2015_03_03 1

Installation and Operating Instructions

Calculator with Ultrasonic Flow Sensor (Heat Meter, Cooling Energy Meter, Combined

Heat/Cooling Energy Meter)

microCLIMA ULTRA/SENSOSTAR®2C_US

Certificate no:

DE-09-MI004-PTB018 (MID heat); 22.72/09.01 (National German cooling)

1Application and Function

Thermal energy meter (heat meter, cooling energy meter or combined heat/cooling meter) designed for the

measurement of the consumed thermal energy in a closed heating or cooling or heating/cooling system.

2Scope of delivery

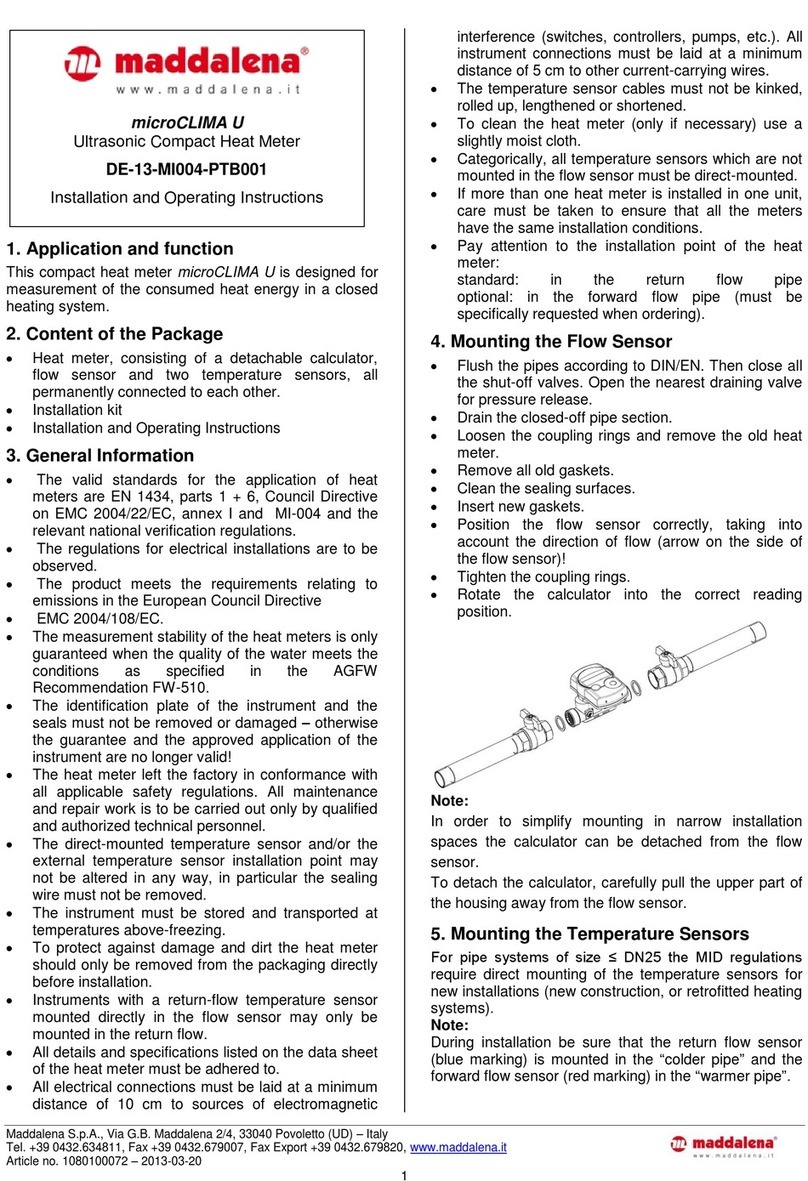

-Calculator with ultrasonic flow sensor (heat meter, cooling energy meter, combined heat/cooling energy

meter)

-Installation kit: 5 self-lock seals + 5 seal-wires; O-ring ; 2 screws + 2 dowels for direct screw mounting

-2 gaskets for the flow sensor

-Installation and Operating Instructions

3General Information

-Valid standards for the application of heat meters: EN 1434, parts 1 –6; the Measuring Instrument

Directive 2004/22/EC, Annexes I and MI-004; and the relevant national verification regulations.

-For the selection, installation, commissioning, monitoring and maintenance of the instrument observe the

standard EN 1434 part 6 as well as Annex 22 of the verification regulations (for Germany).

-National regulations for the consumption measurement of cooling must be observed.

-The technical regulations for electrical installations are to be observed.

-This product fulfils the requirements of the European Council Directive on Electromagnetic Compatibility

(EMC Directive) 2004/108/EC.

-The identification plate of the instrument and the seals must not be removed or damaged –otherwise the

guarantee and the approved application of the instrument are no longer valid!

-To achieve measurement stability of the meter is it necessary that the water quality meet the requirements

of the AGFW-recommendation FW-510 and the document VDI (Association of German Engineers) VDI 2035.

-The heat meter left the factory in conformance with all applicable safety regulations. All maintenance and

repair work is to be carried out only by qualified and authorized technical personnel.

-The instrument must be stored and transported at temperatures above-freezing.

-Instruments with activated radio function are not allowed on air freight.

-The correct installation point in the system must be chosen: forward or return flow, as stated on the type

identification label.

-The temperature sensor cables and the cable between the calculator and flow sensor must not be kinked,

rolled up, lengthened or shortened.

-To clean the heat meter (only if necessary) use a slightly moist cloth.

-To protect against damage and dirt the meter should only be removed from the packaging directly before

installation.

-If more than one meter is installed in one unit, care must be taken to ensure that all the meters have the

same installation conditions.