i

Model No.

Weight (gms.)

AI-5982

240

1OIM AI-5X82 V2.1 Page 1 of 6

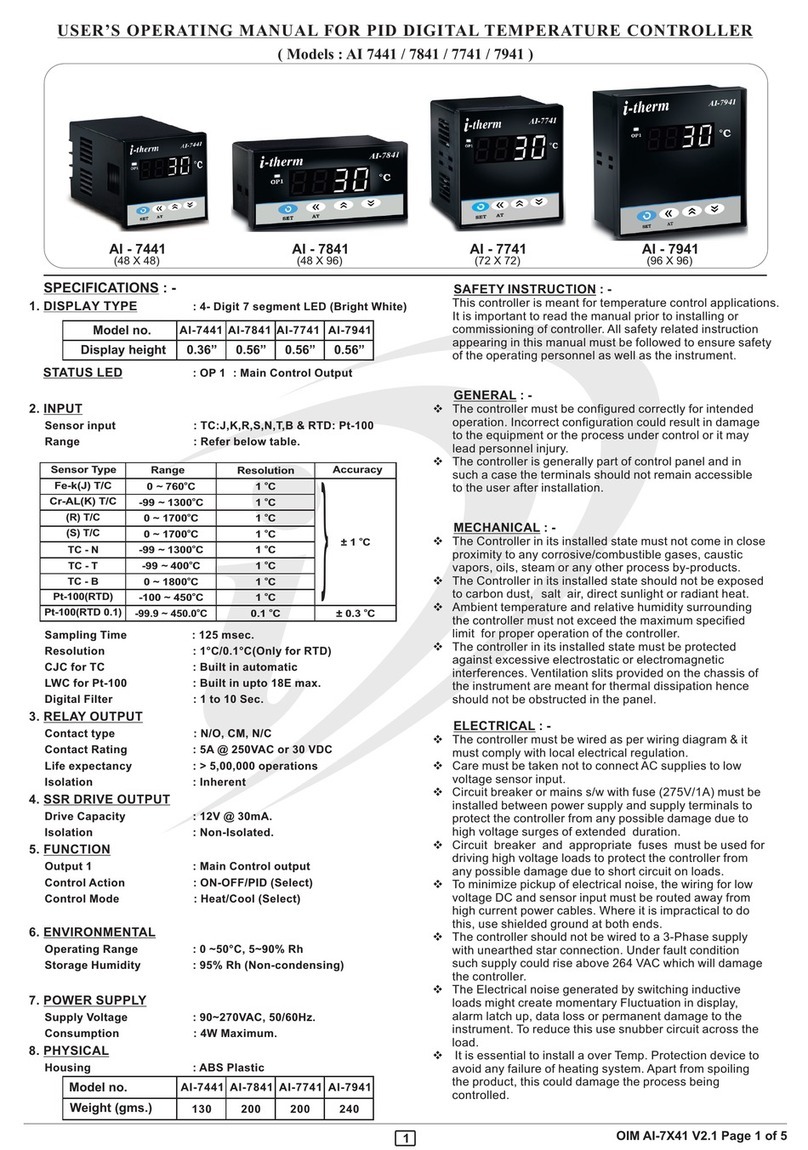

USER’S OPERATING MANUAL FOR DIGITAL TEMPERATURE CONTROLLER

(Models: AI - 5982 )

AI - 5982

(96 X 96)

Fe-k(J) T/C

Cr-AL(K) T/C

Sensor Type Accuracy

o

± 1 C

o

0 ~ 1700 C

o

0 ~ 1700 C

o

-100 ~ 450 C

Resolution

Range

o

1 C

o

1 C

o

1 C

}

(R) T/C

(S) T/C

Pt-100(RTD)

Pt-100(RTD 0.1)

o

0 ~ 760 C

o

-99 ~ 1300 C

o

-99.9 ~ 450.0 C

o

1 C

o

1 C

o

0.1 C

o

± 0.3 C

SAFETY INSTRUCTION :

This controller is meant for temperature control

applications. It is important to read the manual prior to

installing or commissioning of controller. All safety related

instruction appearing in this manual must be followed to

ensure safety of the operating personnel as well as the

instrument.

GENERAL

vThe controller must be configured correctly for intended

operation. Incorrect configuration could result in damage

to the equipment or the process under control or it may

lead personnel injury.

vThe controller is generally part of control panel and in

such a case the terminals should not remain accessible

to the user after installation.

MECHANICAL

vThe Controller in its installed state must not come in close

proximity to any corrosive/combustible gases, caustic

vapors, oils, steam or any other process by-products.

vThe Controller in its installed state should not be exposed

to carbon dust, salt air, direct sunlight or radiant heat.

vAmbient temperature and relative humidity surrounding

the controller must not exceed the maximum specified

limit for proper operation of the controller.

vThe controller in its installed state must be protected

against excessive electrostatic or electromagnetic

interferences. Ventilation holes provided on the chassis

of the instrument are meant for thermal dissipation hence

should not be obstructed in the panel.

ELECTRICAL

vThe controller must be wired as per wiring diagram & it

must comply with local electrical regulation.

vCare must be taken not to connect AC supplies to low

voltage sensor input.

vCircuit breaker or mains s/w with fuse (275V/1A) must be

installed between power supply and supply terminals to

protect the controller from any possible damage due to

high voltage surges of extended duration.

vCircuit breaker and appropriate fuses must be used for

driving high voltage loads to protect the controller from

any possible damage due to short circuit on loads.

vTo minimize pickup of electrical noise, the wiring for low

voltage DC and sensor input must be routed away from

high current power cables. Where it is impractical to do

this, use shielded ground at both ends.

vThe controller should not be wired to a 3-Phase supply

with unearthed star connection. Under fault condition

such supply could rise above 264 VAC which will damage

the controller.

vThe Electrical noise generated by switching inductive

loads might create momentary Fluctuation in display,

alarm latch up, data loss or permanent damage to the

instrument. To reduce this use snubber circuit across the

load.

v It is essential to install a over Temp. Protection device to

avoid any failure of heating system. Apart from spoiling

the product, this could damage the process being

controlled.

SPECIFICATIONS : -

1. DISPLAY TYPE : Dual 4- Digit 7 segment LED

4 Digit Bright White (PV)

4 Digit Luminous Green (SV)

STATUS LED’S : OP1 : Main Control Output

OP2 : Alarm Status

SOAK : Soak Timer

2. INPUT

Sensor : TC:J,K,R,S & RTD: Pt-100

Range : Refer below table

Sampling Time : 125 msec.

Resolution : 1°C/0.1°C(Only for RTD)

CJC for TC : Built in automatic

LWC for Pt-100 : Built in up to 18E max.

Digital Filter : 1 to 10 Sec.

3. RELAY OUTPUT

Contact Type : N/O, CM, N/C

Contact Rating : 5A @ 250VAC or 30 VDC

Life Expectancy : > 5,00,000 operations

Isolation : Inherent

4. SSR DRIVE OUTPUT

Drive Capacity : 12V @ 30mA.

Isolation : Non-Isolated.

5. FUNCTION

Output 1 : Main Control output

Output 2 : Programmable

1) Auxiliary control

2) Alarm

3) Soak timer

Control Action : ON-OFF/T.P (user selectable)

Control Mode : Heat/Cool (user selectable)

Compliance : ----

6. ENVIRONMENTAL

Operating Range : 0 ~50°C, 5~90% Rh

Storage Humidity : 95% Rh (Non-Condensing)

7. POWER SUPPLY

Supply Voltage : 90~270VAC, 50/60Hz.

Consumption : 4W Maximum.

8. PHYSICAL

Housing : ABS Plastic.

Model no.

Display height (PV)

Display height (SV)

0.56”

0.56”

AI-5982