Table of Contents

1 Introduction and Safety..............................................................................................................3

1.1 Introduction.......................................................................................................................... 3

1.2 Safety terminology and symbols........................................................................................3

1.3 User safety.............................................................................................................................4

1.4 Special hazards.....................................................................................................................4

1.4.1 Confined spaces........................................................................................................... 4

1.4.2 Biological hazards.........................................................................................................4

1.4.3 Wash the skin and eyes................................................................................................5

1.5 Protecting the environment................................................................................................5

1.6 Spare parts............................................................................................................................5

1.7 Warranty................................................................................................................................5

2 Transportation and Storage...................................................................................................... 6

2.1 Precautions........................................................................................................................... 6

2.2 Position and fastening......................................................................................................... 6

2.3 Examine the delivery........................................................................................................... 6

2.3.1 Examine the package................................................................................................... 6

2.3.2 Examine the unit............................................................................................................6

2.4 Transportation guidelines...................................................................................................7

2.4.1 Lifting..............................................................................................................................7

2.5 Remove from the pallet: Unit delivered right-side up.....................................................7

2.6 Turn the unit to an upright position: Unit with anchoring ring (foot)............................ 8

2.7 Turn the unit to an upright position: Unit without anchoring ring (foot).................... 10

2.8 Long-term storage.............................................................................................................12

3 Product Description................................................................................................................. 13

3.1 Products included..............................................................................................................13

3.2 Design................................................................................................................................. 13

3.2.1 Anchoring ring (foot)..................................................................................................13

3.2.2 Parts..............................................................................................................................13

3.2.3 Intended use............................................................................................................... 14

3.2.4 Application limits........................................................................................................ 14

3.2.5 Dimensions..................................................................................................................15

3.2.6 Weight..........................................................................................................................16

3.2.7 Materials.......................................................................................................................16

3.2.8 External loads..............................................................................................................16

3.2.9 Pumping station identification.................................................................................. 16

3.3 Pump versions....................................................................................................................17

3.4 Monitoring equipment......................................................................................................17

3.5 The data plate.................................................................................................................... 17

4 Installation................................................................................................................................. 18

4.1 Precautions......................................................................................................................... 18

4.1.1 Underground utilities................................................................................................. 18

4.1.2 Excavations.................................................................................................................. 18

4.1.3 Inspect the work area before permit-required hot work....................................... 19

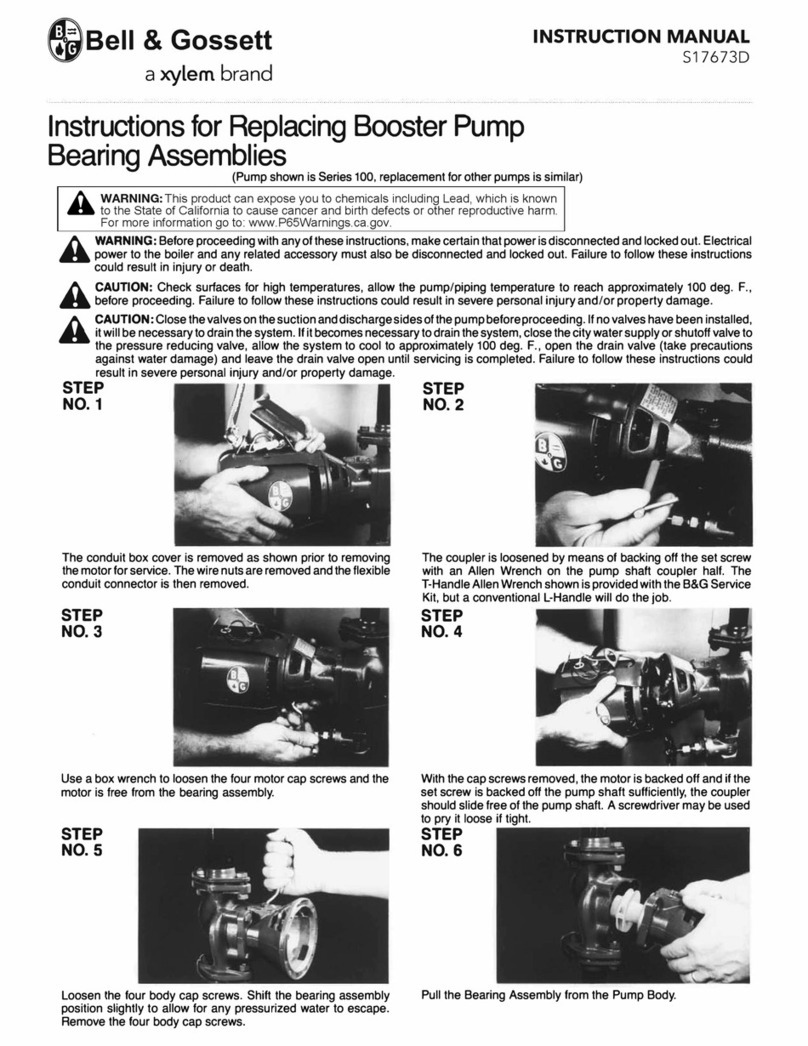

4.2 Installing the unit................................................................................................................19

4.2.1 Prepare the site........................................................................................................... 19

4.2.2 Prepare the pit base................................................................................................... 20

4.2.3 Attach the anchoring ring (foot)................................................................................20

4.2.4 Install the unit.............................................................................................................. 21

Table of Contents

Flygt Compit 901 Installation, Operation, and Maintenance Manual 1