3

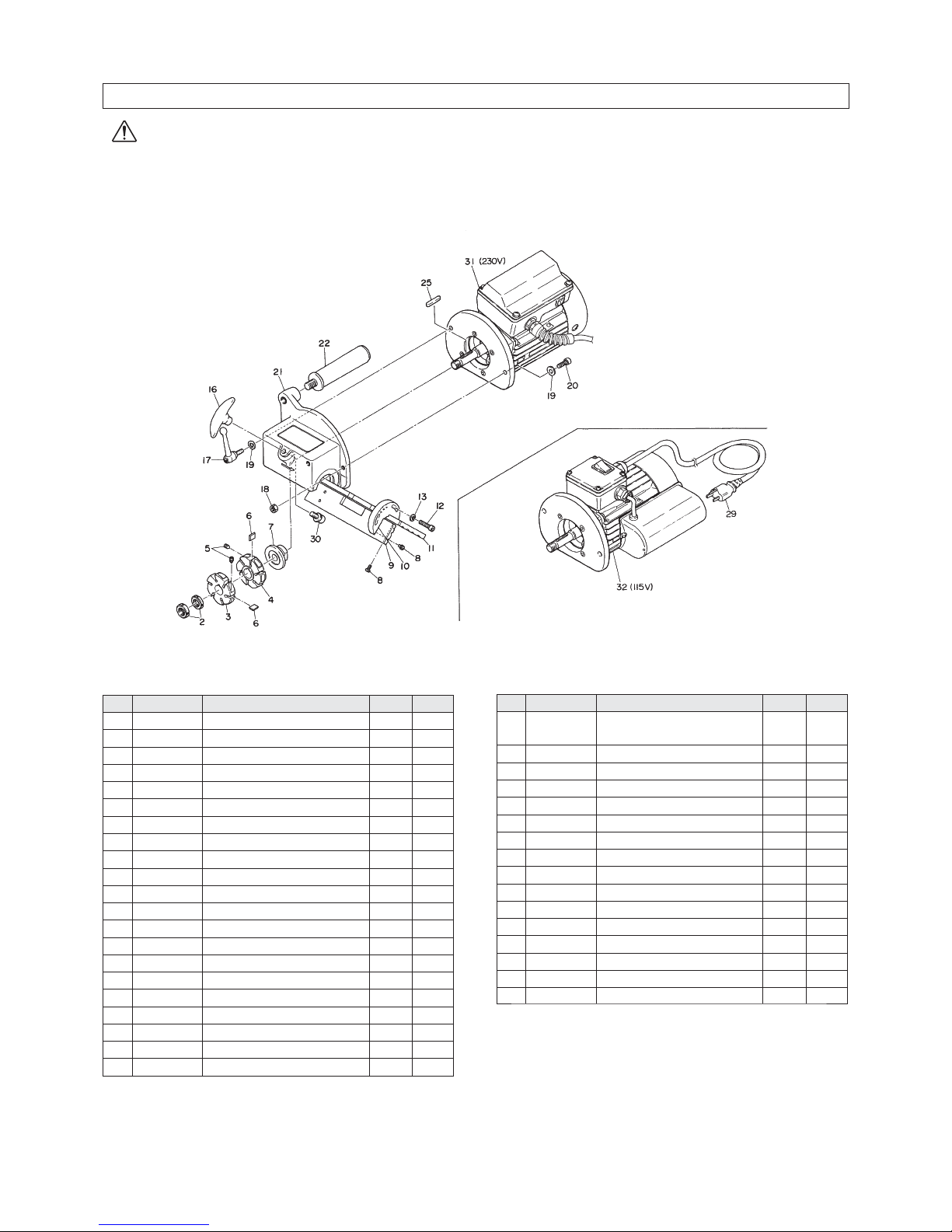

MAINTENANCE/SERVICE

●Do not take apart or modify tool.

Disassembly or modification carried out without

the supervision of a qualified or authorized service

engineer could result in an accident or injury.

●Inspect cutting tool and accessories, etc.

Always check to see that the cutting tool and

accessories, etc. are in good operating condition

without damage or deterioration before you mount

them on the tool. Should you find any damage to

an accessory or part, please contact sales agent

through which you have purchased your tool or an

authorized dealer near you for repair.

●Check parts for damage.

When you have found damage to the accessory

or other part, carefully check the damaged part to

determine the extent of influence it has upon the

functions of the tool – that is, determine whether it

can still perform its normal functions.

Check to see that the linkage of the moving parts

is OK, that all parts are OK without damage,

that they are properly mounted, and that the tool

functions normally. Should you find any damage

to an accessory or part that may hamper proper

functioning of the tool, please contact sales agent

through which you have purchased your tool or an

authorized dealer near you for repair.

●Have your tool repaired at an authorized Nitto

Service Center.

For repair or parts replacement, please contact the

sales agent through which you have purchased your

tool or an authorized dealer near you.

●Use only Nitto genuine parts.

Use of improper parts may result in serious accident.

To obtain a Nitto genuine part, consult this Manual

or contact the sales agent from which you have

purchased your tool directly.

●Do not detach label or nameplate from tool.

When a label/nameplate gets damaged, worn or

becomes missing, contact the sales agent through

which you have purchased your tool or Nitto Kohki

Co. Ltd, directly for a replacement.

DISPOSAL

When a tool is taken permanently out of service, it is

advised that the tool is disassembled, degreased and

parts separated by material and recycled locally in the

appropriate manner.

GENERAL: POWER

TOOLS

WARNING

●Always use power source per specifications on

the nameplate.

●Never connect the earthing conductor to a gas

Pipe: if you do so explosion may result.

●Check to see that there is no abnormality in

earth- clipping or earthing conductor.

Conduct continuity check between the earth clip

and a metal portion of the machine with a tester or

insulation resistance tester, if you have one. Wiring

connections involving the installation of earth bar

or plate into the ground will call for the expertise

of a qualified electrician. Please contact your local

electrical contractor.

●Don’t abuse cord.

Don’t carry tool with a cord in your hands; don’t pull

a cord to disconnect it from the socket. Don’t give

damage to cord by abusive use, such as, reworking,

forced bending, exposure to heat, pulling, twisting,

bundling, application of weight, pinching, hanging

from metal hardware, etc.

●Before using the tool, ensure that ground-fault

circuit interrupter for electrical shock guard is

installed in the power source to which the tool

will be connected, as required by the Ordinance

on Labor Safety and Hygiene and/or the

Technical Standard for Electrical Installation.

●Avoid abrupt, unintentional start.

Before connecting a power supply plug to power

source, make sure that the switch is turned off.

●Turn off the switch and disconnect the power

supply plug from power source before setting

up for operation or getting down to inspection or

maintenance work.

●Do not replace the supply cord.

When replacing the supply cord, please contact the

sales agent through which you have purchased your

tool or an authorized dealer near you.