5

43

21

3

2

1

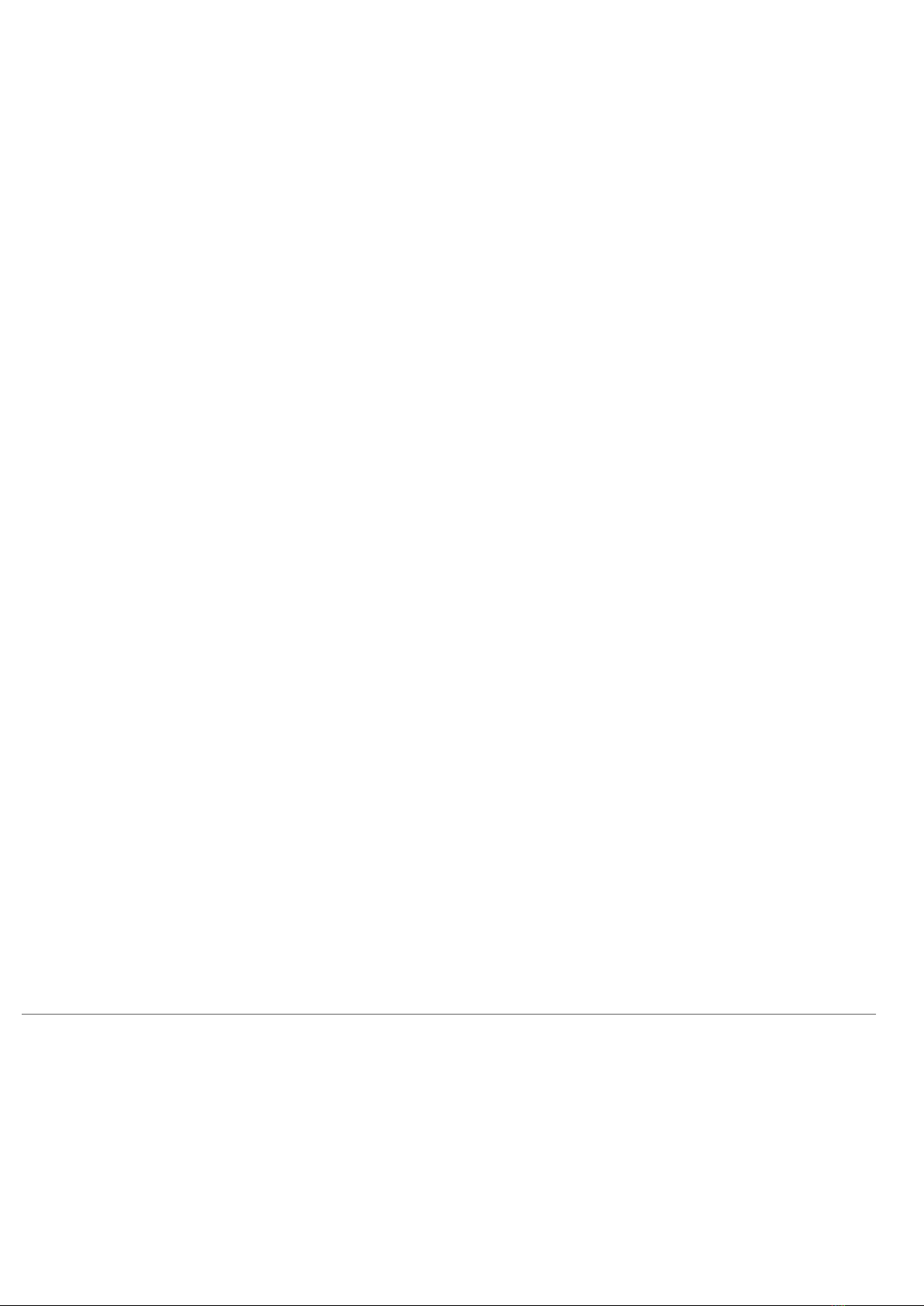

12 V

Battery

Sensor

8

7

6

5

Ph 4N 109

Ph

N

System

Fault

Relay Main

Alarm

Relay

Pre-Alarm

NC NC NC

C

C

C

NO NO

NO

Fuse

230V AC Voltage

8109

Relay Main

Alarm

NC

C

NO

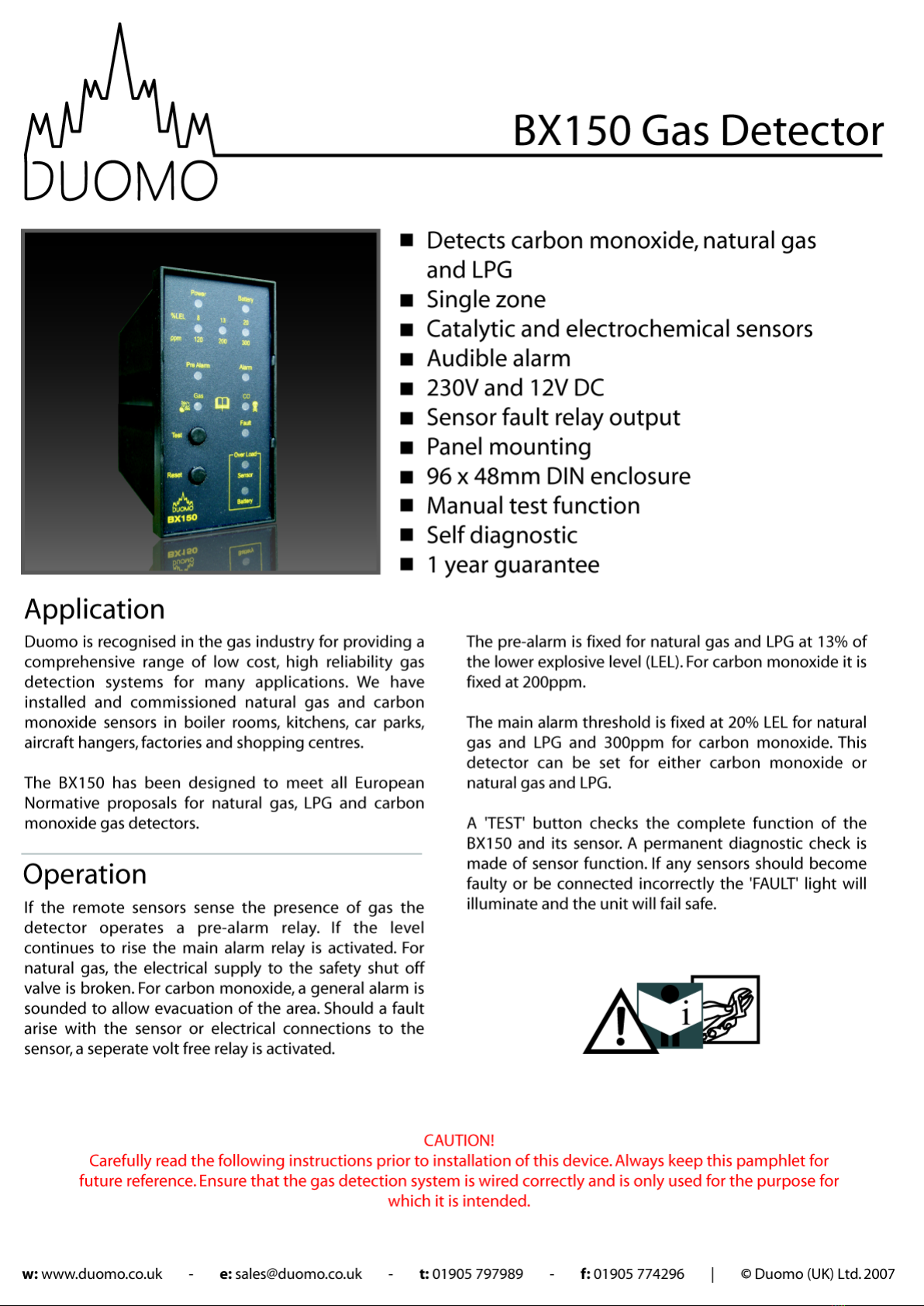

Electrical Installation Installing A Sensor

The BX150 is a safety device designed to give audible alarms

and automatically provide latched electrical isolation of

associated gas safety shut off valves in the event of a gas leak or

build up of toxic gases. The sensor can be located up to 100m

from the gas detector. Cable size should be 1mm2 CSA. If the

sensor cables are run seperately in specific conduit it is not

essential to use screened cable but if the cables are routed

through conduit or trunking containing other wiring the use of

screened cable is advisable.The wiring should be performed by

a qualified person in accordance with current regulations. The

plug-in terminal rail makes installation easy and quick. Do not

mou nt close to any heat source or in an area where moisture is

likely to effect operation. The IP rating of this unit is IP44.

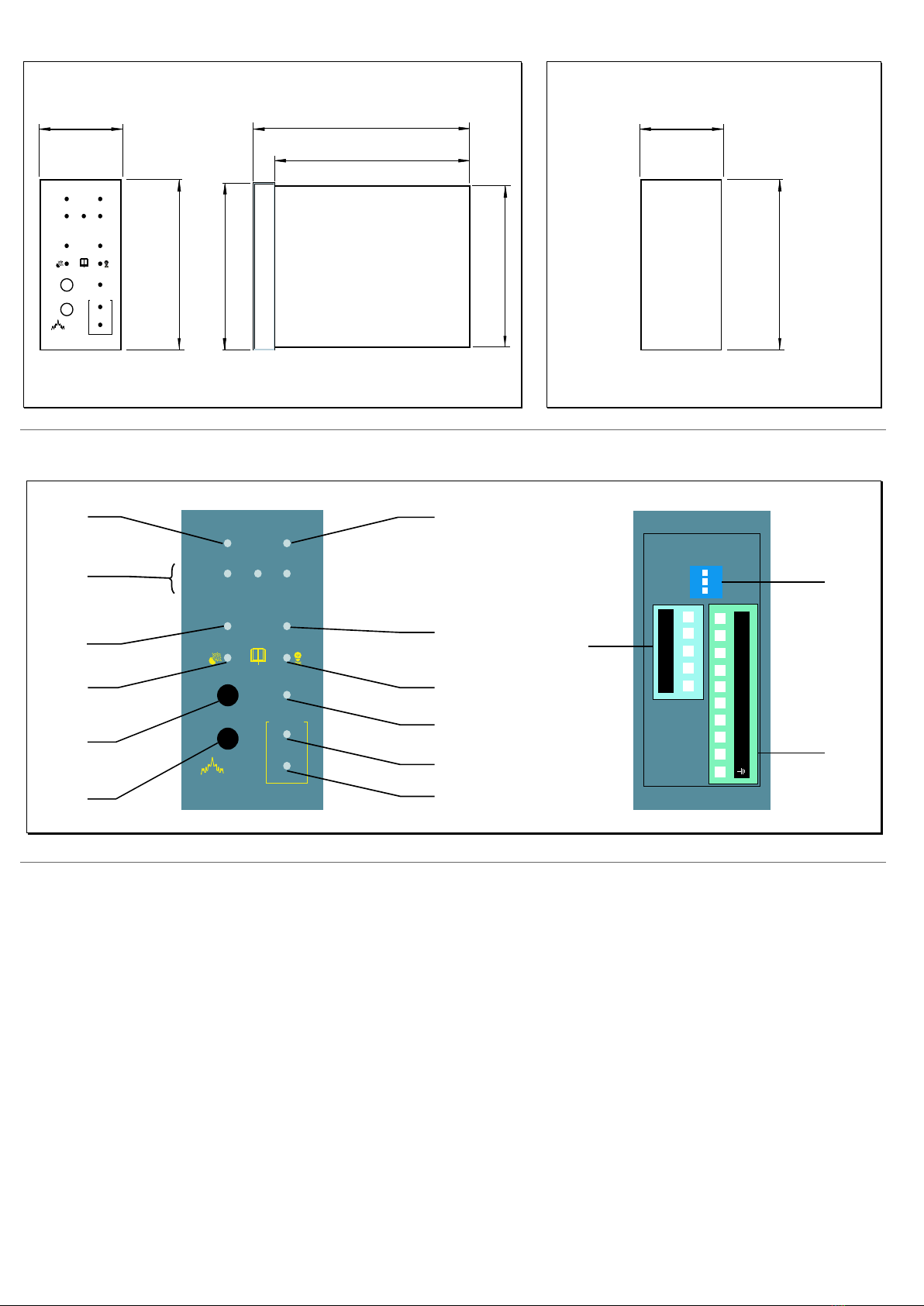

Sensors should be positioned as shown below. If you require

any guidance on this please call our technical help on 01905

797989.

The sensors must be mounted as shown below with

the sintered head pointing vertically down. When

replacing sensors never seperate a sensing head from

its PCB. The sensor will have been calibrated using

this particular board and therefore will not function

correctly with any other.

Important Notes

Always check the wiring before powering up the

system.

Do not test this sensor with anything other than

Duomo test gas (see 'BX150 Operation' section for

further information). Concentrations above this will

damage the sensor and shorten sensor life. The

installation of this gas detector does not release the

user from observing all the regulations concerning

the characteristics, installation and and the use of gas

appliances; the ventilation of the environment and

the elimination of combustion products in

accordance with the local recommendations,

regulations and bylaws. For any damage caused to

people, property or animals resulting from incorrect

connection, installation or application of this gas

detector Duomo will not be held responsible or liable.

To ensure correct function after installation Duomo

provide a commissioning service using calibrated test

gases. For this service call 01905 797989.

SGM595

autosetting

ON

SGM595

autosetting

ON

SGM595

autosetting

ON

300

1600

300

Natural Gas

Carbon

Monoxide

L.P.G.

Typical Wiring Schematic for BX150

Signal Terminal Block

Power Terminal Block * Intrinsic Safety

switch on

8

7

6

5

Ph 4

N109 5

4

3

2

1

3

2

1

12 V

Battery

Power Supply Unit

(If required)

12V

(Volt-free relays -

Link to energise)

(Optional standby

battery - If required)

w: www.duomo.co.uk - e: sales@duomo.co.uk - t: 01905 797989 - f: 01905 774296 | ©Duomo (UK) Ltd. 2007

12V Supply Typical

Configuration

230V Supply Typical

Configuration