IGD 2-Wire Systems Assembly instructions

2-WIRE SYSTEMS

2 - W i r e G a s D e t e c t i o n S y s t e m I n s t a l l e r s G u i d e V 4 . 5 1

Triton House

Crosby Street

Stockport

SK2 6SH

England

Tel: +44 (0)161 483 1415

Fax: +44 (0) 161 484 2345

Email: [email protected]

Website: www.internationalgasdetectors.com

Addressable

2-Wire

FS646773

REF: T550-INST V4.51

EMS696504

1

2-WIRE

GAS DETECTION

www.internationalgasdetectors.com

Display

&

Volt Free

Relay

Analogue in

Analogue in

Sounder

Output

Digital Out

Digital Out

or

or

Gas

Gas

Detector

Detector

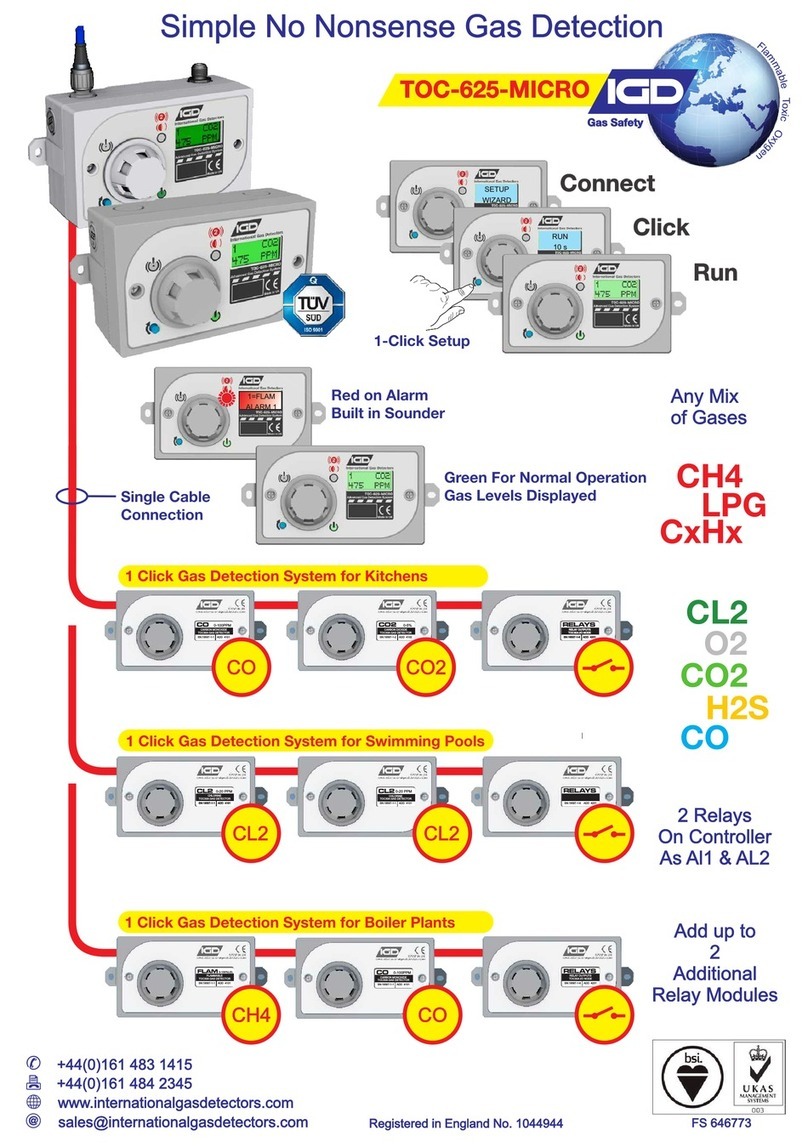

Each Detector Node Has Multiple I/O

ALL

OK

First Fit Cabling

Fit Detector Nodes

Fit Additional Devices

Where You Need Them

Safety Assured

CO H2S LPG

4-20

Addressable

2-Wire

HUB

APP Based Setup and Service Tools

No Specific Cable Type

No Cable Polarity

2 Core Cable Connects Detector Nodes

350 Detector Nodes/Devices Possible

Communicate over 3000M Possible

Cascade Hubs or Control Panels

Modbus and Bacnet Compatible

BlueTooth

Ethernet

USB

Battery Backup

FS646773

2

Interaction Between the Gas Detection System and Other Systems

Clear Indication to workers That a Gas Hazard Exists and the Action They Must Take

All Gas Detectors shipped from IGD are pre-calibrated. It is not always necessary to re-calibrate a

newly installed system on site but it is recommended that commissioning is undertaken.

Commissioning should be undertaken by persons trained to do so. Commissioning should ensure that

the system performs and interfaces correctly to all connected devices, host systems and operates to

the required cause and effect.

Failure to follow this installers guide could compromise operation of the 2-Wire gas detection system

so please follow the enclosed information carefully.

A competent person is someone who has sufficient training and experience or knowledge and other

qualities that allow them to assist you properly. The level of competence required will depend on the

complexity of the situation and the particular help you need.

IGD’s gas detection systems are capable of installation by electrical installation engineers. Design of

a system is not covered in this guide and should be undertaken by a competent person. The design

should include:

IGD can provide help to design systems where help is required and can also provide training for

surveyors, specifiers, designers and installers.

This installers guide is intended for the use of system specifiers, surveyors, designers and installers.

The intention of this guide is to provide information for the correct installation of IGD’s range of 2-Wire

gas detection systems. This guide indicates correct cabling practice, types of cabling which can be

used and options available to correctly design and install a 2-wire gas detection system. This guide is

not intended as a design or specification guide, these are available separately.

Note that System control panels, detector nodes, battery backup modules and power boosters are all

supplied with their own manuals. Their general specifications and performances are available both in

their individual manuals and published data sheets. This data is not reproduced in this guide.

The Nature of the Gas Hazard and Appropriate Placement of Detectors

The Necessary Safe Operating Procedures That Must be in Place

IGD are available to answer question using our on-line ticketing system available through our website.

NOTE that ATEX equipment has specific requirements for cable protection and glanding to housings.

These requirements are detailed in manuals for such equipment available through our website.

Systems should be designed and installed by competent persons. A competent person being defined

by the UK Health and Safety Executive as:

Introduction

3

SECTION 1

MOUNTING DETAILS FOR EQUIPMENT

4

Tocsin 750 Physical

Installation Cables

FRONT VIEW

382mm

292mm

72mm

120.5mm

134mm

20mm

48.5mm

Front Face

Top Face

Side Face

56.5mm

30mm

10 off 20mm

Cable Entries

360mm

Supported Installation Cables 2 Core 1.5mmSQ or 2.5mmSQ See IGD Cable System Calculator

Typically SWA, MICC, FP200, SY, CY, H03VVH2-F Mains Cable Screened, screened or Similar

Note 150W and 24V DC Versions Can be

Flush mounted into walls up to the front face flange

300W Versions have active ventilation and must be

surface mounted allowing 100mm clearance all round

Note that the rear case can be rotated to allow

20mm entries to face either up or down

Addressable

2-Wire

5

TOCSIN 650 PHYSICAL

Installation Cables

FRONT VIEW

382mm

292mm

72mm

120.5mm

134mm

20mm

48.5mm

Front Face

Top Face

Side Face

56.5mm

30mm

10 off 20mm

Cable Entries

360mm

Supported Installation Cables 2 Core 1.5mmSQ or 2.5mmSQ See IGD Cable System Calculator

Typically SWA, MICC, FP200, SY, CY, H03VVH2-F Mains Cable Screened, screened or Similar

Addressable

2-Wire

Note 150W and 24V DC Versions Can be

Flush mounted into walls up to the front face flange

300W Versions have active ventilation and must be

surface mounted allowing 100mm clearance all round

Note that the rear case can be rotated to allow

20mm entries to face either up or down

6

Mounting Details and Dimensions Safe Area Versions

Gas Detector Types

Mounting Details and Dimensions ATEX Versions

172

158

76

48

43

86

98 18

5

20mm Entries Top, Bottom & Either Side

Note TOC-750-AN3 Shown

Detectors, Annunciators and

Nodes Share Common

Mounting Details

145.0

126.0 128.5

COVER SECURING SCREW

M20 x 1.5

40.0

25.0

Ø7.0

EXTERNAL EARTH

MKIII FLAMMABLE

GAS DETECTOR

SHOWN

40.0

Ø110

128.0

The ATEX version uses IGD’s JB3 series ATEX EXD terminal enclosure. Please note that cable glanding

and sealing must conform to ATEX requirements which is more fully described in the ATEX JB3 manual

Relative response to Methane @ 4.4% Vol = 100% LEL Equivalent to 55% LEL N-Butane

Refer to individual data sheets for specific data relevant to available gas detectors, types,

accuracies and sensitivities available.

For pellistor type gas detectors complying to BS EN 60079-29-0 and 1, these general purpose

flammable gas detectors are suitable for Methane and LPG detection in the range 0-100% LEL.

7

FRONT VIEW

382mm

292mm

72mm

120.5mm

134mm

20mm

48.5mm

Front Face

Bottom Face

Side Face

56.5mm

30mm

10 off 20mm

Cable Entries

360mm

Battery Backup Modules

TOC-750-BAT1 7AH Battery Backup with 150W PSU

TOC-750-BAT2 17AH Battery Backup with 300W PSU

460mm

292mm

115mm

20mm

Front Face

Bottom Face

Side Face

25mm

60mm

95mm

4 off 20mm

Cable Entries

8

SECTION 2

SITING GAS DETECTORS

9

Gas detectors usually fall into two groups for placement

Each site should be surveyed and assessed on its own merits. This document presents general

guidance only.

1. Plant Protection. Typically flammable gas detectors fall into this category. Aside from asphyxiation

flammable gases are typically not directly toxic and so detectors are placed strategically where the gas is

expected to accumulate based on its relative density to air (lighter or heavier)

Note that in many cases both life safety and plant protection sensors may be appropriate on a site. For

example a plant using liquid helium may have plant protection sensors at high level to ventilate roof

spaces in the event of leaks. However in the event of ventilation failure Helium could accumulate down

towards the zone where personnel operate. In this case a second set of life safety sensors would be

appropriate.

2. Life Safety Systems. Here the concern is that a toxic or asphyxiant gas is directly hazardous to

personnel and so the gas detection is placed based on the normal operating zone for the people present

Lighter than air gases, detectors placed at highest ceiling points

Consider fitting collector cones at lower level for gas bottle stores

boiler plant and gas meters (see separate application note).

400mm

1000mm

1800mm

Life Safety Zone

Consider ceiling divisions, follow rules for smoke detectors

Methane, Helium, Hydrogen, Ammonia etc

LPG, CO2

CO, CO2, O2

H2S, NO2, NO

HCN, HCL, HF

NH3 etc

Consider fitting splash/dust guards to protect low level sensors

Consider sensors in under floor areas/voids/drains where heavier than air gases are present

LPG 0-100%LEL

SN:20235-1-1 ADD:4110

GAS DETECTOR

LPG 0-100%LEL

SN:20235-1-1 ADD:4110

GAS DETECTOR

Siting Gas Detectors

10

High Concentrations Local to Release Source or Cloud Development Scenario

5M

100%

CO2

For this CO2 Example

Expect Higher

Concentrations at Low

Levels. Use for

Ventilation Trigger and

Pre-Alarms

For this CO2 Example

use Detectors in

the Life Safety Zone

to Trigger Ventilation

and Evacuation Alarms

5M is a Maximum Detection Distance and

Will be Effected by Topography.

Gas Levels Will Drop as Distance to Leak

Source Increases Requiring Lower Alarm

Set Points

Siting Gas Detectors

Heavier Than

Air Gases Can

Show a Gradient

in Room Levels

With Higher

Concentrations at

Floor Level or

Slow Leak Scenario

This Example Illustrating

A CO2 Gas Release From

A Storage Cylinder. Typical

Scenario, Broken or Blown

off Hose, Regulator Incorrectly

Connected, Ruptured Gauge

or Similar.

11

Area Coverage for Gas Detectors

Cryogenic Gas Detection

Calibration and service Requirements for Gas Detection Systems

Typically up to 75 SQ M Coverage

In a similar manner to smoke detectors, a gas detector can provide up to 75SQ M area coverage based on

a 5M radius of operation. There are many factors affecting this, geometry of a room, equipment in the area,

gas characteristics, ventilation air flows etc. IGD can support throughout the survey, design and installation

process to ensure the best possible result on site.

Applications involving Cryogenically cooled gases such as liquid Nitrogen or Helium need careful

consideration for gas detection. On initial release as cryogenically cooled gases can typically be at lower

temperature and high density than their surroundings they will behave differently than when in their

gaseous state. In such cases it should be considered if two sets of detection is required, one for the life

safety zone and one for low level detection in the gases cooled state. Applications involving such gases

are recommended to be surveyed.

All gas detection systems require regular checking and calibration to be in compliance with the UK

factories act. The service and calibration period will be a function of the application based on

environmental in service conditions. It is extremely important to ensure a service plan is in place for any

gas detection system installed as part of a site safety system. IGD can work with operators to provide

advice, service and spares to ensure an appropriate level of cover.

Max 5M Radius

12

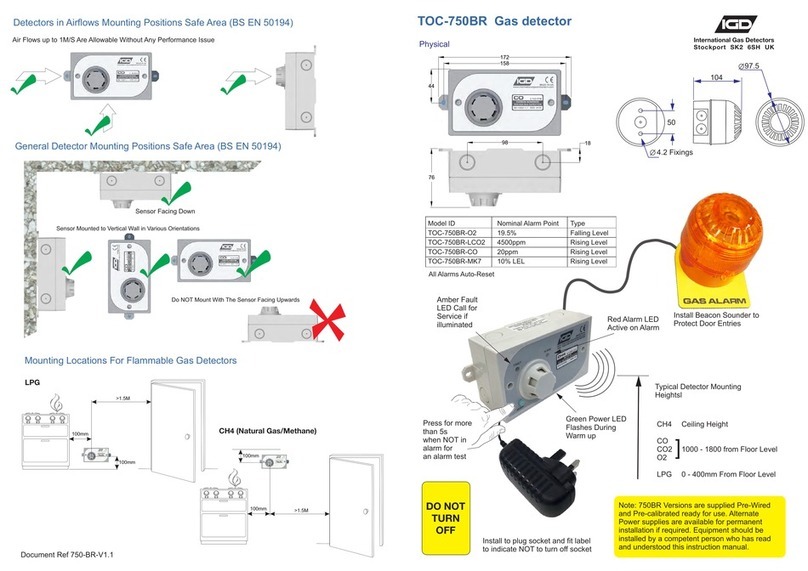

General Detector Mounting Positions Atex (BS EN 60079-29-1)

General Detector Mounting Positions Safe Area (BS EN 50194)

Detectors should be

mounted vertically with the

sensor face facing

downwards to protect from

contamination.

Sensor Facing Down

Sensor Mounted to Vertical Wall in Various Orientations

Do NOT Mount With The Sensor Facing Upwards

13

Detectors in Airflows Mounting Positions Atex (BS EN 60079-29-1)

Do NOT mount Detectors Where

Airflows Are Likely to be Directed

either onto or Away From the Sensor

Face. This Situation May Result in

Contamination and/or reduced

Detection Capability

Air Flows up to 6M/S Are

Allowable Without Any

Performance Issue Across

the front of The Sensor Face

Air Flows up to 1M/S Are Allowable Without Any Performance Issue

Detectors in Airflows Mounting Positions Safe Area (BS EN 50194)

14

Siting System Components

Consider the use of mimic panels, HMI panels or GSM options available

from IGD to provide additional remote indication/alarm

Control Panels:

These should be located outside of the area protected by its connected

gas detectors.

The control panel should be accessible such that in the event of an

alarm the area can be evacuated and gas levels viewed from the

controller.

As a general rule if there is gas detection fitted to an area then there

should be an audio-visual alarm (beacon sounder) to alert personnel

who may be in the same area. Typically these will be standard beacon

sounders where the sounder can be silenced from the control panel

once an alarm is accepted. Standard LED beacon sounder modules are

available from IGD and can be run from addressable I/O points to

minimise cabling. Another option is to fit IGD’s range of annunciators.

Audio-Visual alarms

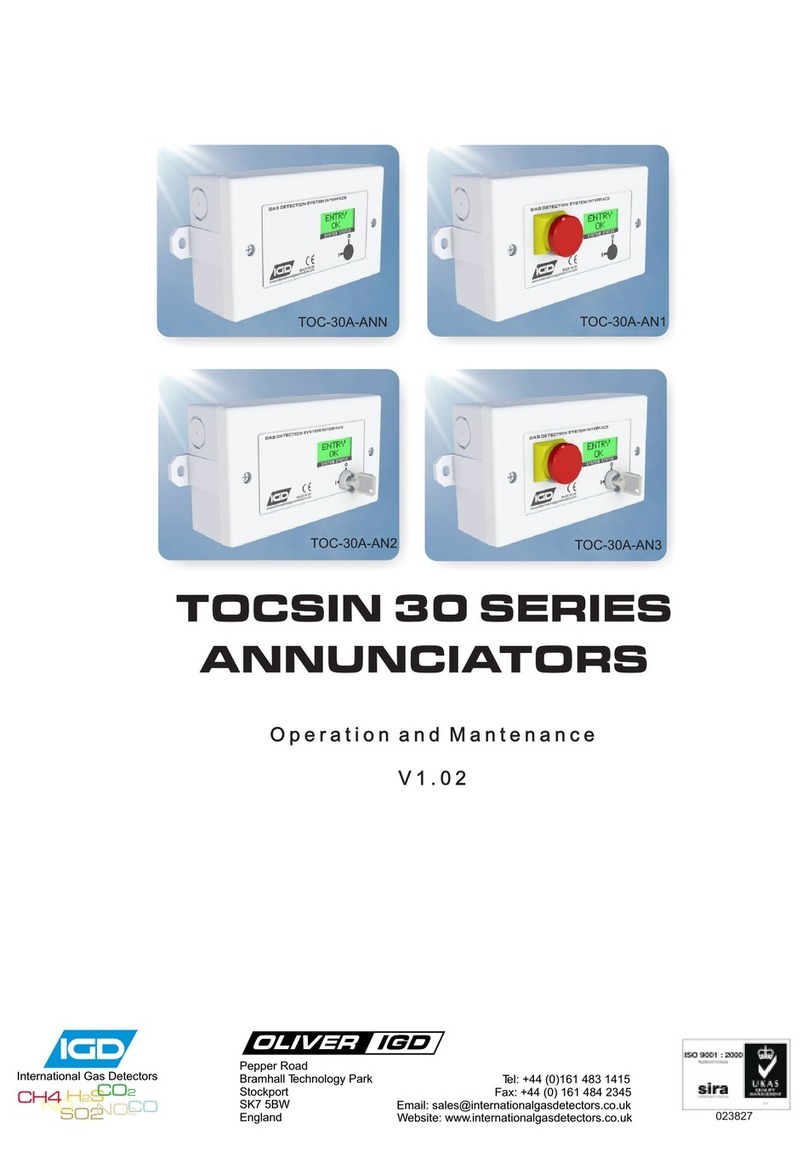

Annunciators are addressable devices typically fitted at door entry

points. They provide a clear audible visual alarm in the event of a gas

alarm to warn persons from entering an area where a gas hazard could

be present.

They offer many advantages over standard beacon sounders. They can

be fitted to standard dado trunking systems; cannot be confused with

other alarms; the displayed alarm message and flashing colour display is

unambiguous; they can be fitted with slam switches.

Annunciators

Gas Collector Cones and splash Guards

For detectors fitted at low level, fitting splash guards may be appropriate

to protect sensors from dust, rain splash, floor washing etc.

Where detectors are located above gas plant such as boilers or meters in

rooms with high ceilings then consider the use of gas collector cones.

These are fitted to detectors sited just above gas plant to enhance the

detectors capability to detect gas leaks (see separate application note)

15

SECTION 3

GENERAL CABLING PRINCIPLES

CABLE TYPES

AND

CABLE SIZING

16

Cable Type Guidance

L1 L1

L2

L2

Cable Screens direct to

commoning blocks provided

CY Style Cable

Recommended Cable Preparation

FP Style Cable (Preferred Option)

SWA Style Cable

CY Type cable has a braided screen which should be trimmed

back to ensure no trimmed conductor ends up on sensitive

PCB components, tracks or terminals where it may short. The

screens of the incoming cables should be terminated to the

floating terminal block provided to ensure screen continuity.

Trim back any unused conductors and ensure the braid is

insulated with heat shrink or insulation tape and/or sleeve.

Unused

L1

L2

Unused

L1

L2

Drain Wire Screen

FP style cable is fitted with a foil screen and drain wire. Generally this is easier to terminate than

CY type cable. Trim back any unused cores and foil screen. Ensure the drain wire is insulated

with suitable size sleeving and terminates to the cable screen terminal

SWA style cables are usually only recommended for used with ATEX EXD housings where the

universal cable glands ground the cable armour to the housing. This provides both an effective

EMC screen and mechanical protection. Ensure unused conductors are trimmed back and

isolated. If terminating to plastic enclosures fit ‘pan handles’ and terminate on the outside of the

enclosure to ensure screen continuity

IGD’s 2-Wire gas detection systems operate using screened cabling of appropriate cross sectional

area. There are no specific requirements and our typical advised cable types are indicated below.

Cable screens, either foil and drain wire, braid or armouring must be continuous between devices and

grounded for effective operation. Ancillary devices such as stop buttons, beacons, sounders etc should

commoned to the earth blocks provided as indicated below.

Strip Conductors 7mm Ensure No Stray

Strands

17

Main Base PCB Connectors

When unplugging detectors from the main PCB DO NOT lever them off. This will potentially cause

damage to the PCB and/or connector mating parts and invalidate any warranty. If it is necessary

to remove the PCB connectors use long nose pliers.

Note that connectors can be plugged either

vertically or Horizontally to the PCB

18

System Example

LPG 0-100%LEL

SN:20235-1-1 ADD:4110

GAS DETECTOR

LPG 0-100%LEL

SN:20235-1-1 ADD:4110

GAS DETECTOR

Typically 1.5mmSQ

24V L1,L2

Unscreened Cable

2 Core Highway as:

Controller in Supervisors Office

ATEX Zoned Area

Mix Annunciators With Other

Addressable Devices Such as

TOC-750 Series Detectors.

Use ATEX Rated detectors

where required

Use Annunciators For Door

Entry Control.

Use Annunciators with Gas

Detector Interfaces to Detect

& Alarm in Specific Areas

Use the Detector or

Annunciator I/O

Capability to Control

Gas Supply Valves,

Beacon-Sounders or

other devices

Laboratory

Gas Bottle Store

Addressable

2-Wire

Where Required For Longer Cable Runs

or Where Device and Accessory Density

is High add Power Boosters or Cascade

Hubs to Increase Distance Capability to

up to 3KM

Cabling: When using stranded cable fit bootlace ferrules to

prevent stray wire strands shorting.

Cable glands must be used for cable entries.

19

B

A

0V DC

B

A

0V DC

Screen

B

A

0V DC

RS485 Modbus

Comms Port

RS485 Modbus

Comms Port

RS485 Modbus

Comms Port

Interfacing to the Remote Modbus Port

Cable Sizing

Tocsin 650/750 Controller (slave) Tocsin 650/750 Controller (slave)

Master DCS/BMS

Note only the A,B and 0V DC Connections are

Used. 0V DC between master and slave should

be connected for correct operation and to prevent

damage to both master and slave systems

The Tocsin 750 series controllers have an in-built memory map allowing access to alarm status, panel

status, readings etc using Modbus RTU protocol. Wiring between units is as follows:

Refer to users guide for Modbus channel mapping

More than one controller can be interfaced on the same Modbus cable by

assigning individual Modbus addresses to each controller.

2

Up to 400m use minimum 1.0mm cable with an overall cable screen.

2

Cable runs over 400m use 1.5mm cable with an overall screen

Modbus

Address

100

Modbus

Address

99

Fit terminating

resistor at last

device across

A-B 120 Ohms

Table of contents

Other IGD Gas Detector manuals

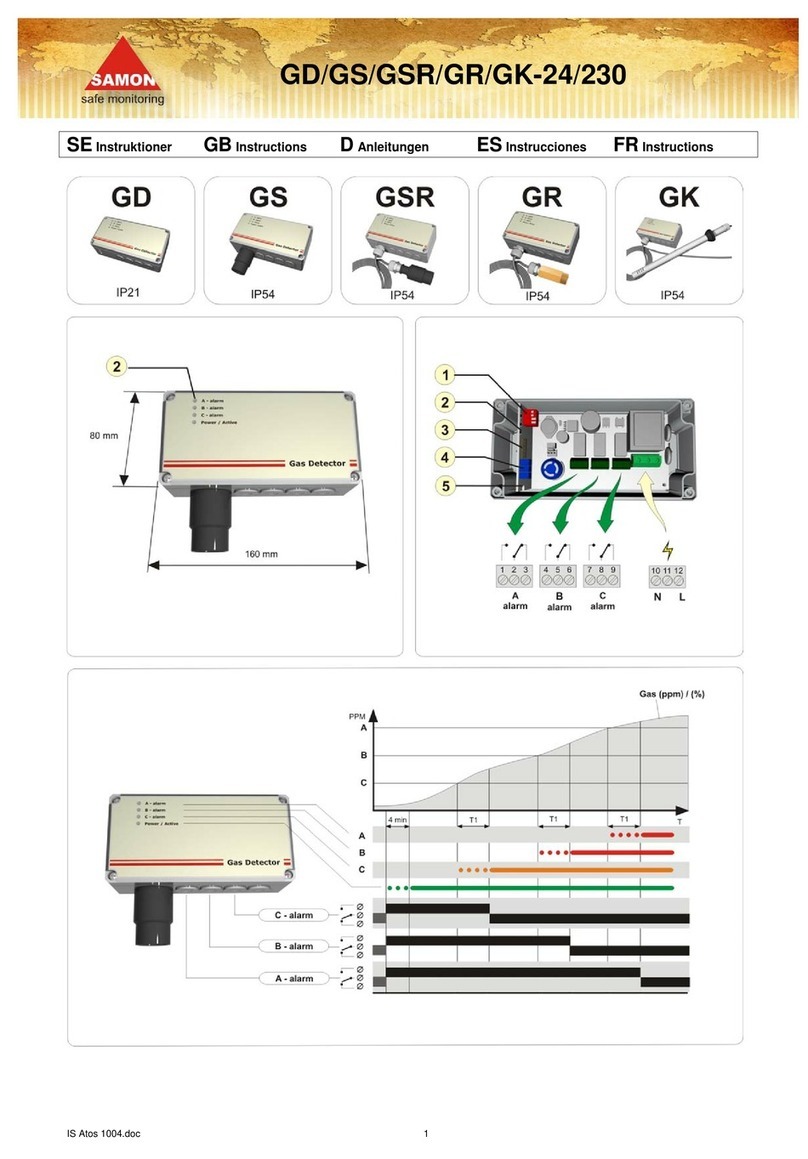

Popular Gas Detector manuals by other brands

S&S Northern

S&S Northern Merlin 1500ppm user guide

Riken Keiki

Riken Keiki 590-04W Operating instructions manual

DEGA

DEGA NB*-*IL III Series instruction manual

Siemens

Siemens Sinteso Cerberus PRO FDA241 datasheet

RKI Instruments

RKI Instruments 61-1020 Operator's manual

Levenhuk

Levenhuk ERMENRICH NG40 user manual