DESCO WEST - 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178

DESCO EAST - One Colgate Way, Canton, MA 02021-1407 • (781) 821-8370 • Website: Desco.com

TB-3031 Page 2 of 8 © 2014 DESCO INDUSTRIES, INC.

Employee Owned

Maintenance

“All ionization devices will require periodic maintenance for

proper operation. Maintenance intervals for ionizers vary

widely depending on the type of ionization equipment and

use environment. Critical clean room uses will generally

require more frequent attention. It is important to set-up

a routine schedule for ionizer service. Routine service is

typically required to meet quality audit requirements.” (ESD

Handbook TR20.20 section 5.3.6.7 Maintenance / Cleaning)

EIA-625, recommends checking ionizers every 6 months, but

this may not be suitable for many programs particularly since

an out-of-balance may exist for months before it is checked

again. ANSI/ESD S20.20 section 6.1.3.1 Compliance

Verification Plan Requirement states: “Test equipment shall

be selected to make measurements of appropriate properties

of the technical requirements that are incorporated into the

ESD program plan.”

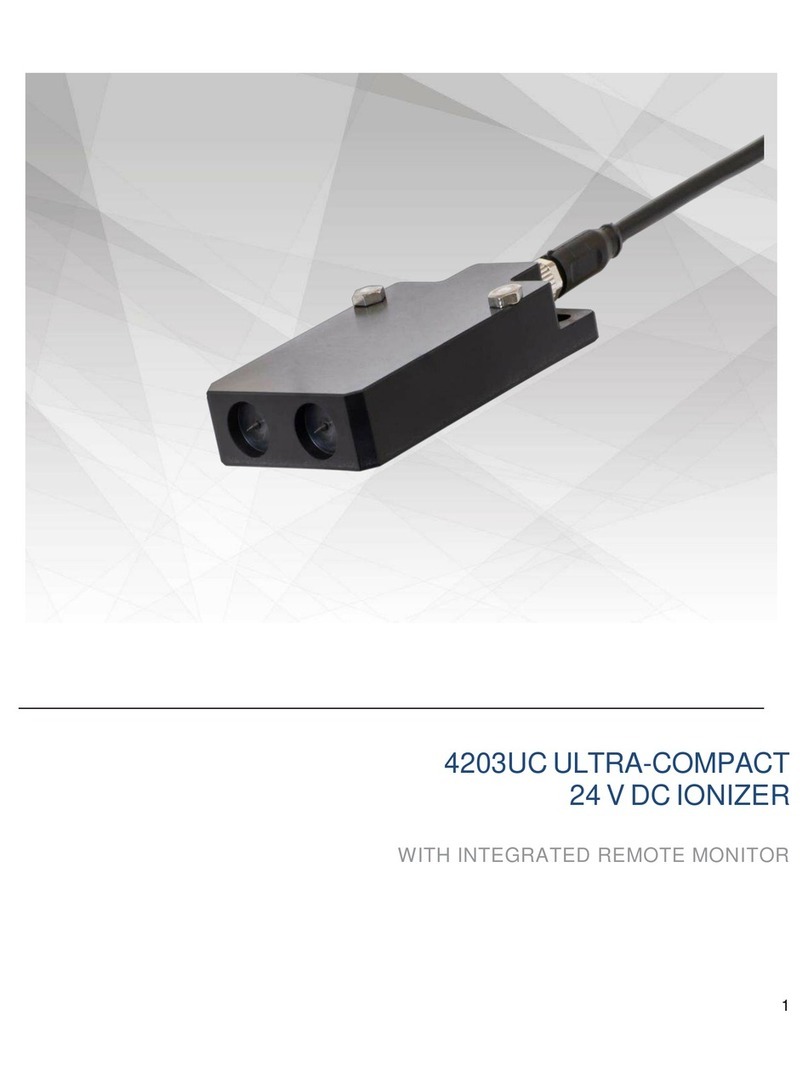

CLEANING THE EMITTER POINTS

Under normal conditions, the ionizer will attract dirt and dust

(especially on the emitter points). To maintain optimum

neutralization efficiency and operation, cleaning should be

performed on a regular basis.

In the event of circuit failure, the unit will enter shutdown

mode.

When the unit enters shutdown mode, ionization will be

stopped, the LED on the front of the unit will illuminate a

constant red, and the audible alarm will continuously sound.

The user must then reset the unit by turning it OFF and back

ON.

The emitter points should be cleaned using the included

Emitter Point Cleaners or a swab dampened with Isopropyl

alcohol.

1. Turn the unit OFF and unplug the power cord.

2. Open the top screen by

loosening the screw and

swinging the grill to one

side.

3. Clean the emitter points

using the included Emitter

Point Cleaners or a swab

dampened with Isopropyl

alcohol.

4. Reattach the top screen.

5. Plug in the power cord

and turn the unit ON.

6. Verify the performance of

the ionizer by using a

charged plate monitor, or

ionization test kit.

With normal handling, the emitter points should not require

replacement during the life of the unit. If necessary,

item 60507 Replacement Emitter Points are available for

purchase.

Adjustments and Compliance Verification

BALANCE OFFSET VOLTAGE ADJUSTMENT

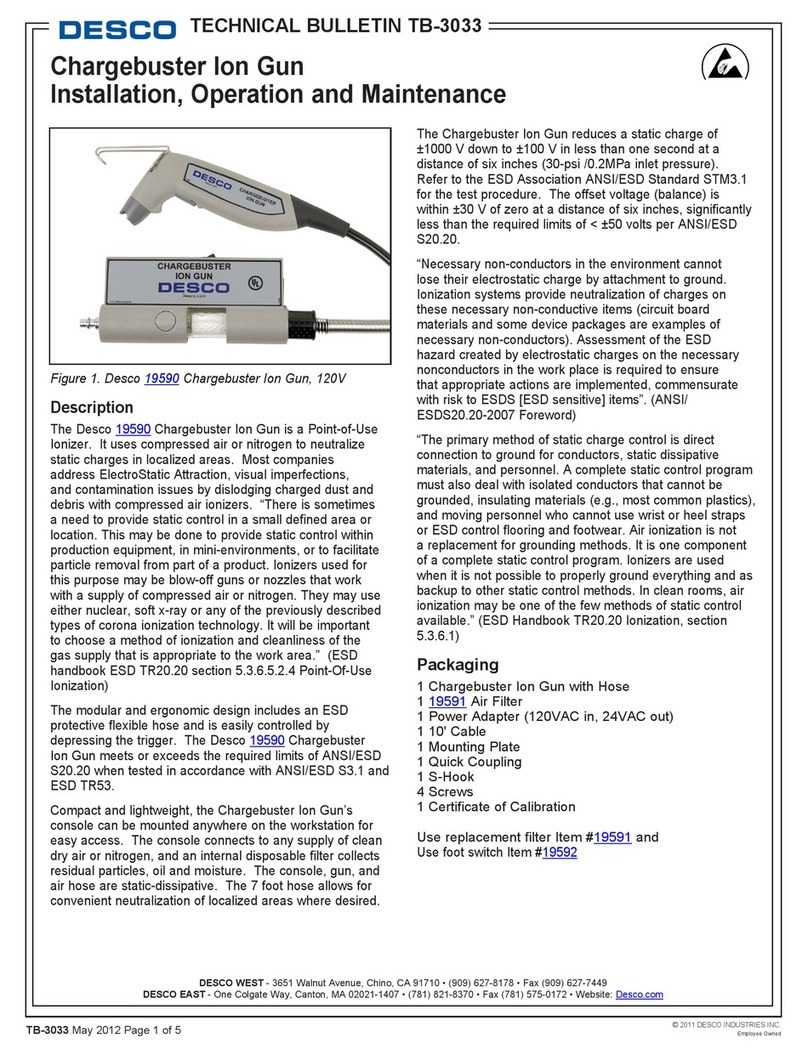

The Chargebuster® Overhead Ionizer is an auto-balancing

unit. However, tuning or manual adjustment can be

accomplished by inserting a small screwdriver or trimmer

adjustment tool into the balance adjustment hole. To

increase the output in a positive direction, turn the

potentiometer clockwise. To increase the output in a

negative direction, turn the potentiometer counter-clockwise.

INPUT VOLTAGE CONFIGURATION

WARNING - Risk of electric shock

These servicing instructions are for use by qualified

personnel only. Do not perform any servicing of internal

parts unless you are qualified to do so.

NOTE: The AC power cord MUST always be disconnected

before the unit is disassembled.

The input voltage may be verified or reset by opening the

ionizer’s enclosure. This can be accomplished by removing

the 10 screws that secure the cover to the base.

The ionizer’s input voltage can be configured to 120 VAC or

220 VAC using the JH1 jumpers located on its PCB. See

Figures 3 and 4 for these configurations.

Figure 3. 120 VAC jumper

setting

Figure 4. 220 VAC jumper

setting

If the supply voltage drops from 110 Volts to below 85 Volts

or from 200 Volts to below 170 Volts, the unit will shut down,

the audible alarm will beep and the LED will blink red. The

unit will automatically reset when the minimum voltage is

restored.

Auto-balancing closed-loop feedback technology can save

money and extend the maintenance interval of the ionizer.

What the sensor detects is that the offset voltage (balance)

has shifted and the circuits will attempt to compensate. In

the case of corona ionizers, one of the reasons for a shift in

offset voltage is frequently the particle buildup, commonly

called a “fuzz ball”, observed on the emitter points.

Compliance Verification should be per ESD TR53. Offset

voltage (balance) and both polarity’s discharge time should

be checked on every ionizer periodically using an Ionization

Test Kit or a Charged Plate Analyzer. Measure offset

voltage (balance) and both polarity’s discharge times. Clean

the emitter points (with electrical power off), adjust offset

voltage (balance) to zero and then re-test for offset voltage

(balance) and discharge times recording the measurements.