Alarm Change Over relay (volt free)

Relay is normally ON, De-energising

on alarm condition.

NC

COM

NO

Power Supply:

Environmental:

Response Time:

Nominal Alarm Levels:

Expected Life:

Target Gas:

Standards Applied:

Cabling:

Service:

12 to 28V DC 4W

0 to +55 Degrees Centigrade

0-95%RH Non-condensing

Terminal Enclosure IP54 Cable Glands Must be used

<30 Seconds

See preset alarm levels Relay Active SPCO 5A @ 230V AC Non inductive

5 Years, no user replaceable parts

See cover markings as CO, CO2, O2, LPG, CH4

This equipment must only be serviced by competent persons and checked

periodically using traceable calibration gases. Do not test using lighter fuel or

similar fuel gases as this can give misleading results. In extreme cases this can

result in sensor damage.

EN50194-1:2009 Type A Equipment

When using stranded cable fit bootlace ferrules to

Prevent stray wire strands shorting

EN60335-1:2002 EN50270

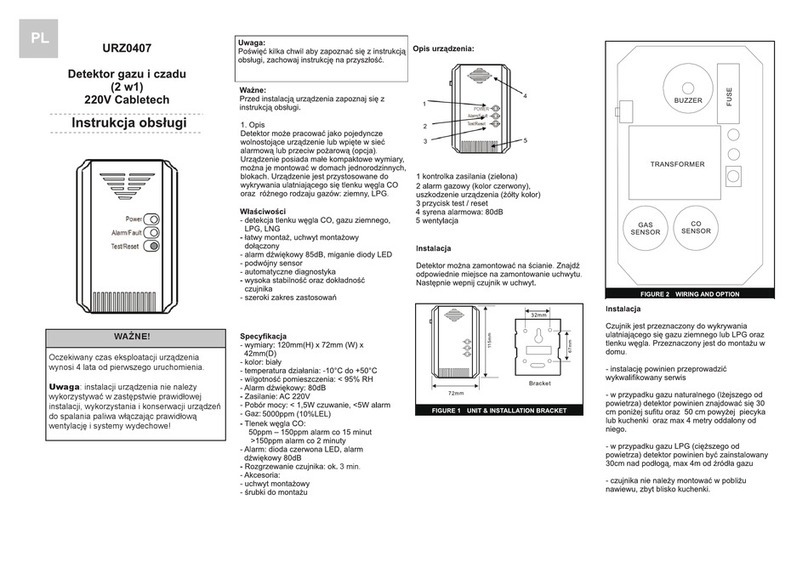

Internal Terminal Functions

24V DC

0V DC

Installation of this device when connecting to a mains power supply should only be made by a competent

person. The unit is supplied pre-calibrated. Clean only using a damp cloth, DO NOT USE CLEANING

PRODUCTS.

Do not tamper with this equipment. To do so may cause incorrect operation or risk electric shock.

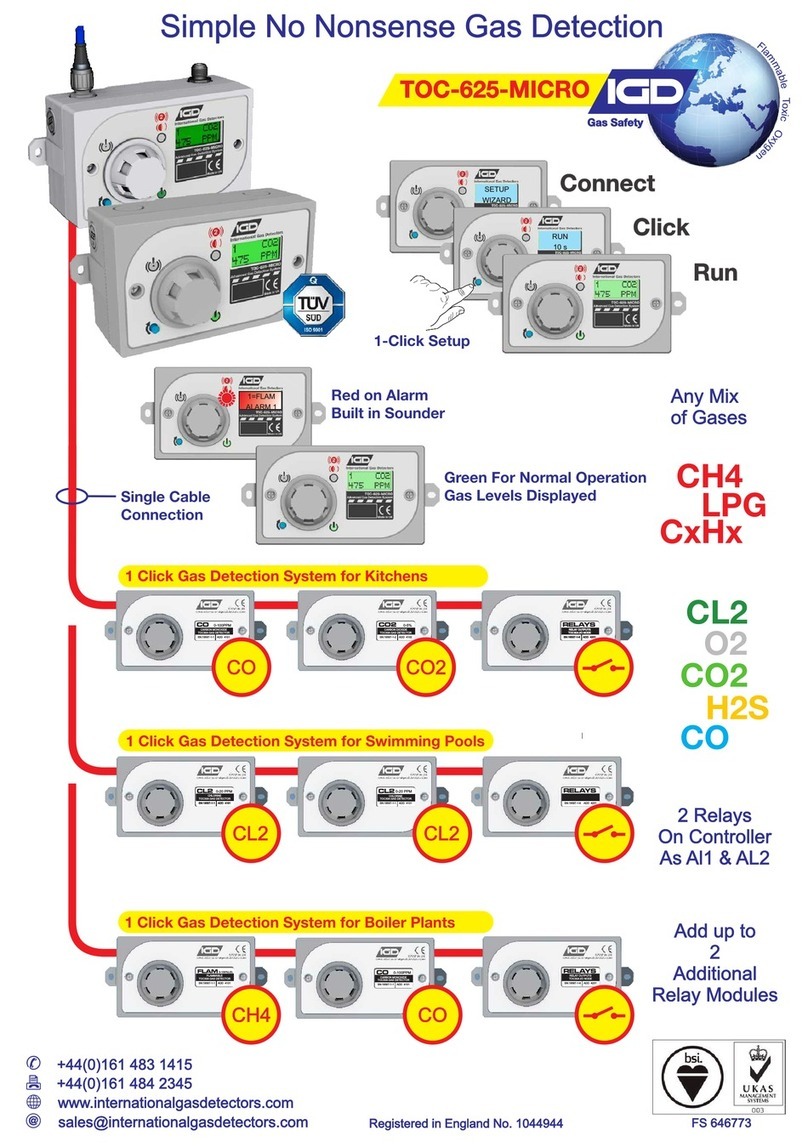

Connection for flammable gas detector

Connection for

O2/Toxic/IR gas detector

Connection Point for LED Module

Digital Output

(Sounder)

Digital Input

(Push Button)

Supply

Out

Supply

IN

NOTE: The unit is shipped configured and Pre-Calibrated for its detector and options and alarm levels

Internal Relay Active on alarm

Note relay is normally energised and

turns OFF on alarm.

Relay is mains rated to 5A and can be

used to control other 3rd party devices

(Flammable Gas Detectors)

Main Base PCB Connectors

When unplugging detectors from the main PCB DO NOT lever them off. This will potentially cause damage to the

PCB and/or connector mating parts and invalidate any warranty. If it is necessary to remove the PCB connectors use

long nose pliers.

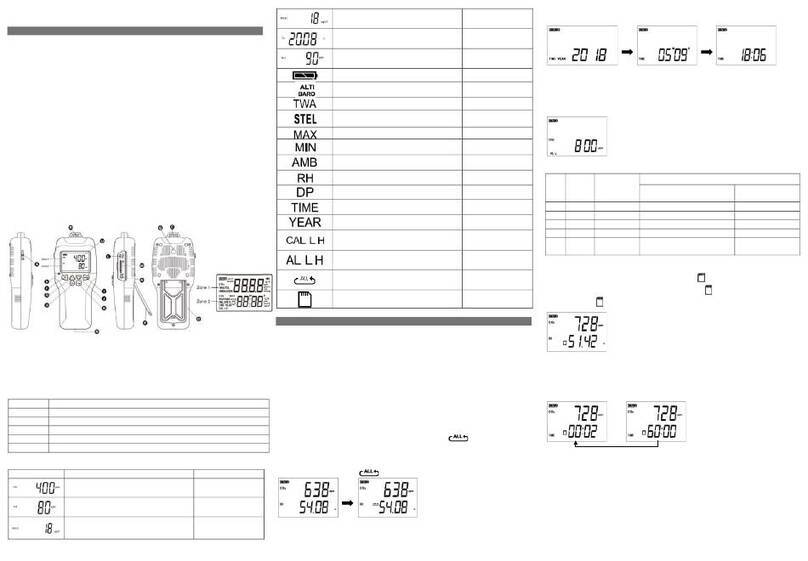

+55 C

-10 C

Locating the Detector

The TOC-750 Flammable gas detector is factory calibrated for its target gas. The target gas is indicated on the

product (i.e CH4, LPG etc). The TOC-750 will respond to any flammable gas but can only be calibrated to be

correct response to one. The following list indicates common materials that may also cause a response in

operation:

Aerosol propellants (Butane)

Paint solvents (VOC’s)

Hot vaporised cooking oils

Solvent based adhesives (VOC’s)

Some commonly occurring substances may cause long term detector damage, typically:

Silicones (furniture polishes etc)

Hair sprays (silicones, VOC’s etc)

Chlorinated cleaning agents