CK WORLDWIDE PC2000-24-220V User manual

CK

Worldwide,Inc.

1

How To Use Your New Flexible Purge Chamber

January,2000

CKWorldwide,Inc.

P.O.Box1636Auburn,WA.USA98071

tel:(253)854-5820

fax:(253)939-1746

www.ckworldwide.com

NOTE: Theimportantsafeguardsandinstructionsappearingin

thispamphletshouldbereadandunderstoodpriorto

operatingyourequipment.

SafetyGuidelines ........................................................................................................................

Warranty ...............................................................................................................................

Introduction ..........................................................................................................................

Description ............................................................................................................................

Specifications ........................................................................................................................

Checklist ...............................................................................................................................

Optionalitems ......................................................................................................................

Suggestions ............................................................................................................................

Assembly ...............................................................................................................................

Installation ............................................................................................................................

Operation ..............................................................................................................................

Questions ..............................................................................................................................

TechnicalData .......................................................................................................................

TABLEOFCONTENTS:

2

4

4

4

5

5

6

6

6

6

7

7

8

2

CK Worldwide, Inc.

SAFETYRULES: WARNING: UNSAFEPROCEDURESORPRACTICESCANCAUSE

SERIOUSPERSONALINJURYORDEATH.

All end users of this equipment, the operators and helpers, read and

understand these safety rules.

PREVENTELECTRICALSHOCK:

Touching live electrical parts can cause severe burns or fatal shock.

1. Do not touch live electrical parts.

2. Do not work in wet or damp areas.

3. Wear dry insulating gloves and body protection.

4. Disconnect all power before installing or servicing this equipment.

5. Turn off all equipment when not in use.

6. Properly install and ground the welding power source according to

its Owner's Manual and all applicable codes.

7. Do not use worn or damaged cables or cables that are too small or

poorly spliced.

8. Do not wrap cables around your body.

9. Do not touch electrode and any grounded object or circuit at the

same time.

10. Use only well-maintained equipment. Repair or replace damaged

parts at once.

PROVIDEPROTECTIONFROMFUMESANDGASES:

Breathing welding fumes and gases can be hazardous to your health.

1. Keep your head out of welding fumes.

2. Use adequate ventilation in the work area to keep fumes and gases

from your breathing zone and the general work area.

3. If ventilation is inadequate, use an approved breathing device.

4. Read and understand the Material Safety Data Sheets (MSDSs) and

the manufacturer's instructions for any materials used.

Gas cylinders are normally used when welding, treat them with care.

PROTECTCOMPRESSEDGASCYLINDERS:

1. Protect compressed gas cylinders from excessive heat, mechanical

shocks and arcs.

2. Install and secure cylinders so that they cannot fall or tip over by

fastening them to a mounting bracket, wall or other stationary

support.

3. Keep cylinders away from any welding or other electrical circuits.

4. Never allow a welding electrode to touch any cylinder.

PROTECTEYESANDSKINFROMARCRAYS,PROTECTEARS

FROMNOISE:

Welding arc rays produce intense heat and ultraviolet rays that can burn

eyes and skin. Noise from some processes can also damage hearing.

1. Wear a welding helmet fitted with a proper filter lens (see ANSI

Z49.1 for detailed information).

2. Use protective screens or barriers to protect others from welding

flash and glare.

3. Wear protective clothing and foot protection.

3

Purge Chamber Manual

The hot workpiece, hot equipment, spatter, and arc sparks can cause

fires and burns.

1. Wear correct eye, face, and body protection in the work area.

2. Allow work and equipment to cool before handling.

3. Do not weld near flammable materials.

4. Watch for fire, and keep a fire extinguisher nearby.

5. For additional information, refer to NFPA Standard 51B, "Fire

Prevention in Use of Cutting and Welding Processes", available

from the National Fire Protection Association, Batterymarch Park,

Quincy MA 02269.

PREVENTFIRESANDBURNS:

PROVIDEPROTECTIONFORSPECIALSITUATIONS:

1. Do not weld or cut containers or materials which have held or been

in contact with hazardous substances unless they are properly

cleaned and inspected.

2. Do not weld or cut painted or plated parts unless special ventilation

is provided to remove highly toxic fumes or gases.

3. Since welding can affect pacemakers, keep all pacemaker wearers

out of the work area. Have them consult a doctor before coming

near a welding operation.

PROVIDEPROPEREQUIPMENTMAINTENANCE:

Improperly maintained equipment can result in poor work, but most

importantly it can cause physical injury or death through fires or

electrical shock.

1. Always have qualified personnel perform the installation,

troubleshooting, and maintenance work. Do not perform any

electrical work unless you are fully qualified.

2. Before performing any maintenance work inside a power supply,

disconnect the power supply from the electrical power source.

3. Maintain cables, grounding wire, connections, power cord, and

power supply in a safe working order. Do not operate any

equipment in questionable condition.

4. Do not abuse any equipment or accessories. Keep equipment away

from heat sources such as furnaces, wet conditions such as water

puddles, oil or grease, corrosive atmospheres, and inclement

weather.

5. Keep all safety devices, guards, panels, and covers in position and

in good repair.

6. Use equipment for its intended purpose. Do not modify it in any

manner.

SAFETYRULES:

For more information on safe practices for setting up and operating electric welding and

cutting equipment and on good working habits, ask your welding equipment supplier.

For your protection, read and comply with the latest editions of the following standards:

1. ANSI Standard Z49.1

2. ANSI Standard Z87.1

3. AWS Standard A6.1

4. AWS Standard F4.1

5. CSA Standard W117.2

6. NFPA Standard 51B

7. NFPA Standard 70

8. OSHA Standard 29 CFR, Part 1910,

Subpart Q

ADDITIONALSAFETYINFORMATION:

4

CKWorldwide,Inc.

WARRANTY: CKWorldwide,inc.warrantstheFlexiblePurgeChamberagainstdefectsin

materialsandworkmanshipforaperiodofoneyearfromthedateofpurchase.

Shoulditbecomedefectiveforsuchreason,themanufacturerwillrepairit

withoutcharge,ifitisreturnedtothemanufacturer'sfactory,freightprepaid.

Priortoreturningtheequipment,writtenauthorization,intheform ofanRGA

numbermustbeobtainedpriortoanyreturnsforanyreason. Thiswarrantydoes

notcover:(1)failureduetonormalwearandtear;(2)damagebyaccident,improper

use,neglect,unauthorizedrepairoralteration;(3)anyoneotherthantheoriginal

purchaser. Inanyevent,CKWorldwide,Inc.willonlyberesponsibleforits

productswhenusedwithaccessoryitemsmanufacturedbyCKWorldwide,Inc.

Thislimitedwarrantyisinlieuofallotherwarranties,expressedor implied.

Themanufacturershallnotbeliableforanyinjurytopersons,includingdeath;or

lossordamagetoanyproperty,directorconsequential,including,butnotlimited

tolossofuse,arisingoutoftheuse,ortheinabilitytouse,theproduct.Theuser

assumesallriskandliabilitywhatsoeverinconnectionwiththeuseofthis

product,andbeforedoingsoshalldetermineitssuitabilityforitsintendeduse,

andshallascertainthepropermethodofusingit. Thiswarrantygivesyou

specificlegalrights,andyoumayhaveotherrightswhichvaryfromstatetostate.

ThepatentedCKFlexiblePurgeChamberisusedintheGasTungstenArc

Welding(GTAW)/TungstenInertGas(TIG)processtoprovideacompletelyinert

atmospherefortheweldingofreactivemetalssuchastitanium,molybdenum,

nickel-basedandaluminum-basedalloys,aswellasnon-reactivemetalslike

stainlesssteel. Uniquetothisdesignistheabilitytodrawavacuumaroundthe

producttobeweldedwhichcollapsesthechamber,removingallatmospheric

gases. Thechamberisthenfilledthroughaperforatedhosethatcoversthe

circumferenceofthechamber. Thisfillingprocessallowstheargongastoexpel

allatmosphericgasesmoreeffectivelythantraditionalfillingmethods. This

significantlyreducesthetimerequiredtoreachatotallyinertatmospherethatis

suitableforweldingandusesconsiderablylessgasthanthetraditionalrigidpurge

chambers.

INTRODUCTION:

DESCRIPTION: TheFlexiblePurgeChamberisdesignedtorestonasupportdevicethatisthe

samediameterasthechamber'sbase. Whentheunitiscompletelydeflated,with

thechamber'swallsdrapedoverthesidesofthesupportbase,avacuumisdrawn

byeither1.)blowingcompressedairthroughtheexternalvacuum"Y"creatinga

venturicapableofexpellingtheatmosphericairinsidethechamber,or2.)

installinganauxiliaryvacuumpump. Onceavacuumisperformedthechamberis

theninflatedat35cubicfeetperhour(Excessivefillrateswillcauseturbulence

resultinginthemixingoftheargonshieldinggaswiththeairinthechamber

whichextendsthetimeittakestoobtainacompletelyinertatmosphere). The

purposeistodisplaceanyremainingatmosphericairouttheexhaustportonthe

topofthechamberusingargonwhichissignificantlyheavierthanair. Partscan

thenbeweldedinatotallyinertatmosphere.

Toremaincompetitiveinthedomesticandinternationalmarkets,weareallowing

customerstoprovidetheirownweldingtableandotheraccessoriestofitinside

thechamber.

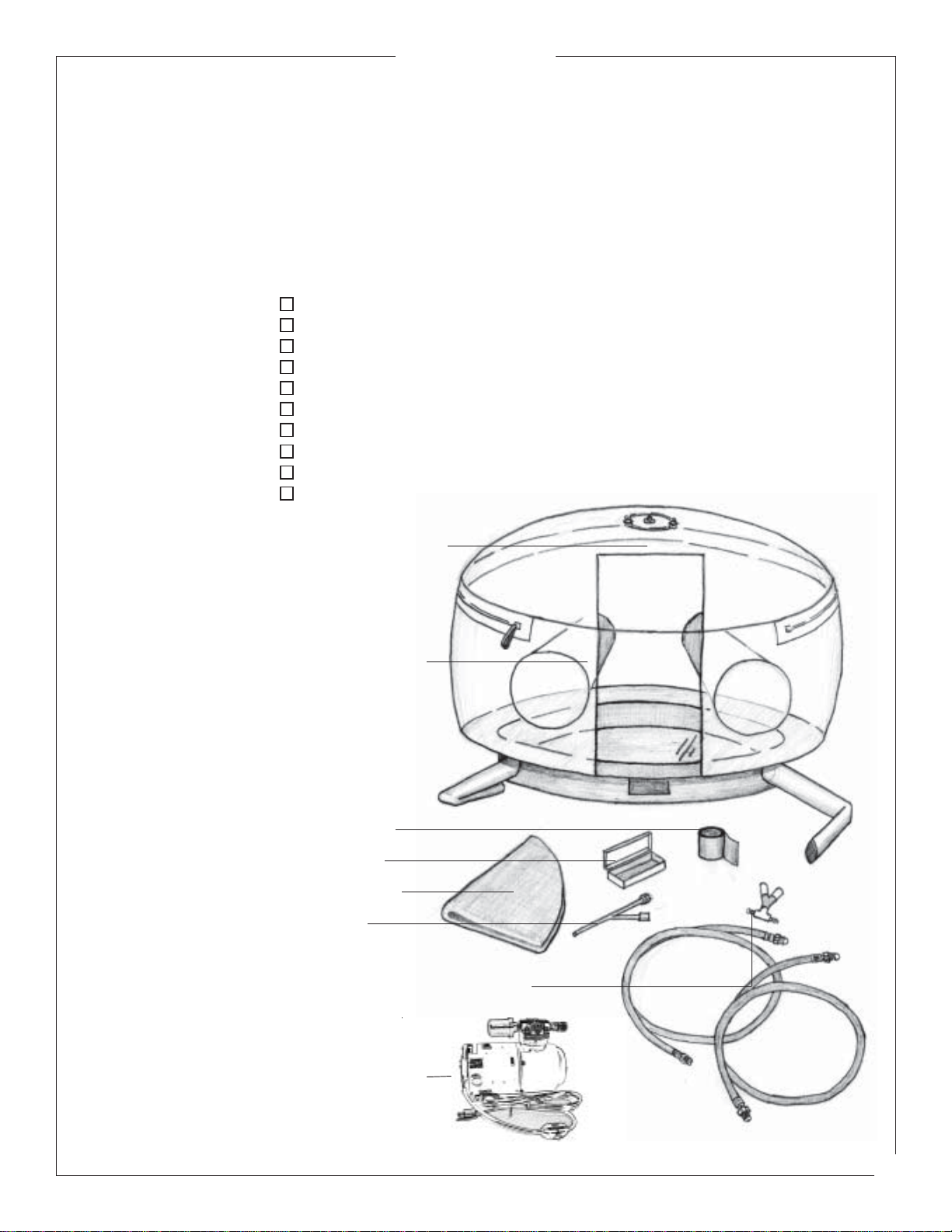

NeopreneGloves

RollofTape

TransparentFlexiblePurge

ChamberEnclosure

GasValveAssemblywithHoses

RepairKit

HeatBlanket

Venturi

5

PurgeChamberManual

SPECIFICATIONS: FLEXIBLEPURGECHAMBER:

20"

30"*

17lbs.

30"Diameter

30"RangeofMovement

24"Base

*Contactfactoryforpriceandavailabilityonothersizes.

Height:

Width:

ShippingWeight:

StandardSize*:

CHECKLIST: One(1)TransparentFlexiblePurgeChamberEnclosure

Four(4)NeopreneGloves-Two(2)Installed

One(1)RollofTape

One(1)RepairKit

One(1)HeatBlanket

One(1)Venturi

One(1)GasValveAssembly(installed)withHoses

One(1)ElectricVacuumPump

One(1)Flow-meter/RegulatorwithArgonhose

One(1)StorageContainer

VacuumPump

6

CKWorldwide,Inc.

OPTIONAL

ITEMS: TIGTorchandaccessories-refertoextravaluebrochure(form3000).

ColdWireFeedUnit.

Extraneoprenegloves.

SUGGESTIONS: 1. Ifweldedpartsaretoohottohandle,useforcedgascoolingwithasmallfan

tospeedupthecoolingprocessinsidethechamber. Donotuseleathergloves

insidethechamber,astheycancausecontamination.

2. Tokeephandscomfortable,cottonglovescanbeworninsideneoprene

gloves.

3. Thecomponentsbeingputintothechambermustbecleanedwithasuitable

solventanddried. Thepartsshouldbehandledwithcleanhands.

4. Donotcollapsechamberbeforepartshavecooled.

ASSEMBLY: Ifthechamberhasbeenexposedtotemperatureextremes,itshouldbeleftfor

severalhourstoreachroomtemperature. Prematureunpackingcouldleadto

cracking,scuffingand/ordeformation. Thechamberisquotedandnormally

suppliedinitsbareformandwillneedahardinternalbase,anexternalsupport

table,anargongassupplywithflowmeter,compressedair(forvacuumprocess),a

weldingtorchandgroundcable.

Unpackthechambercarefullytoavoidcracking,scratchingortearing. Placethe

chamberonapreparedtabletop,thesamediameterastheinnerbasering. At

thistimetheheatblanketshouldbeplacedontheplasticbaseinsidethechamber.

Asteelplateshouldthenbeplacedontopoftheheatblanket.Astainlesssteel

plateisrecommended(1/4"-1/2").Theblanketsedgeswillbeexposedaround

theperimeterinsidethechamber,toprotectthesidesofthechamber.

Note:Theheatblanketactsasalowtemperatureprotectorthatinsulatesthesteel

baseplatefromtheplasticbase.Theblanketisnotintendedtobeweldedon.

INSTALLATION: Insertthetorchassemblyintothechamberthroughoneoftheaccessoryports.

Youwillneedtopierceaholeattheportentranceofthechamber. Removeall

front-endpartsfromTIGtorch. Oncethetorchhasbeeninserted,usethetape

provided,orducttape,tosealtheportsleeveontothetorchcable. Theground

cableandotheraccessoriesshouldbeinstalledthroughoneoftheaccessoryports

inthesamemanner,thensealed.

Connectthegashoseassemblytothechamberatthe1/4"NPTinlet. Next,

connectthehosecomingfromthe"Y"labeled"GAS"toaregulator/flowmeter.

Theunitisnowreadytohavepartsinsertedforwelding.

7

PurgeChamberManual

OPERATION: Ensurethereissufficienthighpurityargoninthepurgechambersupplybottle

andthetorchgassupplybottletocompleteallweldingoperations. Failureto

dothiswillresultintheintroductionofairduringabottlechangewhichwill

requirere-purgingofthesystem. Checktoensurethatallgaslinestothe

chamber,theweldingmachine,andregulator/flowmeteraretight. Also,check

toensurethatallaccessoryportsthatareinuseareproperlytaped. Check

glovesforanydamage.

Loadthecomponentsintothechamberandclosethezipper. Purgeoutthe

torchlines. Thechambercanbepresseddownaroundthepartstoexpelthe

majorityoftheair. Makesurethattheexhaustventonthetopofthechamber

isclosed. Tocompletethevacuumprocess,oneoftwomethodscanbeused:

1.)"Y"Vacuum:Compressedairisblownthroughtheinletofthe"Y"which

createsaventurieffect,extractingalloftheremainingairinthechamber,or

2.)ElectricVacuumPump:Plugpumpinto115VACcircuit,leaveonuntilall

airisvacatedfromthechamber.

Note:Makesurewhenperformingavacuumthatthevacuumvalveisopen

andthegasvalveisclosedonthegas"Y".

Atthistime,turnonargongassupply,openexhaustvalveontopofthe

chamber,makingsurevacuumvalveisclosedandgasvalveisopenongas"Y".

Theargonflowrateshouldnotexceed35cubicfeetperhour,otherwise

turbulencewillcausemixingoftheargonshieldinggaswiththeairinthe

chamber. Whenthechamberiscompletelyinflatedatestweldonapieceof

scrapmaterialshouldbeperformed. Ifanydiscolorationorcontaminationis

present,repeatthepurgeprocess.

QUESTIONS: Anyuserrequiringfurtheradviceinanymatterconcerninginstallation,

operation,maintenanceorsafetycancallorwrite:

CK Worldwide, Inc.

P.O.Box1636

Auburn, WA. 98071

tel:+ 1 253 854 5820

fax:+ 1 253 939 1746

www.ckworldwide.com

CK

Worldwide,Inc.

TUNGSTEN

ELECTRODE

SELECTOR

CHART:

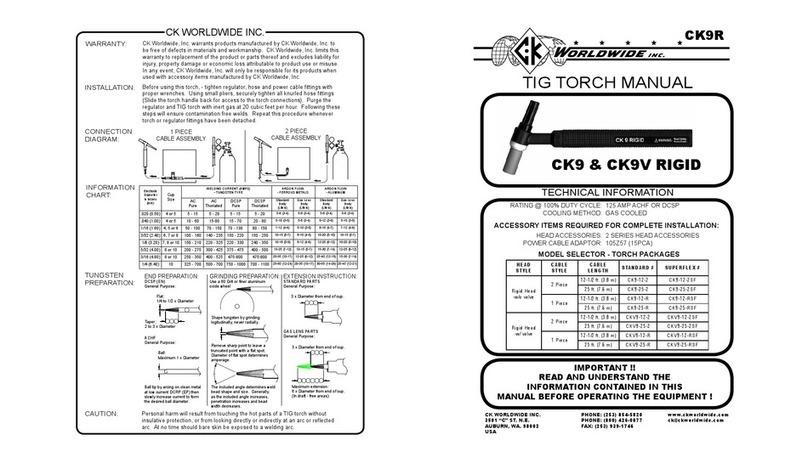

ENDPREPARATION GRINDINGINSTRUCTIONS EXTENSIONINSTRUCTIONS

TUNGSTEN

PREPARATION: STANDARDPARTS

General Purpose:

Extension:

3 x Diameter from end of

cup.

GASLENSPARTS

General Purpose:

Extension:

3 x Diameter from end of

cup.

Maximumextension:

6 x Diameter from end of

cup.

(In draft-free areas)

Shapetungsten bygrindinglogitudinally,neverradially.

Removesharp pointtoleaveatruncatedpointwith a

flatspot. Diameterofflat spotdetermines amperage.

Theincludedangledeterminesweldbeadshapeand

size. Generally,astheincludedangleincreases,

penetrationincreasesandbeadwidthdecreases.

Usea 60grit orfiner aluminumoxide wheel.

Balltip byarcingon cleanmetalatlow

currentDCRP(EP)thenslowlyincrease

currenttoform thedesiredball

diameter.

DCSP(EN)

General Purpose:

Flat:

1/4to1/2xDiameter

Taper:

2 to 3 x Diameter

ACHF

General purpose:

Ball:

Max. 1 x Diameter

BASEMETAL

TYPE Ballseasily,tendstospitathighercurrents,

usedfor noncriticalweldsonly.

Ballswell,high current, littlespitting,good

arcstarts,goodstability.

Mediumerosionrate,highcurrentrange,little

spitting,good arcstarts,goodstability.

Lowesterosionrate,widestcurrentrange,no

spitting,best arcstarts,beststability.

Mediumerosionrate,mediumcurrentrange,

mediumspitting, goodarcstarts,best stability.

Lowerosionrate,wide currentrange,no

spitting,consistent arcstarts,goodstability.

Mediumerosionrate,mediumcurrentrange,

mediumspit, goodarcstarts,best stability.

Lowerosionrate,wide currentrange,no

spitting,consistent arcstarts,best stability.

Rapiderosionrateathighercurrents,low

currentrangerecommended,spittingonstarts.

Lowerosionrate,wide currentrange,no

spitting,consistent arcstarts,goodstability.

Mediumerosionrate,mediumcurrentrange,

mediumspitting, goodarcstarts,best stability.

Lowerosionrate,wide currentrange,no

spitting,consistent arcstarts,goodstability.

Lowerosionrate,widestcurrentrange,no

spitting,best (DC)arcstarts,best stability.

Rapiderosionrateathighercurrents,low

currentrangerecommended,spittingonstarts.

Lowerosionrate,wide currentrange,no

spitting,consistent arcstarts,goodstability.

Lowesterosionrate,highestcurrentrange,no

spitting,best (DC)arcstarts,best stability.

SHIELDGAS

ELECTRODE

TYPE

Pure(EW-P)

WELDING

CURRENT

DESIREDRESULT

MATERIAL

RANGE

75%Argon

25%Helium

50%Argon

50%Helium

75%Argon

25%Helium

75%Argon

25%Helium

75%Argon

25%Helium

Argon

Argon

Helium

Argon

75%Argon

25%Helium

75%Argon

25%Helium

75%Argon

25%Helium

75%Argon

25%Helium

Helium

Argon

75%Argon

25%Helium

Zirconiated

(EW-Zr)

2%Thoriated

(EW-Th2)

2%Ceriated

(EW-Ce2)

2%Thoriated

(EW-Th2)

2%Ceriated

(EW-Ce2)

2%Thoriated

(EW-Th2)

2%Ceriated

(EW-Ce2)

Zirconiated

(EW-Zr)

2%Ceriated

(EW-Ce2)

2%Thoriated

(EW-Th2)

2%Ceriated

(EW-Ce2)

2%Lanthanated

(EW-Ce2)

Zirconiated

(EW-Zr)

2%Ceriated

(EW-Ce2)

2%Lanthanated

(EW-Ce2)

ACHFGeneralpurposeAll

Only thin

sections Controlpenetration DCRP

DCSPGeneralpurposeAll

Increasepenetration

ortravelspeed

Onlythick

sections

Only thin

sections Controlpenetration ACHF

Increasepenetration

ortravelspeed

Onlythick

sections

DCSPGeneralpurposeAll

Only thin

sections Controlpenetration ACHF

Increasepenetration

ortravelspeed

Onlythick

sections

Aluminum

alloysand

Magnesium

alloys

Copperalloys

Cu-NIalloys

and

Nickelalloys

Mildsteels

Carbonsteels

Alloysteels

Stainlesssteels

andTitanium

alloys

TUNGSTENPERFORMANCE

CHARACTERISTICS

DCSP

DCSP

DCSP

TECHNICAL

INFORMATION

CHART:

WELDINGCURRENT (AMPS)

-TUNGSTENTYPE ARGON FLOW (CFH)

-FERROUSMETALS ARGON FLOW (CFH)

- ALUMINUM

AC

PURE AC

THORIATED DCSP

PURE DCSP

THORIATED STANDARD

BODY GASLENS

BODY STANDARD

BODY GASLENS

BODY

CUP

SIZE

ELECTRODE

DIAMETER

(inches)

.020 4 or 5 5-15 5-20 5-15 5-20 5-8 5-8 5-8 5-8

.040 4 or 5 10-60 15-80 15-70 20-80 5-10 5-8 5-12 5-10

1/16 4,5or6 50-100 70-150 70-130 80-150 7-12 5-10 8-15 7-12

3/32 6,7or8 100-160 140-235 150-220 150-250 10-15 8-10 10-20 10-15

1/8 7, 8 or 10 150-210 220-325 220-330 240-350 10-18 8-12 12-25 10-20

5/32 8or10 200-275 300-425 375-475 400-500 15-25 10-15 15-30 12-25

3/16 8or10 250-350 400-525 475-800 475-800 20-35 12-25 25-40 15-30

1/4 10 325-700 500-700 750-1000 700-1100 25-50 20-35 30-55 25-45

FormNo. 5702

CKWorldwide,Inc.

P.O. Box1636Auburn,WA.98071

tel: (206)854-5820

fax: (206)939-1746

8

Table of contents

Other CK WORLDWIDE Welding Accessories manuals

Popular Welding Accessories manuals by other brands

Lincoln Electric

Lincoln Electric K2613-5 Operator's manual

Antra

Antra Digital-Pro Series user manual

Kemper

Kemper VacuFil 125 operating manual

FRONIUS

FRONIUS TTG 1200 operating instructions

FRONIUS

FRONIUS TTB Series installation instructions

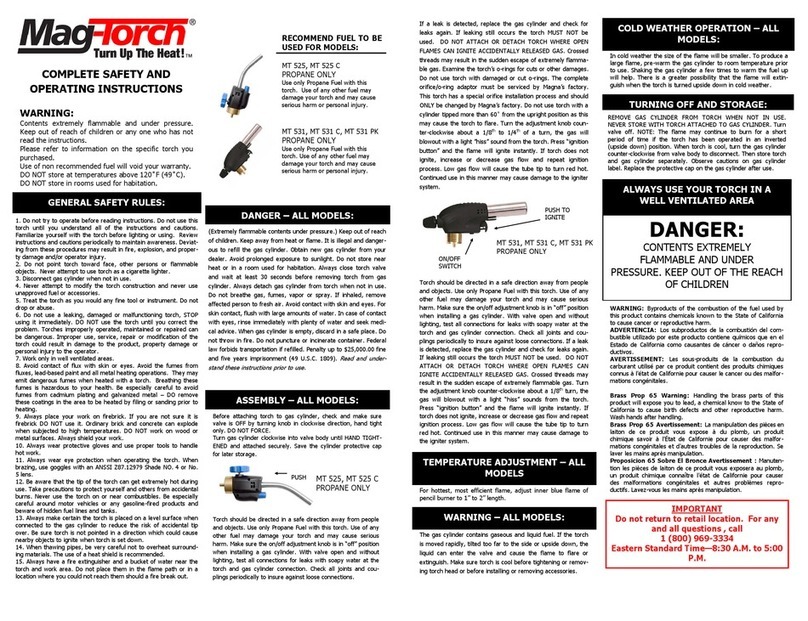

Mag-Torch

Mag-Torch MT 525 Safety and operating instructions