3

Triax A/T Quick Start Guide

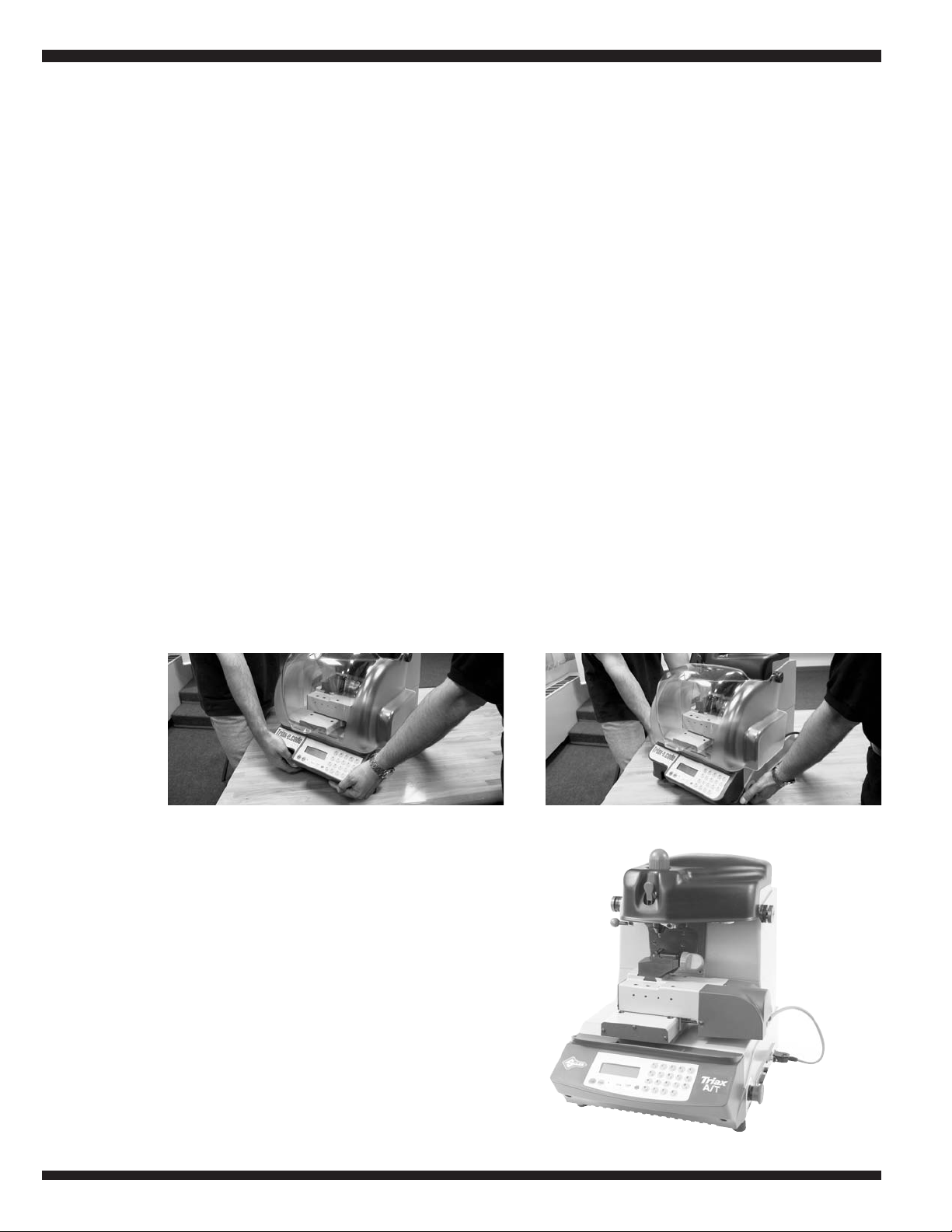

C. Place the machine on a horizontal surface,

solid enough to support the weight of

93 lbs (45kg). The dimensions of the

Triax A/T are 17” (43.2 cm)L X 20”

(50.8 cm)W X 20” (50.8 cm)H. It is strong-

ly suggested to have 12-inch clearance

around the top and back of the machine

and a 24-inch clearance on the bottom right

side of the machine. This will allow easy

access to the serial port; Y-axis connection

port and the emergency stop button.

Ensure that the main power supply is the

same as the machine, 110V/AC. This sup-

ply should be properly grounded and the

machine connected to a surge protected

power strip.

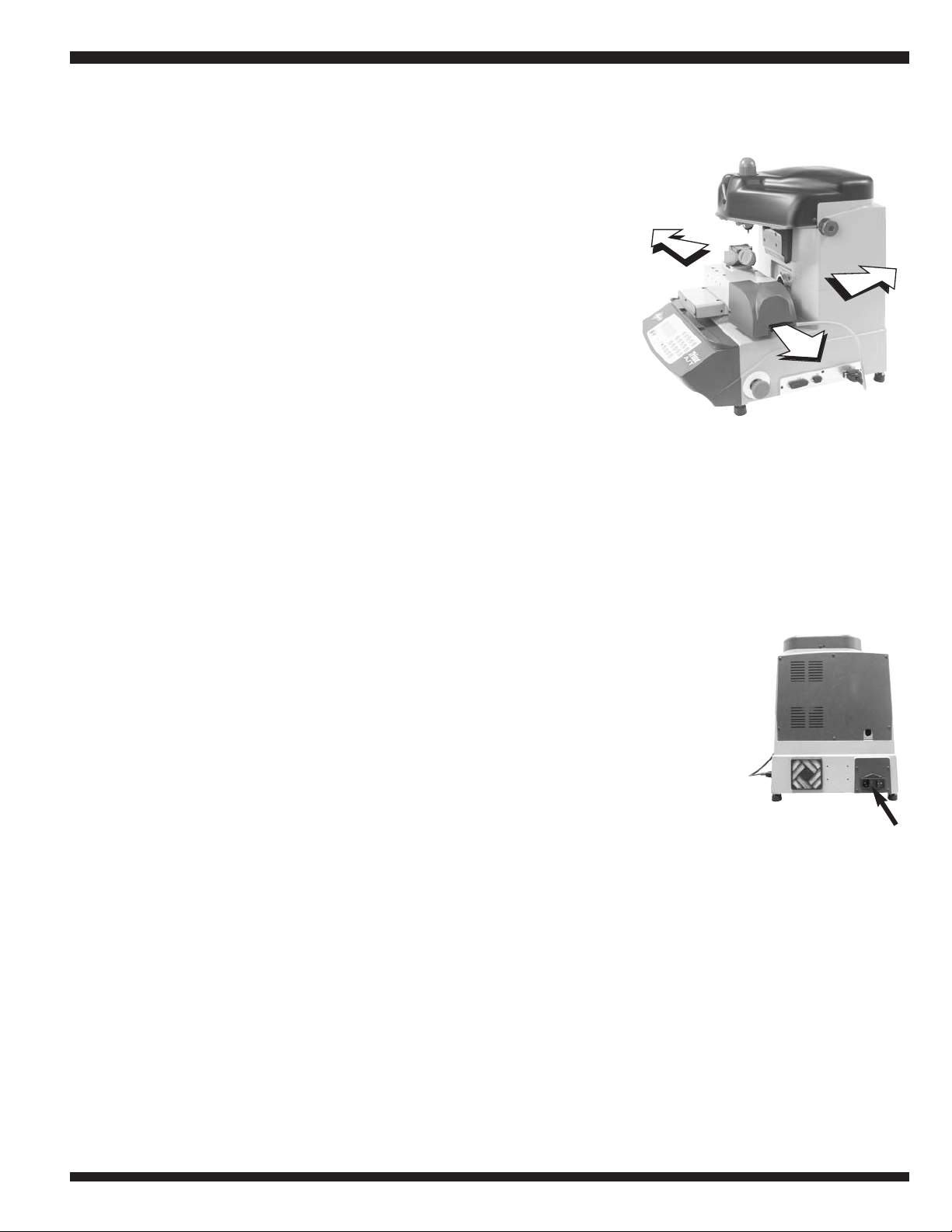

D. VERY IMPORTANT: The serial cable on the right hand side of the machine

must be plugged into the uncovered serial (Y) port, also located on the right

hand side of the machine. This allows the X, Y and Z-axis to function prop-

erly.NOTE:It is essential the Yaxis cable be plugged into its designated serial

port BEFORE the machine’spower switches are activated. If this is not done,

the machine’smotherboard could be damaged resulting in expensive repairs

and down time.

E. Attach the power cord to the Triax A/T and plug it into

an 110V/AC circuit. The on/offmain rocker switch is

located on the back left hand side of the machine.

Make sure that the red emergency stop button, locat-

ed on the right hand side of the machine, is disen-

gaged. To make sure that the emergency stop button

is disengaged, push the button in towards the

machine to activate it and then rotate the

button 45° clockwise, to deactivate it. The button

should “pop” out away from the machine.

F. Turn the Triax A/T machine ON.

G. Push the SHIFT and STOP buttons simultaneously to bring the carriage to

the starting position. Once the carriage has come to a complete stop, the

operator may remove the styrofoam behind the X and Y-axis, then proceed

with setting up the Triax A/T machine.

2. Initial Operations

A. When the machine has been turned on, the display will show the machine

model and the internal software version for a few seconds. This version

should be 036 or higher. If not, please contact Ilco Technical Assistance.

power supply