Ilsintech SWIFT KF4 User manual

SWIFT KF4 USER MANUAL

OPTICAL FIBER ARC FUSION SPLICER

Read carefully before running KF4

www.fibrecart.com

1 SAFETY INSTRUCTIONS 3

2 PRODUCT SPECIFICATIONS AND COMPONENTS 6

2.1 | PRODUCT SPECIFICATIONS 6

2.2 | PRODUCT PACKAGE 6

3 PRODUCT OUTLINE 7

3.1 | FUNCTION BUTTONS 7

3.2 | COMPONENT NAME 8

4 INSTRUCTIONS FOR USE 9

7 ERROR MESSAGES 48

7.1 | TOO DIRTY FIBER 48

7.2 | REPLACE FIBER 48

7.3 | TOO LONG FIBER 49

7.4 | FIBER OVER ANGLE 49

7.5 | LOSS LIMIT OVER 50

7.6 | FIBER THIN ERROR 50

7.7 | FIBER THICK ERROR 50

7.8 | BUBBLE ERROR 50

7.9 | CLEAVED SURFACE ERROR 50

8 SPLICING PROBLEM SOLVING 51

8.1 | WHEN LOSS IS HIGH 51

8.2 | ABNORMAL SPLICING OPERATION 51

9 PROBLEM OCCURRENCES AND QUESTIONS 52

9.1 | POWER 52

9.2 | SPLICE 52

9.3 | SLEEVE HEATER 53

9.4 | OTHERS 53

10

WARRANTY AND REPAIR RESPONSIBILITY LIMIT 54

10.1 | INFORMATION NECESSARY FOR REPAIR 54

10.2 | TRANSPORTATION 54

10.3 | REPAIR 54

TABLE OF

CONTENTS

2

4.1|

POWER SUPPLY

9

4.2|

HOW TO TURN THE POWER ON/OFF

10

4.3|

KF4 SLEEVE HEATER

10

4.4|

SPLICE PROCEDURE

11

4.5|

REMOVING THE SPLICED FIBER

12

4.6|

HEATING PROTECTION SLEEVE

12

4.7|

USE OF WORK BELT

13

5

MAINTENANCE OF SPLICE QUALITY

14

5.1| CLEANING AND INSPECTION BEFORE SPLICE

14

5.2|

REGULAR INSPECTION AND CLEANING

15

6

MENU

17

POPUP MENU

19

6.1| SPLICE

22

6.2| HEATER

26

6.3| HISTORY (SPLICE RESULT)

31

6.4| OPTION

32

6.5| CALIBRATION

35

6.6| ELECTRODES

39

6.7| SETTING

42

6.8| INFORMATION

45

1

SAFETY INSTRUCTIONS

The KF4 is designed for convenient use on indoor and outdoor work sites. Please read all instructions to

prevent accidents and malfunctions. This user guide provides the information necessary for safe operation.

!

Keep this user guide with the product at all times.

UCL SWIFT does not take any responsibility for equipment damage and personal or physical loss incurred due

to improper use or alteration.

WARNINGS

If any of the following situations occur during use, turn off the power immediately and contact your local UCL

SWIFT office or representative:

•

Smoke, abnormal smell, noise or abnormal overheating

•

A foreign substance or liquid falls into the equipment

•

The splicer is visibly damaged

Use only the power cord and connecting devices provided with or intended for the KF4. Failure to do so may

result in fire, electrical shock or injury.

Do not touch the electrodes when the power is on. High voltage and high temperatures generated from the

electrodes may result in serious shock or burn.

Connect the provided AC power cord only as directed. Ensure that there is no foreign substance on the

terminal before connecting it to the AC power socket. Improper use may result in smoke, electrical shock, fire,

equipment damage, serious injury or even death.

Use proper power voltage.

AC power for the charger is AC100-240V, 50~60 Hz.

Test the AC power before use. When the output voltage of AC power is high or abnormal frequency is

generated, the product is damaged thus serious injury or even death may result.

AC output voltage should be measured using a circuit tester before connecting the AC power cable. Regular

inspection should also be conducted.

Do not pull the AC power cord with excessive force, apply heat or transform it.

When a damaged power cord is used, it may cause fire or injury.

Use a three-plug AC power cord. Never use a two-plug power cord, cable or plug.

Do not touch the AC plug, AC power cord or splicer with wet hands. It may cause electrical shock.

Do not disassemble the AC charger, battery or KF4. Disassembly may cause fire, electrical shock or injury.

Refer to the following when using the battery:

•

Failure to use batteries and chargers provided by UCL SWIFT may result in smoke, equipment damage,

burn, injury or even death.

•

Do not burn any conductive materials.

•

Do not charge the battery near a flame.

•

Do not give an excessive shock to the battery.

•

When the battery does not completely charge in two hours, or when the green LED is not turned on, stop

charging immediately and contact UCL SWIFT.

•

Do not put anything on the AC charger while charging.

Use only the AC charger provided. Do not use another AC power cord or battery. Excessive current may result

in equipment damage or injury.

Do not use the KF4 where there is harmful gas or flammable liquid. Explosion or fire may result.

Do not use compressed air or compressed gas when cleaning the KF4.

Inspect the carry case belt before transportation. Equipment damage or injury may occur if the carrying case is

damaged.

Always follow safety best practices, including the use of safety goggles and protective clothing when working

with fiber optic products, including the KF4.

Do not use the KF4 around high temperatures or flame. Injury or equipment damage may occur.

Be aware of and avoid hot surfaces associated with thermal strippers and sleeve heaters. Allow sleeves to cool

before handling.

| CAUTION: HIGH TEMPERATURES

| CAUTION: DO NOT SPRAY FREON GAS

| CAUTION: HIGH VOLTAGE

!

3 4

PRODUCT SPECIFICATIONS AND COMPONENTS

2.1|

PRODUCT SPECIFICATIONS

CATEGORY DESCRIPTION

2.1.2|

PRODUCT PACKAGE

2.2.2|

OPTIONAL ACCESSORIES

CATEGORY MODEL Q’TY CATEGORY MODEL

CAUTIONS

Use the KF4 only on a stable surface to avoid falls that may cause damage or injury.

The KF4 should be accurately adjusted and treated in alignment. Do not give it a strong shock. Use the

carrying case provided for transporting and storing the KF4 to reduce humidity, vibration and shock.

When replacing the electrodes:

•

Always use UCL SWIFT-approved replacements

•

Ensure correct positioning

•

Always replace in pairs

Failure to follow all warnings and cautions to ensure proper function of the KF4 may result in equipment

damage or a faulty splice.

Use only ethyl alcohol (96% or higher) or other approved cleaning solutions to clean the lens, V-groove, LCD

monitor and main body.

Use the splicer only within the stated operating environmental ranges. Store in a controlled environment to

avoid long-term exposure to damaging temperatures and humidity levels.

The KF4 should receive regular service by a UCL SWIFT-authorized service technician to ensure long-term

functionality and safety.

Cleaver blade

BI-07

Electrode

EI-24

Work belt

WB-01

Work table

WK-02

Sleeve

S09-C, S09, S30-C, S30

SOC connector

SC, LC, FC, ST

External power

DC 12V (availablefor car cigar jack)

Optical fiber holder

HS-2.5, HS-IN, KF4-ST-01

!

Fiber alignment

IPAAS, Active V-Groove Alignment

Applicable type of fibres

SM (G.652; MM (G.651); DS (G.653); NZDS (G.655); SM (G.657 A1, A2/B2, B3)

Fiber count

Single fiber

Applicable fiber dimensions

Cladding diameter: 125µm; Coating diameter: 150µm-3mm

Fiber setting and cleaved length

7mm to 16mm (0.28in to 0.63in)

Splicing modes

Splice mode: 300; Heat mode: 100

Typical splice loss

SM: 0.03dB; MM: 0.01dB; DS:0.05dB; NZDS:0.05dB

Return loss

>60dB

Splicing time

Typical 7 sec. with SM

Splice loss estimate

Available

Sleeve heating time

Typical 13 sec. with IS-60 mode, IS-60 sleeve

Applicable protection sleeve

40mm (2.4in); 60mm (1.5in) micro sleeve

Storage of splice result

Data: up to 5,000 ea; Image: up to 5,000 ea

Tension test

1.96N to 2.25N

Operating condition

Altitude: 0-5,000m above sea level; Temperature: -10ºC~50ºC (-14ºF~122ºF);

Humidity: 0-95%; Wind: 15m/s, non-condensing, dust proof, water proof, shock proof

Storage condition

Temperature: -40ºC~80ºC (40ºF~176ºF); Humidity: 0-95%

Dimension

124(W) x 189(L) x 75(H)mm (without rubber protector)

Weight

1.1kg (including battery)

Viewing method and display

2 AXIS Two CMOS cameras with 109mm (4.3in) color LCD monitor

Fiber view and magnification

X/Y: 130X; Max: 260X

Power supply

Li-ion battery (DC 14.8V, 3400mAh); 100~240V AC charger

No. of splice cycles with battery

Typical 200 cycles

Electrode life

Up to 38,000 splices

Blade life

Up to 77,000 cleaves

Terminals

USB

Arc fusion splicer

SWIFT KF4

1

Battery

KF-3400

1

Battery adapter

FY1701000

1

Instructions for use

—

1

Spare electrode

EI-24

1 pair

Transporting case

Hard case

1

Cooling tray

CT-01 (40mm(1.5in))

1

Screw driver

LD-3300

1

USB cable

—

1

Sleeve clamp

SC-01

1

Cleaver

CS-01BT

1

Manual stripper

CF-02

1

Alcohol dispenser

POM

1

Cleaning brush

Tweezer

Optical fiber holder

—

—

HS-250(Pair), HS-900(Pair),

LS-900L(Loose tube),

KF4-SC/FC, KF4-ILC

1

1

5 6

PRODUCT OUTLINE

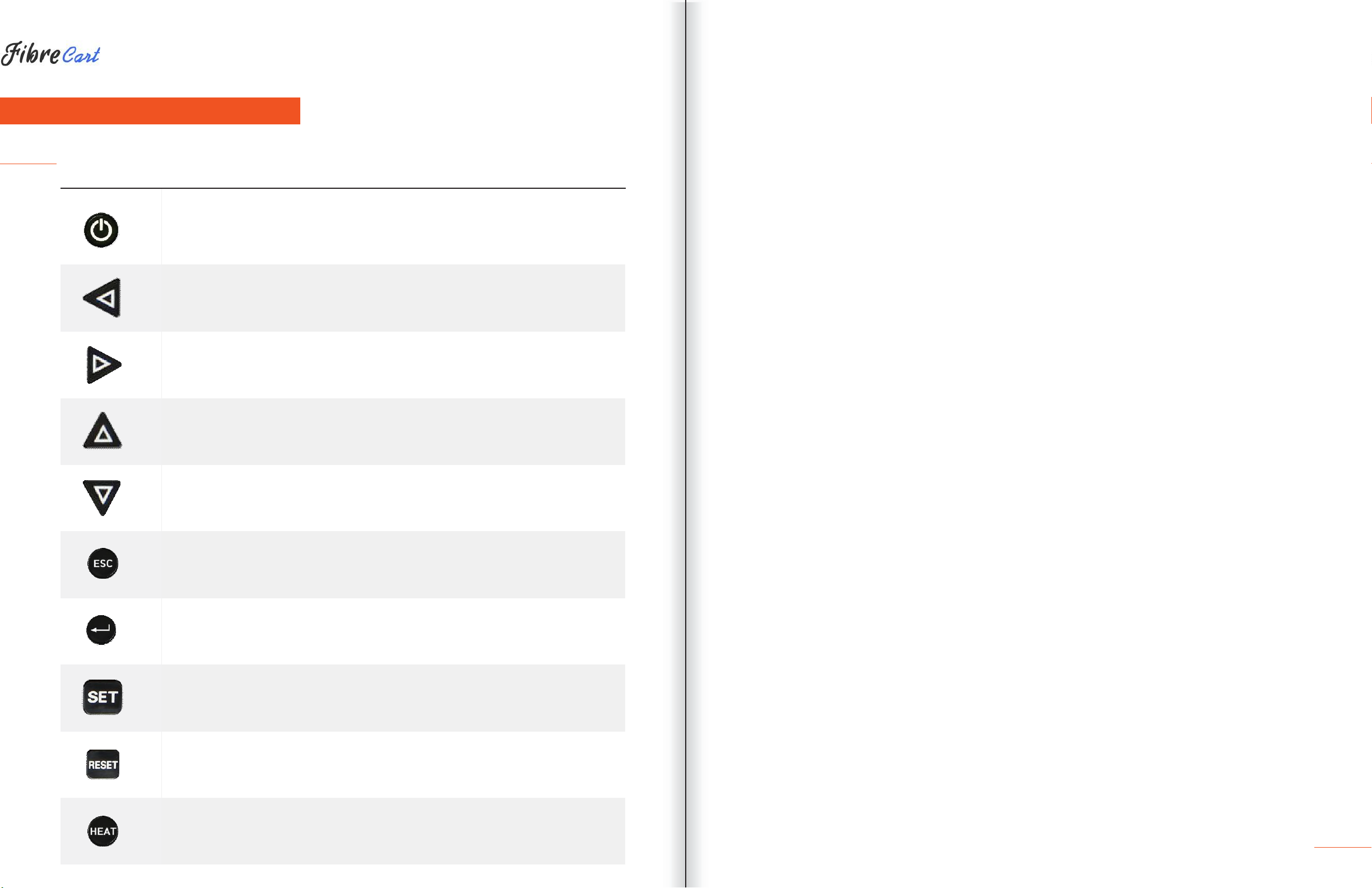

3.1

| FUNCTION BUTTONS

BUTTON DESCRIPTION

Press and hold about 1 second to turn the power on/off.

Move the cursor to the left.

Move fiber to manual mode and adjust the camera’s focus. Stripping popup

menu should load.

Move the cursor to the right.

Move fiber to manual mode and adjust the camera’s focus.

Move the cursor upward.

Move each motor to manual mode. Splice popup menu should load.

Move the cursor downward. Move each motor to manual mode. Heater

popup menu should load.

Initialize the splice function. Return to the menu screen.

Complete a selection.

Follow the next step on the menu screen.

Splice execution.

Return to the initial screen and initialize splice function.

Turn on the heater.

When it is on, the lamp on the left is in the red.

Press once more when it is on, and the heater is turned off.

7

3.2

| COMPONENT NAME

8

|

SLEEVE HEATER

|

WIND COVER

|

MONITOR

|

BATTERY

|

DC IN/CHARGE-IN

|

USB

|

OPEN

|

HEATER

|

HEATER COVER

INSTRUCTIONS FOR USE

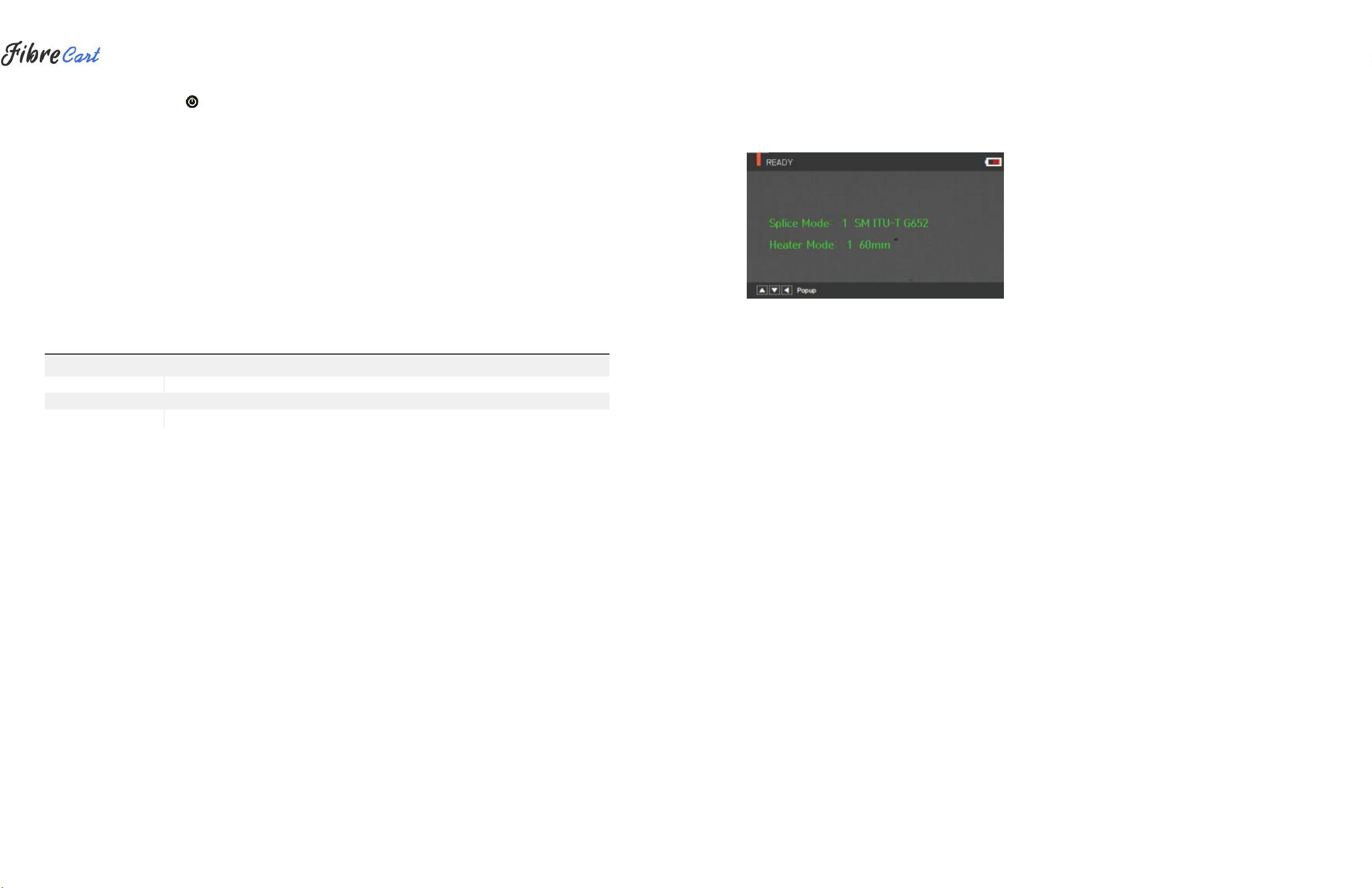

The following is the KF4’s initial screen. For accurate splice results, splice mode and heater mode should be

selected. Basic information about the KF4 is displayed on the initial screen. Check that the proper mode is

selected before splicing.

|

BATTERY STATUS INDICATOR

|

CURRENT SPLICE MODE

|

CURRENT HEATER MODE

4.1

| POWER SUPPLY

The battery pack is built into the battery chamber. Loosen the bottom-cover bolts and exchange the battery.

Please be cautious when you detach the battery from the chamber.

4.1.1

BUILT IN BATTERY

4.1.2

BATTERY CHARGING

Before connecting the AC/DC charter’s DC cable to the DC jack of the battery to charge the battery, make sure

you check the voltage and frequency. When the battery is fully charged, the LED will turn green and power is

disconnected, activating protection circuit to avoid overcharge. The power is turned back on as the battery

needs to be charged. Charging resumes when the charger’s DC cable is connected to the battery’s DC jack.

9

4.2

| HOWTO TURN THE POWER ON/OFF

To power on the KF4, press and hold about 1 second with the wind cover closed. After the functions of

motors and initialize, the screen will display the following. Then splice and heater mode should be selected.

The current splice and heater mode are displayed at the bottom of the screen.

4.3

| KF4 SLEEVE HEATER

The sleeve heater of the KF4 reinforces the spliced point of the single

fiber.The quality of fusion splicing on the fiber should be good.

The fiber and inserted sleeve tube should be properly aligned and installed on the heater.

Close the heater cover while the heater is on.

ITEM DESCRIPTION

Cable diameter

250µm, 900µm, 2.0mm —3.0mm

Sleeve length

Standard 32mm

Heating time

10 —35 seconds

Temperature range

130°C —200 °C

1| Choose the heater mode after the confirmation of the length for the sleeve tube when placing a sleeve tube

on a heater.

2| Place the spliced point in the middle of the sleeve tube first. Then, check the heating part on the heater and

place the sleeve tube on right position.

10

CAUTION

Choosing the improper mode of the heater for a sleeve tube may not shrink the sleeve tube properly. Specifically,

the SOC (Splice-On-Connector) should be placed on the right side edge of the heater in order to line up the

right end of the sleeve tube to the right side edge of the heater as shown on the picture below (Right picture). If

the SOC is placed in the middle or on the left side, the sleeve tube of the SOC does NOT shrink.

|

OPTICAL FIBER

|

SOC CONNECTOR

3| After settling the fiber, turn on the heater by pressing . (Heating time 20sec)

4| Remove the sleeve protected fiber by opening the cover when the cooling is completed.

CAUTION

The appropriate sleeve position helps reduce heating operation time.

4.4

| SPLICE PROCEDURE

The status and cleaved quality of the fiber can be monitored by using a KF4 image processing system.

However, for better splice results, visual inspection is also required.

In auto mode, the splicing procedure begins automatically as the wind cover is closed.

1| Fibers installed on the splicer advance toward each other and stop. The fibers align once arc cleaning is

done. After that, the splicer checks the cleaved angle of each fiber, the shape of the end-face contaminations

and so on. When the measured cleaved angle is bigger than the preset value, or damage is detected on the

fiber, an error message is displayed on the screen. The splice procedure stops as well. Even if there is no error

message displayed, visual inspection of the monitor screen is always recommended.

2| Check that the Wind cover is properly closed at more than 900µm cable (Ø2.0~Ø3.0µm)

3| Fibers are aligned, cladding to cladding, after inspection. Deviation on clad axis can be displayed on

the screen.

4| After alignment completes, arcing is conducted to splice fibers.

5| After splicing is completed, the estimated value of the loss is displayed on the screen. The estimated value of

splice loss is subject to various factors related to the error. These factors related to an error affect the estimation

and calculation of estimated loss value as well. Calculation of estimated loss is based on factors such as MFD.

When estimated loss value exceeds the preset value, an error message is displayed on the screen. The error

message is also displayed when the spliced fibers are too thick or thin, or when bubbles are generated on the

spliced point. If the splice result shown on the screen is not considered good enough, it is recommended that

splicing be conducted again.

6| The splice result is saved as follows.

7| When splice is completed, the splice result is automatically saved.

4.5

| REMOVING THE SPLICED FIBER

1| Open the cover of the sleeve heater.

2| Open the wind cover.

3| Hold the fiber on the left and open the clamp on the left.

4| Open the fiber clamp on the right.

5| Hold both sides of the spliced fiber and separate the fiber from the KF4 with care.

4.6

| HEATING PROTECTION SLEEVE

1| Move the spliced point to the center of the protecting sleeve. Place the protected pin face down in the sleeve.

2| Place the protecting sleeve at the center of the sleeve heater.

!

!

3| Hold and put down both fibers as shown in the figure. The heater cover will automatically close.

11 12

4| Heating starts by pressing .

5| LED turns off when heating is completed.

6| Open the heater cover and take out the fiber. Do not touch the protecting sleeve or heater at any point

during or right after heating.

7| Conduct a final inspection to check for bubbles, fragments or dust on the sleeve.

4.7

| USE OF WORK BELT

The work belt of Swift KF4 is a type of auxiliary equipment that combines with its main body to facilitate

working at a manhole, utility pole, etc.

|

WORK BELT COMPONENTS

MAINTENANCE OF SPLICE QUALITY

5.1

| CLEANING AND INSPECTION BEFORE SPLICE

5.1.1

V-GROOVE CLEANING

When the inside of the V-groove is contaminated, splice quality may deteriorate. It is important to regularly

inspect and frequently clean the V-groove as follows.

1| Open the wind cover.

2| Clean the V-groove using a cotton swab moistened with alcohol and any proper cleaning agents. Remove

the remaining alcohol from the V-groove using a clean, dry, lint-free cotton swab.

3| When a foreign substance cannot removed with a cotton swab, clean it with the tip of a cleaved fiber and

repeat the steps above.

5.1.2

PUSHER BLOCK CLEANING

Pusher block contamination causes poor splice quality due to irregular pressure applied to the fibers. It is

important to frequently inspect and regularly clean it.

13 14

5.2

|

REGULAR INSPECTION AND CLEANING

To ensure splicing quality, regular inspection and cleaning are required.

5.2.1

OBJECT LENS CLEANING

Contamination on the object lens surface disturbs the identification of fiber core location and consequently

causes high splice loss. Object lenses should be kept clean at all times. If dust accumulates for a prolonged

period, it may be difficult to remove. Clean the lens frequently as follows.

1| Turn the power off before cleaning the object lens.

2| Separate the electrodes.

3| Use a soft cotton swab moistened with alcohol to clean in a circular motion from the center as shown in the

figure below. Dry the remaining alcohol using a clean, dry, lint-free cotton swab.

4| The surface of the object lens should be clean without any lines or stains.

5| Reassemble the electrodes.

6| Turn the power on and check for any lines or stains on the monitor. Conduct a self-diagnosis.

5.2.2

ELECTRODES REPLACEMENT

The electrodes should be replaced after being used approximately 4000 times. If the number of arcs exceeds

the replacing cycle, an electrode replacement message is displayed on the screen. If electrodes are not

replaced, splice loss increases and the tensile force at the splicing point weakens.

1| Turn the power off when replacing the electrodes.

2| Open the wind cover and unscrew the clamp screw on the electrodes block.

3| Remove the electrode block and the electrodes.

4| Clean the electrodes carefully by using a soft cotton swab moistened with alcohol, then install.

5| Turn the power on and conduct the electrode stabilization process in the menu.

15 16

MENU

The main menu has eight submenus. Press to load the main menu.

The eight submenus can be selected by using , or by pressing the screen. The main menu

screen displays as follows.

SPLICING

•

Replace: Selects and replaces a certain splice mode within the database

•

Add: Selects and adds a certain splice mode within the database

•

Select: Selects a splice mode to run

•

Edit: Edits set values of splice mode

•

Cancel: Closes the menu window

•

Delete: Deletes splice mode

HEATER

•

Replace: Selects and replaces a certain heater mode within the database

•

Add: Selects and adds a certain heater mode within the database

•

Select: Selects a heater mode to run

•

Edit: Edits set values of heater mode

•

Cancel: Closes the menu window

•

Delete: Deletes heater mode

HISTORY (SPLICE RESULTS)

•

DISPLAY HISTORY: Displays splice result and image

•

CLEAR HISTORY: Deletes all data

OPTION

•

DEFAULT: Auto, pause, auto heater

•

MENU LOCK: Menu lock setting

•

PASSWORD: Password sets upon locking

CALIBRATION

•

ARC CALIBRATION: Adjusts arc calibration intensity

•

ARC TEST: Check arc quantity through arc test

•

DIAGNOSTIC TEST: Diagnoses equipment state

•

MOTOR DRIVE: Operates motor manually

•

MOTOR CALIBRATION: Initializes motor speed and location

ELECTRODE

•

ELECTRODE STABILIZE: Conducts stabilization of electrodes

•

ELECTRODES CAUTION: Sets the number of uses to inform about electrode replacement

•

ELECTRODES REPLACE: Explains how to replace the electrodes

•

ELECTRODE USED: Displays the electrode-use count

SETTING

•

LANGUAGE: Selects a language

•

DATE: Sets the present time

•

POWER SAVE: Sets sleep mode

•

VOLUME: Adjusts the intensity of the buzzer sound

•

LCD BRIGHTNESS: Adjusts screen brightness

INFORMATION

•

MAINTENANCE INFO: Displays maintenance schedule

•

SENSOR VALUE: Indicates temperature and pressure

•

VERSION: Shows the current version of the product

•

HELP: Consists of:

—

NAME OF PARTS

—

CLEAN AND INSPECT

—WARNINGS

—

A/S CONTACT LIST

17 18

POPUP MENU

The purpose of the popup menu is to facilitate quick, easy access to the splice mode and heater mode. The

user can access the popup menu in various ways.

[Displaying popup menu]

1| Splice popup menu can display the current splice mode by pressing on the initial screen.

2| Heater popup menu can be displayed by pressing on the initial screen.

[Splice popup menu]

ADDING SPLICE MODE

1| Display splice popup menu by pressing on the initial screen.

19

Table of contents

Popular Welding Accessories manuals by other brands

Lincoln Electric

Lincoln Electric VIKING 3350 Series Operator's manual

STAYER WELDING

STAYER WELDING GS-0 operating instructions

Chicago Electric

Chicago Electric 61610 Owner's manual & safety instructions

Amada

Amada MK-110B Operation manual

Sealey

Sealey PWH620.V2 Instructions for use

AMERICAN WELDQUIP

AMERICAN WELDQUIP 607CG manual