Table of contents

SMART CLEARER - i -

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

TABLE OF CONTENTS

INTRODUCTION

How to use this manual.............................................................................................................................................. I.1

Symbols used .............................................................................................................................................................. I.1

Chapter 1 - OVERVIEW

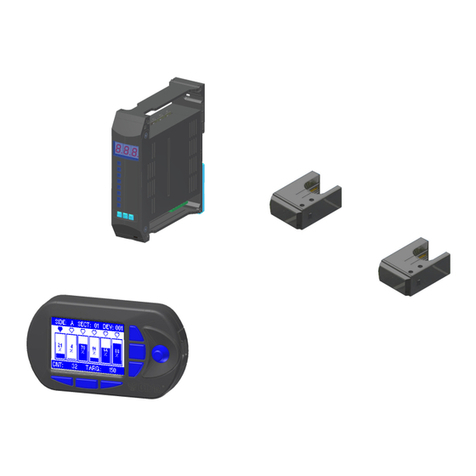

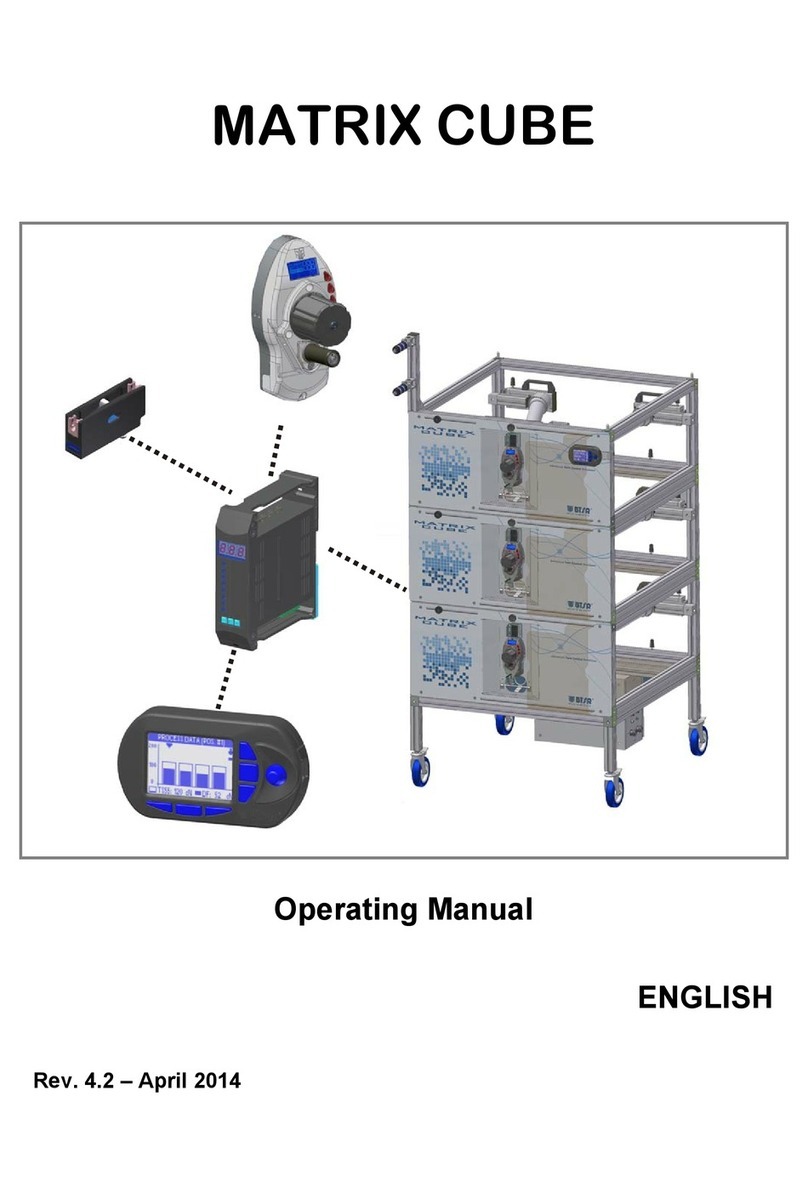

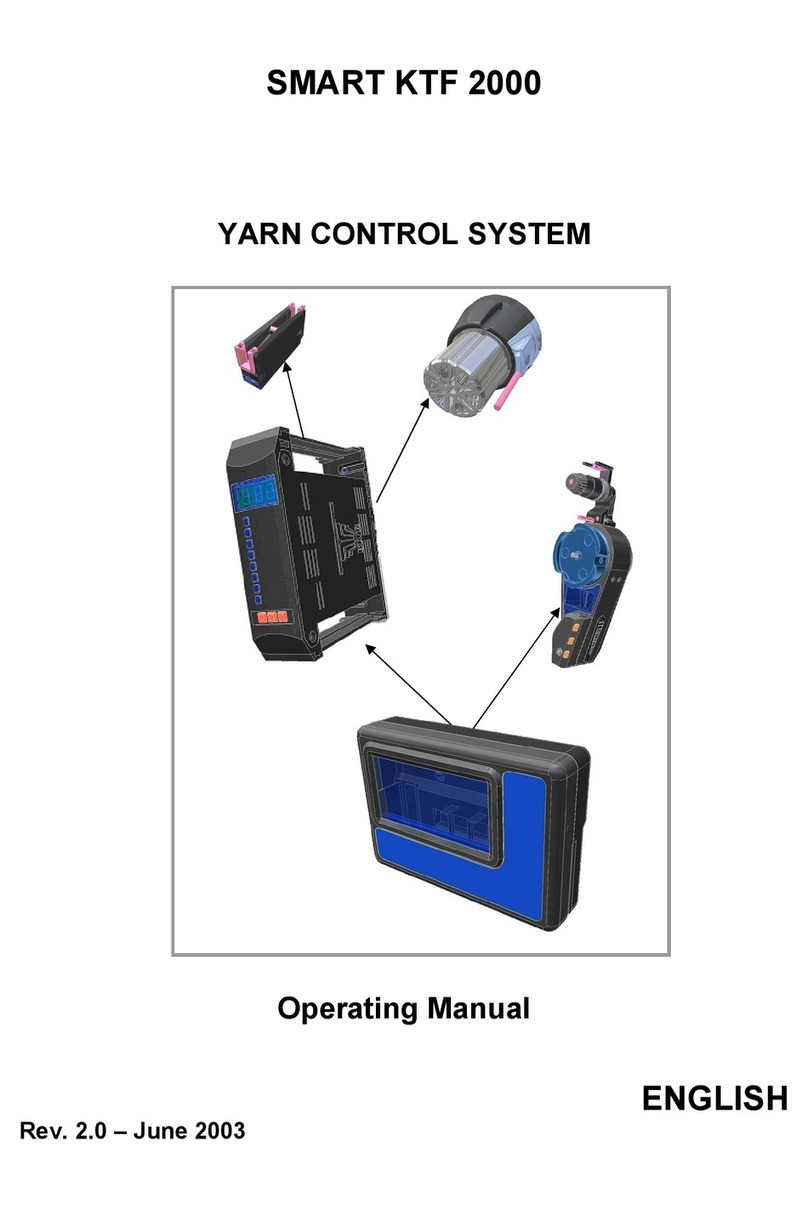

System components ....................................................................................................................................................1.1

System’s Operation Principles ..................................................................................................................................1.1

Special Features of SMART CLEARER system .....................................................................................................1.1

General Features of SMART systems ......................................................................................................................1.2

Chapter 2 –TECHNICAL DATA AND INSTALLATION

Technical Features .....................................................................................................................................................2.1

Installation ..................................................................................................................................................................2.1

Interface Connectors on SMART CLEARER.....................................................................................................2.2

Connection Cables and Power Supply Devices....................................................................................................2.3

Example of Generic Application Connection.......................................................................................................2.4

Chapter 3 – OPERATION

SMART CLEARER Terminal Features ..................................................................................................................3.1

ISSC.. Sensor Features ..............................................................................................................................................3.4

Function of the ISSC.. Sensors..................................................................................................................................3.4

Interface specification ...............................................................................................................................................3.5

Interpretation of the signalling lights located on the sensors .................................................................................3.6

Parameters that affect the sensor detection features ..............................................................................................3.7

Preliminary operations for using the SMART CLEARER terminal...................................................................3.11

Operating Sequences .............................................................................................................................................3.12

Machine Start Procedure.........................................................................................................................................3.13

Preliminary Instructions for the Correct Use of ISSC.. Sensors......................................................................3.13

Restart after an Alarm Condition on a Single Position ....................................................................................3.13

Enabling the SETUP Menu Functions (CONFIG)................................................................................................3.14

Enabling the SETUP Menu Functions (NEW, MODIFY, ERASE).....................................................................3.15

Enabling the WORK Menu Function.....................................................................................................................3.16

Enabling the READ Menu Function ......................................................................................................................3.16

CONTROL Function ..............................................................................................................................3.17

DEVICE Parameters setting for Initial installation ........................................................................3.18

DCNTR Configuration of Sensor delay time before entering the Control status........................3.19

lk-ULK Enabling/Disabling the Touch Light button operation...................................................3.20

MO-CTR Configuring the system operation in either MONITOR mode

or CONTROL mode ..........................................................................................................3.21

EN-NCO Configuring the level of ENABLE signal as Normally Closed or Normally Open.......3.23

ST-NCO Configuring the level of STOP signal as Normally Closed or Normally Open.............3.24