IFR STD-7000 Manual

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

I

I

I

I

I

I

I

I

111

I

I

I

I

I

I

I

tt

I

OPERATION I

MAINTENANCE

MANUAL

STANDARD

DIGITAL INTERFACE SYSTEM

STD-7000

PUBLISHED

BY

IFR

AMERICAS,

INC.

COPYRIGHT

©

IFR

Americas,

Inc.

1999

All

rights

reserved.

No

part

of

this

publication

may

be

reproduced,

stored

in a

retrieval

system,

or

transmitted

in

any

form

or

by

any

means,

electronic,

mechanical,

photocopying,

recording

or

otherwise

without

the

prior

permission

of

the

publisher.

10200

West

York

/

Wichita,

Kansas

67215

U.S.A.

/

(316)

522-4981

/

FAX

(316)

524-2623

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

I

I

I

I

I

I

I

I

II

I

I

I

I

I

I

I

fI

I

I

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

I

~~

OPERATION/MAINTENANCE

MANUAL

~'A

STD-7000

WARNING:

FIRST AID

HIGH VOLTAGE EQUIPMENT

RESCUE OF SHOCK VICTIMS

1.

DO

NOT

ATTEMPT

TO

PULL

OR

GRAB

THE

VICTIM

2.

IF

POSSIBLE,

TURN

OFF

THE

ELECTRICAL

POWER.

3.

IF

YOU

CANNOT

TURN

OFF

ELECTRICAL

POWER,

PUSH,

PULL

OR

LIFT

THE

VICTIM

TO

SAFETY

USING

A

WOODEN

POLE,

A

ROPE

OR

SOME

OTHER

DRY

INSULATING

MATERIAL.

1.

AS

SOON

AS

VICTIM

IS

FREE

OF

CONTACT

WITH

SOURCE

OF

ELECTRICAL

SHOCK,

MOVE

VICTIM

A

SHORT

DISTANCE

AWAY

FROM

SHOCK

HAZARD.

2.

SEND

FOR

DOCTOR

AND/OR

AMBULANCE.

3.

KEEP

VICTIM

WARM,

QUIET

AND

FLAT

ON

HIS/HER

BACK.

4.

IF

BREATHING

HAS

STOPPED,

ADMINISTER

ARTIFICIAL

RESUSCITATION.

STOP

ALL

SERIOUS

BLEEDING.

THIS

EQUIPMENT

CONTAINS

CERTAIN

CIRCUITS

AND/OR

COMPONENTS

OF

EXTREMELY

HIGH

VOLTAGE

POTENTIALS,

CAPABLE

OF

CAUSING

SERIOUS

BODILY

INJURY

OR

DEATH.

WHEN

PERFORMING

ANY

OF

THE

PROCEDURES

CONTAINED

IN

THIS

MANUAL,

HEED

ALL

APPLICABLE

SAFETY

PRECAUTIONS.

~-----

I

I

I

I

I

I

I

-

I

I

I

I

I

I

I

IArtisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

OPERATION/MAINTENANCE

MANUAL

STD-7000

CAUTION:

------

INTEGRATED

CIRCUITS

AND

SOLID

STATE

DEVICES

SUCH

AS

MOS

FETtS,

ESPECIALLY

CMOS

TYPES,

ARE

SUS-

CEPTIBLE

TO

DAMAGE

BY

ELECTROSTATIC

DISCHARGES

RECEIVED

FROM

IMPROPER

HANDLING,

THE

USE

OF

UNGROUNDED

TOOLS,

AND

IMPROPER

STORAGE

AND

PACKAGING.

ANY

MAINTENANCE

TO

THIS

UNIT

MUST

BE

PERFORMED

WITH

THE

FOLLOWING

PRECAUTIONS:

1.

BEFORE

USING

IN

ACIRCUIT,

KEEP

ALL

LEADS

SHORTED

TOGETHER

EITHER

BY

THE

USE

OF

VENDOR-SUPPLIED

SHORTING

SPRINGS

OR

BY

INSERTING

LEADS

INTO

A

CONDUCTIVE

MATERIAL.

2.

WHEN

REMOVING

DEVICES

FROM

THEIR

CONTAINERS,

GROUND

THE

HAND

BEING

USED

WITH

A

CONDUC-

TIVE

WRISTBAND.

3. TIPS

OF

SOLDERING

IRONS

AND/OR

ANY

TOOLS

USED

MUST

BE

GROUNDED.

4.

DEVICES

MUST

NEVER

BE

INSERTED

INTO

NOR

REMOVED

FROM

CIRCUITS

WITH

POWER

ON.

5.

PC

BOARD,

WHEN

TAKEN

OUT

OF

THE

SET,

MUST

BE

LAID

ON

A

GROUNDED

CONDUCTIVE

MAT

OR

STORED

IN

A

CONDUCTIVE

STORAGE

BAG.

6.

PC

BOARDS,

IF

BEING

SHIPPED

TO

THE

FACTORY

FOR

REPAIR,

MUST

BE

PACKAGED

IN

A

CONDUC-

TIVE

BAG

AND

PLACED

IN

A

WELL-CUSHIONED

SHIPPING

BOX.

I

I

I

I

I

I

I

I

-I

I

I

I

I

I

I

I

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

I

I

,

I

I

I

I

I

I

I

--

I

I

I

I

I

I

I

I

~-

OPERATION/MAINTENANCE

MANUAL

~R

STD-7000

LIST

OF

EFFECTIVE

PAGES

---------------------

Cha£!~~LSe£!i~~L~~Q~~£l

E~~~

Date

--------

Ti t 1e

Pa

ge Apri 1

1/87

Copyright

Pa

ge Apri 1

1/87

Warning

Pa

ge Apri 1

1/87

Caution

Pa

ge Apri 1

1/87

Record

of

Revisions

Pa

ge Apri 1

1/87

List

of

Effective

Pa

ges 1

thru

2

April

1/87

Table

of

Contents

1

thru

2

April

1/87

Introduction

1

thru

2

April

1/87

I-Table

of

Contents

1

thru

4Apri 1

1/87

I-List

of

Illustrations

1

thru

2Apri 1

1/87

I-List

of

Tables

1

thru

2Apri 1

1/87

1-1-

11

thru

4Apri 1

1/87

1-

2-1

1

thru

8Apri 1

1/87

1- 2- 2 1

thru

6

April

1/87

1- 2- 3 1

thru

22

April

1/87

1-

3-1

1

thru

4Apri 1

1/87

1-4-1

1

thru

2Apri 1

1/87

1-5-1

1

thru

2

Ap

r i 1

1/87

2-Table

of

Contents

1

thru

4

April

1/87

2-List

of

Illustrations

1

thru

4

April

1/87

2-List

of

Tabl es 1

thru

2Apri 1

1/87

2-1-1

1

thru

2

April

1/87

2-

2-1

1

thru

30 Apri 1

1/87

2- 2- 2 1

thru

34 Apri 1

1/87

2- 2- 3 1

thru

10

Ap

r i 1

1/87

2- 2- 4 1

thru

62 Apri 1

1/87

2- 2- 5 1

thru

14 Apri 1

1/87

2- 2- 61

thru

12 Apri 1

1/87

2-

2-7

1

thru

34

Apri 1

1/87

2- 2- 8 1

thru

16

April

1/87

I-APPENDIX

A1

thru

6Apri 1

1/87

I-APPENDIX

B1

thru

4Apri 1

1/87

I-APPENDIX

C1

thru

2Apri 1

1/87

I-APPENDIX 01

thru

8

Ap

r i 1

1/87

I-APPENDIX E1

thru

2Apri 1

1/87

LIST

OF

EFFECTIVE

PAGES

Page 1

April

1/87

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

~~

OPERATION/MAINTENANCE

MANUAL

Aft.

STD-7000

THIS

PAGE

INTENTIONALLY

LEFT

BLANK.

I

I

"I

I

I

I

I

I

I

-I

I

I

I

I

I

I

LIST

OF

EFFECTIVE

PAGES

Page 2 I

April

1/87

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

I

~R~

OPERATION/MAINTENANCE

MANUAL

-,rA

STD-lOOO

'Ole

TABLE

OF

CONTENTS

-------------

I

I

I

I

I

I

I

lit

I

I

I

I

I

I

I

I

Title

Title

Page

Copyri

ght

Page

Caution

Page

Warning Page

Record

of

Revisions

List

of

Effective

Pages

Table

of

Contents

Introduction

Chapter

1

Description

Operation

Specifications

Shipping

Storage

Chapter

2

Servicing

Troubleshooting

Appendix A - Pin Out

Tables

Appendix B -

Test

Equipment

Requirements

Appendix C -

WRX/WRC-7708

GPIB

Command

Tables

Appendix D - STD-7000 I/O

Map

Appendix E - STD-7000

Memory

Map

Appendix F -

Abbreviations

1

1-1

1-

2

1-

3

1-4

1-

5

2

2-1

2-

2

TABLE

OF

CONTENTS

Pa

ge 1

Apri 1

1/87

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

OPERATION/MAINTENANCE

MANUAL

STD-7000

THIS

PAGE

INTENTIONALLY

LEFT

BLANK.

I

I

I

I

I

I

I

III

I

I

I

I

I

I

I

TABLE

OF

CONTENTS

Page 2I

April

1/87

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

I

I

I

I

I

I

I

I

-

I

I

I

I

I

I

I

I

~R~

OPERATION/MAINTENANCE

MANUAL

IrA STD-7000

.NC

INTRODUCTION

- STD-7000

STANDARD

DIGITAL

INTERFACE

SYSTEM

-------------------------------------------------

This

manual

contains

operation

and

maintenance

instructions

for

the

STD-7000

Bus

Controller

and

its

optional

Operator

Terminal

designated

as

the

Standard

Digital

Interface

(with

keypad)

System

(SDIS).

.

The

information

provided

in

this

manual

will

familiarize

the

operator/technician

with

the

STD-7000

to:

1.

Understand

general

operating

capabilities

of

each

unit

and

how

both

are

to

be

implemented

into

a

functional

test

system.

2.

Identify

and

understand

function

of

all

equipment

controls.

3.

Properly

interface

STD-7000

to

its

Operator

Terminal

and

pre-

pare

for

further

interface

to

accessory

test

equipment

and

UUT.

4.

Power-up

STD-7000/0perator

Terminal

and

understand

all

phases

of

start-up

operations.

5.

Certify,

test,

repair

or

replace

any

major

assembly

or

module

within

the

STD-7000

Bus

Controller.

6.

Sufficiently

understand

the

circuitry

and

principles

of

opera-

tion

of

the

optional

Operator

Terminal

and Keypad.

7.

Maintain

the

operation

of

each

unit

in

the

Standard

Digital

Interface

System

to

comply

with

expected

performance

standards

as

depicted

in

the

"specifications"

for

each

unit.

8.

Understand

the

principles

of

operation

as

they

relate

to

the

overall

operation

of

the

system,

as

well

as

to

individual

circuits.

Due

to

the

diverse

range

of

applications

for

which

this

equipment

can be

used,

this

manual does

not

contain

detailed

operating

instructions

for

any

specific

application.

After

thoroughly

fami-

liarizing

oneself

with

all

contents

of

this

manual and

sequentially

performing

all

required

installation/operation

procedures,

operator

should

refer

to

appropriate

System

Operation

Manual

for

detailed

operating

instructions.

INTRODUCTION

Pa

ge 1

April

1/87

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

~R~

OPERATION/MAINTENANCE

MANUAL

7rA

STD-7000

'NC

The

information

in

this

manual

applies

to

each

unit

in

the

Standard

Digital

Interface

System

(SOlS),

which

includes

the

STD-7000 Bus

Controller

Unit,

ESP

6515

CRT

Display

Terminal,

CRT

Interface,

Numeric Keypad and

associated

interface

cabling.

The

information

is

relative

to

the

mechanical

and

electrical

characteristics

of

the

Standard

Digital

Interface

System

(SOlS).

This

manual

contains

requirements

for

evaluating

the

SOlS

during

annual

certification

or

at

any

time

performance

is

in

doubt.

Even

though

its

history

indi-

cates

a

high

reliability

rate,

the

SOlS

may

require

"in

depth"

maintenance,

such

as

prudent

testing,

troubleshooting

and

or

exten-

sive

repair.

With

this

in

mind,

the

material

and

procedures

in

this

manual

will

be

helpful

to

the

technician

during

the

main-

tenance

process

from

problem

isolation

to

final

repair.

INTRODUCTION

Pa

ge 2

Apri 1

1/87

I

I

I

I

I

I

I

I

til

I

I

I

I

I

I

I

I

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

---------------------------------------------------------

I-TABLE

OF

CONTENTS

Pa

ge 1

April

1/87

~R~

OPERATION

MANUAL

~rA

STD-7000

.-

SECTION

1 -

DESCRIPTION

1

1

1

2

2

2

2

2

1

1

1

3

3

3

4

5

5

1

1

1

1

1

2

2

3

3

3

3

3

3

4

4

1-1

1-1-

1

1-1-

1

1-1-

1

1-

1-1

1- 1- 1

1- 1- 1

1- 1- 1

1- 1- 1

1-

2

1-

2-

1

1-

2-1

1-

2-1

1-

2-1

1-

2-1

1-

2-

1

1-

2-1

1-

2-1

1-

2-1

1-

2-

2

1-

2-

2

1-

2-

2

1-

2-

2

1-

2-

2

1-

2-

2

1-

2-

2

1-

2-

2

1-

2-

2

1-

2-

2

1-

2-

2

1-

2-

2

1-

2-

2

1-

2-

2

1-

2-

2

CHAPTER

ONE

STQ~ZQQQ_~TANDARQ_QIQlI~h_llilfRf~ff_~r~If~

QfIRATIQ~MANQ~h

IABhf-Qf_£Q~IfNI~

£h~~L~~!iQ~L~~£I~£!

Installation

A. Gene"ral

(1)

Safety

Precautions

(2)

Equipment

Inspection

(3)

Power

Requirements

(4)

Installation

Equipment

(5)

Bench/Rack

Installation

B. System

Interface

(1)

System

Interface

Procedure

Description

of

Controls,

Connectors

and

Indicators

A. STD-7000

Front

Panel

(1)

Magnetic

Tape

Transport

(2)

Keypad Mount

(3)

Reset

Switch

(4)

Tape

Cassette

Eject

Button

(5)

AC

Power

Switch

B. Rear Panel

(1)

Discrete

Functions

Interface

Connector

(2)

CRT

Power

Receptacle

(3)

STD-7000 Power

Receptacle/Line

Fuse Compartment

(4)

RS-232C

Interface

Connector

(5)

IFR Bus

Interface

Connector

(6)

IEEE-488

Bus

Interface

Connector

(7)

IEEE-488

Address

Switch

2•

Tit1e

SECTION

2 -

OPERATION

1•

1.

General

2.

Functional

A. STD-7000 Bus

Controller

B.

Operator

Terminal

3.

Functional

Block Diagram

4.

Software

Implementation

A.

Magnetic

(or

"Per s onal tt

y'")

Tape

B.

PROM

Card

Memory

(Optional)

I

~

I

I

I

I

I

I

I

I

I

-

I

I

I

I

I

I

I

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

~

I

I-TABLE

OF

CONTENTS

Pa

ge 2 I

April

1/87

1.

STD-7000

Specifications

A.

Bus

Characteristics

B. Rear Panel

Interfaces

C.

Processor

System

D.

Magnetic

Tape

Transport

E.

Physical

Characteristics

F. Opti onal

Peri

pheral

s

I

I

I

I

I

I

I

I

-.

I

I

I

I

I

I

I

1

1

2

2

3

3

4

16

20

f!S~

3

3

3

4

4

5

5

5

5

5

6

6

6

6

1

1

1

1

1

1

2

2

2

2

3

7

7

11

11

11

12

13

15

1-

2-

2

1-

2-

2

1-

2-

2

1-

2-

2

1-

2-

2

1-

2-

2

1-

2-

2

1-

2-

2

1-

2-

2

1-

2-

2

1-

2-

2

1-

2-

2

1-

2-

2

1-

2-

2

1-

2-

3

1-

2-

3

1-

2-

3

1-

2-

3

1-

2-

3

1-

2-

3

1-

2-

3

1-

2-

3

1-

2-

3

1-

2-

3

1-

2-

3

1-

2-

3

1-

2-

3

1-

2-

3

1-

2-

3

1-

2-

3

1-

2-

3

1-

2-

3

1-

2-

3

1-

2-

3

1-

2-

3

1-

3

1-

3-1

1-

3-1

1-

3-1

1-

3-1

1-

3-1

1-

3-1

1-

3-1

OPERATION

MANUAL

STD-7000

.-

Ti

tl

e

C. ESP-6515

CRT

Display

Terminal

(1)

CRT

Power

Switch

(2)

CRT

Keyboard

D.

Numeric Keypad

(1)

Basic

Keypad

Operations

E.

CRT

Interface

Front

Panel

(1)

Terminal

Connector

(2)

Keypad

Connector

(3)

STD-7000

Connector

(4)

Power

Indicator

Lamp

F.

CRT

Interface

Rear Panel

(I)

Fuse

(2)

Power

Input

Connector

(3)

Power

Output

Connector

.

3.

General

Operati

ng

Procedures

A. Power-Up

Behavior

(1)

Automatic

Start-Up

Routine

(2)

Diagnostic

Test

Program

(3)

Tape Program

{4}

PROM

Program

B. IEEE-488 Address

Switch

Settings

C. IEEE-488 Address

Switch

Functions

(I)

Selection

of

Start-Up

Routines

{2}

Selection

of

Bus

Address

D.

Automatic

Start-Up

Routine

E.

Set-Up

Mode

.

{I}

Set-Up

Mode

Procedure

F.

Personality

Display

(1)

Men

uFo

rm

at

(2)

Reset

vs.

Personality

Menus

{3}

Personality

Menus

(4)

Master

Menu

{5}

Function

Control

Menu

(6)

Data

Fields

(Identification

and

Manipulation)

(7)

Data

Entry

Format

SECTION

3 -

SPECIFICATIONS

---------------

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1.

STD-7000

Shipping/Repacking

A.

Shipping

Information

B. Repacking

Procedure

I

.,

,

I

I

I

I

I

I

I

•

I

I

I

I

I

I

I

.-

Title

SECTION

4 -

SHIPPING

SECTION

5 -

STORAGE

1.

Storage

Precautions

OPERATION

MANUAL

STD-7000

£h~£!~~L~~£!i~~L~~£i~£!

1-

4

1-

4-1

1-4-1

1-

4-1

1-

5

1-

5-1

1

1

1

1

I-TABLE

OF

CONTENTS

Pa

ge 3

April

1/87

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

-----------------------~---------------.

OPERATION

MANUAL

STD-7000

THIS

PAGE

INTENTIONALLY

LEFT

BLANK.

1-TABLE

OF

CONTENTS

Page 4

April

1/87

I

-;

..

I

I

I

I

I

I

I

III

I

I

I

I

I

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

~R~

OPERATION

MANUAL

-,rA

STD-7000

INC

LIST

OF

ILLUSTRATIONS

---------------------

f!.9.~

3

5

7

4

6

1

2

3

4

5

6

2

6

7

7

7

8

8

8

8

9

13

15

16

17

18

19

2

1-

2-

3

1-

2-

3

1-

2-

3

1-

2-

3

1-

2-

3

1-

2-

3

1-

2-

3

1-

2-

3

1-

2-

3

1-

2-

3

1-

2-

3

1-

2-

3

1-

2-

3

1-

2-

3

1-

2-

3

1-

4-1

£~£!~~L~£!i£~L~g£~~£!

1- 1- 1

1- 1- 1

1- 1- 1

1-

2-

1

1-

2-

1

1-

2- 2

1-

2-

2

1-

2-

2

1-

2-

2

1-

2-

2

1-

2-

2

1-

2-

3

Ti t1e

STD-7000

Functional

Block Diagram

STD-7000

Composite

CRT

Interface

Composite

Recommended

Installation

Configuration

System

Interface

Diagram

STD-7000

Front

Panel

STD-7000 Rear

Panel

CRT

Display

Terminal

(Front

View)

16-Key Numeric Keypad (Top View)

CRT

Interface

Front

Panel

CRT

Interface

Rear Panel

STD-7000 IEEE-488 Address

Switch

Settings

Automatic

Start-Up

Routine

(Sequence

of

Operation)

.

Directory

Menu

Display

Menu

General

Menu

Comm

Menu

Printer

Menu

Keyboard

Menu

Tab

Menu

Response

Menu

Master

Menu

(Typical

Display)

Function

Control

Menu

(Typical

Display)

Function

Control

Menu

(Binary

Data

Fields)

Function

Control

Menu

(Numeric Data

Fields)

Function

Control

Menu

(Alpha Data

Fields)

Function

Control

Menu

(Alphanumeric

Data

Fields)

Repacking

Procedure

I

I

I

I

I

I

I

I

.-

I

I

I

I

I

I

I

I

I-LIST

OF

ILLUSTRATIONS

Pa

ge 1

April

1/87

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

OPERATION

MANUAL

5TD-7000

I

THI5

PAGE

INTENTIONALLY

LEFT

BLANK.

I

I

I

I

I

I

I

til

I

I

I

I

I

I

I

I-LIST

OF

ILLUSTRATIONS

Page 2 I

April

1/87

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

-------------------------------------~------~

-~~

I

!PR~

OPERATION

MANUAL

-,rA

STD-7000

'000

LIST

OF

TABLES

I

I

I

I

I

I

I

.-

I

I

I

I

I

I

I

Ti

tl

e

Rack

Mounting

Kits

Segment

Positioning

£h!£!~rL~~£!iQ~LSubj~£!

1-

2-1

1-

2-

3

f!.9.~

4

2

I

1-LIST

OF

TABLES

Pa

ge 1

Apr;

1

1/87

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

OPERATION

MANUAL

STD-7000 I

THIS

PAGE

INTENTIONALLY

LEFT

BLANK.

I

I

I

I

I

I

I

til

I

I

I

I

I

I

I

I-LIST

OF

TABLES

Page 2

April

1/87

I

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2•

£.Q!!..£liQ!!.~l

Until

programmed

for

a

specific

appl

ication

and

implemented

within

a

test

system

thru

an

appropriate

interface,

the

capabi-

lities

of

the

SOlS

are

limited

to

normal

power-up

functions

.

This

manual

therefore

describes

the

capabilities

of

the

SOlS on

a

general

level

only,

as

they

exist

within

any

ARINC

700

series

test

system.

Detailed

operation

of

the

system,

when programmed

for

specific

applications,

are

described

within

separate

System

Operation

Manuals.

I

I

I

I

I

I

I

I

.-

I

I

I

I

I

1 •

OPERATION

MANUAL

STD-7000

SECTION

1 -

DESCRIPTION

General

-----

The

Standard

Digital

Interface

System (SOlS)

is

comprised

of

the

STD-7000 Bus

Controller

and

Operator

Terminal

(CRT

Display,

CRT

Interface

and Numeric

Keypad).

These

components

make up a

standard

hardware

configuration

com-

mon

to

several

different

ARINC

compatible

avionics

test

systems.

The

primary

function

of

the

configuration

is

to

generate

and

receive

ARINC

429/453

buses

and

display

the

con-

tents

of

those

buses

on a

CRT,

thereby

permitting

an

operator

to

verify

the

integrity

of

the

system

under

test.

A

prime

design

goal

of

the

SOlS

is

to

provide

a

clear

and

simple

format

for

monitoring

and

controlling

ARINC

bus

activity

from and

to

the

unit

under

test

(UUT),

while

allowing

the

operator

to

interpret

and

manipulate

data

with

aminimum

of

effort.

A. STD-7000 Bus

Controller

The STD-7000

is

a

programmable

ARINC

bus

controller

designed

to

control

serial

bus

communication

within

ARINC

700

series

avionics

test

systems.

The

controller

contains

the

following

bus

provisions:

(1)

Six

(6)

programmable

high/low

speed

ARINC

429 I/O

buses

and

three

(3)

programmable

very

high

speed

ARINC

453 I/O

buses.

(2)

One

(1) IFR

I/O

bus used

for

interface

of

auxiliary

IFR

test

equipment.

(3)

One

(1)

IEEE

Standard

488-1978

bus

for

interface

of

an

external

ATE

Controller.

(4)

One

(1)

EIA

RS232C

bus

for

interface

of

Operator

Term

ina

1•

1-1-1

Page 1

Apr; 1

1/87

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Table of contents

Popular Controllers manuals by other brands

AutomationDirect

AutomationDirect DL05 user manual

DGFLOW

DGFLOW PRESFLO user manual

AutomationDirect

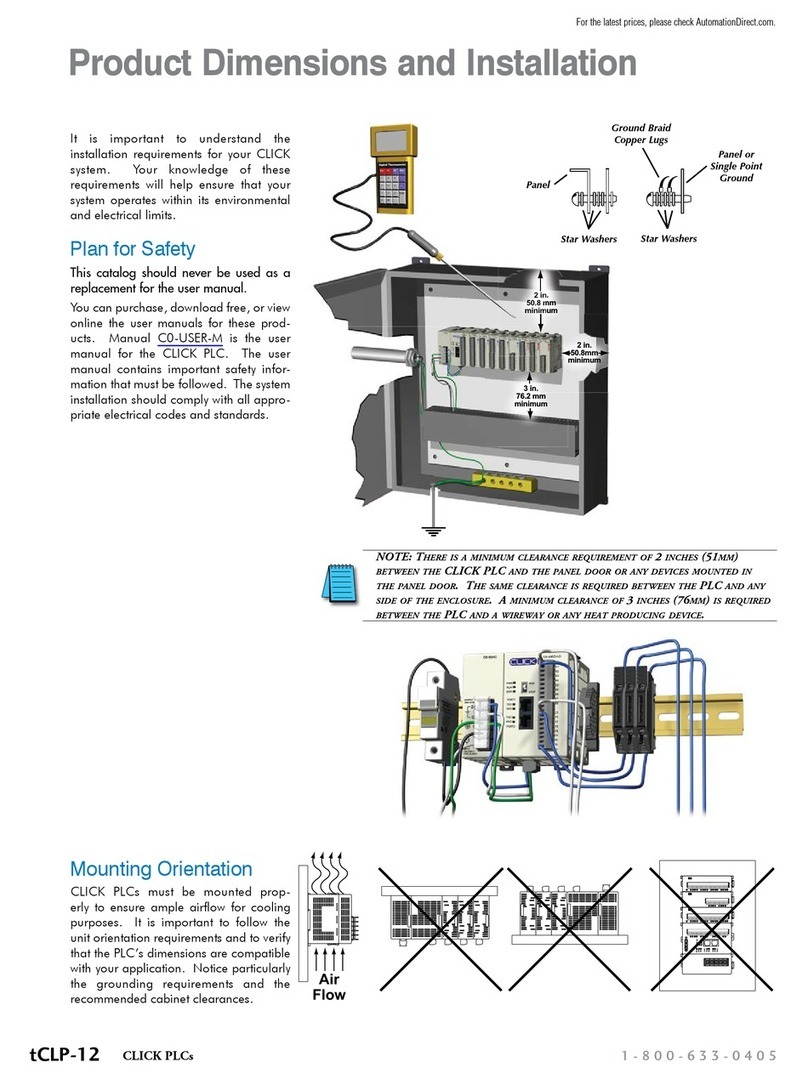

AutomationDirect CLICK Product Dimensions and Installation

Fairchild

Fairchild 1600A Installation, operation and maintenance instructions

IFM Electronic

IFM Electronic AS interforce AC1303 installation instructions

ABB

ABB ACS880-07 Hardware manual