SMC Networks LEJS Series User manual

Other SMC Networks Controllers manuals

SMC Networks

SMC Networks LECP2 Series User manual

SMC Networks

SMC Networks LEF Series User manual

SMC Networks

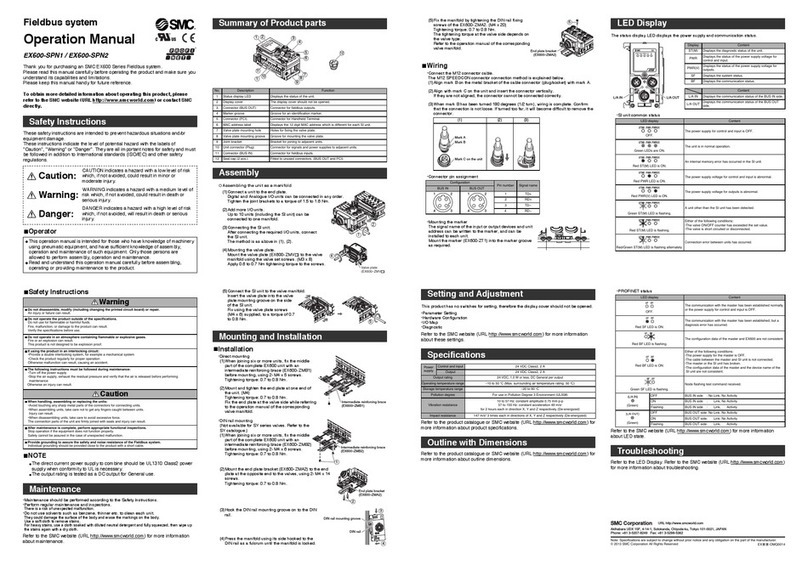

SMC Networks EX600-SPN1 Installation manual

SMC Networks

SMC Networks LEF Series User manual

SMC Networks

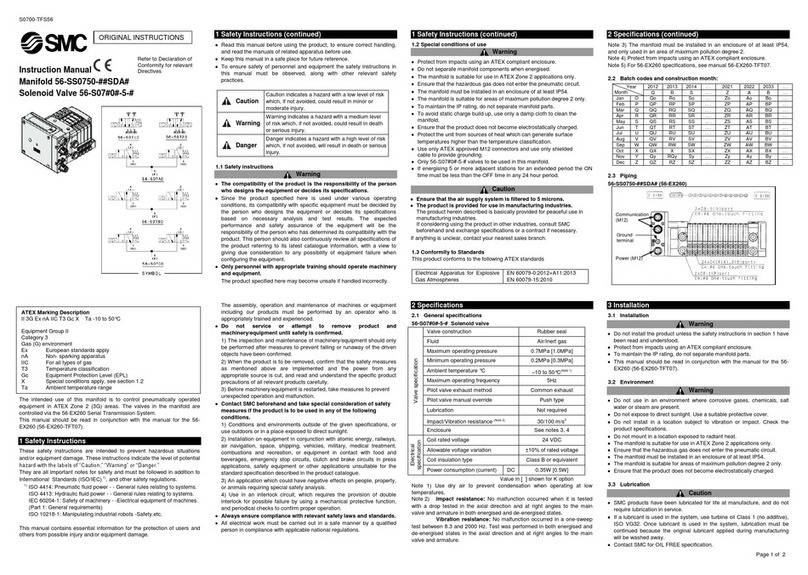

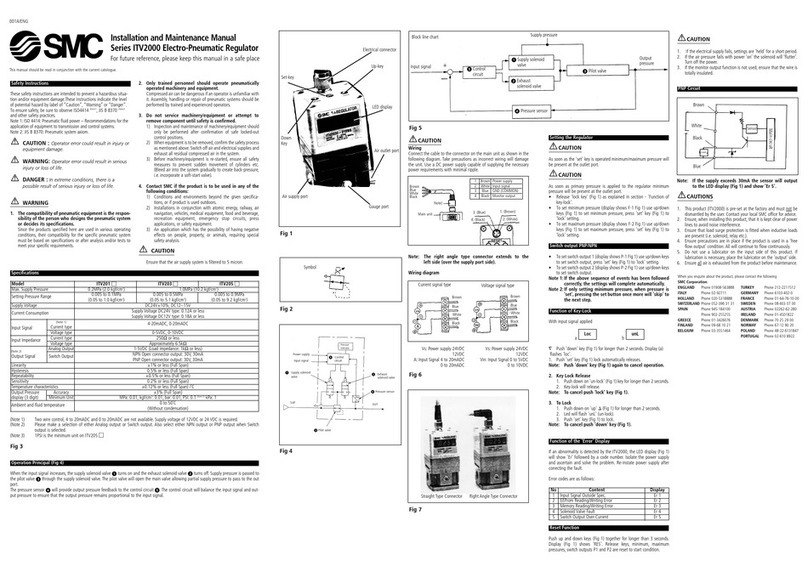

SMC Networks ITV2000 series Manual

SMC Networks

SMC Networks 4011 Series User manual

SMC Networks

SMC Networks ITVX Series User manual

SMC Networks

SMC Networks VXFC-06D User manual

SMC Networks

SMC Networks ITV2000 series Operating instructions

SMC Networks

SMC Networks LEC-W2 User manual

SMC Networks

SMC Networks IR2000-A Series User manual

SMC Networks

SMC Networks ASBL Series User manual

SMC Networks

SMC Networks THERMO-CON HEC001 Series Use and care manual

SMC Networks

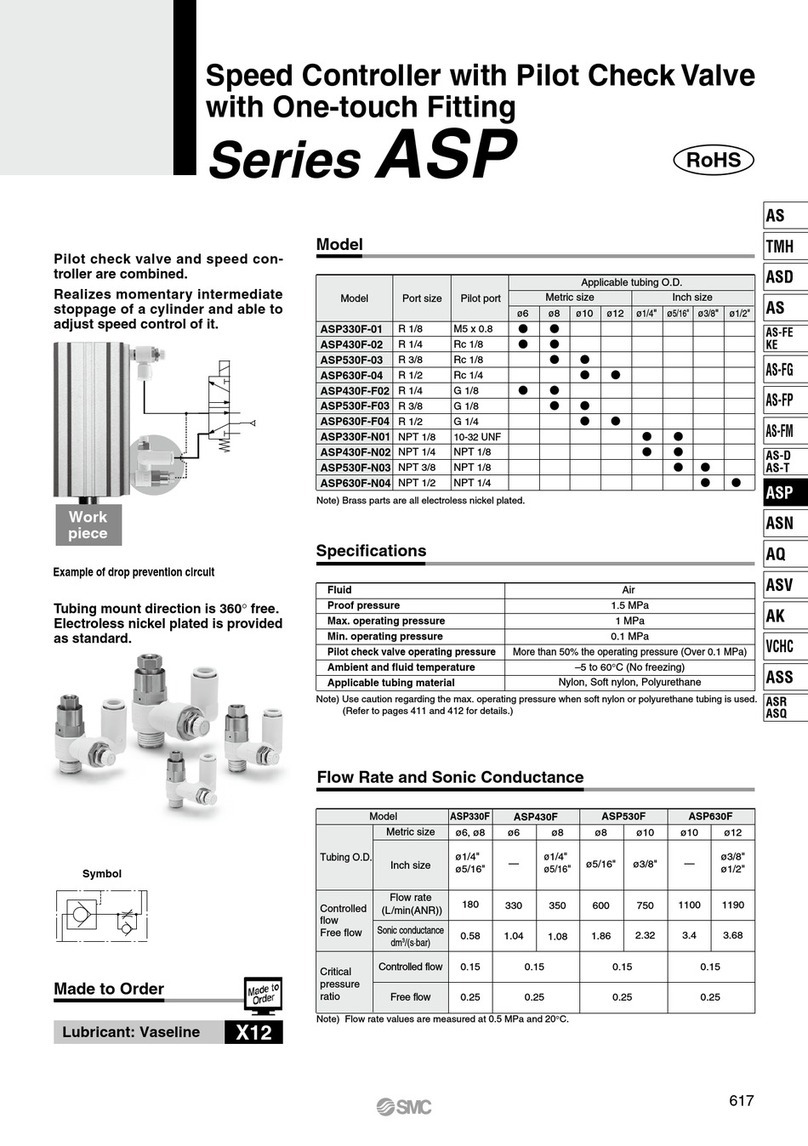

SMC Networks ASP Series User manual

SMC Networks

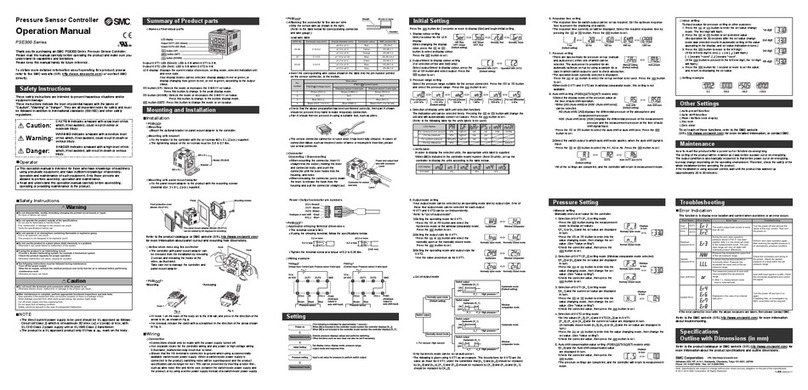

SMC Networks PSE300 Series User manual

SMC Networks

SMC Networks PSE300 Series User manual

SMC Networks

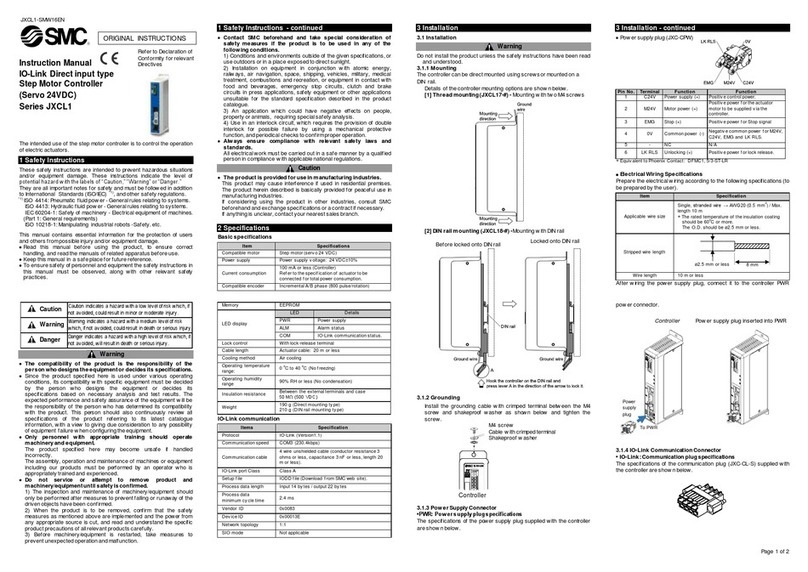

SMC Networks JXCL1 Series User manual

SMC Networks

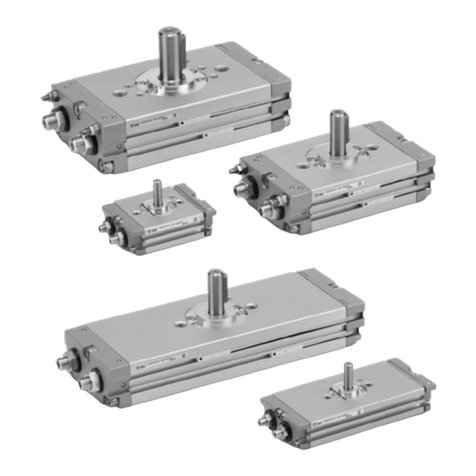

SMC Networks CRQ2 Series User manual

SMC Networks

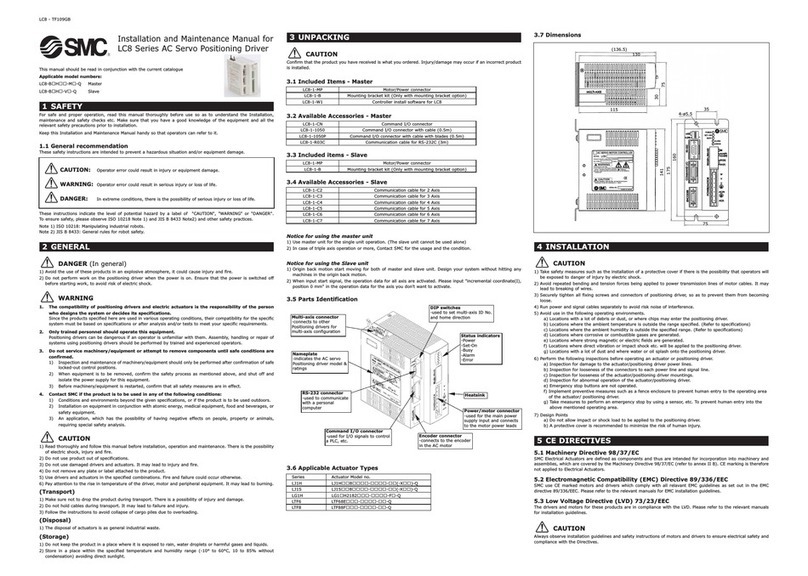

SMC Networks LC8-B*H*-M*-Q Series Manual

SMC Networks

SMC Networks JXCP1 User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions