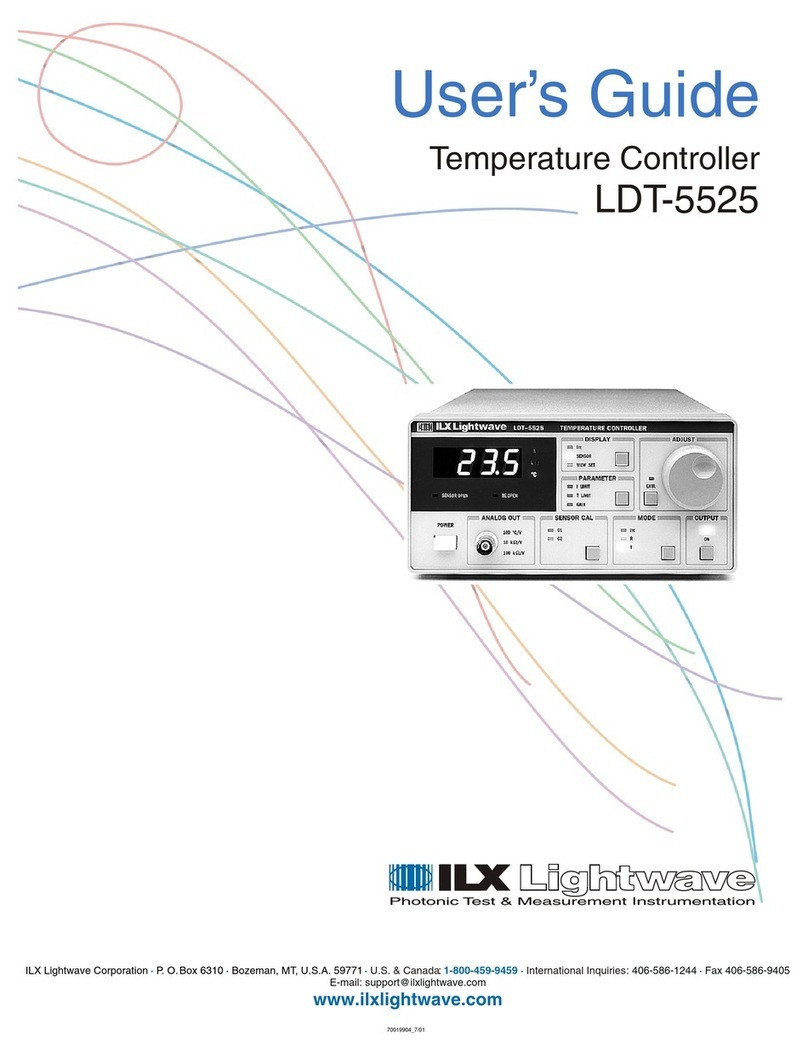

ILX Lightwave LDT-5416 User manual

User’s Guide

Thermoelectric Temperature Controller

LDT-5416

700527 November 2016

ILX Lightwave · 31950 Frontage Road · Bozeman, MT, U.S.A. 59715 · U.S. & Canada: 1-800-459-9459 ·International Inquiries: 406-556-2481 · Fax 406-586-9405

www.newport.com/ilxlightwave

November 2016 i LDT-5416

Table of Contents

Safety Information and the Manual............................................................................ iii

General Safety Considerations.................................................................................. iii

Safety Symbols .........................................................................................................iv

Warranty.....................................................................................................................v

Limitations..................................................................................................................v

Returning an Instrument............................................................................................vi

Claims for Shipping Damage........................................................................................................... vi

Comments, Suggestions, and Problems .................................................................. vii

Chapter 1: Introduction and Specifications.................................................1

Safety Considerations ................................................................................................1

Initial Inspection..........................................................................................................1

Product Overview.......................................................................................................2

Options and Accessories............................................................................................3

Specifications.............................................................................................................4

Chapter 2: General Operation....................................................................5

Grounding Requirements ...........................................................................................5

AC Line Power Requirements....................................................................................5

The Power Up Sequence ...........................................................................................5

Connections ...............................................................................................................6

Front Panel Operation................................................................................................7

Power On / Off..................................................................................................................................8

I LIMIT Knob.....................................................................................................................................8

Setpoint Adjustment Knob................................................................................................................8

Display Mode and 7 Segment LED Display .....................................................................................8

Error Indicators.................................................................................................................................8

Output Off/On Button........................................................................................................................9

General Operating Procedures...................................................................................9

Warm-Up and Environmental Considerations..................................................................................9

November 2016 ii LDT-5416

General Guidelines for Sensor Selection and Safety Limits .....................................10

Sensor Options...............................................................................................................................10

General Operation....................................................................................................13

Chapter 3: Troubleshooting......................................................................15

Troubleshooting Guide.............................................................................................16

November 2016 iii LDT-5416

Safety and Warranty Information

Details about cautionary symbols

Safety markings used on the instrument

Information about the warranty

Customer service contact information

Safety Information and the Manual

Throughout this manual, you will see the words “Caution”and “Warning”indicating potentially

dangerous or hazardous situations which, if not avoided, could result in death, serious or minor injury,

or damage to the product. Specifically:

Caution indicates a potentially hazardous situation which can result in minor or moderate injury or

damage to the product or equipment.

Warning indicates a potentially dangerous situationwhich can result in serious injury or death.

General Safety Considerations

If any of the following conditions exist, or are even suspected, do not use the instrument until safe

operation can be verified by trained service personnel:

Visible damage

Severe transport stress

Prolonged storage under adverse conditions

Failureto performintended measurementsor functions

If necessary, return the instrument to ILX Lightwave, or authorized local ILX Lightwave distributor, for

service or repair to ensure that safety features are maintained.

All instruments returned to ILX Lightwave are required to have a Return Authorization Number

assigned byan official representative of ILX Lightwave Corporationprior to shipping the instrument.

See Returning an Instrument for more information.

November 2016 iv LDT-5416

Safety Symbols

This section describes the safety symbols and classifications.

Technical specifications including electrical ratings and weight are included within the manual. See

the Table of Contents to locate the specifications and other product information. The following

classifications are standard across all ILX Lightwave products:

Indoor use only

Ordinary Protection: This product is NOT protected against the harmful ingress of

moisture.

IEC Class I Equipment (grounded type)

Mains supply voltage fluctuations are not to exceed ±10% of the nominal supply voltage.

Pollution Degree II

Installation (overvoltage) Category II for transient over-voltages

Maximum Relative Humidity: <85% RH, non-condensing

Operating temperature range of 10°C to 40°C

Storage and transportation temperatureof –40°C to 70°C

Maximum altitude: 3000m (9843ft.)

This equipment is suitable for continuous operation.

November 2016 v LDT-5416

Safety Marking Symbols

This section provides a description of the safetymarking symbols that appear on the instrument.

These symbols provide information about potentially dangerous situations which can result in death,

injury, or damage to the instrument and other components.

Caution, refer

tomanual

Earth ground

Terminal

Alternating current

Visible and/or

invisible laser

radiation

Caution, risk of

electricshock

Protective

Conductor

Terminal

Caution,

hot surface

Frame orchassis

terminal

Warranty

ILX Lightwave Corporation warrants this instrument to be free from defects in material and

workmanship for a period of one year from date of shipment. During the warranty period, ILX will

repair or replace the unit, at our option, without charge.

Limitations

This warranty does not apply to defects caused by abuse, modifications, or to use of the product for

which it was not intended.

This warranty is in lieu of all other warranties, expressed or implied, including any implied warranty of

merchantabilityorfitness for any particular purpose. ILX Lightwave Corporation shall not be liable for

any incidental, special, or consequential damages.

If a problem occurs, please contact ILX Lightwave Corporation with the instrument's serial number,

and thoroughly describe the nature of the problem.

November 2016 vi LDT-5416

Returning an Instrument

If an instrument is to be shipped to ILX Lightwave for repair or service, be sure to:

Obtain a Return Merchandise Authorization number (RMA) from ILX Customer Service prior

to shipping the instrument.

Attach a tag to the instrument identifying the owner and indicating the required service or

repair. Include the instrument serial number from the rear panel of the instrument.

Attachthe anti-staticprotective capsthat were shipped with the instrument.

Place the instrument in the original packing container with at least 3 inches (7.5 cm) of

compressible packaging material. Shipping damage is not covered by this warranty.

Secure the packing box with fiber reinforced strapping tape or metal bands.

Send the instrument, transportation pre-paid, to ILX Lightwave. Clearly write the return

authorization number on the outside of the box and on the shipping paperwork. ILX

Lightwave recommends you insure the shipment.

If the original shipping container is not available, place your instrument in a container with at

least 3 inches (7.5 cm) of compressible packaging material on all sides.

Repairs are made and the instrument returnedtransportation pre-paid. Repairs are warranted for the

remainder of the original warranty orfor 90 days, whichever is greater.

Claims for Shipping Damage

When you receive the instrument, inspect it immediately for any damage or shortages on the packing

list. If the instrument isdamaged, file a claim with the carrier.The factorywill supply you with a

quotation for estimated costs of repair. You must negotiate and settle with the carrier for the amount

of damage.

November 2016 vii LDT-5416

Comments, Suggestions, and Problems

To ensurethat you get the most out of yourILX Lightwave product, we ask that you direct any

product operation or service related questions or comments to ILX Lightwave Customer Support. You

may contact us in whatever way is most convenient:

Phone: (800) 459-9459 or (406) 586-1244

Fax: (406) 586-9405

On the web at: http://www.newport.com/locations/brandcontacts.aspx?brandid=19

Or mail to:

ILX Lightwave Corporation

31950 East Frontage Road

Bozeman, Montana, U.S.A 59715-8642

www.newport.com/ilxlightwave

When contacting ILX Lightwave, please have the following information:

Model Number

Serial Number

End-user Name

Company

Phone

Fax

Description of what is connected to the ILX Lightwave instrument

Description of the problem

If ILX Lightwave determines that a return to thefactory is necessary, a Return Merchandise

Authorization (RMA) number will be issued. Please mark this number on the outside of the shipping

box.

You or your shipping service is responsiblefor any shipping damage when returning the instrument

to ILX Lightwave; ILX recommends you insurethe shipment. If the original shipping container is not

available, place your instrument in a container with at least 3 inches (7.5 cm)of compressible

packaging material on all sides.

We look forward to serving you even better in the future!

November 2016 viii LDT-5416

November 2016 1 LDT-5416

Chapter 1:

Introduction and Specifications

This chapter is an introduction to the LDT-5416 Thermoelectric Temperature Controller.

Safety Considerations and unpacking information

Product Overview

Options and accessories

Specifications

Safety Considerations

If any of the following symptoms exist, or are even suspected, remove the LDT-5416 from

service. Do not use the LDT-5416 until trained service personnel can verify safe operation.

Visible damage

Severe transport stress

Prolonged storage under adverse conditions

Failure to perform intended measurements or functions

If necessary, return the LDT-5416 to ILX Lightwave for service and repair to ensure that

safety features are maintained.

Initial Inspection

When you receive your LDT-5416 Thermoelectric Temperature Controller, verity that the following

items were shipped with the instrument

Certificate of Calibration

USB Flash Drive with LDT-5416 Thermoelectric Controller Manual

Power Cord

November 2016 2 LDT-5416

Product Overview

The LDT-5416 is a thermoelectric temperature controller capable of stably and accurately

controlling thermoelectric mounts in low power applications. This is achieved by modulating the

current through a thermoelectric load and continuously monitoring the feedback signal

generated from a thermistor temperature sensor. The linear output stage of the LDT-5416 offers

the low current noise necessary to achieve the temperature stability required in most low-noise

and frequency-stabilized laser applications.

Features of the LDT-5416 include:

Long term temperature stability of ±0.01°C

Linearized thermistor mode allows temperature readout accurateto ±1°C with specific 10kΩ

thermistors

Bipolar 16Watt linear output stage

PI control loop with adjustable P gain and fixed I gain

12 Volt bias for operating external fans

Buffered analog measurement output

If cleaning is required, use a clean dry cloth. Do not use solvents.

Figure 1.1 –LDT-5416 Front Panel

November 2016 3 LDT-5416

Figure 1.2 –LDT-5416 Rear Panel

Options and Accessories

Options and accessoriesavailable for LDT-5416 Thermoelectric Temperature Controller include the

following:

DESCRIPTION

MODEL / PART NUMBER

Temperature Controller Interconnect Cable (terminated with 9-pin DSUB)

CC-505S

Temperature Controller Interconnect Cable (unterminated)

CC-501S

Calibrated 10kΩ Thermistor

TS-510

Uncalibrated 10kΩ Thermistor

TS-520

Uncalibrated 100kΩ Thermistor

TS-525

Unipolar Control Adapter

UCA-350

TO-Can Laser Diode Mount

LDM-4405

Telecommunications Series Laser Diode Mount

LDM-4980

Production Line TO-Can Laser Diode Mount

LDM-4990

November 2016 4 LDT-5416

Specifications

November 2016 5 LDT-5416

Chapter 2:

General Operation

This chapter is an overview of the operation of the LDT-5416 Thermoelectric Temperature

Controller.

Power requirements

Front panel operation

General operating procedures

Grounding Requirements

The LDT-5416 Thermoelectric Temperature Controller comes with a three conductor AC power

cable.The power cable must be plugged into an approved three-contact electrical outletor used

with a three-contact totwo-contact adaptor with the grounding wire connected to an electrical

ground (safety ground). ILX Lightwave recommends connecting the instrument only to properly

earth grounded receptacles. The power cord connector and provided power cable meet IEC

safety standards.

AC Line Power Requirements

The LDT-5416 Thermoelectric Temperature Controller features a universal input and can be

operated at nominal line voltages of 90 - 240 VAC and 50 –60 Hz.

The Power Up Sequence

Prior to power up ensure that the ventilation holes located on the left and right hand side

as well as on the top of the instrument have no obstructions that would impede airflow.

With the LDT-5416 connected to an AC power source, pressing POWER supplies AC line power to

the instrument. After power-up, make sure that the OUTPUT is off (LED unlit) until you have

configured the instrument for your application.

November 2016 6 LDT-5416

Connections

Temperature Control Output: A 15-pin D-Subminiatureconnector is located on the back panel of

the instrument. The connections for each terminal are shown below.

LDT-5416

PIN NUMBER

CONNECTION

1

TE Module (+)

2

TE Module (+)

3

TE Module (-)

4

TE Module (-)

5

External Setpoint

6

External Setpoint

7

Sensor (+)

8

Sensor (-)

9

Analog Ground

10

Control Signal

11

N/C

12

N/C

13

N/C

14

Fan (+)

15

Fan (-)

Figure 2.1 –LDT-5416 Output Connector

The TE drive current is available at the 15 pin connector. Pins 1 and 2 and pins 3 and 4 are tied

together internally. Pins1 and 2 source current while cooling and sink current while heating. Pins 3

and 4sink current while cooling and source current while heating.

An NTC Thermistor is required to sensethe load temperature and must be connected between pins

7 and 8.

An external resistor may be used to control the setpoint resistance; this resistor must be connected

between pins 5 and 6. The SET RESISTANCE switch must be in the EXT position in order to use the

external resistor as a setpoint, otherwise the setpoint is controlled by the front panel knob.

The control signal on pin10 provides approximatelya 1 V/A signal referenced to pin 9, which can be

used to drive an isolated booster current supply.

Pins 14 and 15 provide the ability to power an external fan through the 15-pin DSUB connector.

This circuit can provide up to 100 mA at a nominal voltage of 12 VDC. This feature includes

current limiting and over-power shutdown for the external fan.

November 2016 7 LDT-5416

THERMISTOR MODE: A three position switch that adjusts the measurement and setpoint current

sources and also determines how the values are displayed on the front panel.The 10µA and 100µA

positionsconfigure the sensor current source for the selected value and displays the value of the

setpoint and current sensor in kon the front panel. °C LINEARIZED FOR 10kis a special mode

that places a 10kresistor in parallel with the thermistor to linearize the temperature response. The

front panel is calibrated to display the approximate temperature with an accuracy of ±1.0°C in °C

when a 10kthermistor is used as the sensor.

SET RESISTANCE: Allows the operator to bypass the set resistance function of the front panel and

externally control to a known resistance. When the switch is in theEXT position, the temperature is

controlled to match the resistance measured between pins 5 and 6 of the OUTPUT connector. This

mode is useful if always operating at the same setpoint. When the switch is in the INT position, the

external resistor is ignored and the front panel knob controls the temperature setpoint.

ANALOG OUTPUT: An isolated BNC connector is located on the rear panel of the LDT-5416 that

provides the capability to externally measure the voltage at the thermistor terminals. The nominal

gain of this connection is 10mV/kΩ in the 10µA range and 100mV/kΩ in the 100µA range. In the

linearized operating mode the voltage present at this connection mirrors the voltage present across

the parallel combination of the thermistor and a 10kΩ resistor with 100µA passing through the

combination. The nominal output impedance of this connection is 2kΩ.

GAIN: A single turn potentiometer which adjuststhe control loop gain. This adjustment affects the

slew rate and settling time of the LDT-5416 when reaching the desired setpoint. If the GAIN is set too

low (counter-clockwise), the LDT-5416 will take longer to reach the desired setpoint. If the GAIN is

set too high (clockwise), the LDT-5416 may oscillate around the desired setpoint.To adjust, use a

small blade screwdriver.

Front Panel Operation

This section describes the fundamentals of operation for the LDT-5416 Thermoelectric Temperature

Controller. The order of descriptions will follow the normal progression of how the user would typically

configure the instrument for use for the first time.

Figure 2.2 –LDT-5416 Front Panel

November 2016 8 LDT-5416

Power On / Off

The POWER button applies power to the LDT-5416.

I LIMIT Knob

The current LIMIT knob allows the user to set the upper limit of the output current. The user may

adjust the output current from zero (LIMIT knob turned fully counterclockwise CCW) to 4 Amps

(LIMIT knob turned fully clockwise CW). This LIMIT knob is recessed to prevent accidental

readjustment of the output current during operation.

The LIMIT current value is not displayed, but the adjustment is linear. For example, setting the

LIMIT knob half-way between 0 and 4 Amps will limit the output current to 2 Amp. A more

accurate LIMIT setting may be attained by the following procedure:

1. Connect a short between pins 2 and 3 of DB15 (TE OUTPUT connector on rear panel). Connect

a 10 kresistor across pins 7 and 8 of DB15.

2. Set the DISPLAY MODE switch to TE CURRENT. Turn the OUTPUT switch on (LED lit). Adjust

the Main Control Knob fully counter-clockwise (CCW).

3. Adjust the LIMIT control until the display reads the desired limit current. Turn the OUTPUT off,

remove the short from pins 2 and 3 of DB15, and remove the resistor form pins 7 and 8 of DB15.

During operation the TE output current is unconditionally limited to the value set by the LIMIT

adjustment

Setpoint Adjustment Knob

The Setpoint Adjustment knob is located on the upper right side of the LDT-

5416 front panel and is used to set the desired operating, or setpoint,

resistance or temperature of theload. The setpoint may be set from 0.00kΩ

to ~20.00kΩ when the instrument is in the 100µA Sensor Mode (see

SENSOR MODE below),from 0.0kΩ to ~200.0kΩ in the 10µA mode and

from approximately 10°C to 70°C but will only meet the stated accuracy

specification when set between 10°C and 40°C (see LINEARIZED MODE

below). Rotating the knob clockwise in 10/100µAmode will increase the

resistance (decrease the temperature) and rotating counterclockwise will decrease the resistance

(increase the temperature). When the LDT-5416 is in °C LINEARIZED FOR 10krotating the knob

counter clockwise will increase the temperature and when rotating clockwise will decreasethe

temperature. This is dueto the negative temperature coefficient of NTC thermistors where in a

decrease in resistance represents an increase in temperature.

Display Mode and 7 Segment LED Display

Using the button located under the DISPLAY MODE will allowthe user to cycle between ACTUAL,

SET, and TEC CURRENT on the 7 segment LED display. When the ACTUAL LED is illuminated the

display reads the measured resistance or temperature (linearized mode) of the thermistor, the SET

LED when illuminated displays the set point resistance or temperature (linearized mode), and when

the TE CURRENT LED is illuminated the LDT-5416 will display the actual measured TEC current.

Error Indicators

TEC OPEN: Indicates that the thermoelectric voltage exceeds the rated compliance voltage of the

instrument. The output must be on to enable monitoring of TEC OPEN. Detection of a TEC OPEN

November 2016 9 LDT-5416

state will shut the output off. The indicator will remain illuminated aftera fault until the output is

enabled or power is cycled. In some instances a TEC OPEN fault may occur with high impedance

TECs and can be remedied by reducing the current limit as toreduce the maximum voltage

generated.

SNS OPEN: Indicates that the thermistor or external setpoint resistance has exceeded 50kwhen

the 100µA or Linearized sensor mode is selected or500kwhen the 10µA sensor mode is selected.

Like the TEC OPEN indicator, the output must be on to enable monitoring of SNS OPEN. Detection

of a SNS OPEN state will shut the output off. The indicator will remain illuminated after a fault untilthe

output is enabled or power is cycled.

I LIMIT: This LED indicates that the current output is limited by the limit setpoint. It is normal for this

indicator to illuminate shortly after turning the output on, or when load power changes significantly. If

the indicator stays on or occasionally turns on after a long period, the controller cannot maintain

temperature due to the power requirements of the load. Changing the temperature setpoint, or

increasing the current limit, if it is safe to do so, can fix this problem.

Output Off/On Button

The OUTPUT off/on switch is located in the lower right-hand corner of the front panel. This

switch has a toggling action which turns the output current of the LDT-5416 off and on. When

the output is active, the LED indicator just above the switch will be lit.

When the OUTPUT is off, it is safe to connect or disconnect sensitive devices from the LDT-

5416, even though the power supply is on. The OUTPUT is off when AC power is first applied to

the instrument. Additionally, there are three other conditions which will automatically cause the

output to reset to the off state:

•Power Drop-outs - AC line power drop-outs lasting more than about 1 second will trigger an

internal power monitor and cause the output to switch unconditionally to the off state. This

sequence is also initiated when the LDT-5416 is switched off or unplugged.

•SNS OPEN - If the externally connected thermistor or set point resistor is open, the output is

switched to the off state and the SNS OPEN LED indicator is illuminated.

•TEC OPEN –If the connected TEC exceeds the rated voltage of the LDT-5416 the output will be

disabled and the TEC OPEN LED will be illuminated.

If any of these conditions occur and the OUTPUT turns off; output may be turned on again by

first correcting the cause of the fault and then pressing the OUTPUT off/on switch.

General Operating Procedures

The discussion below presentsguidelinesfor operation as well assome commonoperating

procedures.

Warm-Up and Environmental Considerations

To achieve the rated accuracy, allow the LDT-5416 to warm-up for at least onehour before use.

Operate the controller within the environmental limits specified in Chapter 1.

November 2016 10 LDT-5416

General Guidelines for Sensor Selection and Safety Limits

This section presents some guidelines to assist in selecting the optimal settings for your

application.

Sensor Options

The LDT-5416 Thermoelectric Temperature Controller can measure resistance of a thermistor

and display the output either in resistance or a calculated temperature. When the rear panel

switch is set to 100µA or 10µA the LDT-5416 will display resistance. When the rear panel switch

is set to °C LINEARIZED FOR 10kthe LDT-5416 will display a calculated temperature.

Thermistor Range

Thermistors can span a wide temperature range, but their practical range is limited by their non-

linear resistance properties. As the sensed temperature increases, the resistance of the

thermistor decreases significantly and the thermistor resistance changes less for an equivalent

temperature change, therefore the thermistor becomes less sensitive. Consider the temperature

and sensitivity figures in Table 2.2.

Table 2.2 Thermistor Sensitivity Values

Temperature

Sensitivity

-20°C

5600 Ω/°C

25°C

439 Ω/°C

50°C

137 Ω/°C

In the LDT-5416 the practical upper temperature limit is the temperature at which the thermistor

becomes insensitive to temperature changes. The lower end of the temperature range is limited

by the maximum input voltage of the LDT-5416. Thermistor resistance and voltage are related

through Ohms Law (V = I x R). The LDT-5416 supplies current to the thermistor, either 10µA or

100µA, and as the resistance changes, a changing voltage signal is available to the thermistor

inputs of the LDT-5416. The LDT-5416 will over-range when the input voltage exceeds about

2.0 Volts. The maximum temperature ranges for a typical 10kΩthermistor (a 10kΩthermistor

has a resistance of 10kΩohms at 25°C) are given in Table 2.3 below.

Table 2.3 Temperature Ranges (10kΩ Thermistor)

Temperature

Sensitivity

10 µA

-37°C to over +60°C

100 µA

+8°C to over +100°C

Selecting and Using Thermistors

The type of thermistor you choose will depend primarily on the operating temperature range.

From Figure 2.3 you can also see that 10kΩthermistors are generally a good choice for most

laser diode applications where high stability is required at near room temperatures. Similarly,

5kΩthermistors are often a good choice for detector cooling applications where you want to

operate at temperatures from -30°C to room temperature. Much higher or lower temperature

ranges can be controlled through the use of higher or lower resistance thermistors. For more

information on thermistor selection, see ILX Lightwave Application Note #2, Selecting and Using

Thermistors for Temperature Control.

Table of contents

Other ILX Lightwave Temperature Controllers manuals

ILX Lightwave

ILX Lightwave LDT-5525 User manual

ILX Lightwave

ILX Lightwave LDT-5900 Series User manual

ILX Lightwave

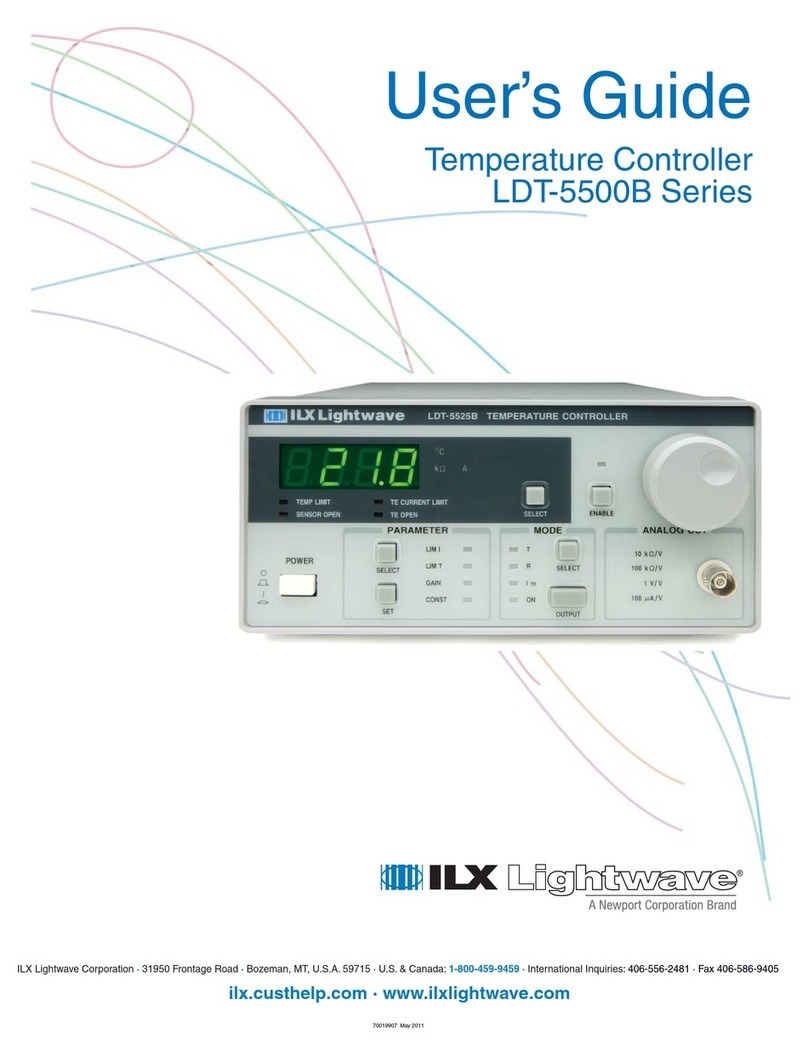

ILX Lightwave LDT-5525 User manual

ILX Lightwave

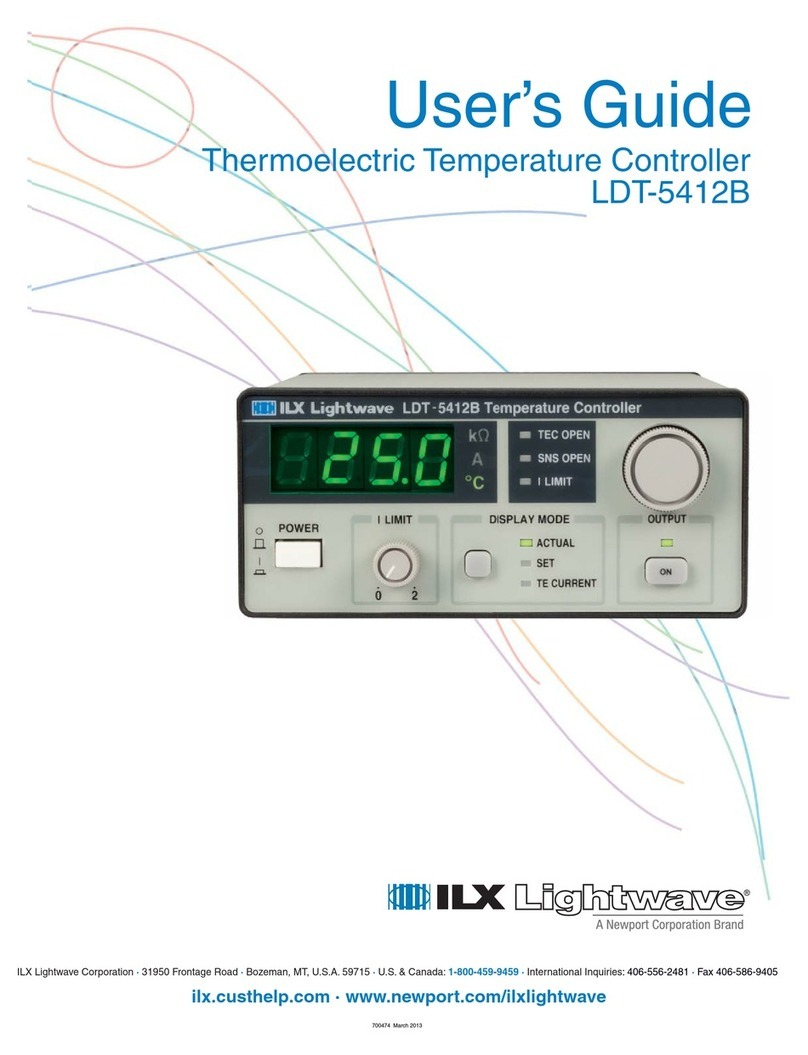

ILX Lightwave LDT-5412B User manual

ILX Lightwave

ILX Lightwave LDT-5412 User manual

ILX Lightwave

ILX Lightwave LDT-5910 User manual

ILX Lightwave

ILX Lightwave LDT-5500B Series User manual