Ihlas Ev Aletleri aura Cebilion iflow 101IFL User manual

Direct

Flow

USER MANUAL

D

I

R

E

C

T

F

L

O

W

R

E

V

E

R

S

E

O

S

M

O

S

I

S

Table of Contents

FIELD OF USE 3

TECHNICAL SPECIFICATIONS 3

OPERATING PRINCIPLE 3

PARTS AND FUNCTIONS 4

INSTALLATION SCHEME 5

WATER CONNECTION 6

INSTALLING THE FAUCET 6

WASTE WATER CONNECTION 7

PRE-TESTS 7

POINTS FOR ANNENTION 7

MEINTENANCE 8

RECOMMENDED FILTER REPLACEMENT PERIODS 8

TROBLESHOOTING 9

DIGITAL SCREEN FUNCTIONS 10

Thank you for choosing our product. We want

Cebilon Reverse Osmosis System, manufactured

in modern facilities with high quality standards

to provide you with the best efficiency. Therefore,

please read the entire user manual carefully and

keep it as a reference.

Dear Customer,

3

Operating principle

The first filter of the system is the 5-micron sediment filter where the solid particles

are retained. The water from the sediment filter is passed through the carbon

filter. Granular Active Carbon (GAC) filter retains organic matter especially free

chlorine and eliminates unwanted odors, carbon and other particles that may

escape from the filter, is passed through the 1 micron Sediment Filter and it is

ensured that the pre-membrane filter is even more suitable. This is also a factor

affecting the life of the membrane. The water cleaned in three pre-filters, solid

ions dissolved in the membrane that is the basis of the RO water treatment

system, small particles, bacteria, viruses are retained to a large extent and given

to the waste water. Among these ions are many ions such as heavy metals,

sodium, lead, arsenic, nitrate, asbestos, etc. While the waste water containing the

undesirable substances are discharged from one line of the membrane running

with cross-flow method, waterreceived from the other line of the cross-flow is

collected in a pressurized tank. The amount of waste water should always be

more than the clean water so that the membrane works in a healthy way and

has a long life. Through the ready the water in the tank, water is supplied faster.

Through the mineralized pos carbon filter, which filters out unpleasant odors ende

tastes that may have been left in the water and adds useful minerals to the water.

Technical Specifications

DAILY CAPACITY

PURIFICATION RATE

EFFICIENCY RATIO

RECOVERY RATING

PUMP FLOW RATE

PUMP PRESSURE

POWER SUPPLY PUMP

PRODUCT SIZE

BOX SIZE

GROSS WEIGHT

330 gpd (1.250 L/day)

%85-%98

% 4134,89%

% 45

3,2 L/min.

110 psi-150 psi (758-1.034 kPa)

24 V DC, 4A

374x452x207 mm

395x585x215 mm

11 kg

This appliance is used to obtain drinking water

from the mains water that have passed through

the municipal treatment processes. This water

should be microbiologically safe, subjected to the

necessary disinfection. If the parameters of the

inlet water are within the following ranges efficient

operation of the appliance is ensured. Systems

designed differently for waters such as sea water,

well water, muddy water etc. with a very high TDS

value are also available.

Fields of use

INLET WATER FEATURES

TEMPERATURE

OPERATING

RESSURE

pH RANGE

MAXIMUM FE

MAXIMUM TDS

TURBIDITY

HARDNESS

5 ˚C - 38 ˚C / (38 ˚F - 100 ˚F)

40 psi-145 psi / (2,8 bar-10 bar) /

(275 kPa - 1.000 kPa)

3-11

0,2 (ppm=mg/L)

1.250 (ppm=mg/L)

5 NTU

17 ˚Fr-10 ˚dH - 170 mg/L CaCO3

• Do not use this system with any water that is microbiologically unsafe, that does

not have adequate disinfection before or after operation or that of the quality is

unknown.

• Cebilon I’flow contains critical components that are required to be replaced

periodically to purify the total dissolved solid materials (TDS) efficiently. To check

the efficiency of the system, water from the appliance must be periodically tested.

4

Low Pressure Switch, if the water is cut or if the

pressure is lower than 0.2 bar (3 psi), it prevents

unnecessary operation of the pump.

5M Sediment Filter, it retains the substances and

particles floating in water to make the water clear.

Pressure Pump, brings the pressure of the water

from the pre-filtration to the level required for the

operation of the membrane.

Carbon Filter, retains free chlorine, organic

substances and unpleasant odors.

1M Sediment Filter / Carbon Filter, it retains the

substances and particles floating in water to make

the water clear.

Mineralized Post Carbon Filter provides mineral

to the clean water collected directly from the

membrane before if flows from the faucet, enriches

the water and regulates the pH. THROTTLE ensures

formation of required pressure in the membrane

by restricting flow so that the membrane can

perform the separation process. It is located on the

line where the waste water is drained.

Clean Water Faucet is where clean water is taken.

Pump Adapter is the power supply of the pump, it

converts the mains voltage to 24 V DC.

Water Leakage Shut off Closes the water inlet

mechanically in case of water leakage.

Automatic shut-off Valve closed the inlet water to

the membranes when pumps stop

Membrane Filter is the place where the reverse

osmosis occurs. A long film made of a

semi-permeable material is wrapped onto a reel in

two layers. These two layers are merged together

with a separator between the edges of this film with

two layers and it is closed to water passage. It is like

a closed long narrow bag except its end wrapped

on the reel with rowed holes that is on the end

which allows clean water output only. This double

layer film is wrapped onto a reel. Through the

separator film placed between the windings, dirty

water reaches all surfaces of this bag, clean water

enters the bag under pressure and taken from the

outlet holes. While dirty water passes by the film

surfaces with a flow called cross-flow, a part of

water passes through the internal part of the film

as clean water.

High Pressure Switch is stops the pump when the

pessure of clean water line reaches 2,6bar (38 psi).

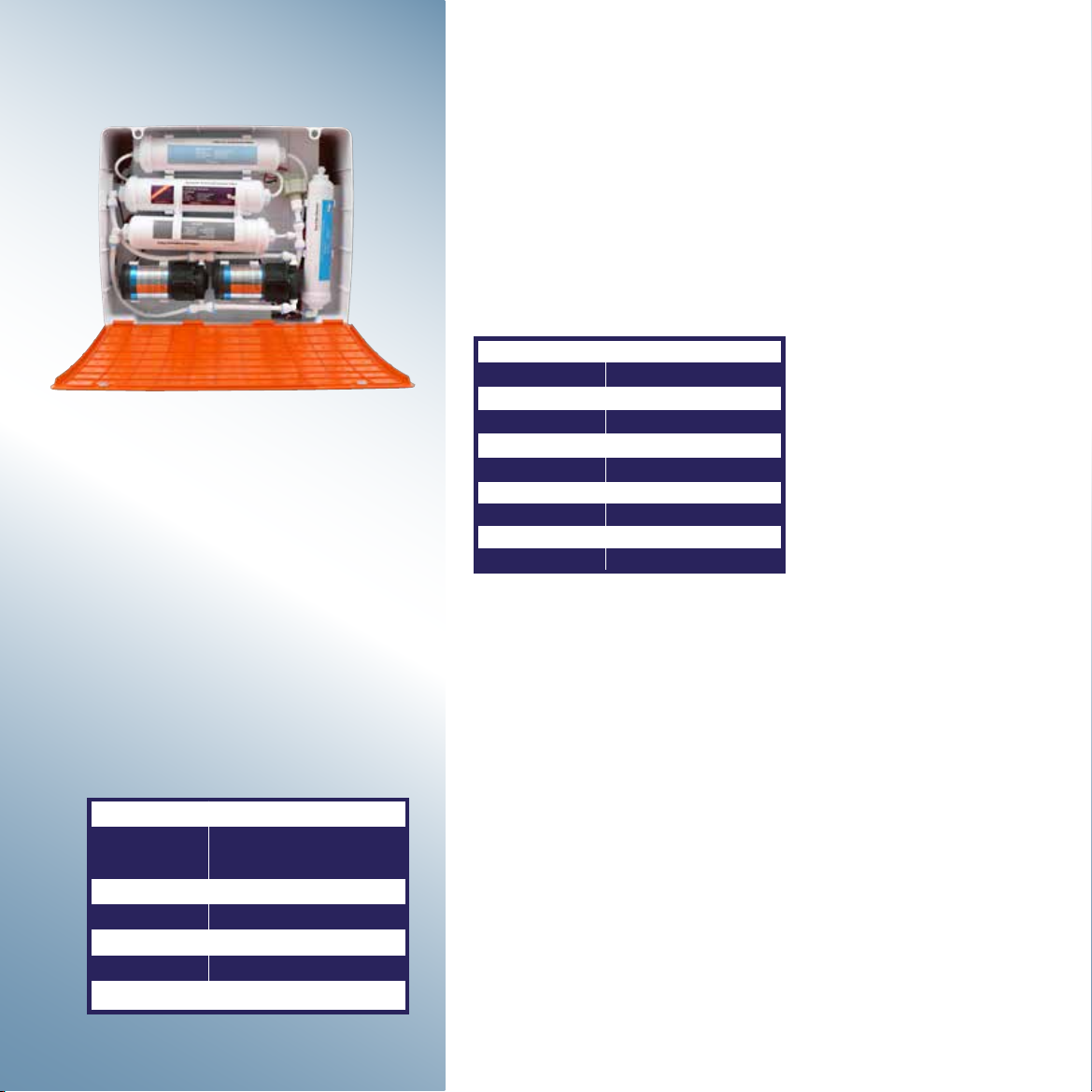

Parts and functions

Figure 2. RO System Diagram

Mains water

Waste water

6 4

55

8

9

9

10

12

14

11

Mains Water

Water with Sediment Eliminated

Water with Sediment and Chlorine Eliminated

RO-Water

Waste Water

1- Adapter

2- Water leakage shut off

3- Low pressure switch

4- 5M sediment filter

5- Pump (pressure pump)

6- Carbon (Granul Active Carbon) filter

7- 1M sediment filter

8- Automatic shut-off valve

9- Membrane filter (100 GPD)

10- Membrane filter (130 GPD)

11- Flow restrictor

12- Mineralized post carbon filter

13- High pressure switch

14- Clean water faucet

1- 100 GPD Membran Filter

2- 100 GPD Membran Filter

3- 130 GPD Membran Filter

2

3

1

5

Installation

scheme

Please make sure that, flushing the filters, before you

start using the device. For filters flushing, you can follow

the instructions below.

!

WARNING

1- Measures should be taken against freezing.

2- Waste water should not interfered with.

3- When muddy (clay) water comes from the mains,

close the water inlet of theappliance.

4- If a water supply other than the mains will be used,

you must receive a drinking water report from relevant

institutions.

5- If it is a water source other than the mains water,

make sure that the disinfection process is performed.

6- Filters are considered as supplies and are outside

the scope of warranty.

7- Free chlorine in water may cause membrane filter in

the system to deteriorate.

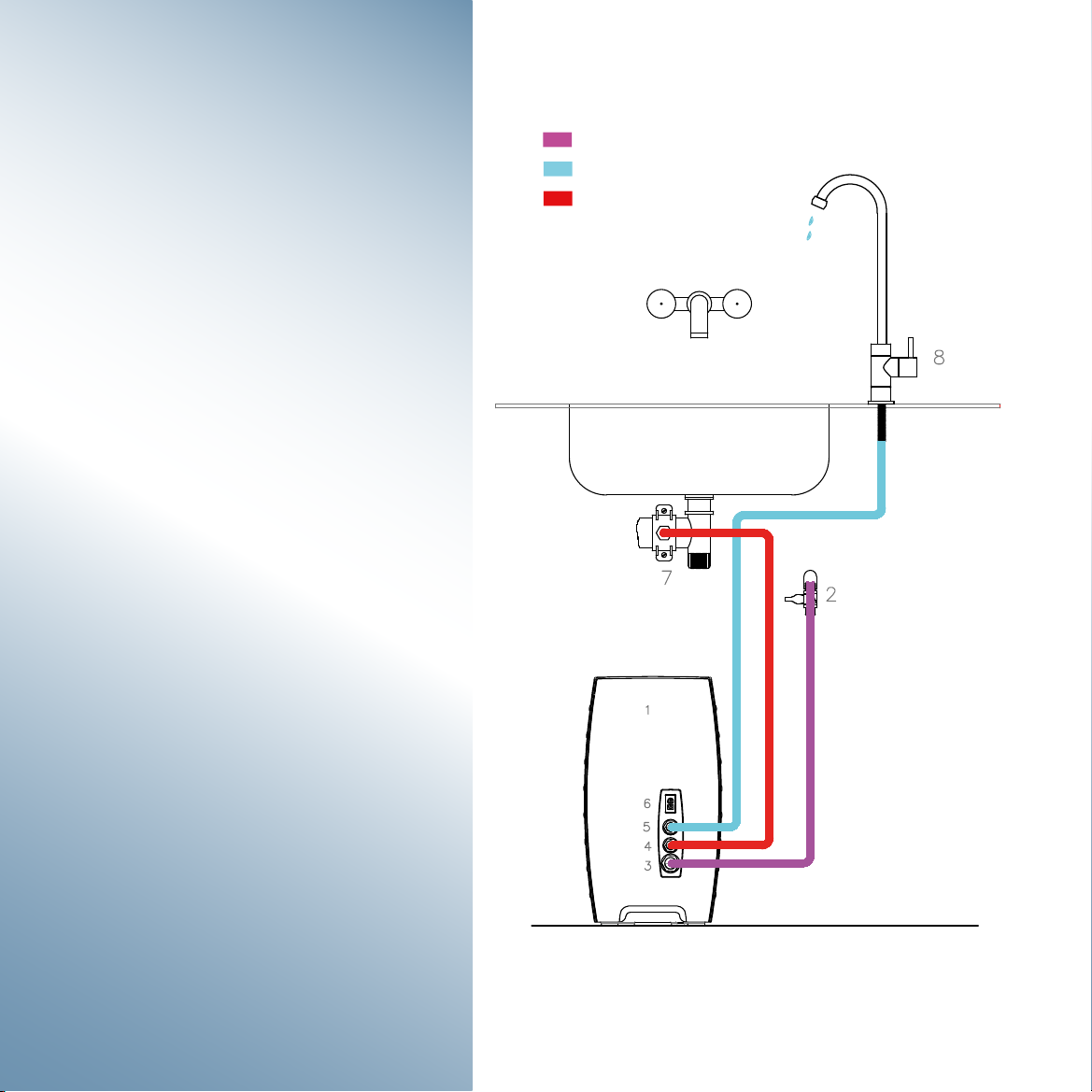

Mains Water

RO-Water

Waste Water

1 Cebilon

2 Water Inlet Valve

3 Appliance Water Inlet

4 Waste Water Outlet

5 RO Water Outlet (Clean Water)

6 24 V Input

7 Waste Water Bracket

8 Clean Water Faucet

Figure 4. RO Installation Scheme

6

Installing the faucet

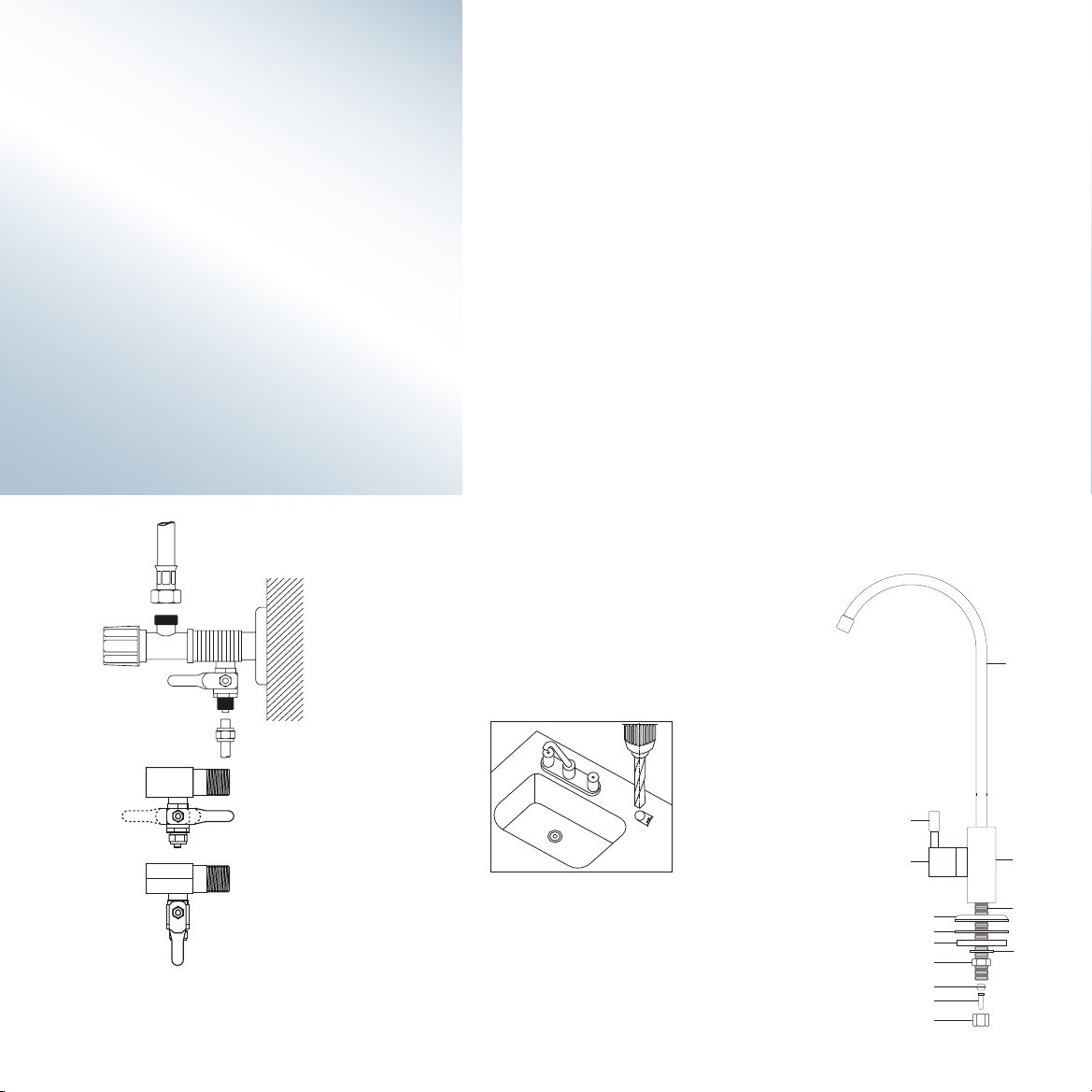

• Close the mains water from the apartment inlet valve.

• After draining the water left in the pipes from proper

places, mount the three-way adapter to the mains by

ensuring the sealing.

• First, mount the 1/4 ball valve to the three-way

adapter by wrapping a teflon tape in a position so that

the valve is opened and closed easily (Figure 5.a).

• Connect the water inlet hose to the ball valve (Figure 5.b).

• Make sure the ball valve is closed (Figure 5.c).

• Open the mains water, check whether there is any

leakage (Figure 5.d).

• Place the appliance on a suitable place underneath the

counter in upright position.

Clean water faucet should be mounted carefully in terms of use and aesthetics.

If the counter or kitchen sink will be drilled, drilling process should be proceed-

ed after the dimensions are obtained so as to install the washers, nuts and

unions under the counter or kitchen sink (Figure 6). Otherwise, drillingmay be

incorrect.

The location to be drilled may be granite, marble, concrete or stainless sink. If

the counter is granite, it must be drilled with a 20 mm diameter bore bit. Bore

bit is attached to the end of the drill and it is set to low speed. Water is poured

on the ground to be drilled (do not drill without water). Bend the bore bit as 45

degrees and press slightly, it makes a trail on the granite. Then it is brought to

an upright position slowly without lifting. When it reaches the upright position,

drilling iscompleted by applying enough force. If the bore bit is not kept

constant when we start drilling, parts can break off from the granite surface. The

o-ring on the faucet's mirror cannot ensure sealing and may cause the water

leakage down from the counter. Marble countertops can be drilled by the same

drilling bit or bore bit. Concrete countertops are drilled with a contact tip and

hammer drill. If concrete is coated with tiles, a pre drill is made

with a small-diameter drill bit to avoid cracking the tiles.

Bore bit for the stainless sinks is different.

Water Connection

d

b

c

a

Figure 5. Water connection fittings

Figure 6. Faucet

1 - Faucet Pipe

2- Faucet body

3- Handle

4- Hub cover

5- Faucet screw

6- Escutcheon plate

7- Tap oring

8- Bottom oring

9- Mounting washer

10- Compression nut

11- 1/4” ferrule

12- 1/4” Insert

13- Compression nut

1

2

5

6

7

89

10

11

12

13

3

4

7

Waste water

connection

Pre-tests

• The appliance is designed for domestic use.

Parts such as storage tank, waste water hose,

faucet must be attached indoor environment.

Necessary measures should be taken to prevent

freezing and waste water flow.

• Use the appliance after the necessary measures

are taken in microbiologically unsafe or

disinfected waters.

• The appliance must be supplied with its own

power adapter.

• If the appliance will not be used for a long time

(such as more than 1 month), the inlet water

valve must be closed (figure 9), the adapter

should be plugged out and the authorizes service

must be called to disinfect the appliance when

reactivating.

• When there not anyone in the house, close the

water inlet valve of the appliance for safety

purposes (Figure 8).

• The appliance must not be interfered for repair

and maintenance purposes. Otherwise, it falls out

of the warranty scope, these operations are

carried out by Cebilon Authorized Service.

• As the inlet water temperature changes, the

amount of clean water to be received and the

efficiency may change. Therefore, water obtained

may be low in winter and high in summer.

• In any unfavorableness (Figure 8) close the

water inlet valve and consult Cebilon Authorized

Service.

• The adapter is plugged in after it is placed

into the place where "24 V DC" is written on

the appliance. In this case, it will not work

due to lack of water and pressure in the

system.

• Clean water faucet is turned on.

• Mains water is supplied to the system by

opening the 3/8 ball valve (Figure 8). It is

seen that the pump is running.

• The faucet is closed after a small amount

of water flows from the clean water faucet.

• After the operation of the pump stops,

leak test of all the connections in the

system is performed.

• This system should be used after the

twenty-four hours washing process,

(Installation is done after this process is

carried out by an authorized service.)

• If waste water pipe of the sink is not a

throat hose but a 40 mm plastic pipe, it

is mounted in a 3/8" clamp sealing

sponge affixed state (Figure 7a).

• The flush is drilled from the hole of the

clamp in 8 mm diameter on the same

axis (Figure 7b). One end of the 3/8"

waste water faucet is connected to this

clamp and the other end is connected to

the 3/8" waste water union.

• If waste water hose will be mounted on

the 50 waste water installation, a 3/8"

clamp will be mounted and the waste

water hose will be mounted on its

location above this. A seal must be used

when mounting the adapter to the waste

water installation.

Points for

Attention

a

b

Figure 8. Mains inlet valveFigure 7. Waste water connection

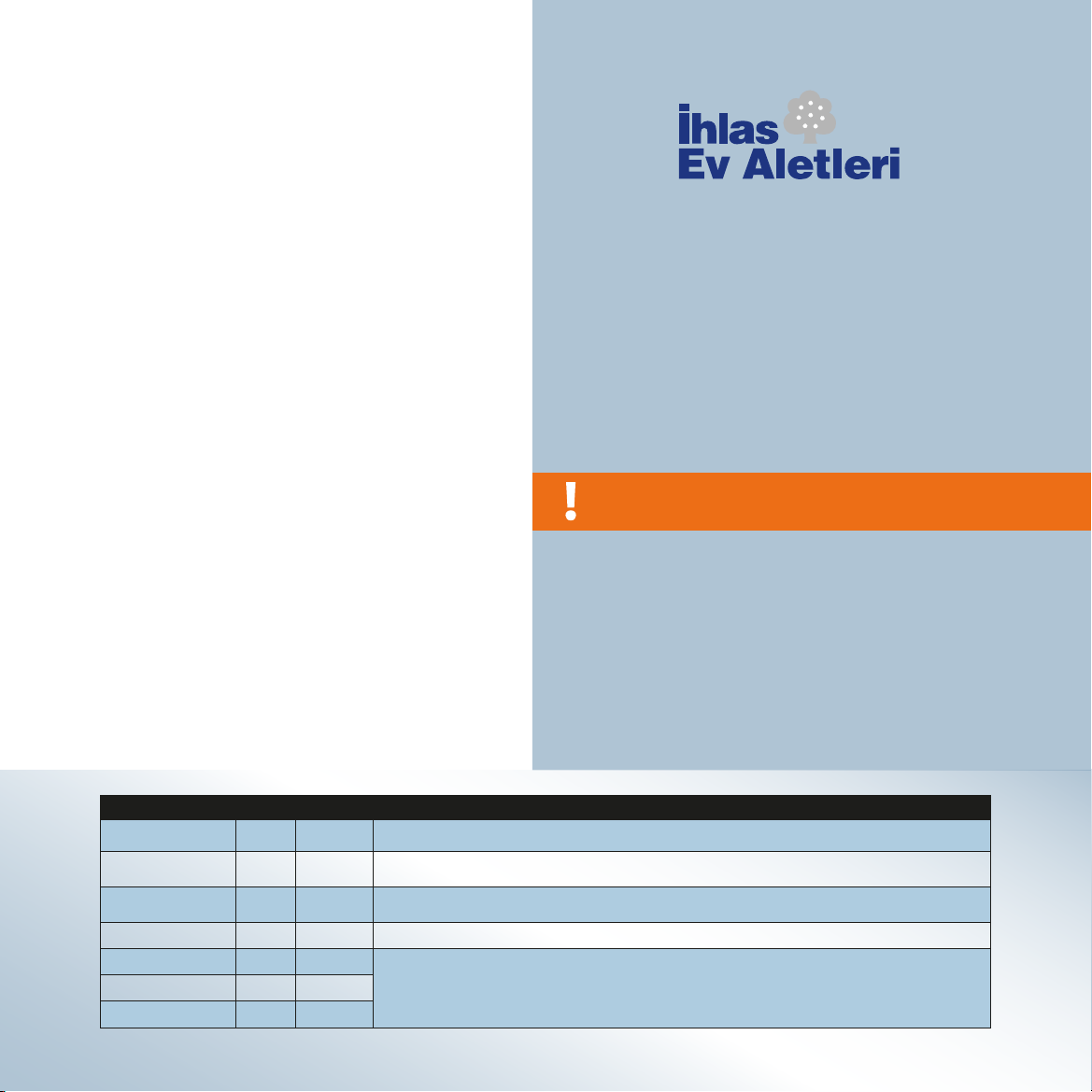

MANUFACTURER : İHLAS EV ALETLERİ İMALAT

COMPANY SANAYİ VE TİCARET A.Ş.

BOSB Mermerciler Sanayi Sitesi, 7.Cd, No:14,

34524, Beylikdüzü, İstanbul / TURKEY

Phone : +90 212 875 3562

Faks : +90 212 875 3664

Model No : 101 - IFL

Cebilon i’flow Reverse Osmosis System

Have timely periodic maintenance of your appliance to use your

system efficiently and for longer time. The following replacement

periods are the recommended durations for appliances used in

mains water under normal conditions. The usage condition of your

appliance may change depending on the properties of inlet water,

amount of chlorine and sediment.

Our authorized services will perform periodic maintenance

required for your system to work efficiently every six months.

Recommended Filter Replacement Periods

Filter Name

Part Code

5 Micron Sediment Filter 350010Z 6 mounts

Carbon Filter 350002Z 6-12 mounts

1 Micron Sediment Filter 350003Z 6-12 mounts

Mineralized Post Carbon Filter 340005Z 6-12 mounts

Blue Membrane 100 GPD 349004Z 3 years

Blue Membrane 100 GPD 349004Z 3 years

Red Membrane 130 GPD 331014Z 4 years

This is where Reverse Osmosis occurs. Life of the filter will change depending on the ion concentration in the mains water, amount

of the distilled water and whether the maintenance is carried out in a timely manner.

Duties

Replacement

Period

Sediment filtration is performed by taking coarse particles in water. Clears the water at a micron level. Its life varies depending on

the nature of the inlet water.

This filtration is performed by taking coarse particles in water. Clears the water at a micron level. Its life varies depending on the

nature of the inlet water.

Keeps all the gas in water chemically in itself. The excess chlorine reduces the life of the carbon filter. Timely replacement protects

from damage of chlorine and extends the life of the membrane filter.

Regulates the pH by supplying mineral to water. Filters bad oders that may have been left in the water.

!

The ball valve in the appliance is closed before the filter

replacement. The pressure in the system is removed by opening

the faucet of the appliance sand. Filter replacement is carried.

After the filter replacement process is finished, the ball valve is

opened. Turn off the tap when water starts to flow from the tap.

Filter must not be replaced when inlet water is open and without

removing the pressure in the appliance.

WARNING

Maintenance of your appliance must be performed by an

Authorized Service, appliances that of the maintenance is not

performed by an Authorized Service will fall out of warranty.

The life of the filters used in Cebilon I’flow Reverse Osmosis

System changes depending on various factors with the amount

of water used. These major factors are inlet water quality,

chlorine amount, residue amount etc. Filters are considered as

supplies and they are out of warranty.

Maintenance

8

9

Troubleshooting

Foam in water or

milky coloured

water.

Low water from the

appliance.

The pump is running

continuously.

Air in the system.

Pump is not operating and there is

no sufficient pressure.

There is bending, crushing on the

hoses.

Pre-filter group is clogged.

Membrane does not perform well.

Inlet water temperature dropped.

Check valve is defective.

High Pressure Switch may be defective.

Low Pressure Switch may be defective.

Check valve may be defective.

Shut off valve may be defective.

Pump may be defective.

Air in the system is a normal occurrence after

initial installation. Sometimes, air caused by

the mains may exist. This will return to

normal after usage for a while. There is no

inconveniency for using this water.

Check whether the pump adaptor is

plugged in. If adaptor is plugged in, consult

to your service.

Check all the hoses connected to the

appliance, eliminate bendings, if any.

Please consult the service.

Please consult the service.

This is not a fault. Decrease in clean

water is normal during winter.

Please consult the service.

Close the inlet water and consult to your service.

Close the inlet water and consult to your service.

Please consult the service.

PROBLEM POSSIBLE CAUSES RECOMMENDED SOLUTION

10

DIGITAL SCREEN FUNCTIONS

Press and hold the ON/OFF button for 3 seconds to switch the device On/Off.

Each light indicates the service life of the respective filter.

GREEN LIGHT illuminates continuously under normal operating conditions.

RED LIGHT indicates that it is time to replace the 5 Micron Sediment,

Activated Carbon, 1 Micron Sediment and Post Carbon filters.

BLUE LIGHT (MEMBRANE) indicates that it is time to replace two 100 GPD

membrane filters.

RED LIGHT (MEMBRANE) indicates that it is time to replace 130 GPD

membrane filter.

Complies with WEEE Regulation

This symbol on the product or packaging shows that the product should not be disposed of with

normal domestic waste and should be transmitted to the collection points for recycling the

electrical and electronic appliances. If you dispose of this product correctly, you will be contributing

to the protection of the nature and human health. Wrong disposal will be harmful to the nature and

human health. You may find further information on recycling this product from your municipal,

waste collection service or from the store you have purchased the appliance.

BOSB Mermerciler San. Sitesi

7. Cad. No: 14 Beylikdüzü - İstanbul

Tel: 0212 875 35 62 Faks: 0212 875 36 64

338001Z

P.D. 2020.02.11

Table of contents

Popular Laboratory Equipment manuals by other brands

Analytik Jena

Analytik Jena qTOWER3 operating manual

Keysight

Keysight E6640A Getting started guide

Thermo IEC

Thermo IEC Medilite 6 Place Operation manual

Bibby Sterilin

Bibby Sterilin Techne No ICE Operator's manual

AVL DITEST

AVL DITEST IRP 120 user manual

WLD-TEC

WLD-TEC gasprofi1 micro operating instructions