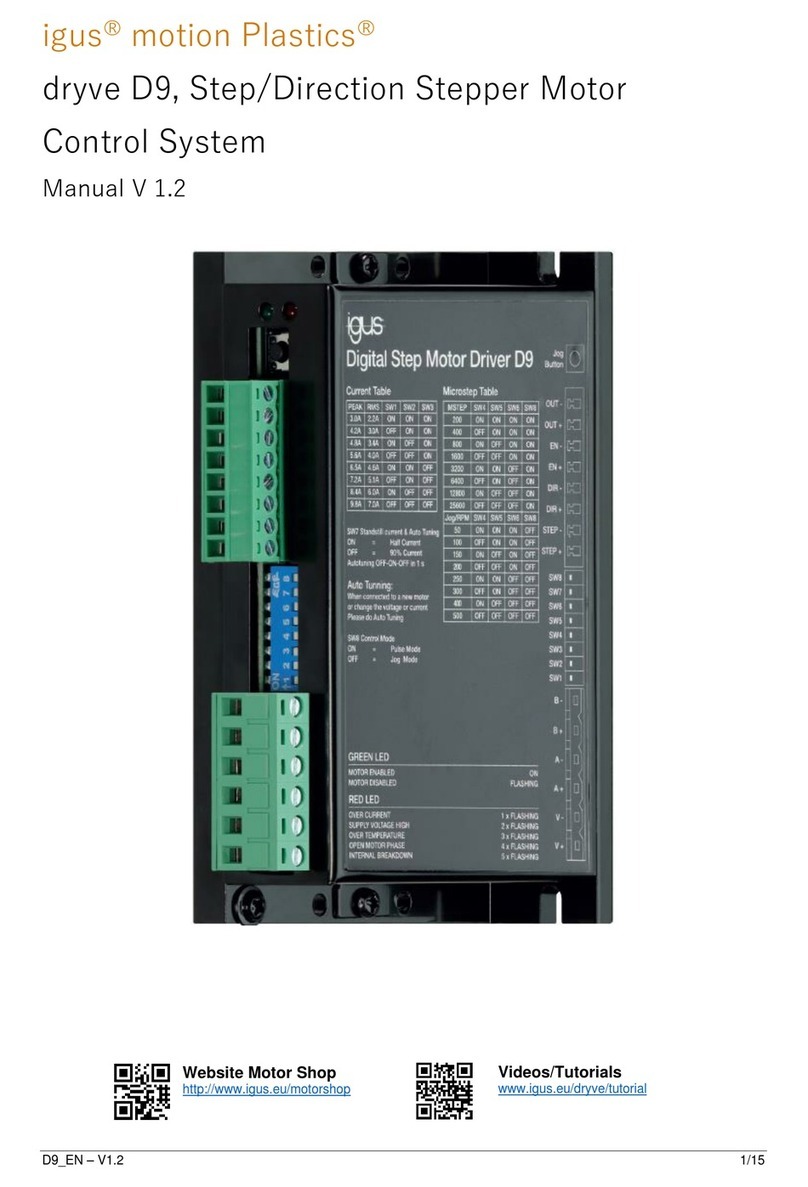

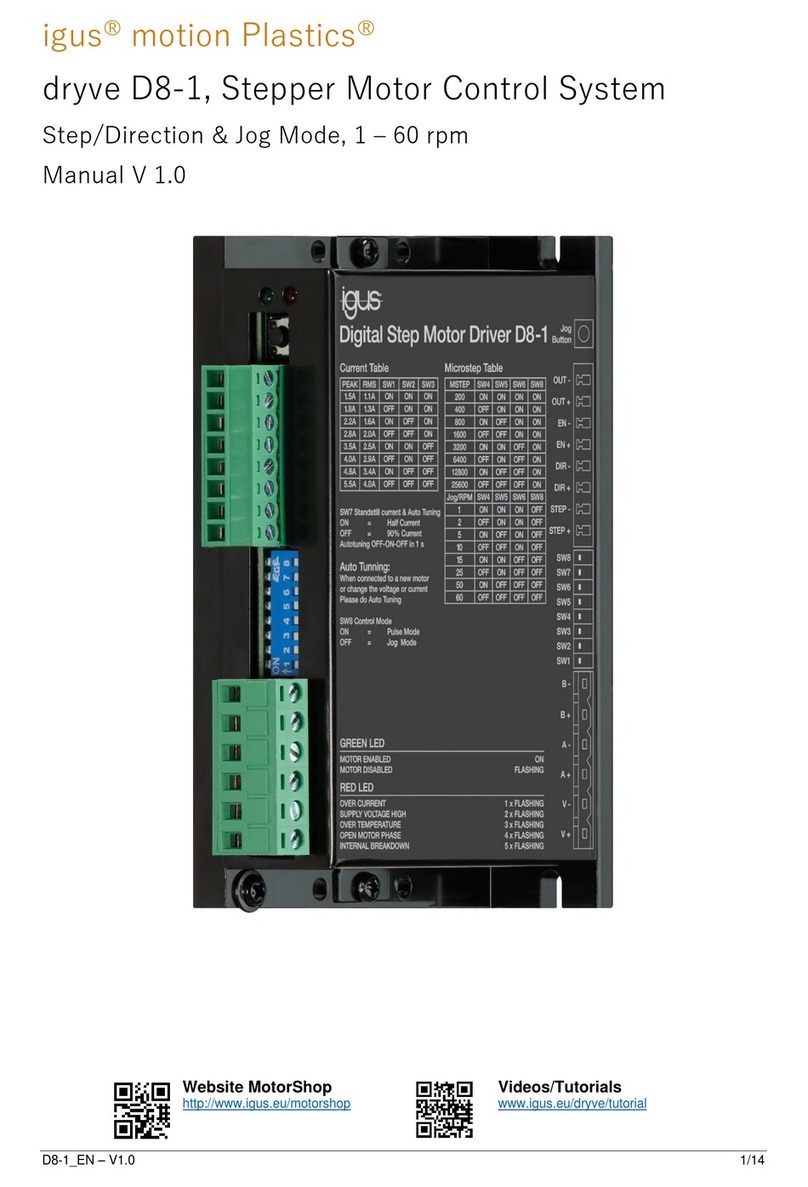

igus Motion Plastics dryve D1 User manual

Table of contents

2/121

Operating Manual dryve D1, ST-, DC-, EC/BLDC-Motor Control System - V2.4

Table of Contents

1Safety Instructions, Protective Measures and Guidelines............................ 5

1.1 Important Instructions........................................................................ 5

1.2 Qualified Personnel........................................................................... 5

1.3 Maintenance...................................................................................... 5

1.4 Safety Instructions............................................................................. 6

1.4.1 Information Classification.................................................................. 6

1.5 Electromagnetic Compatibility........................................................... 6

2Quick Setup...................................................................................................... 7

3Product Overview............................................................................................13

3.1 Operating Modes..............................................................................13

3.2 Technical Data .................................................................................14

4Installation.......................................................................................................16

4.1 Mechanical Installation.....................................................................16

4.2 Electrical Installation.........................................................................17

4.2.1 Power supply selection.....................................................................18

4.2.2 Pin Assignment ................................................................................21

4.2.3 Communication Interfaces................................................................26

5Initial Operation and User Interface...............................................................27

5.1 User Interface Connection Establishment........................................27

5.1.1 Connection Loss ..............................................................................28

5.2 User Interface Information................................................................29

5.2.1 Entering Parameters ........................................................................30

5.3 Start..................................................................................................31

5.3.1 Language.........................................................................................31

5.3.2 Measuring System............................................................................31

5.3.3 Movement Type ...............................................................................31

5.3.4 Time Units........................................................................................31

5.3.5 Configuration....................................................................................32

5.3.6 Firmware..........................................................................................32

5.3.7 Password .........................................................................................33

5.4 Motor configuration...........................................................................34

5.4.1 Motor................................................................................................35

5.4.2 User-Defined Motor..........................................................................36

5.4.3 Gear.................................................................................................37

5.4.4 Feedback .........................................................................................37

5.4.5 Closed-Loop.....................................................................................38

5.4.6 Self-Tuning.......................................................................................38

5.4.7 Brake................................................................................................39

5.4.8 Braking Resistor for EC/BLDC Motors .............................................40

5.4.8.1 Braking Resistor selection for igus motors.......................................40

5.4.8.2 Braking Resistor dimensioning for custom motors ...........................41

5.4.8.3 Braking Voltage Setting....................................................................44

5.5 Axis Configuration............................................................................45

5.5.1 Axis ..................................................................................................45

5.5.2 Motion Limits....................................................................................45

5.5.3 Limit Switch......................................................................................47

Table of contents

3/121

Operating Manual dryve D1, ST-, DC-, EC/BLDC-Motor Control System - V2.4

5.5.4 Homing.............................................................................................49

5.5.5 Analogue Absolute Feedback ..........................................................50

5.6 Communication ................................................................................51

5.6.1 Ethernet TCP/IP...............................................................................51

5.6.2 Transmission Protocol......................................................................52

5.6.3 Bus Systems....................................................................................53

5.6.4 Ethernet MAC address.....................................................................54

5.7 Inputs/Outputs..................................................................................55

5.7.1 Digital Inputs ....................................................................................55

5.7.2 Digital Outputs..................................................................................58

5.7.3 Digital Outputs Signal Characteristics..............................................58

5.7.4 Analogue Inputs ...............................................................................60

5.7.5 Digital Input Switch Characteristics..................................................60

5.8 Drive Profile......................................................................................61

5.8.1 Drive Mode Selection.......................................................................61

5.8.2 Test Function ...................................................................................62

5.8.3 Position Adoption .............................................................................62

5.8.4 Binary...............................................................................................63

5.8.5 Tipp/Teach.......................................................................................67

5.9 Oscilloscope and Controller Data.....................................................68

5.9.1 Oscilloscope Settings.......................................................................68

5.9.2 Controller Data.................................................................................69

5.9.3 Controller Data Fine-Tuning.............................................................70

5.10 Feed Rate Specification...................................................................71

5.11 Absolute Feedback...........................................................................73

5.12 Impulse check ..................................................................................73

5.12.1 Impulse Check with Physical Limitation............................................74

5.12.2 Impulse Check without Limit.............................................................74

5.13 Restore Factory Settings..................................................................74

6External Signal Exchange ..............................................................................75

6.1 Binary...............................................................................................75

6.1.1 Binary Mode Requirements..............................................................75

6.1.2 Binary Signal Sequence...................................................................76

6.2 Tipp/Teach.......................................................................................78

6.2.1 Tipp/Teach Requirements................................................................78

6.2.2 Tipp/Teach Signal Sequence...........................................................79

6.3 Step/Direction...................................................................................81

6.4 CANopen..........................................................................................82

6.4.1 Special Features of SDO/PDO Communication...............................82

6.4.2 Telegram Structure...........................................................................82

6.4.3 PDO mapping...................................................................................82

6.4.4 Network management......................................................................83

6.4.5 Necessary User Interface Settings...................................................84

6.4.6 State Machine Visualisation.............................................................85

6.4.7 Statusword.......................................................................................86

6.4.8 Controlword......................................................................................87

6.4.9 Parameter Entry...............................................................................87

6.4.10 Homing.............................................................................................88

6.4.11 Profile Position Mode .......................................................................89

6.4.12 Profile Velocity Mode........................................................................89

Table of contents

4/121

Operating Manual dryve D1, ST-, DC-, EC/BLDC-Motor Control System - V2.4

6.4.13 Cyclic Synchronous Position Mode..................................................90

6.4.14 Error.................................................................................................90

6.4.15 Object information............................................................................91

6.4.16 Overview of available objects...........................................................91

6.4.17 Detailed description of the objects for motion control.......................92

6.5 Modbus TCP Gateway...................................................................102

6.5.1 Necessary User Interface Settings.................................................102

6.5.2 Conversion of Integers into Double Word.......................................103

6.5.3 Communication Verification............................................................103

6.5.4 Byte Assignment Modbus TCP Gateway Telegram .......................104

6.5.5 RX/TX Telegram Example..............................................................105

6.5.6 Exception Codes Modbus TCP Gateway.......................................110

7Alerts and Errors...........................................................................................111

8Troubleshooting............................................................................................113

9FAQs ..............................................................................................................114

10 Accessories...................................................................................................115

11 Abbreviations................................................................................................116

12 Explanation of terminology..........................................................................116

13 Overview of input values..............................................................................118

14 Service ...........................................................................................................121

Safety Instructions, Protective Measures and Guidelines

5/121

Operating Manual dryve D1, ST-, DC-, EC/BLDC-Motor Control System - V2.4

1 Safety Instructions, Protective Measures and Guidelines

1.1 Important Instructions

Read this manual carefully before operating the dryve D1 motor control system. Familiarise with the safety instructions and

ensure that the required safety measures are followed.

This manual was created according to the best of our knowledge and belief. It is used for technical documentation and for

assisting the user during the initial operation. The warnings, cautions and instructions issued by igus® regarding the dryve D1

motor control system must in any case be passed on to the end user if the dryve D1 motor control system is used as part of an

overall system.

igus®undertakes warranties only for igus®products in accordance with the standards, norms and specifications given in this

manual. The guarantee covers only the replacement or repair of a defective dryve D1 motor control system. There is no liability

for consequential damage and consequential errors. The igus®GmbH does not take any responsibility for the integration of the

dryve D1 motor control system into the overall system. The responsibility for it lies with the plant designer or the end user.

Please observe the instructions under "Qualified Personnel". The company igus®assumes no liability for personal injury or

damage to property resulting from misuse or unauthorised technical modification of the dryve D1 motor control system.

The igus®GmbH reserves the right to make changes and improvements to the product or the technical documentation at any

time without prior notice.

The dryve D1 motor control system must only be used if:

- All information and safety instructions in this manual have been observed.

- The control system has been properly installed in a control cabinet in accordance with the instructions under Electrical

Installation (p.17)

- No changes have been made to the dryve D1 motor control system and it is in a technically flawless condition.

- The operating limits that are specified in Technical Data (p.14) are complied with.

1.2 Qualified Personnel

The operation of the product must only be carried out by qualified personnel.

- The personnel must have read and understood this manual and any other additional documentation that exists

- The personnel must be familiar with all relevant applicable standards, provisions and accident prevention regulations.

- The personnel must be able, due to their training, to anticipate or recognise any hazards that may arise when using the

control system.

- The personnel must ensure the safety of persons and objects when using the motor control system in the overall

system.

1.3 Maintenance

The dryve D1 is maintenance-free Apart from the connectors, the dryve D1 does not contain any components that the user can

replace from the outside. Never open the motor control system. If hardware problems occur, please get in touch with Customer

service (p.101).

Opening the housing will void the warranty.

Sebastian Probst

Safety Instructions, Protective Measures and Guidelines

6/121

Operating Manual dryve D1, ST-, DC-, EC/BLDC-Motor Control System - V2.4

1.4 Safety Instructions

1.4.1 Information Classification

The degree and type of hazard are marked unambiguously. All safety instructions are assigned to one of the following classes.

DANGER!

Safety instructions marked with DANGER indicate an imminently hazardous situation. A disregard of the notice inevitably

leads to a serious or even fatal accident.

WARNING!

Safety instructions marked with WARNING indicate a potential hazardous situation. Failure to observe the instruction can

possibly lead to a serious or even fatal accident or to equipment/property damage.

NOTE

Safety instructions marked with NOTE indicate a potential hazardous situation. Disregard of the notice may possibly result

in property damage.

1.5 Electromagnetic Compatibility

WARNING!

•Risk of injury due to interference with signals and devices

Disturbed signals can cause unforeseen device reactions.

Carry out the wiring in accordance with the EMC measures. Failure to follow these instructions can result in death, serious

injury, or material damage

Measures for EMC

Effect

Device assembly

Use cable clamps for the shield support,

connect metal parts over a large area.

Good conductivity due to surface contact.

Switching devices such as contactors, relays

or solenoid valves with interference

suppression units or spark suppressors (e.g.

diodes, varistors, RC elements).

Reduce mutual interference couplings.

Wiring

Keep cables as short as possible.

Avoid capacitive and inductive interference.

Do not place fieldbus cables and signal cables

for direct and alternating voltage over 60 V

together in a cable conduit.

Avoid reciprocal interference.

Earth the shields of digital signal cables at both

ends or by means of conductive connector

housings.

Avoid interference on control cables, reduce

emissions.

CAUTION!

Safety instructions marked with CAUTION indicate potential danger. Failure to comply with the notice may possibly result in

an accident or property damage.

Quick Setup

7/121

Operating Manual dryve D1, ST-, DC-, EC/BLDC-Motor Control System - V2.4

2 Quick Setup

Thank you very much,

for choosing the dryve D1 motor control system!

In the following, "quick initial operation" it is explained how to setup the dryve D1 and to control a stepper or DC-Motor with a

PC. The dryve D1 motor control system has been designed for operation with direct voltage. In this “quick initial operation” guide

a voltage of 24 V is being used.

Within just a few minutes, you will be able to operate your motor and even create your first fully automatic motion program.

Have fun!

Minimum requirements for initial operation of the dryve D1 with a PC

1. Voltage supply of 12 to 24 V with cables

2. Motor without feedback or

brake with appropriate cable

3. Ethernet cable

4. PC/Notebook

Quick Setup

8/121

Operating Manual dryve D1, ST-, DC-, EC/BLDC-Motor Control System - V2.4

Connect the components in accordance with the following diagrams and instructions. When connecting the cores, take note of

the following illustrations, which are intended to assist you.

1. Press the orange spring

into the connector by hand

or with pliers and hold

the spring down.

2. After removing the insulation, push

the cores (X1 and X5: 10 mm, X2: 8 mm)

deeply into the opening.

3. Release the orange spring

X1 Logic/Load Voltage Connector

1. Connect inputs X1.1 and X1.3 to the voltage supply

2. Connect input X1.2 to 0 V

X2 Digital Inputs Connector

1. Connect inputs X2.11 and X2.12 in accordance with the following diagram.

Quick Setup

9/121

Operating Manual dryve D1, ST-, DC-, EC/BLDC-Motor Control System - V2.4

X5 Motor Connector

For a Stepper Motor:

1. Connect inputs X5.1 - X5.4 in accordance with the following diagram.

For a DC-Motor:

1. Connect inputs X5.1 and X5.2 in accordance with the following diagram

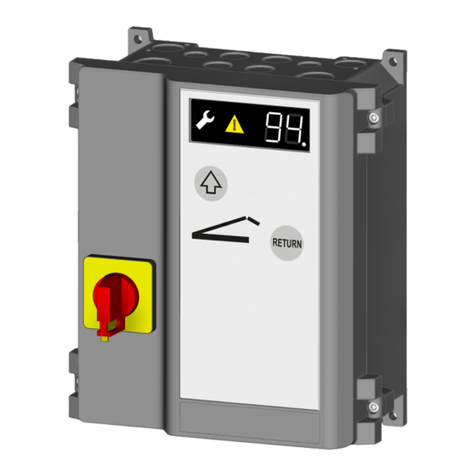

IP address

The IP address which is assigned by the PC to the dryve D1 must be entered in the browser in order to establish a connection

to the dryve D1. If the dryve D1 is set to factory settings, this is done automatically.

Start an Internet browser (Google Chrome, Microsoft Edge etc.)

1. Connect the dryve D1 to the PC with an Ethernet cable.

2. Switch on the voltage supply the connected power supply.

3. The status display of the dryve shows the IP address

(e.g. 169.254.1.0). Type the address in the address bar

of your browser and press Enter.

4. You will be forwarded to the user interface.

5.

NOTE

The IP address is displayed anew after the ethernet connector is plugged out and in again

You can navigate using the tabs in the Navigation menu on the left-hand side

Help buttons display detailed descriptions of the individual settings.

Settings are changed via entering values, use of drop-down menus or sliders.

Quick Setup

10/121

Operating Manual dryve D1, ST-, DC-, EC/BLDC-Motor Control System - V2.4

After a connection has been established, the user is automatically transferred to the Start page of the dryve. All the necessary

settings for "quick initial operation" of the system have already been made ex works.

1. Specify the motor type

2. Select the igus®article number that is shown on the motor label

3. The parameters are set automatically

4. Leave the field by clicking in a free area

5. Click on "Apply"

If an customer motor is to be used, select "User Defined Article" at the "Article Number" dropdown menu and set the parameters

manually.

Quick Setup

11/121

Operating Manual dryve D1, ST-, DC-, EC/BLDC-Motor Control System - V2.4

1. Enter the Available Stroke and the Feed Rate. The Feed Rate defines the performed movement with each motor shaft

revolution. A possible value for the Available Stroke is for example 100 mm and 60 mm for the Feed Rate.

These values must be adopted to the used linear axis.

2. The "Movement Limits" must be specified to ensure a safe and reliable operation. If the user is operating the dryve D1

for the first time, choose low values such as:

Max. Velocity: 5 mm/s

Jog Velocity: 2 mm/s

Max. Acceleration: 100 mm/s²

Quick Stop: 1000 mm/s²

Following Error: 10 mm

Positioning Window: 0 mm

Positioning Time: 0 ms

3. In addition, the Reference Method must be set. Please select “SCP (Current Position)

All necessary communication settings for "quick initial operation" have been completed ex works.

1. Activate "DI 7 Enable" to enable the motor.

The set Motor Current will now be applied to the motor.

NOTE

As soon as the motor is supplied with electric current, it generates a holding torque. Make sure that the motor can move

freely.

Quick Setup

12/121

Operating Manual dryve D1, ST-, DC-, EC/BLDC-Motor Control System - V2.4

A first test run can be carried out to

test the wiring.

1. In the drop-down menu, select the "Binary" travel profile.

2. Use the "clockwise" and "counter-clockwise" buttons

under the table to move the motor.

4. Check to make sure that the "Clockwise" button

moves the motor shaft clockwise. If this

is not the case, disconnect the power supply and

check the wiring.

Now, an example of parameterisation can be carried out.

5. Using the buttons, move the carriage or rotation arm manually

to the middle of the distance available for travel.

6. Create the motion sequence shown in the table.

7. Select Row 1 by clicking in the number field of the row.

8. Start the program with the "Start" button.

The program can be stopped with the "Stop" button. If the program were to be started again,

it would continue from the marked row.

For igus®motors, the motor controller data have been set appropriately by default.

For user-defined motors, the controllers must be parameterised.

Use the help notes provided in the manual.

Congratulations!

You are now familiar with the basic functions of the dryve D1.

Product Overview

13/121

Operating Manual dryve D1, ST-, DC-, EC/BLDC-Motor Control System - V2.4

3 Product Overview

Ready to use instantly

The igus®dryve D1 uses standard commercially available Ethernet technology and therefore can communicate directly with

your network or a control unit (PC or PLC) via a standard Ethernet cable. The user interface is displayed in a browser of your

choice, without having to install any additional software. This makes it possible to parameterise the igus®dryve D1 motor

controller in an extremely short time.

Easy to control

You can use the simple intuitive user interface to parameterise positioning movements, accelerations and velocities of your

linear axis without the need of having any prior knowledge. Programs for continuously recurring movements can be created in

just a few seconds. A "Teach" function makes it possible to incorporate current actuator positions into the parameterisation with

just one click of the mouse.

Industry standards

The standard communication protocols CANopen and Modbus TCP Gateway make it very easy to connect the system to

industrial controllers such as the programmable logical controllers (PLC) as of Siemens or Beckhoff. The ten digital inputs, 5 of

which are binary coded for the preselection of 32 positioning movements, and five digital outputs enable extremely easy

communication with higher-level industrial controllers as well as with low-price open-source modules such as an Arduino or

Raspberry Pi.

Powerful technology

The igus® dryve D1 supports stepper, DC and EC/BLDC-Motors in Open-Loop as with Closed-Loop technology. With the

sinusoidally commutated Closed-Loop, a Stepper Motor can be operated as a servo motor. Due to the Closed-Loop, the Motor

Current is controlled according to the load case, because of which the operating temperature of the dryve D1 and the connected

motor can be lowered.

To optimally attune the igus®dryve D1 to a motor, current, velocity and position control parameters are able to be tuned. In

addition an automatic Step Mode selection is available.

The system can be set to the "zero point" by different external and internal homing methods. Position monitoring with automatic

Following Error correction and Closed-Loop control is available via different Feedback systems. The supported load voltage of

up to 48 V ensures high motor velocities, whereby the high rated current of 7 A and peak currents of up to 21 A (depending on

type of motor) enable powerful and dynamic movements.

I²T motor protection

To protect motors against thermal overload, the igus®dryve D1 is equipped with I²T protection for overload monitoring.

I²T protection makes it possible to safely operate the motor for a certain time even if used with overload conditions.

3.1 Operating Modes

In the following section, the different operating modes of the dryve D1 motor control system are described. Due to the different

operating modes, the arrangement of the electric wiring changes depending on the intended application.

Binary

The "Binary" operating mode offers up to 32 individual positioning movements parameterised with different motion types and

movement data such as accelerations and velocities. It is possible to generate a simple programme sequence executed via the

user interface or control it entirely with a higher-level control system via the Digital Inputs/Outputs

In addition, the target position of the command can be specified in the absolute reference system of the axis or relative to the

current position.

It is possible to execute manually controlled movements via the user interface.

Tipp/Teach

With the "Tipp/Teach" mode, positioning movements can be executed by external switches. The motor can be moved manually

with these external switches in the desired direction at a pre-set acceleration and velocity.

Up to 8 individual positioning movements can be pre-set via the user interface. The target positions can be altered with the

external switches without the user interface being used.

Step/Direction

In the "Step/Direction" mode, a step frequency and a direction signal are applied to the dryve D1 motor control system by a

master controller. The acceleration and the speed are fed to Digital Input 1 and the movement direction is fed to Digital Input 2.

BUS communication

The dryve D1 motor control system can be controlled by an external higher-level control system via the CANopen protocol or

the Modbus TCP Gateway protocol.

Product Overview

14/121

Operating Manual dryve D1, ST-, DC-, EC/BLDC-Motor Control System - V2.4

3.2 Technical Data

Mechanical Data

D x W x H in millimetres, incl. connectors & mounting elements

124 x 31 x 139

Weight in grams

200 g

Electrical Data

CAUTION!

•Risk of destruction

An operating voltage above the voltage indicated in the technical data will destroy the dryve D1

Select an operating voltage within the voltage range specified in the technical data.

Induced voltages from other electrical loads and/or motors may result in a function interference. Allow corresponding safety

reserves and countermeasures.

Make sure that your voltage supply is energy feedback protected if the logic voltage and load voltage are supplied from the

same power supply unit or from the same transformer.

CAUTION!

•Danger of burning

The housing of the dryve D1 motor control system as well as the driven motor may reach very high temperatures.

Revision

HW: RE, FW: G

Voltage Supply

Logic

12 to 24 V, max. 26 V

Load

12 to 48 V, max. 50 V

Digital I/O

5 to 24 V, max. 26 V

Current Drain Logic

Min. 75 mA to 225 mA

Current Drain Load

5 mA to 7 A, max 22 A (Boost)

Current Drain Digital I/O

35 mA to 1,1 A

Motor Types

ST

2 Phase Stepper Motor, bipolar

DC

DC Motor

EC/BLDC

Electronically Commutated Motor

Continuous Motor Current

7 A

Boost Current

Output Duration

Max. 2 s

ST

10.5 A

DC

14 A

EC/BLDC

21 A

Load Power Output

Max. 340 W

Peak Power Output

Max. 1000 W

Dissipation Loss

Min. 2,5 W (idle)

Max. 15 W (full load)

Max. Velocity

Stepper

25,000 steps/s

DC

Motor dependent

EC/BLDC

Min.14,000 rpm

Feedback

Permissible Feedback Types

5 V

Internal Voltage Source

5V ±10%

50 mA to 120 mA

Product Overview

15/121

Operating Manual dryve D1, ST-, DC-, EC/BLDC-Motor Control System - V2.4

Feedback

Internal Voltage Source

Short Circuit Protected

Resolution

1 –4096 increments

Encoder Input Frequency

Min. 300 kHz

Hall Sensor Input Frequency

5 kHz

Holding Brake

Voltage output

24 V

Current output

Max. 1 A

PWM at 48 V UBat X 1.1

312 kHz

Braking Resistor

External resistor between X5.4 and X5.5

24 V at X1.1

Min. 0,8 Ω

48 V at X1.1

Min. 1,7 Ω

Frequency

24 kHz

Overload protection shut off

After 1 s permanent trigger

Motor and encoder cable lengths

< 30m

Digital Inputs

10 Digital Inputs

Short-Circuit Protected

Galvanically Separated by Optocoupler

ULow 10% UBX2.11

UHigh 60% UBX2.11

PNP

Pull-Down, internal

NPN

Pull-Up, internal

Maximum Frequency DI 1 and DI 2

25 kHz

Maximum Frequency DI 3 to DI 10

100 Hz

Debounce Filter DI 1 to DI 10

(not at Step/Direction Mode)

10 ms

Current Drain

5 V at X2.11

5 mA

24 V at X2.11

8 mA

Digital Outputs

5 Digital Outputs

Short-Circuit Protected

Galvanically Separated by Optocoupler

PNP

Pull-Down, internal

Output Current

Max. 200mA

Output Voltage

UBat X2.11

Analogue Inputs

Voltage Interval

± 10V

Input Resistance

50 kΩ

Accuracy

± 0.1 V

Signal Filter

16 ms, level dependent

± 10 V Signal

12 Bit

0-10 V Signal

11 Bit

Internal Voltage Supply

10 V ±2%

Max. 15 mA

Regulated

Short Circuit Protected

External resistor between X4.1 and X4.4

700 Ω to 50 kΩ

Installation

16/121

Operating Manual dryve D1, ST-, DC-, EC/BLDC-Motor Control System - V2.4

Environmental Conditions

WARNING!

- Danger of malfunction

- Fire hazard

- Explosion hazard

- Danger of electric shock

Never operate the dryve D1 motor control system in water or in an aggressive, flammable or explosive atmosphere.

Ambient Temperature

Operation

-20 °C to +45 °C

Transport

-40 °C to +60 °C

Storage

-40 °C to +60 °C

Relative Humidity

≤ 90 %, non-condensing

Protection Class

IP 30

Degree of soiling according to EN 61010

1

MTTF value @ 25°C

64,72 Years

4 Installation

4.1 Mechanical Installation

- Installation in a control cabinet by mounting it on a TS 35 supporting rail (EN 50022) or by removing the mounting clip

and screwing the base of the housing directly onto a mounting plate.

- The device must be aligned vertically. For horizontal alignment, the maximum power must be reduced by 30% to

prevent overheating

- The installation site must be free of extreme vibrations or shocks.

- Minimum free space above and underneath the device: 50 mm

- The ventilation openings are to be kept free

- 35 mm of space for plug-in connectors and cables must be kept free in front of the device.

- If several dryve D1 devices are placed next to each other, a space of 10 mm must be kept in between (applies for

continuous operation)

- If several dryve D1 devices are placed without space in between, the maximum continuous current must be reduced to

5.5 A or an active cooling system must be used (applies for continuous operation)

- The heated air flow of other devices and components must not be led through the area of the dryve D1.

Installation

17/121

Operating Manual dryve D1, ST-, DC-, EC/BLDC-Motor Control System - V2.4

4.2 Electrical Installation

WARNING!

- Danger of electrical voltage

- Danger of electric arcs

Danger of injury and destruction of components.

Always turn off the power before disconnecting or making electrical connections in the system. Secure the power supply

against restart.

After switching the device off, wait at least 5 minutes. Check for the absence of voltage before working on the system.

Danger of electric arcs with improperly mounted electrical connections.

Wires connected to the dryve D1 must not have exposed wire ends without insulation. Check all connections for being

secured.

In the event of a fault, the motor housing can carry high currents. Connect the motor housing to the ground conductor via the

motor mounting components. In this regard, please observe the instructions in EN 60204-1.

CAUTION!

The maximum current of a Stepper Motor can be above the indicated rated current. The actual occurring current must be

considered for installation.

Any current setting are made at your own risk.

Installation

18/121

Operating Manual dryve D1, ST-, DC-, EC/BLDC-Motor Control System - V2.4

NOTE

Follow the instructions regarding PELV circuits (p.20) and use suitable components for earthing.

NOTE

The logic voltage does not supply the motor windings. If the logic voltage supply collapses, the motor will stop in an

uncontrolled manner or might even accelerate if build in in vertical or rotating applications.

4.2.1 Power supply selection

For the correct dimensioning of the power supplies to be used, various aspects must be considered

1. Number of used motor controller per power supply

2. Maximal current draw of each motor (consider the set Boost)

3. Maximal current draw of used peripheral devices (e.g. sensors and other devices)

4. Maximal current draw of the Logic

The current draw must be added voltage wise. This sum defines the minimal current supply capacity of the power supply.

NOTE

If different power supplies are used for the load and logic voltage, the grounds of both power supplies must be connected to

create a common potential.

CAUTION !

The connection terminals are designed for single wires.

A firm connection cannot be guaranteed due to improper multiple occupancy. There is a risk that wires may slip out of the

terminals and cause short circuits.

If several signals/wires have to be connected to one terminal, they must be brought together via an external terminal and

connected from there with a single wire.

Installation

19/121

Operating Manual dryve D1, ST-, DC-, EC/BLDC-Motor Control System - V2.4

The arrow marks pin 1

Installation

20/121

Operating Manual dryve D1, ST-, DC-, EC/BLDC-Motor Control System - V2.4

Connector

Pin

Assignment

Description

X1

Logic/Load-Voltage

1

12 - 48 V Load

Motor Voltage Supply (necessary for operation)

2

0 V Logic/Load

Common Ground (necessary for operation)

3

12 - 24 V Logic

Controller Voltage Supply (necessary for operation)

X2

Digital Inputs

Binary

Tipp/Teach

Step/Direction

1

Digital Input 1

Bit 0

Bit 0

Step

2

Digital Input 2

Bit 1

Bit 1

Direction

3

Digital Input 3

Bit 2

Bit 2

-

4

Digital Input 4

Bit 3

Jog left

-

5

Digital Input 5

Bit 4

Jog right

-

6

Digital Input 6

Start

Start/Teach

-

7

Digital Input 7

Enable

Enable

Enable

8

Digital Input 8

Limit Switch positive

Limit Switch positive

Limit Switch positive

9

Digital Input 9

Limit Switch negative

Limit Switch negative

Limit Switch negative

10

Digital Input 10

Stop/Reset

Stop/Reset

Reset

11

5 - 24 V

External I/O Supply necessary for operation)

12

0 V

External I/O Supply (necessary for operation)

X3

Digital Outputs

1

Digital Output 1

Ready

2

Digital Output 2

Active

3

Digital Output 3

Referenced

4

Digital Output 4

Alert

5

Digital Output 5

Error

X4

Analog Inputs

1

10 V

Supplied by controller

2

Signal 1

Velocity and position setpoint

3

Signal 2

Position feedback

4

0 V

Supplied by controller

X5

Motor/Brake/

Braking Resistor

1

A (ST), U (EC/BLDC), + (DC)

Motor connection

2

A/ (ST), V (EC/BLDC), - (DC)

Motor connection

3

B (ST), W (EC/BLDC)

Motor connection

4

B/ (ST), RBrake (EC/BLDC)

Motor and Braking Resistor connection

5

Ground, RBrake (EC/BLDC)

Ground and Braking Resistor connection

6

24 V Holding Brake

Holding Brake connection

7

0 V Holding Brake

Holding Brake connection

X6

Feedback

1

5 V

Feedback

2

0 V

Feedback

3

A

Feedback

4

A/

Feedback

5

B

Feedback

6

B/

Feedback

7

N

Feedback

8

N/

Feedback

9

H 1/U (EC/BLDC), 1 (DC)

Feedback

10

H 2/V (EC/BLDC), 2 (DC)

Feedback

11

H 3/W (EC/BLDC)

Feedback

X7

CANopen

1

-

NC

2

CAN_L

CAN Signal Low

3

CAN_GND

CAN Masse

4

-

NC

5

-

NC

6

-

NC

7

CAN_H

CAN Signal High

8

-

NC

8

-

NC

X8

Ethernet

Modbus TCP Gateway

Standard assignment according to

TIA-568A und TIA-568B

X9

Status Display

General electrical installation information

The dryve D1 is designed for DC voltages.

All voltage specifications listed in this operating manual therefore are to be considered as DC voltage.

This manual suits for next models

1

Table of contents

Other igus Control System manuals

Popular Control System manuals by other brands

Johnson Controls

Johnson Controls System 450 Series Technical bulletin

Inovance

Inovance Monarch NICE Series user guide

Maple Systems

Maple Systems HMC7030A-L installation guide

Tormatic

Tormatic HA MS 400V Assembly and operating instructions

RichAuto

RichAuto AutoNow F141 user manual

Badger Meter

Badger Meter MDS 2000 user manual