Connection

examples *6

Performance_Level: e to

DIN EN ISO 13849-1

SIL 3 to DIN EN 61508

Category 4 to EN954-1

We reserve the right to make alterations without prior notice

ifm electronic.gmbh Date: 22.03.07

&RQWHQWV 3DJH

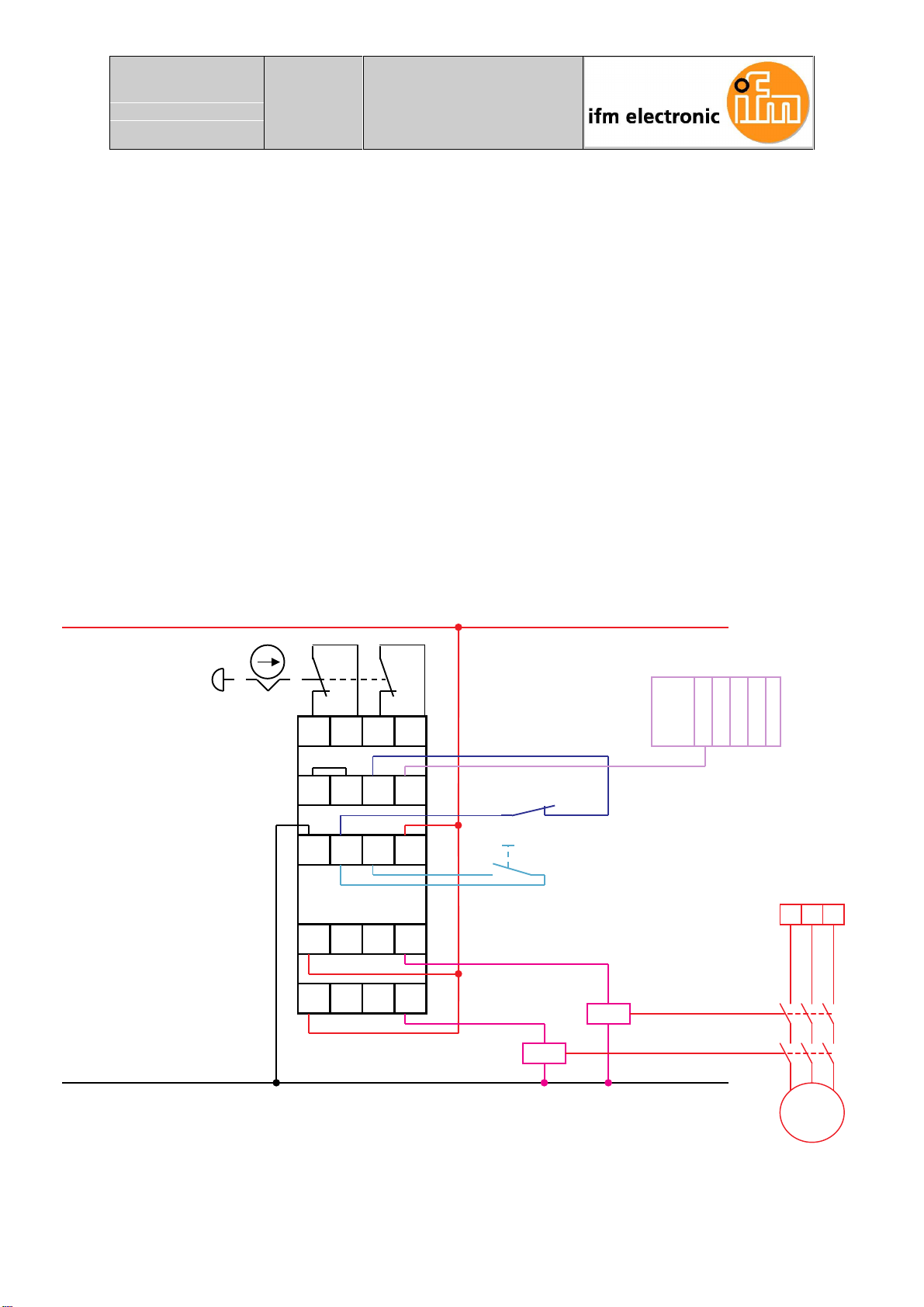

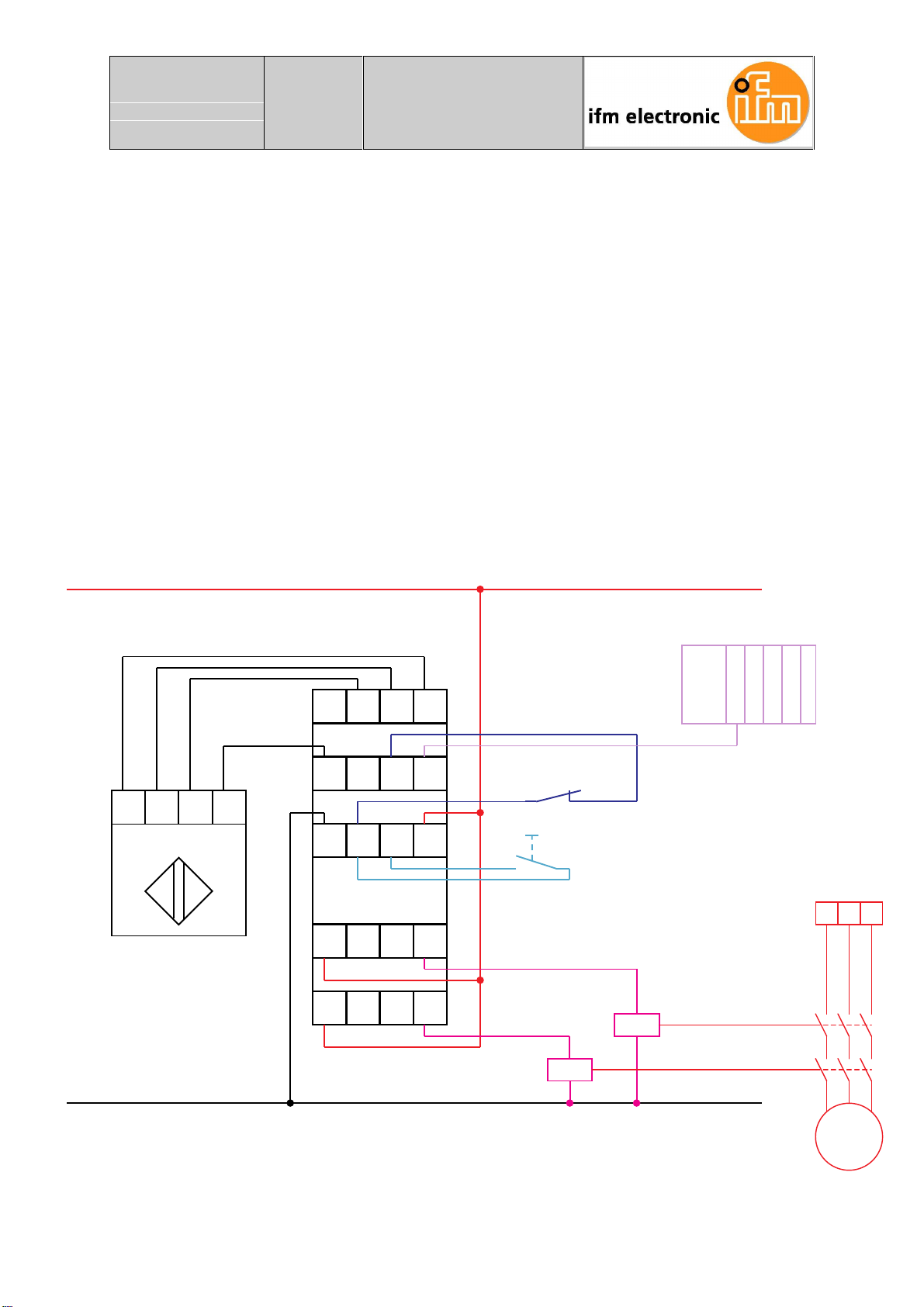

(6723$33/,&$7,21

7ZRFKDQQHOVZLWKPRQLWRUHGVWDUWDQGUHOD\FRQWUROZLWKIHHGEDFNORRSPRQLWRULQJ

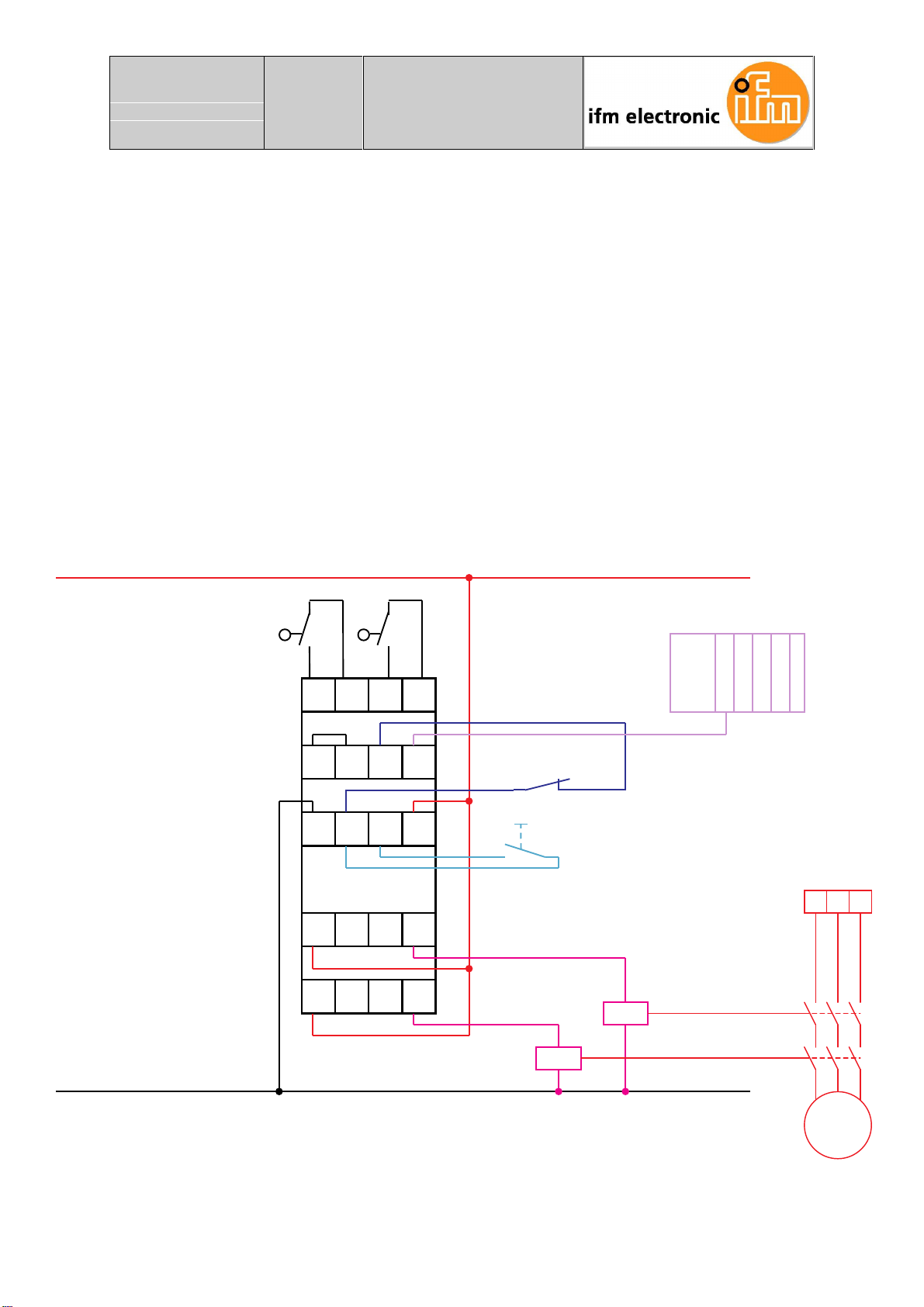

3527(&7,9(*8$5'$33/,&$7,21

:LWKPRQLWRUHGVWDUW

:LWKDXWRPDWLFVWDUW

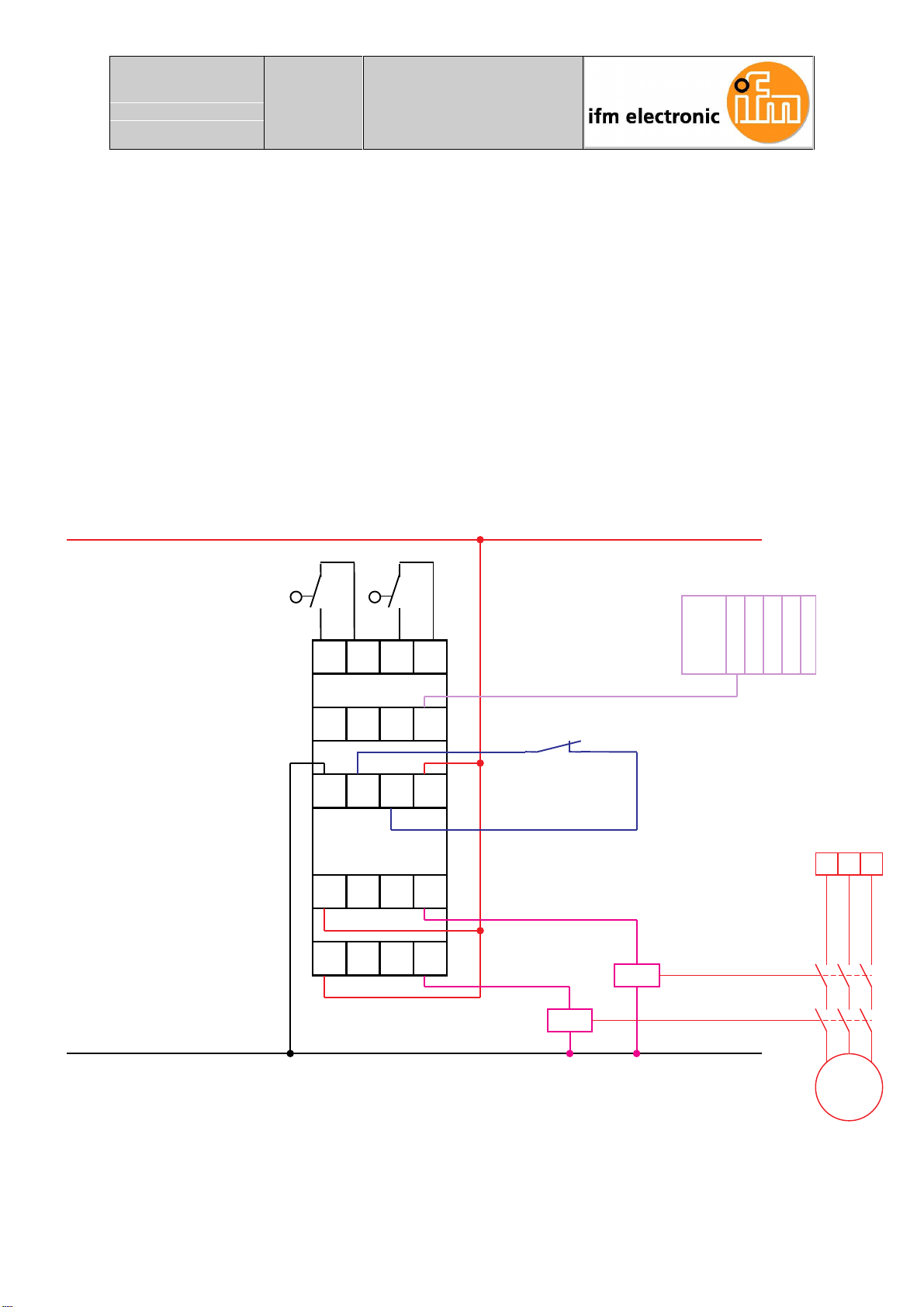

&211(&7,212)$121&217$&76$)(7<'(9,&(:,7+6(0,&21

'8&7252873876;36:,7&+,1*(**067+528*+%($0

6(1625/,*+7&857$,1/$6(56&$11(5

:LWKDXWRPDWLFVWDUWDQGVXSSO\RIWKHQRQFRQWDFWVDIHW\GHYLFHFXUUHQWFRQVXPSWLRQ

P$YLDWKH*6

:LWKPRQLWRUHGVWDUWDQGVXSSO\RIWKHQRQFRQWDFWVDIHW\GHYLFHFXUUHQWFRQVXPSWLRQ

P$YLDWKH*6

:LWKDXWRPDWLFVWDUWDQGH[WHUQDOVXSSO\RIWKHQRQFRQWDFWVDIHW\GHYLFHFXUUHQW

FRQVXPSWLRQ!P$

:LWKPRQLWRUHGVWDUWDQGH[WHUQDOVXSSO\RIWKHQRQFRQWDFWVDIHW\GHYLFHFXUUHQW

FRQVXPSWLRQ!P$

&211(&7,212)$&/2&.(')$,/6$)(6(1625(**06**6

*,6(7&

:LWKDXWRPDWLFVWDUWDQGVXSSO\RIWKHIDLOVDIHVHQVRUYLDWKH*6

:LWKPRQLWRUHGVWDUWDQGVXSSO\RIWKHIDLOVDIHVHQVRUYLDWKH*6

:LWKDXWRPDWLFVWDUWDQGH[WHUQDOVXSSO\RIWKHQRQFRQWDFWVDIHW\GHYLFH

:LWKPRQLWRUHGVWDUWDQGH[WHUQDOVXSSO\RIWKHQRQFRQWDFWVDIHW\GHYLFH

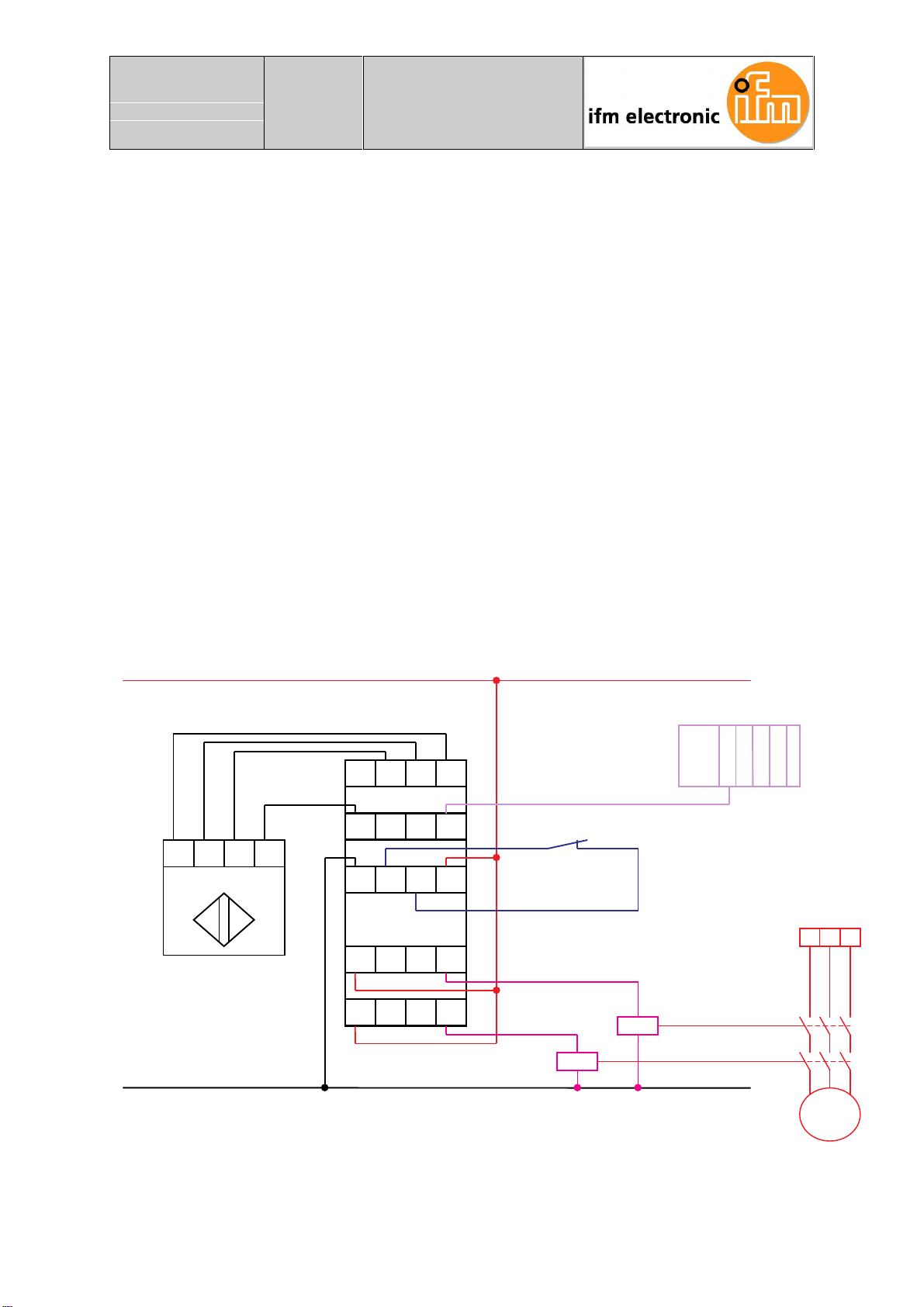

7:2+$1'&21752/86,1*0(&+$1,&$/6:,7&+(6

7:2+$1'&21752/86,1*(/(&7521,&6(16256