Medem AGDS-MC User manual

The Home of

Control & Automation

in Ireland

AGDS MC

Multi Channel

Gas Detection

System

Medem (UK) Limited

L&M Business Park , Norman Road

Altrincham, Cheshire,

WA14 4ES

Tel: +44 (0) 161 233 0600

Fax:+44 (0) 161 233 0601

Website: www.medem.co.uk

e-mail:[email protected]

Cert No. 10213

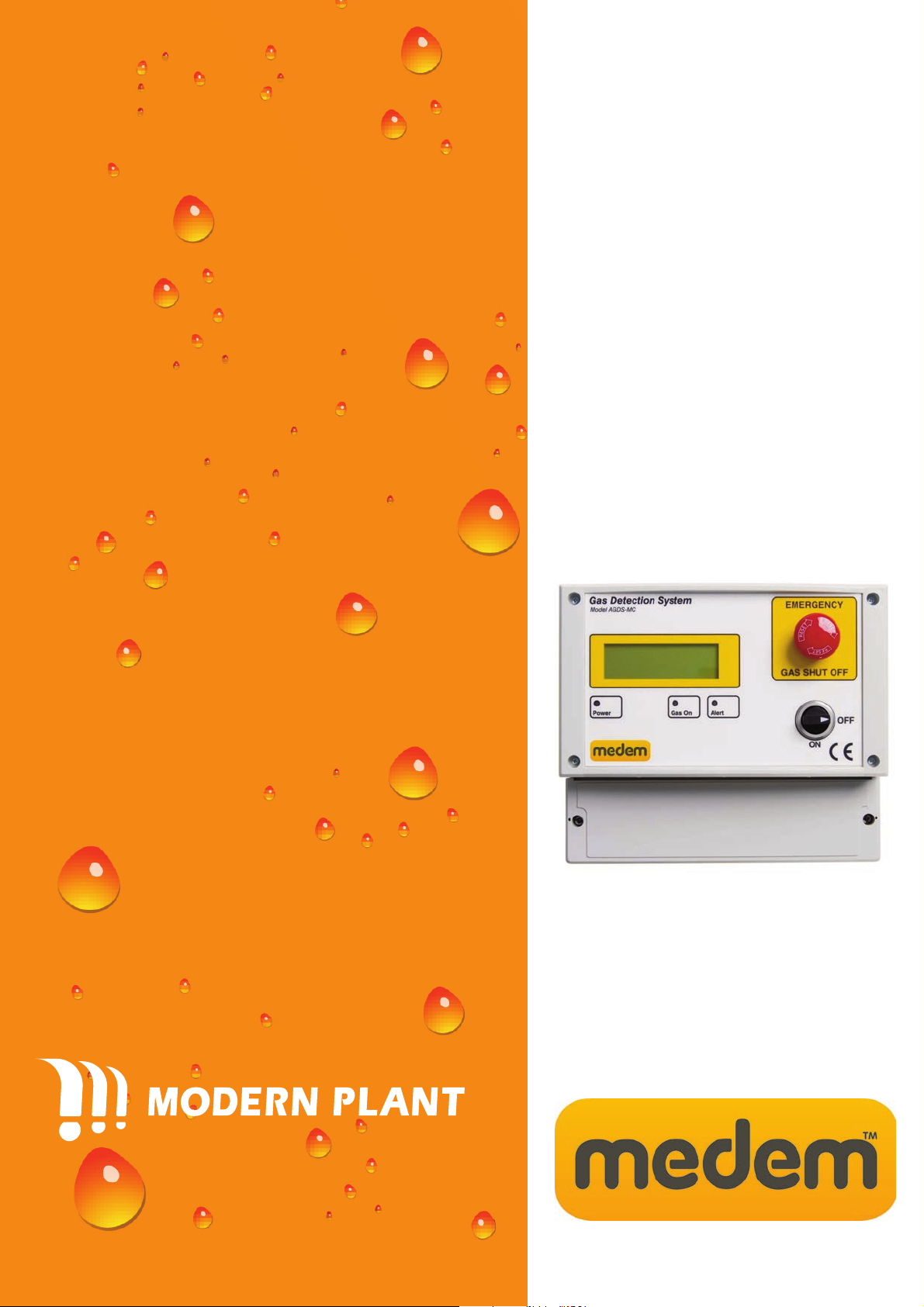

AGDS-MC

Multi-channel

Gas Detection System

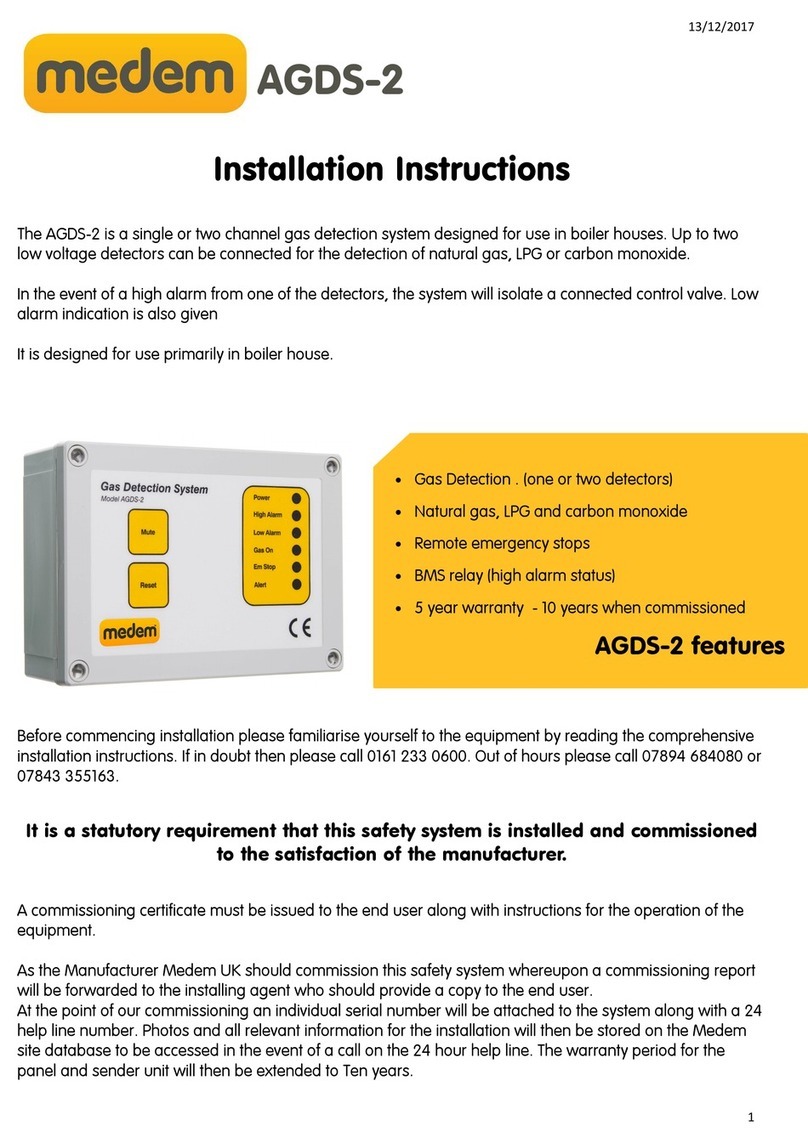

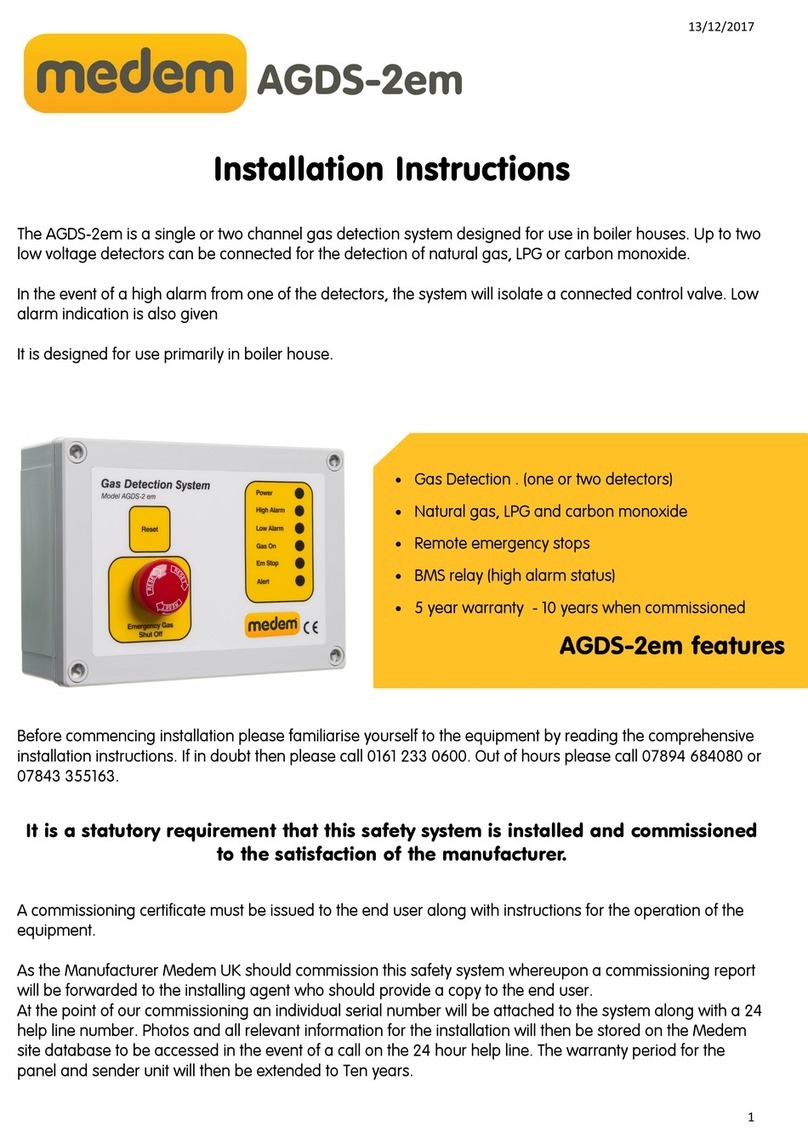

The AGDS-MC, Gas detection system has been designed for use in boiler houses and plant rooms. Up to 16 low

voltage sensors for the detection of natural gas, LPG or carbon monoxide can be connected to the panel. In the

event of a high alarm from one of the sensors the system will isolate the gas supply by closing a connected

electric control valve. The LCD will display appropriate information about alarm situations and

detector status etc.

Medem (UK) Limited

L&M Business Park , Norman Road

Altrincham, Cheshire,

WA14 4ES

Tel: +44 (0) 161 233 0600

Fax:+44 (0) 161 233 0601

Website: www.medem.co.uk

e-mail:[email protected]

Cert No. 10213

Design Features

• Gas detection of Natural gas, Carbon monoxide and Butane/Propane L.P.G.

• Compact easy to install compact system with long detector life.

• Remote signalling can be connected to B.M.S and fire alarm systems.

• User friendly, digital design means clear system status indication at all times.

• Emergency shut off buttons and thermal links, all low voltage, can be connected.

AGDS-MC

Medem (UK) Limited

L&M Business Park , Norman Road

Altrincham, Cheshire,

WA14 4ES

Tel: +44 (0) 161 233 0600

Fax:+44 (0) 161 233 0601

Website: www.medem.co.uk

e-mail:[email protected]

Cert No. 10213

The AGDS-MC gas detection panel has been designed to accept digital signals from up to

sixteen gas detectors.

The AGDS-MC will accept gas detectors for natural gas,

carbon monoxide and LPG. The detectors can be mixed on

the AGDS-MC as each connected sensor is shown as a

separate item on the panel LCD display. Up to four

combustible or four carbon monoxide sensors can be

connected to the main panel, though a total of 16 detectors

can be connected when used with our transformer pack.

In the event of a gas being detected the panel LCD will show

either pre alarm or high alarm and also which detectors

have alarmed and which gas has been detected.

On high alarm the panel isolates the gas supply

by closing the control valve. At the same time a

BMS and a beacon or sounder can be activated.

The AGDS-MC normally uses 240 volt normally

closed valves but it is possible to run other types.

An emergency shut off button is incorporated on

the AGDS-MC panel and remote emergency shut

off buttons can be connected. Remote emergency

shut off button connections are wired low voltage,

normally closed, open on alarm.

Thermal links can be connected to the system , connections are again low voltage. The

AGDS-MC can also take a signal from a fire panel to close the control valve in the event of a

fire alarm situation.

A fire test isolation panel is available from Medem to allow a fire test to be carried out with-

out isolating the gas supply.

All Medem systems are designed built and supported by Medem UK. The sensors have a

design life of five years when used in clean air environments such as a boiler house.

Continuous exposure to combustible gas will shorten the life of combustible gas detectors.

AGDS-MC

Medem (UK) Limited

L&M Business Park , Norman Road

Altrincham, Cheshire,

WA14 4ES

Tel: +44 (0) 161 233 0600

Fax:+44 (0) 161 233 0601

Website: www.medem.co.uk

e-mail:[email protected]

Cert No. 10213

Technical data sheet

The model AGD-MC consists of a mains powered panel capable of operating up to four combustible gas detectors and

four Carbon Monoxide detectors.

Up to sixteen detectors (combustible or CO) can be connected to the AGDS-MC when used with the external transformer

pack. See separate schematic for wiring the transformer pack, designed for when more than four combustibles are to be

used.

The detectors are connected by low voltage 4 wire cable (typically telephone cable) daisy chained back to the control

panel. The sensor units may be mounted up to 100mtrs from the control unit. The complete system is designed to comply

with the latest CE Directives including the low voltage directive.

This is housed in an IP65 rated ABS enclosure measuring 183mm high x 212mm wide x 97mm deep.

This is also the power pack box size AD-PP.

The LED indications on the panel:

Power on Green

Gas on Red

Alert Yellow

The LCD indications on the panel:

In the event of an alarm situation the LCD screen will display the condition that is causing the alarm and will generally

offer a solution. The LCD display will indicate for the following, emergency shut off button activated, gas leak detected

and which type of gas (with detector number).

Audible indications:

An internal buzzer is provided to give the following sounds:

Alarm, beep every 1 second.

There is an option to disable the alarm buzzer on the panel circuit board by removing a jumper plug.

Relay outputs:

Main valve relay rated at 5 amps to provide a switched live to the main solenoid valve.

230 volt rated potential free changeover alarm relay to activate a remote sounder and or beacon or signal a

BMS system.

Gas detection settings

The combustible gas detectors are pre calibrated at works to detect gas at 5% of the low explosion level

(pre alarm) and at 10% of the low explosion level (high alarm).

The CO detectors are calibrated at 80ppm for pre alarm and 100ppm for full alarm

AGDS-MC

Medem (UK) Limited

L&M Business Park , Norman Road

Altrincham, Cheshire,

WA14 4ES

Tel: +44 (0) 161 233 0600

Fax:+44 (0) 161 233 0601

Website: www.medem.co.uk

e-mail:[email protected]

Cert No. 10213

AGDS-MC

Connections to panel: marked on board

1. Live & Neutral 230 volts supply from 3amp switched fuse spur

2. 230 volts out to gas solenoid valve (5amp relay)

3. Earth connection terminals

4. Gas On BMS relay (potential free contact, mains rated, max load 5amp)

5. Remote emergency stop buttons SELV, multiple buttons connect in series (requires a N/C circuit, open for alarm)

6. Power connections for detectors, Methane, LPG, CO.

7. Comms connections for detectors, Methane, LPG, CO.

8. Unused Option button.

9. Display detectors addressed 9 to 16.

10. Display detectors addressed 1 to 8.

11. Option Switches

12. Learn Detectors - Press after connecting & addressing Medem gas sensors.

13. Enable/Disable Internal toner

14. Optional Dual BMS relay (SELV) - Factory fit only, must be requested at point of order

Option Switches (No 11) Relay A Relay B

Opt A - Off Factory set Factory set

Opt A - On Factory set Factory set

Opt B - Off Low gas alert High gas alert

Opt B - On low & High gas alert Emergency Stop

Medem (UK) Limited

L&M Business Park , Norman Road

Altrincham, Cheshire,

WA14 4ES

Tel: +44 (0) 161 233 0600

Fax:+44 (0) 161 233 0601

Website: www.medem.co.uk

e-mail:[email protected]

Cert No. 10213

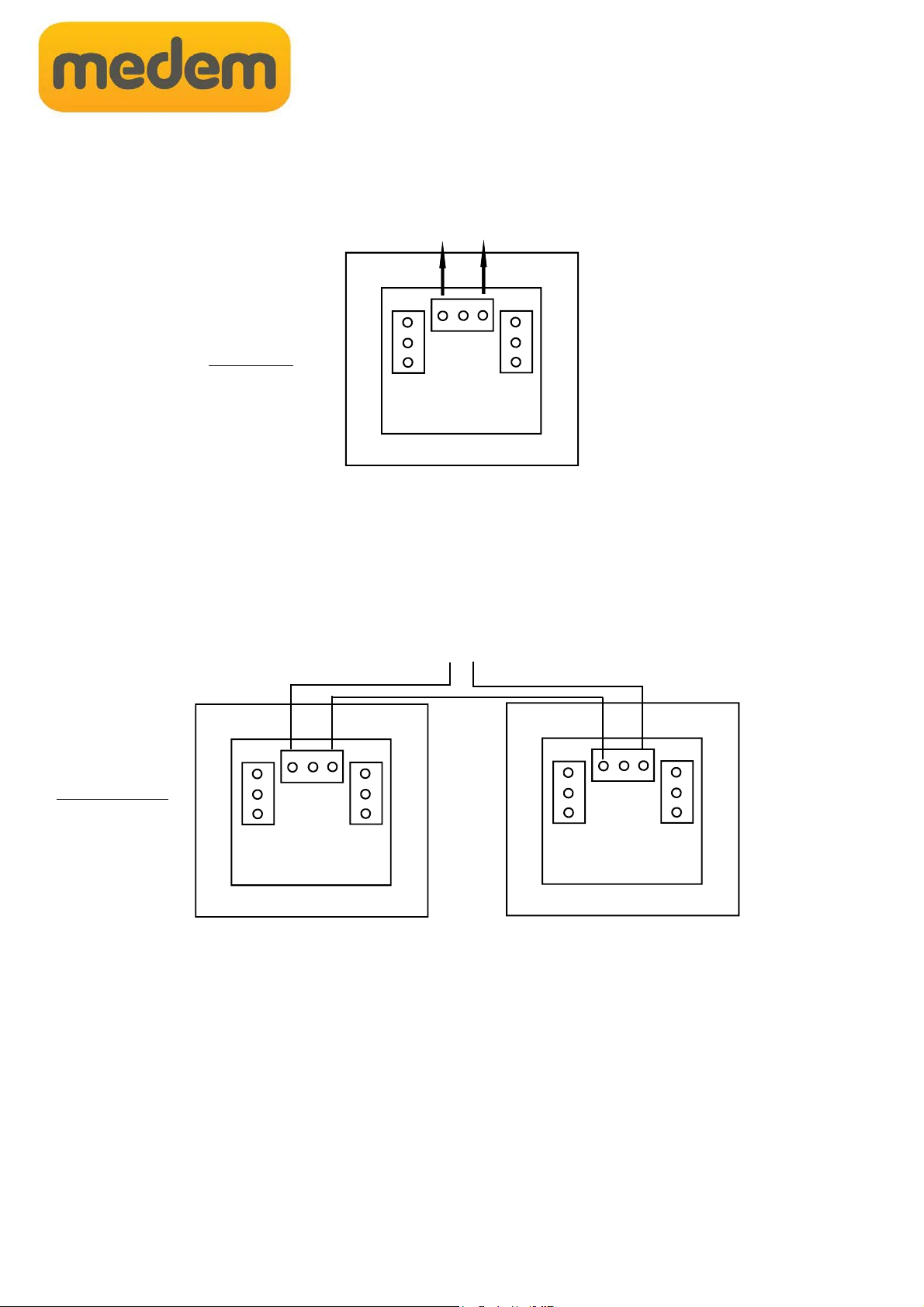

AGDS-MC

Additional sensors can be connected

‘daisy chain’

AD-Med-Sensors

Transformer pack box wall mounting

BOARD & WIRING FOR THE AGDS-MC Gas Detection Panel

Mains

Supply

Fuse at

3 Amps

Minimum 2 Sensors, Maximum 4

to be connected to main panel

Do not remove the PCB

Board from the box.

Use the eye in the

middle of the back box

for the first mounting.

Then use the two holes

on the bottom left and

right of the box, access

to these fixing holes is

under the terminal

cover.

Medem (UK) Limited

Project House, 19 Dallimore Road,

Roundthorn Industrial Estate,

Manchester, M 3 9NX

Tel

:

: +44 (0) 161 33 0600

Fax::+44 (0) 161 33 0601

Website: www.medem.co.uk

e-mail:sales@medem.co.uk

Cert No. 10 13

AGDS-MC Operating and Maintenance

Operation

With the system switch in the off position; the green power LED should be lit and the LCD displaying

the message “Multi Gas Detection System” all other LED’s should be off.

Normal operating procedure for gas (when power is first applied)

Turn system switch to the on position.

The gas valve will open, the LCD will display the message “Gas On” and ‘Gas On’ LED will

light.

Maintenance and testing

To test all features the s stem.

With the s stem switch off; the green power LED should be lit; turn the s stem switch to

on:

The LCD will display ‘Gas On’, the ‘Gas On’ LED will light and the gas valve open, gas should now be

available for use.

Verif all gas detectors are being correctl identified b the AGDS-MC;

Remove the AGDS-MC’s terminal cover and locate the “Display Detectors” buttons (see installation

instructions).

Press and hold the button to display on the LCD screen all “learnt” detectors, ensure all detectors

“type” and “ID” are being correctly identified.

With the gas available for use, appl a small amount of the target gas to each detector:

The AGDS-MC will indicate a low level alarm at 5% LEL for combustible gases, 80ppm for CO, and

a high level alarm at 10% LEL for combustible gases, 100ppm for CO.

The detector LED will turn from ‘Green’ (powered) to ‘Red’ (alarm).

With the AGDS-MC in an alarm state;

The LCD will display the message Low Alarm or High Alarm.

The alert LED will light, the tone will sound and the Gas On LED will go out.

The Gas valve will close

There should be a manual operational test on an installed Emergenc stop buttons,

which when operated will isolate the gas supply and remain isolated until a manual reset is

completed.

A yearly test and inspection of the solenoid valve and let by test should be carried out by a qualified

technician i.e. Gas safe registered engineer.

The detectors are designed to have very low drift so recalibration on site is not required but should

be replaced every 5 years in a clean environment but consideration should be given to

replacement after 3 years if contamination is a possibility. A functionality test should be carried out

every 6-1 months.

If at an time there is an alert or the sounder sounds follow these instructions, further

information can be found both in the installation instructions and b contacting Medem

(UK) Ltd.

AGDS-MC Important

Please read this sheet as it contains

important information

Before commencing installation please familiarise yourself to the

equipment by reading the comprehensive installation instructions. If

in doubt then please call 0161 233 0600. Out of hours please call

0 894 684080 or 0 843 355163.

It is a statutory requirement that this safety system is installed and

commissioned to the satisfaction of the manufacturer.

A commissioning certificate must be issued to the end user along

with instructions for the operation of the equipment.

As the Manufacturer Medem UK should commission this safety sys-

tem whereupon a commissioning report will be forwarded to the in-

stalling agent who should provide a copy to the end user.

At the point of our commissioning an individual serial number will be

attached to the system along with a 24 help line number. Photos and

all relevant information for the installation will then be stored on the

Medem site database to be accessed in the event of a call on the 24

hour help line. The warranty period for the panel and sender unit will

then be extended to Ten years.

INS/1004/001

2

AGDS-MC System description

Multi Channel Gas Detection system

System description

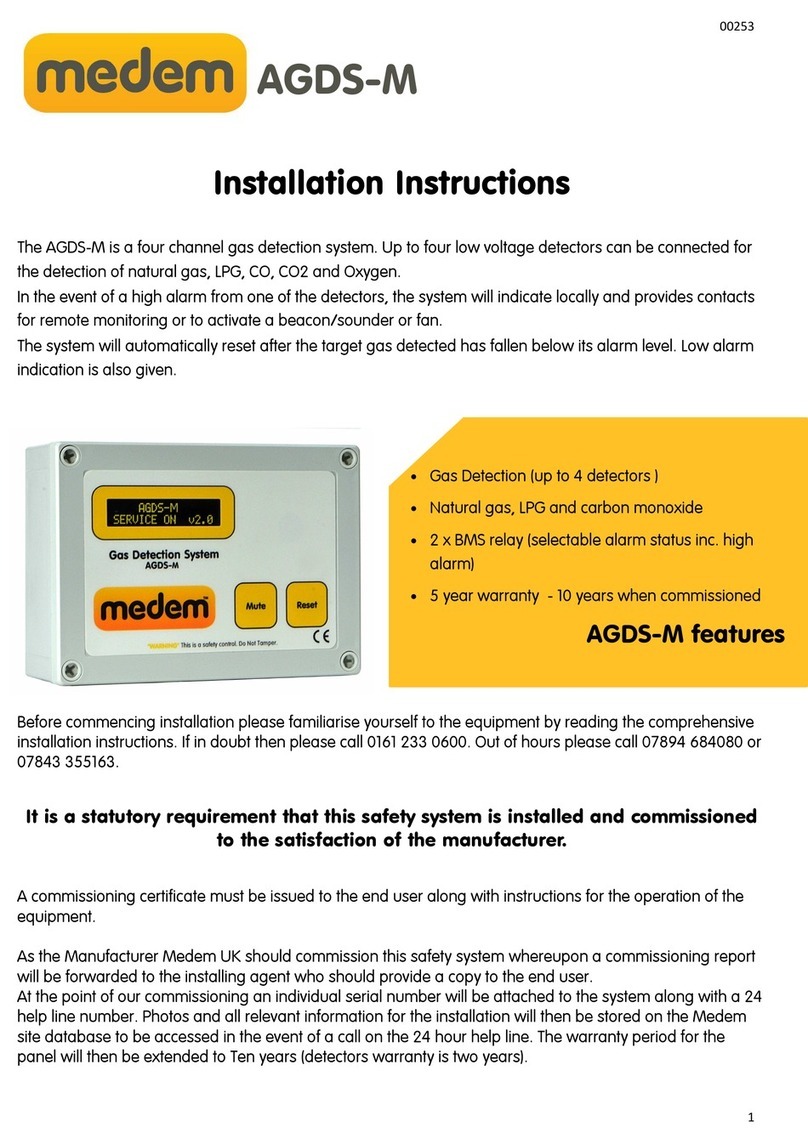

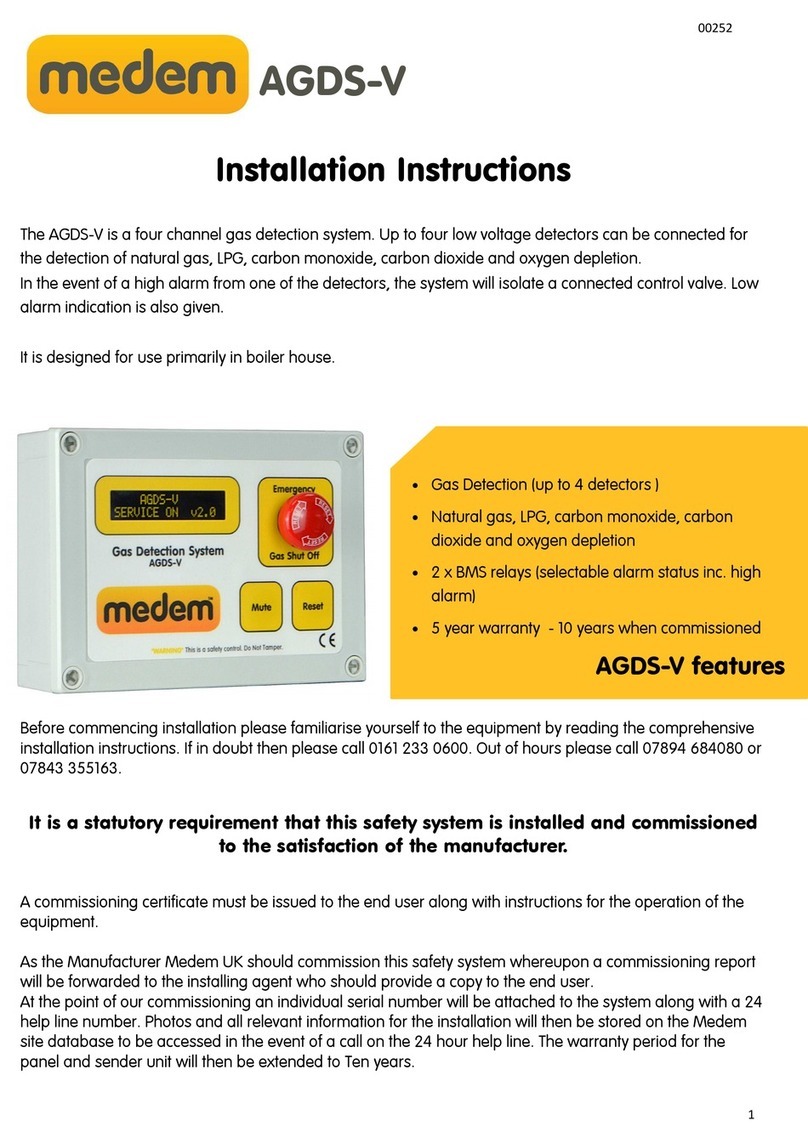

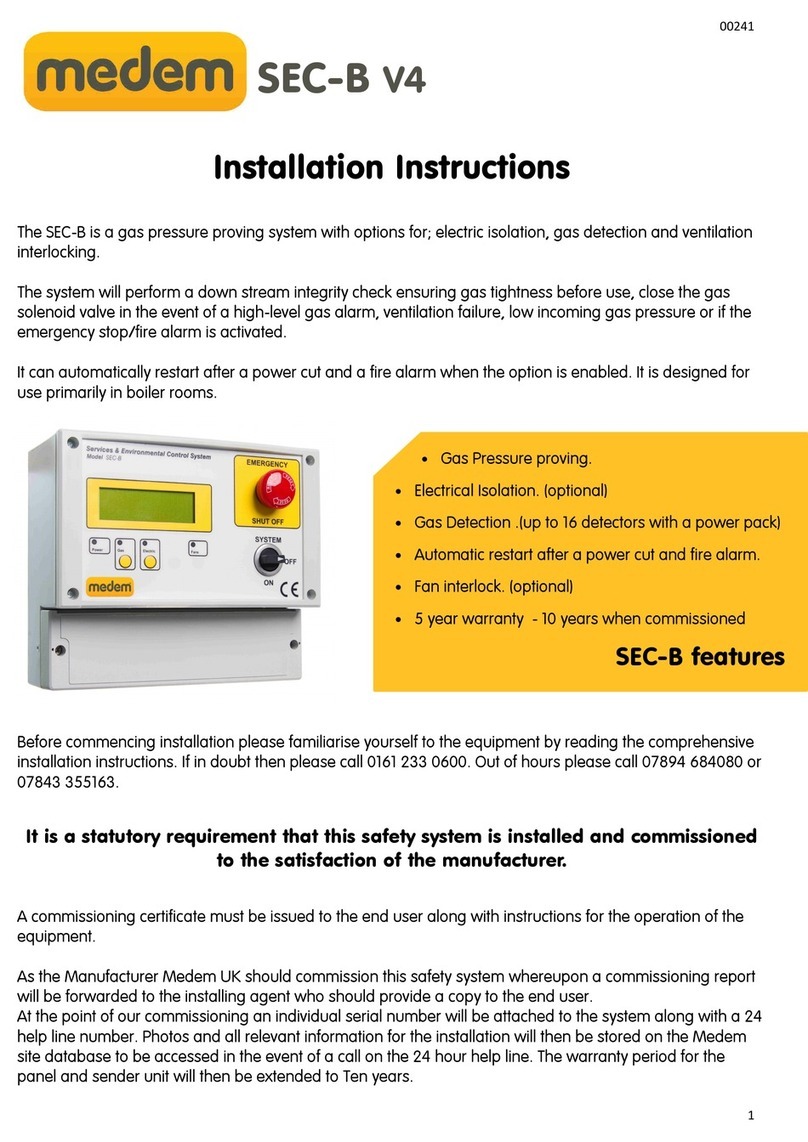

The AGDS-MC is a gas detection system designed to monitor the atmosphere for target gases. The system comprises of a mains

powered panel capable of operating up to four detectors (or 16 in conjunction of the AD-PP transformer pack), either

Combustible, Carbon Monoxide, Carbon Dioxide and Oxygen or a mixture of any. The detectors are pre-calibrated by Medem

(UK) Ltd such that they only require to be connected to the panel and functionally tested.

In the event of a high alarm from one of the detectors the system will isolate the gas supply by closing a connected electric control

valve. Emergency stop buttons and Thermal Links can be fitted and a fire alarm can close the gas valve when connected to the

panel.

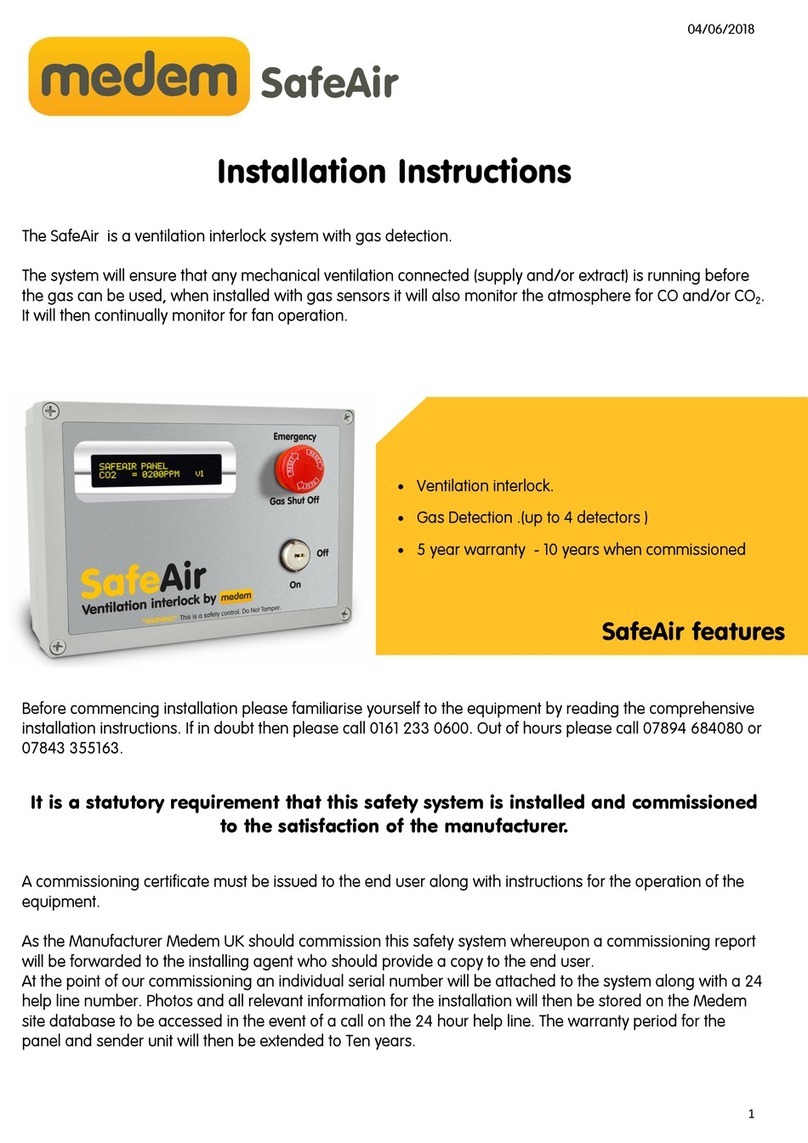

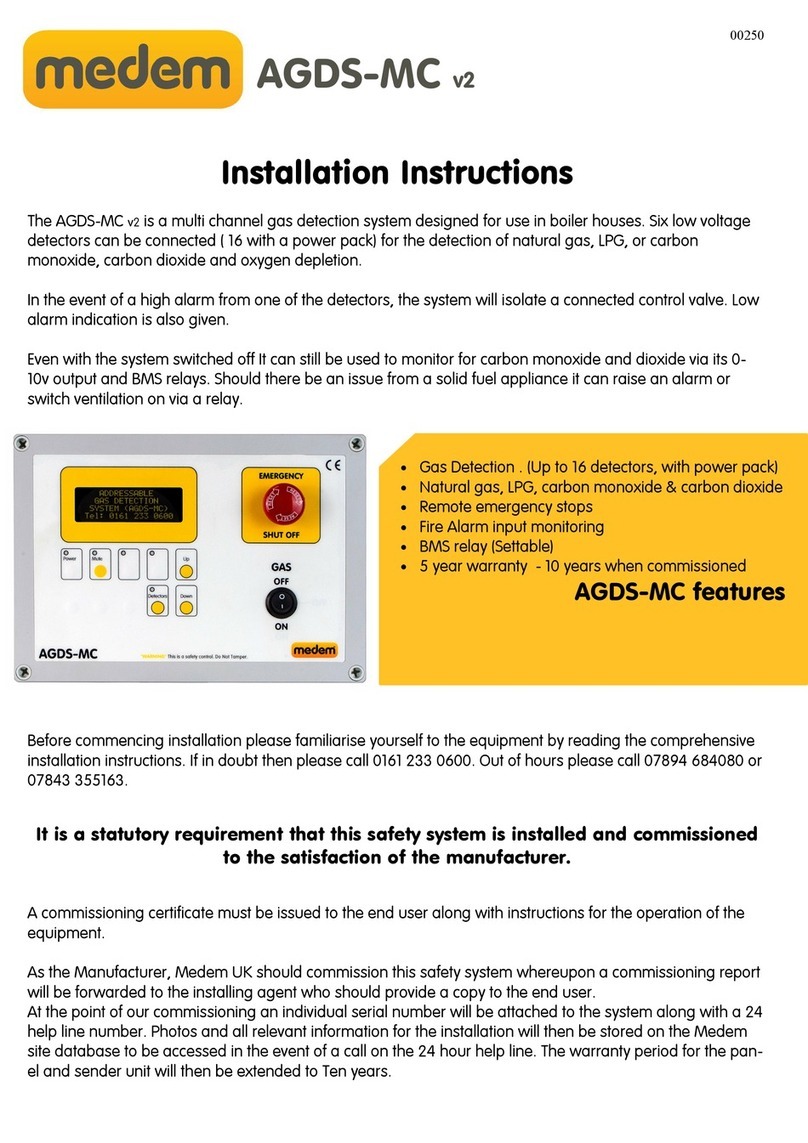

Control Panel the front of the panel has the following controls and indications:

Emergency Stop Button

On/Off Switch

LED indications:

Power On - green

Gas On - red

Alert - yellow

LCD display: Displaying system status and diagnostics

Low Voltage Gas Detectors

The maximum cable(4 core) length between a sensor and the control panel should not exceed 100 metres, If the distance between

the main panel and the detectors is greater than 20meters 1mm cable should be used on the 12v, 0v terminals..

Combustible detectors are pre calibrated at 5% LEL (Pre alarm) and 10% LEL for the High alarm.

Carbon Monoxide detectors are pre calibrated at 80ppm (pre alarm) and 100ppm for high alarm.

Each detector has a rotary address selector switch (0-F) each detector must be set to a unique address. Once connected and

addressed you are required to press the “learn Det’s” button (12). Once pressed the corresponding detector LED’s on the main panel

will light green.

Each sensor unit has an LED which shows green when power is applied.

Note: There is a warm up period after initial power up of approximately 90 seconds. During this time the green LED will flash once

per second and the output signal will be inhibited. This is to prevent spurious alarms. After the warm up period and on application

of gas, the red LED will light when a high gas alarm level is reached.

Emergency Stop

LCD Screen for clear instructions

System n/ ff

Switch on to open gas valve

3

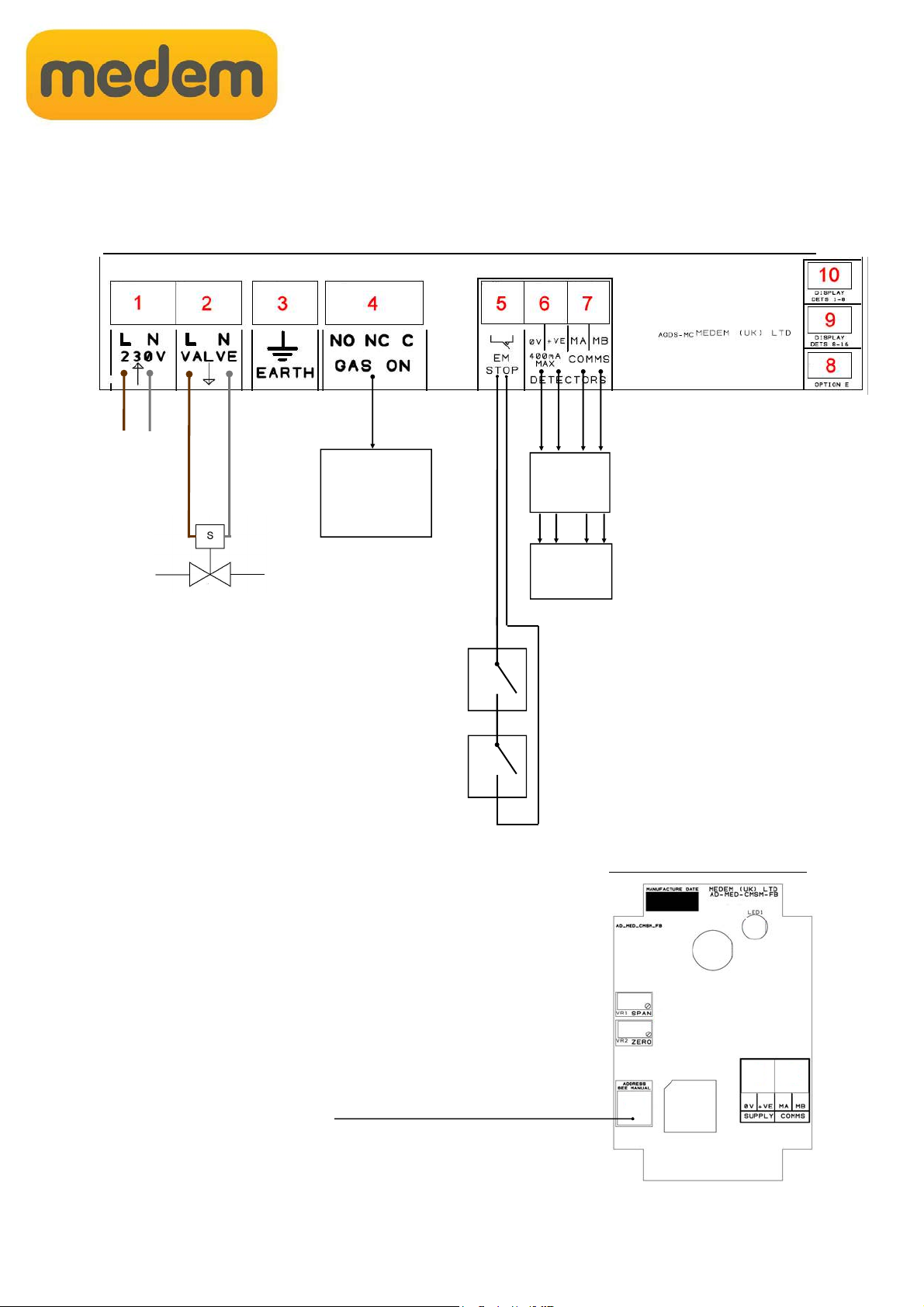

AGDS-MC Main features

Power at 230

volts from a

3amp fused spur

Connections to panel: marked on board

1. Live & Neutral 230 volts supply from 3amp switched fuse spur

2. 230 volts out to gas solenoid valve (5amp relay)

3. Earth connection terminals

4. Gas On BMS relay (potential free contact, mains rated, max load 5amp)

5. Remote emergency stop buttons SELV, multiple buttons connect in series (requires a N/C circuit, open for alarm)

6. Power connections for detectors, Methane, LPG, CO.

. Comms connections for detectors, Methane, LPG, CO.

8. Unused Option button.

9. Display detectors addressed 9 to 16.

10. Display detectors addressed 1 to 8.

11. Option Switches

12. Learn Detectors - Press after connecting & addressing Medem gas sensors.

13. Enable/Disable Internal toner

14. Optional Dual BMS relay (SELV) - Factory fit only, must be requested at point of order

14

ption Switches (No 11) Relay A Relay B

Opt A - Off Factory set Factory set

Opt A - On Factory set Factory set

Opt B - Off Low gas alert low & High gas alert

Opt B - On low & High gas alert Emergency Stop

4

AGDS-4 Schematic

Earth Connections not shown

3 amp fused spur

230v

EM Stop Buttons,

TT- 0c

Fire Alarm

Series connected

Addressable

Gas detectors

Connect in

parallel

Mains Rated

Potential free contact,

Max load 5amp’s

(latching relay)

Gas Solenoid

230v

Example Medem Gas Detector

Address selector switch: use 1 to 16 only

5

AGDS-MC Detector Information

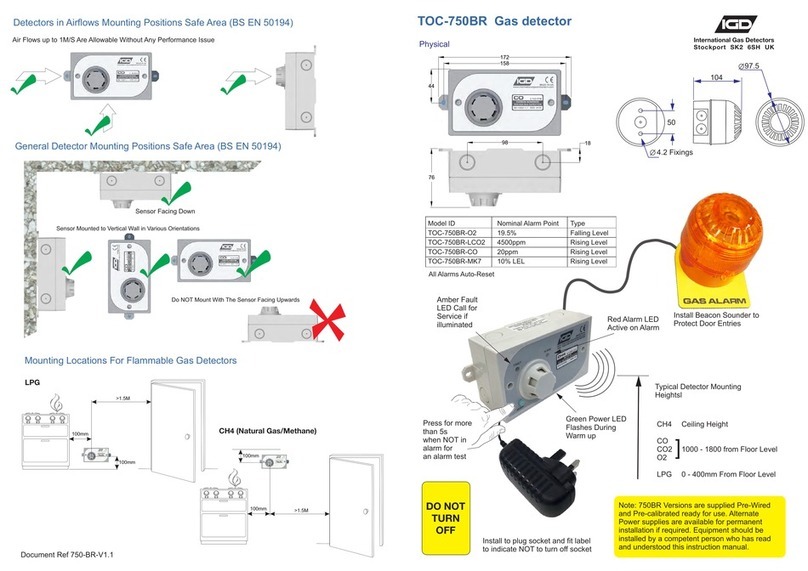

Detector Location

Detector location will vary dependant on the individual characteristics of the target gas that is being monitored for. The descrip-

tions below describe the position for each detector after considering these characteristics.

Natural Gas

Natural gas detectors should be mounted at high level on a wall approximately 150mm from the ceiling height and avoiding

corners and potential dead air areas.

Natural gas detectors should not be mounted below the height of the top of a doorway for example. This is because as the

gas is slightly lighter than air it will rise filling the room from the ceiling down and will spill through the top of a door opening

into the next room. If the detectors are mounted below this height then it will take longer the gas to reach the detector.

LPG

LPG gas is heavier than air so detectors need to be mounted at low level 100mm from the floor, consideration should be given

to any potential mopping or wet floor height.

Carbon Monoxide

Carbon Monoxide is similarly weighted to air so detectors should be mounted between 1 to 2 meters from the floor.

Carbon Dioxide

Classroom

Carbon Dioxide detectors under guidance from IGEM/UP11/Edition2 should be mounted at a seated head height.

However following onsite experience this mounting height can make detectors susceptible to false readings due to direct

breath contact. We would suggest following the guidance for mounting as per a commercial kitchen to reduce the potential for

false alarm readings.

Commercial kitchen

Carbon Dioxide detectors should be installed so they monitor the general level of CO2 within the cooking

area. They should be mounted above standing head height and between 1m and 3m from the cooking line. Care should be

taken so they are not located close to the edge of a canopy or in direct flow of the supply or extract ventilation.

For additional information or guidance on site specific requirements please don’t hesitate to contact us.

Detector Testing

Any installed gas detector can be tested by allowing a small amount of the target gas onto the detector head until a change of

state is registered on the control panel.

If the level of gas applied is of the set low alarm level, the LED on the detector will change from a solid green to a flashing red.

The Alert LED and a message indicating a low level alarm detection combined with an audible alarm on the panel will begin.

If the level of gas drops below the set low alarm level the detector LED will return to a solid green and the panels audible alarm

and the Alert LED and LCD message will clear.

Should an emergency shut-off valve be connected to the panel this will remain open during a low alarm level detection.

If the level of gas applied is of the high alarm level or above, the LED on the detector will change from a solid green to a solid

red. The Alert LED and an LCD message indicating a high level alarm detected combined with an audible alarm on the panel

will begin.

Should an emergency shut-off valve be connected to the panel this will automatically close.

Once the level of gas drops below the high alarm level the audible alarm will continue and the Alert LED and LCD message will

remain.

The valve cannot be reinstated until the gases have been cleared and the control panel reset.

6

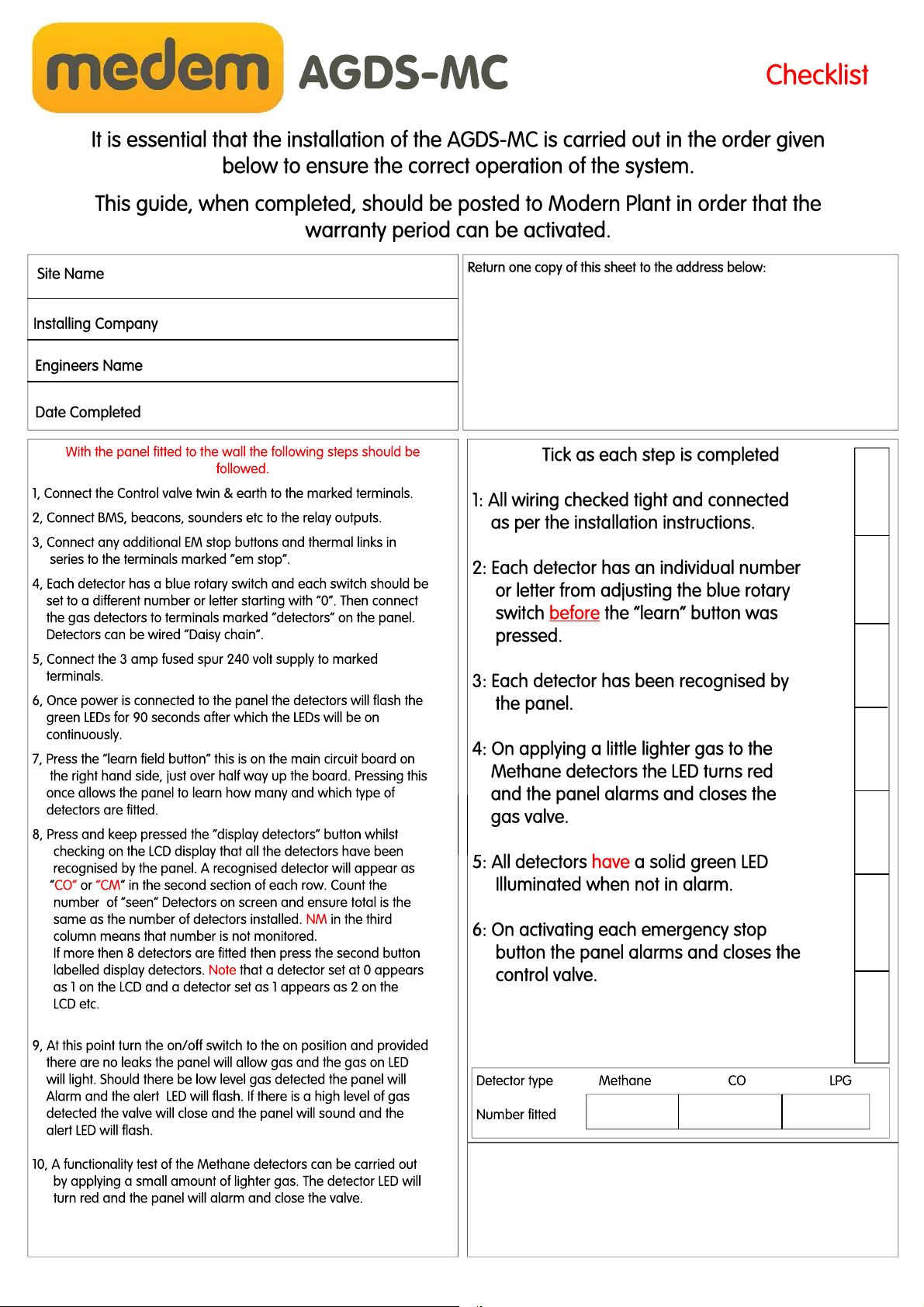

Remote stop buttons

AGDS-MC

Single Switch TB2

TB1 TB3

To EM Stop connections in

Use terminals TB2 A and TB2 C

To EM Stop connections in

the panel

TB2

TB1 TB3

Use terminals TB2 A and TB2 C

TB2

TB1 TB3

Use terminals TB2 A and TB2 C

Multiple Switches

Wire in series

Remote stop buttons can be connected to the panel terminal marked as “EM STOP” (number 6 ). The remote buttons

must be wired as above in order to provide a “closed contact” for the control panel.

Modern Plant Limited,

Otter House, Naas Road, Clondalkin, Dublin 22

Tel: 00353 1 461 4300

E: sales @ modernplant.ie, W: www.modernplant.ie

Please do not hesitate to call for advice on the

following number:

00353 1 461 4300 oce hours

Modern Plant Ltd are an official

stocking distribution centre for

Emerson Rosemount industrial

flow, level, pressure, analytical

and temperature

instrumentation products.

Modern Plant Ltd offer a wide

range of Stiebel Eltron

products, from instantaneous

hot water heating, stored

water and electric space

heating solutions.

As Irelands official distributor for

Grohe, Modern Plant stock-hold

and display a large range of

Grohe Commercial and

Domestic products including,

showers, taps, frames and

accessories.

We stock a large range of

Bobrick washroom

accessories made from

type304 stainless steel... the

material of choice and quality

for public washrooms.

We are one of Ireland leading

suppliers of Stuart Turner

pumps to suit a variety of

water boosting and water

transfer applications across

multiple market sectors.

Modern Plant Ltd are official

stocking distributors for the

full range of SMC products

and have a wide range of

parts available from our

trade counter.

Modern Plant Ltd is the sole

Irish distributors for the

complete Medem gas safety

product range. Both companies

work closely to ensure the

products remain best in class.

We stock a comprehensive

range of Haws AG emergency

equipment. We also supply

special models to the highest

level of quality as well as

attractive, stylish drinking

fountains and water coolers.

We stock Bonfiglioli power

transmission and control products,

providing automation solutions for

all areas of industry including the

packaging, beverage, textile, food,

ceramic, wood, mining and metal

processing industries.

We stock tapware and shower

solutions for commercial changing

facilities, toilets and accessibility to

people with reduced mobility in

collective facilities. High tech

solutions for healthcare, elderly

care and laboratories.

AMG specialise in quarter turn

rack and pinion pneumatic

actuators with many available

from stock held locally in

Modern Plant.

We are official Irish distributor for all

Metso Automation valve and control

products, including NELES branded

flanged ball valves, rotary plug

valves, segment valves, high

performance off-set butterfly valves,

valve actuators and much more.

Modern Plant Limited, Otter House, Naas Road, Clondalkin, D 22

E: sales @ modernplant.ie, W: www.modernplant.ie

For more information call 00353 1 461 4300

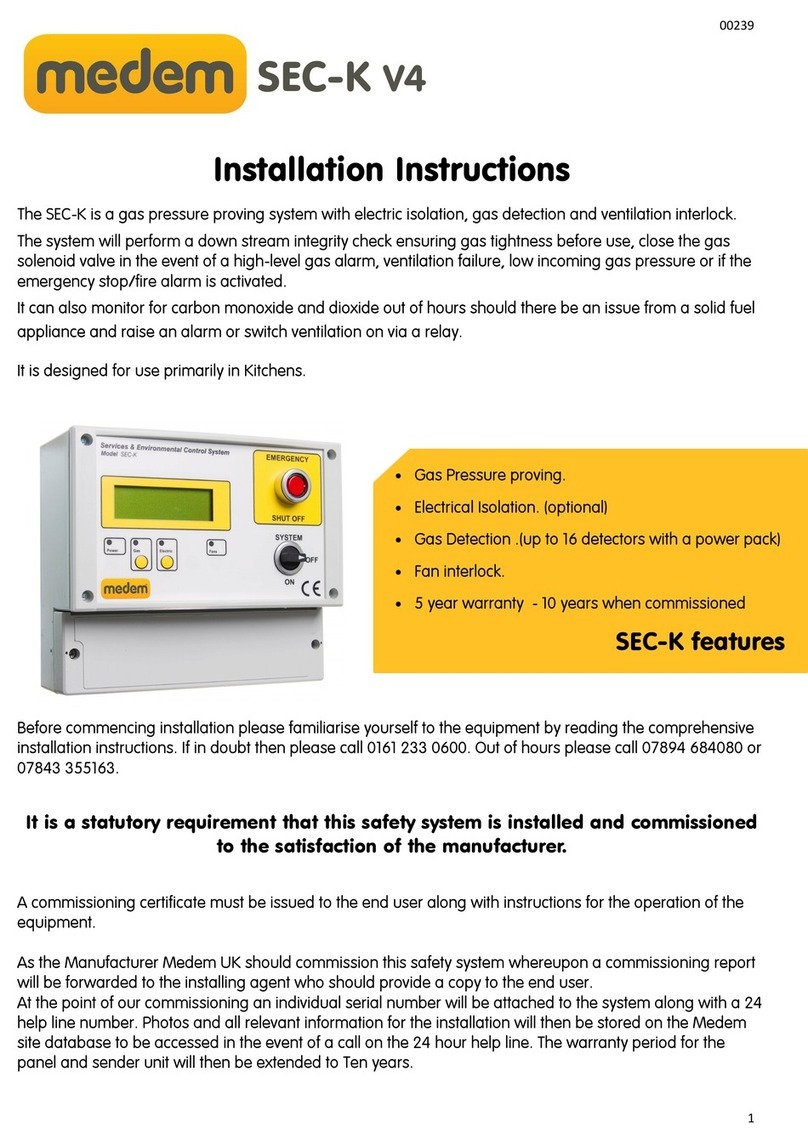

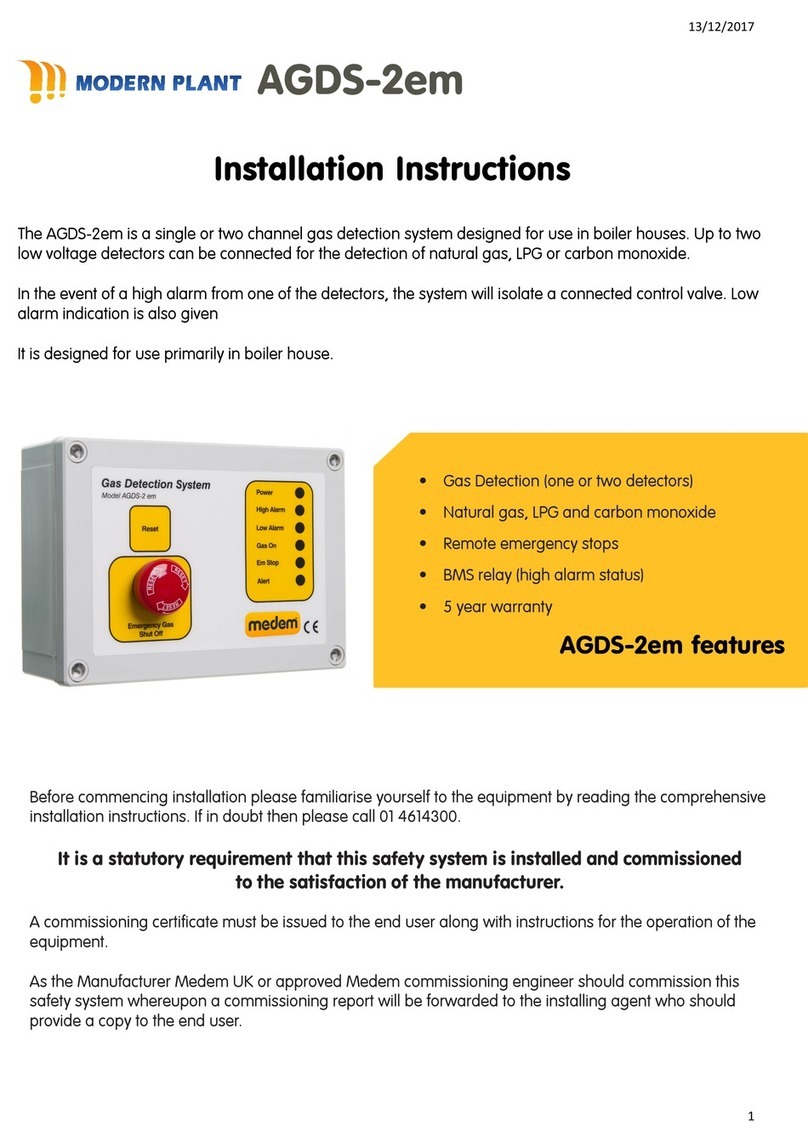

Other manuals for AGDS-MC

1

Table of contents

Other Medem Gas Detector manuals

Medem

Medem AGDS-MCM v2 User manual

Medem

Medem AGDS-4 User manual

Medem

Medem AGDS-2em v2 User manual

Medem

Medem SEC-K V4 User manual

Medem

Medem AGDS-2em User manual

Medem

Medem AGDS-MC v2 User manual

Medem

Medem AGDS-2 User manual

Medem

Medem AGDS-2em User manual

Medem

Medem SEC-L v4 User manual

Medem

Medem SafeAir User manual

Popular Gas Detector manuals by other brands

Somogyi Elektronic

Somogyi Elektronic home COG 01 instruction manual

Riken Keiki

Riken Keiki SD-1RI operating manual

IGD

IGD TOC-750BR quick start guide

PEMTECH

PEMTECH PT495 Series Operator's manual

Hanwei

Hanwei JL269LED Operation manual

TELEDYNE OLDHAM SIMTRONICS

TELEDYNE OLDHAM SIMTRONICS OLCT 80 d user manual