FAIRCHILD MODEL 1600A

VACUUM REGULATOR

Installation, Operation and Maintenance Instructions

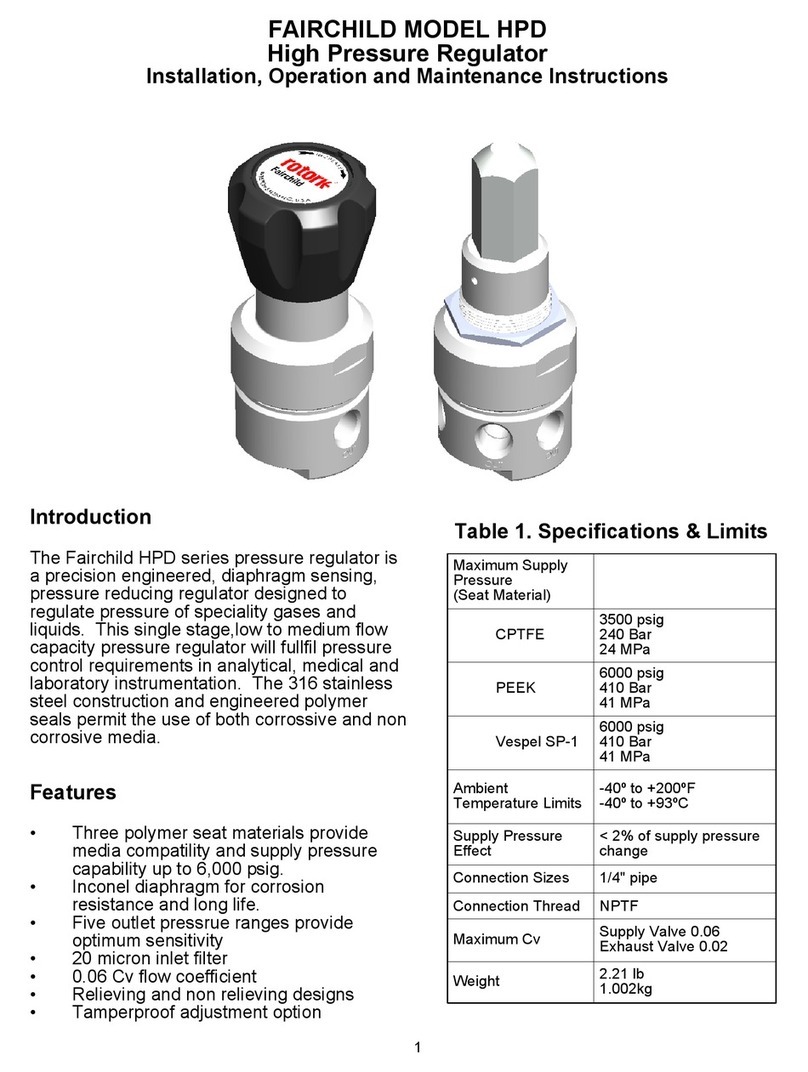

Usethetwo1/4-20tappedholesintheBonnettopanel

mounttheModel1600A. Youcanmounttheregulator

inanypositionwithoutaffectingitsoperation.

Clean all pipelines to remove dirt and scale before

installation.

Apply a minimum amount of pipe compound to the

male threads of the fitting only. Do Not use teflon

tapeasasealant. Startwiththethirdthreadbackand

workawayfromtheendofthefittingtoavoidcontami-

natingtheregulator. Installtheregulatorintheairline.

The Inlet and Outlet ports are labeled “In” and “Out”.

Tighten all connections securely. Avoid undersized

fittingsthatwilllimittheflowthroughtheregulator. For

more information, see Figure 1.

NOTES:

TheModel1600Acontrolspressureinhighflow

systems above and below atmospheric pres-

sure. Toincreasevacuumordecreasetheposi-

tive pressure range, turn the Regulator Knob

counterclockwise. To decrease vacuum or in-

creasethepositivepressurerange,turntheknob

clockwise. Formoreinformation,seeFigure1.

Applications can require a connection for fast

evacuation of a Chamber. For more information,

see Figure 2.

Applications can also require a connection to

control system pressure above and below atmo-

spheric pressure. In vacuum systems, you can

leave the Supply Port open to atmosphere or

pressurize with normal supply air for faster re-

sponse. For more information, see Figure 3.

Oilfreeairmustbeappliedtotheregu-

lator. Use a filter to remove dirt and

entrained liquid in the air line ahead of

the regulator. If an air line lubricator is

used, it MUST be located downstream

of the regulator to avoid interference

withperformance.

OPERATION

INSTALLATION

Figure 1. Model 1600A Outline Dimensions

Figure 2. ChamberEvacuation belowAtmosphere

Figure 3. Chamber Purge with Positive Pressure