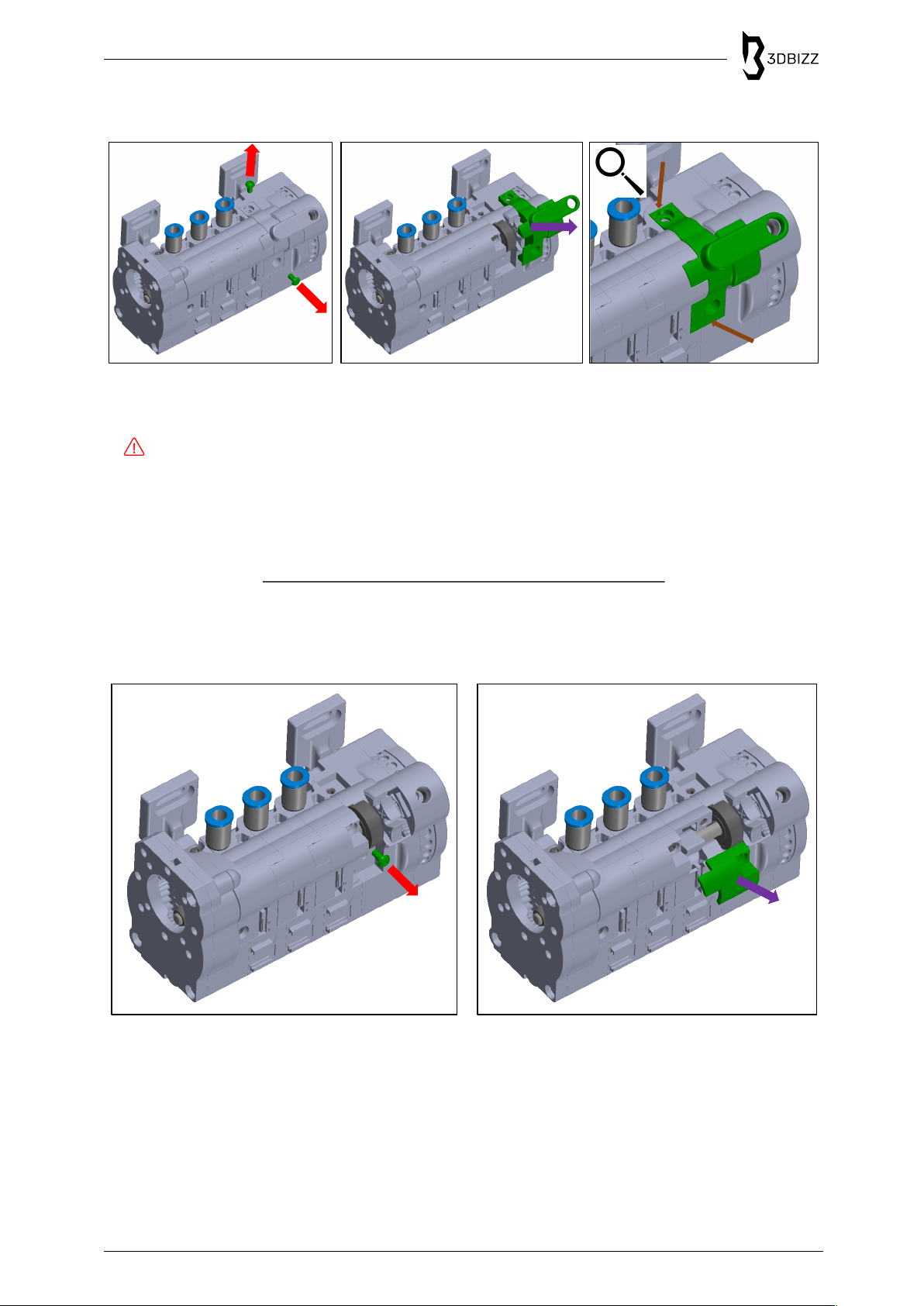

1. Connect Drive Gear to Extruder Drive Motor .................................................................................... 14

2. Connect Extruder Drive Motor to Cover of Drive Unit ...................................................................... 15

2.1. Connect other Extruder Drive Motor sizes to Drive Unit Cover .................................................. 15

3. Marriage: Connect Extruder Drive Motor to 3Dfeedy ....................................................................... 16

3.1. Marriage: Connect other Extruder Drive Motor sizes to 3Dfeedy ............................................... 16

4. Insert Selector Shaft ............................................................................................................................. 17

5. Insert Fourth Selector Cover ................................................................................................................ 18

6. Insert Third Selector Cover .................................................................................................................. 18

7. Insert Second Selector Cover .............................................................................................................. 19

8. Insert First Selector Cover ................................................................................................................... 19

9. Insert Manual Adjustment Fixture ....................................................................................................... 20