ILX Lightwave LDT-5910 User manual

-~

ARTISAN

®

~I

TECHNOLOGY

GROUP

Your definitive source

for

quality

pre-owned

equipment.

Artisan Technology

Group

Full-service,

independent

repair

center

with

experienced

engineers

and

technicians

on staff.

We

buy

your

excess,

underutilized,

and

idle

equipment

along

with

credit

for

buybacks

and

trade-ins

.

Custom

engineering

so

your

equipment

works

exactly as

you

specify.

•

Critical

and

expedited

services

•

Leasing

/

Rentals/

Demos

• In

stock/

Ready-to-ship

•

!TAR-certified

secure

asset

solutions

Expert

team

ITrust

guarantee

I

100%

satisfaction

All

tr

ademarks,

br

a

nd

names, a

nd

br

a

nd

s a

pp

earing here

in

are

th

e property of

th

e

ir

r

es

pecti

ve

ow

ner

s.

Find the Newport / ILX Lightwave LDT-5910 at our website: Click HERE

INSTRUCTION hIANUAL

hIODEL LDT-5910

THERMOELECTRIC TEhIPERATURE CONTROLLER

ILX

Lightwave Corporation

34368 East Frontage Road

Bozeman, Montana,

U.S.A.

(406)

586-

1244

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

WARRANTY

ILX LIGHTWAVE

CORPORATION

warrants this instrument to be frce from dcfccts

in material and workmanship for one year from the date of shipment. During

the warranty period we will repair or replace the unit, at our option, without

charge.

Limitation

This warranty does not apply to fuses, lamps, batteries, defects caused by abuse,

any modifications, or to use of the product for which it was not intended.

This warranty is in lieu of all other warranties, expressed or implied, including

any implied warranty of merchantability or fitness for any particular purpose.

ILX Lightwave Corporation shall not be liable for any incidental, special, or conse-

quential damages.

If a problem occurs, please notify

ILX

Lightwave Corporation and thoroughly

describe the nature of the problem and give the model and serial numbers. You

will be given prompt attention, service information, and return instructions.

Returning an Instrument

Before returning an instrument, obtain a return authorization number from the

factory. The instrument should be shipped in the original packing carton or one

that will provide equal protection. Shipping damage is not covered by this war-

ranty. Send the instrument, transportation pre-paid to the factory, referencing

the return authorization number. Repairs will be made and the instrument will

be returned, transportation pre-paid. Repairs are warranted for the remainder of

the original warranty or for

90

days, whichever is greater.

Claims for Shipping Damage

When you receive the instrument inspect it immediately for any damage or shortages

on the packing list. If the instrument is damaged immediately file a claim with

the carrier. The factory will supply you with a quotation for estimated costs of

repair. You must negotiate and settle with the carrier for the amount of damage.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Table

of Contents

.................

CHAPTER 1

.

GENERAL INFORMATION

1

...........................

1.1 Introduction

1

........................

1.2 Product Overview

1

1.3 Specifications

?

-

..........................

................

1.4 Available Options and Accessories

3

........................

CHAPTER 2

.

OPERATION

4

2.1 Introduction

...........................

4

2.2 Installation

..........................

4

...................

2.3 AC Power Considerations 4

.....................

2.4 Tilt-Foot Adjustment

4

.......................

2.5 Rack Mounting 4

..................

2.6 LDT-5910 Front Panel Controls 4

2.7 Power

............................

6

......................

2.8 Main Control Knob

6

2.9 Auto

.............................

6

2.10 Actual Temp

.........................

6

2.11 Set Temp

...........................

6

2.12 Lock

.............................

6

2.13 Output On

..........................

7

2.14 GPIB Remote/Local Switch

..................

7

2.15 Parameter Set-Up

.........................

7

2.16 Select

............................

7

2.17 Set

.............................

7

2.18 Limit

............................

8

2.19 Gain

.............................

8

2.20 Calibration Constants

-

C1, C2 and C3

.............

8

2.21 Back Panel

............................

8

2.22 Back Panel Connections

...................

10

2.23 Grounding Considerations

...................

10

2.24 Current Switch

........................

10

2.25 Operating Instructions

......................

11

2.26 Warm Up and Environmental Considerations

..........

11

2.27 General Operating Procedure

................

11

CHAPTER 3

.

GPIB/IEEE-488 BUS CONTROL

...............

12

3.1 Introduction

...........................

12

3.2 Capabilities

...........................

12

3.2 Preparation for Bus Control

...................

12

3.3 An Overview of Remote Programming

...............

14

.........................

3.4 Command Set 14

3.5 Remote Programming Procedure

................

17

3.6 Input Syntax

.........................

17

3.7 Device Dependant Commands

...................

19

3.8 Data Entry Commands

....................

19

.....................

3.9 Sct Point Commands 19

3.10 Output Control Commands

..................

20

3.11 Lock Commands

.......................

20

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

......................

3.12

Display Commands

2

1

........................

3.13 Get Commands

22

..........................

3.14

Put Values

23

....................

3.15 Terminator Commands

26

.......................

3.16 Clear Command

26

......................

3.1

7

Self Test Command

26

....................

3.18 Control Mode Command

27

.........................

3.19 Service Requests 28

............

3.20 The Serial Poll Register and the SRQ Mask 28

........................

3.21 Interface Messages

29

........................

3.22 Example Programs

30

.................

CHAPTER 4

.

THEORY OF OPERATION 32

...........................

4.1 Introduction 32

.......................

4.2 Power Supply Board 32

....................

4.3 Internal Power Supplies 32

...........................

4.4 MainBoard 33

...................

4.5 Constant Current Source 33

.........................

4.6 Input Buffer 34

.....................

4.7 Difference Amplifier 34

................

4.8 Digitally Controlled Gain Stage 34

4.9 Integrator

..........................

34

.....................

4.10 Summing Amplifier 34

.......................

4.11 Current Limiting 35

......................

4.12 Current Limit D/A 35

................

4.13 Current Limit Condition Sensing 35

4.14 Voltage Controlled Current Source ............... 35

4.15 Voltage Limit Condition Sensing

................

35

....................

4.16 Set Point Control D/A 35

4.17 Precision Voltage Reference

..................

36

4.18 A/D Convertor

........................

36

4.19 Microprocessor

........................

36

...........................

4.20 Memory 36

4.21 Serial Interface

........................

36

4.22 Latched Parallel 1/0 Port

...................

37

..........................

4.23 Display Board 37

4.24 Display Driver ........................ 37

4.25 Latched Parallel 1/0 Port

...................

37

.........................

4.26 LED Drivers 37

4.27 GPIB Interface Board ....................... 37

..................

4.28 Microprocessor and Memory 37

4.29 Optical Isolators

.......................

37

.......................

4.30 Serial Interface 37

4.3

1

GPIB Interface

.......................

38

CHAPTER 5

.

MAINTENANCE

......................

40

5.1 Overview ............................ 40

5.2 Calibration ............................ 40

...................

5.3 Recommended Equipment 40

5.4 Environmental Conditions

...................

40

5.5 Warm-up

...........................

40

5.6 Calibration Adjustments

.....................

41

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

................

5.7

Manual Resistance Calibration

41

...............

5.8 Manual Current Limit Calibration

41

...........

5.9

Resistance Calibration Over the

GPIB

Bus

42

.........

5.10 Current Limit Calibration Over the GPIB Bus 42.

........................

5.1

1 Fuse Replacement

43

......................

5.12 Line Voltage Selection

43

...........................

5.13 Disassembly 43

CHAPTER 6

.

OPTIONAL MODEL 1227 GPIBIIEEE-488 INTERFACE

....

45

............................

6.1 Overview 45

..........................

6.2 Specifications 45

............................

6.3 Installation 46

.................

Appendix A

.

The Steinhart-Hart Equation 47

Appendix B

.

Sensing Current and Thermistor Selection

...........

57

.....................

Appendix C

.

Schematic Diagrams 60

List of Figures

2-1 LDT-5910 Front Panel Layout

...................

5

2-2 LDT-5910 Back Panel Layout

....................

9

........................

2-3 Back Panel Connector

10

3-1 Address Selection Switch Settings

.................

13

3-2 GPIB Remote Operation Diagram

.................

15

..............

4-

1 Functional Block Diagram of LDT-5910 33

4-2

Functional Block Diagram of 1227 Interface

............

39

5-1 AC Voltage Selection

.......................

44

A-1 Thermistor Resistance verses Temperature

.............

48

B-1 Thermistor Temperature Range

..................

58

Copyright.

1987.

ILX

Lightwave Corporation

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

CHAPTER

1

GENERAL INFORhlATION

1.1

Introduction

This manual explains how to operate and maintain the LDT-5910 Thcrmoclcctric

Temperature Controller and optional model 1227 GPIBIIEEE-488 Intcrface. This

section gives a detailed overview of the LDT-5910. If you want to get started

using the LDT-5910 right away, skip to Chapter 2 (Operation).

1.2

Product Overview

The LDT-5910 is a microprocessor-based, precision thermoelectric temperature con-

troller designed for temperature control of laser diodes, dctcctors and other tcmpcr-

ature sensitive devices. The LDT-5910 can be used for laser diode testing, laser

diode frequency stabilization, IR detcctor cooling, and to dctermine the character-

istics of electronic devices. The LDT-5910 combines high analog stability with

the versatility of a microprocessor-based instrument. The internal microproccssor

controls the operation of the LDT-5910 and performs the non-linear conversion

of thermistor resistance to temperature based on three user defined constants.

You can configure the LDT-5910 to operate with a wide variety of thermistor

temperature sensors and TE modules. The model 1227 GPIB/IEEE-488 interface

allows remote programming and completely automated control of the LDT-5910.

Features of the LDT-5910 include:

Intuitive front panel layout

Large and easy-to-read green LED display

Display resolution of 0.1 degree Centigrade

Output current limit control to safely opcratc all TE coolers

Configurable for most thermistors

Output will supply

4.6

amps

Actual, Set and Auto display modes

Set temperature lock

GPIB/IEEE-488

interface available

Booster modules can be added to extend the output power

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Bipolar constant current source.

8

Volts at 1 A, 7 Volts at

2

A, 6 Volts at

3

A.

4.6

Amps.

15 Watts typical.

1.3

Specifications

Output

Output Type:

Compliance Voltage:

Maximum Current Output:

Maximum Output Power:

Current Limit Control Range:

Current Limit Accuracy:

Temperature Control

Temperature ~ange':

Resolution and ~ccuracy~:

Short Term stability3:

Scnsor Type:

Usable Resistance Range:

Sensing Current:

Calibration:

Display

Display Type:

Maximum Reading:

Resolution:

General

Power Requirements:

Size:

Temperature Range:

Warmup:

-50 "Cto >lo0"C with typical 10

K

thermistor

Temperature Resolution Accuracy

0°C kO.1 "C k0.2

"

C

20°C 20.1 "C k0.2

"

C

50 "C f0.2 "C k0.2

"

C

0.01 "C or better.

2-wire thermistor.

0 to 450

K

ohm typical.

10 uA or 100 uA (user sclcctable).

Thermistors are calibrated by storing three con-

stants of the Steinhart-Hart equation, listed

below, in internal non-volatile memory.

l/~=(Cl*lO-~)+(C2*10-~)(ln

~)+(~3*10-~)(lnR)~.

4

digit green LED display.

9999 mA, 999.9

"

C.

kl.O mA, kO.1 "C.

105-125 or 210-250 VAC(jumper sel

ectable) 50-60 Hz.

88

mm

x

212 mm

x

269 mm (3.5" x

8.4"

x 10.6").

Operating: 0 to 50

"

C, Storage: -40 to 70

"

C.

1 hour

to

rated accuracy.

1.

Temperature control range depends primarily on the type of thermistor and TE module used. The range can be

extended higher and lower by selecting appropriate components. See Appendix B for more details.

2.

Accuracy figures quoted are typical for a 10

K

ohm thermistor and 100 uA source current setting. Accuracy figures

are relative to calibration standard. Both resolution and accuracy are dependent on the user defined configuration

of the instrument.

3.

Short term temperature stability is a strong function of the thermal environment of the thermistor and TE module.

Room air currents in particular can easily cause fluctuations of 0.1

C

in an exposed mounting configuration.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1.4

Available Options and Accessories

The

following options and accessories are available for

the

LDT-5910.

DESCRIPTION MODEL

NUMBER

GPIB/IEEE-488 interface 1227

Output power booster module 5310

Rack mount flange kit 302

Rack mount, 1/2 width

filler panel kit

Enclosure interlocking kit 112

The 1227 interface permits GPIB bus control of the LDT-5910 for automated test

and measurement applications. Chapter

6

describes this option in detail.

The LDT-5910 enclosure can be rack mounted by itself or interlocked with other

ILX Lightwave, X-series instruments. The accessories listed above are for rack

mounting and interlocking these instruments.

1.5

Your Comments

ILX Lightwave Corporation is committed to making the best laser diode instrumenta-

tion available anywhere. To serve you best, we need your ideas and comments on

ways we can improve our products. We invite you to contact us at any time with

your suggestions.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

CHAPTER

2

OPERATION

2.1 Introduction

This chapter describes how to install, program and operate the LDT-5910. It is

divided into five sections covering installation, front pancl controls, proccdurcs

for programming the LIMIT, GAIN and constants

C1,

C2, and

C3,

the back pancl

connections, and normal operating procedures.

2.2 Installation

2.3

AC Power Considerations

You can configure the LDT-5910 to operate at line voltages from 105 to 125 VAC

or 210 to 250 VAC. Before using the LDT-5910 check that the voltage printed

on the rear panel matches the power-line voltage supplied in your area. If it is

necessary to reconfigure the input voltage range refer to chapter 5 (Maintenance).

WARNING

To avoid electrical shock hazard, connect the instrument only to

properly earth-grounded, 3-prong receptacles. Failure to observe

this precaution can result in injury or loss of life.

2.4

Tilt-Foot Adjustment

The LDT-5910 has front legs that extend to make it easier to view the LED display

To use them, place the LDT-5910 on a stable base and rotate the legs downward

until they lock into position.

2.5 Rack Mounting

The LDT-5910 may be rack mounted by installing a rack mount flange on one

side of the enclosure and a half width filler panel on the other side. Alternately,

two X-series enclosures will interlock side-by-side, with a pair of rack mount

flanges, for rack mounting as one unit. All rack mount accessory kits contain

detailed mounting instructions. Refer to Section 1.4 for applicable rack mount

accessory part numbers.

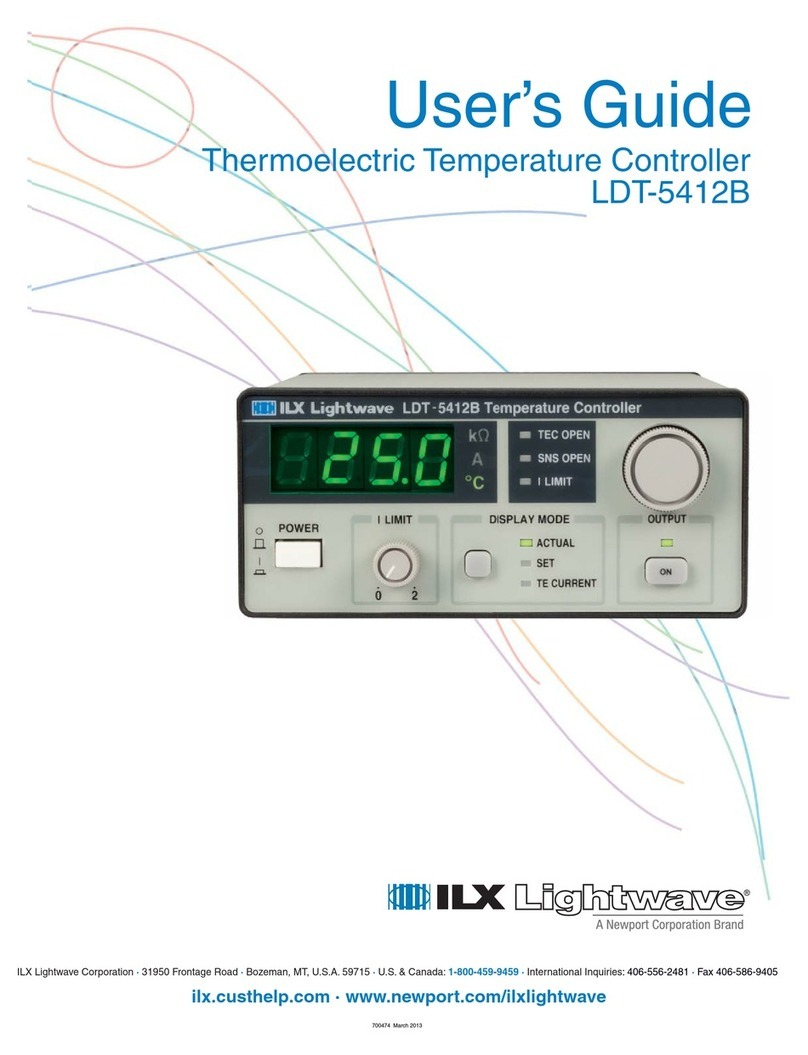

2.6

LDT-5910

Front Panel Controls

The following sections describe the front panel controls on the LDT-5910. Gen-

erally these controls are simple to operate. The setup parameters, however, are

intentionally a bit awkward to use so that their values are not inadvertently

changed. Figure 2-1 shows the LDT-5910 front panel and its controls.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

DISPLAY

POWER

OFFION

SWITCH

GPIBIIEEE-488

REMOTE MODE

INDICATOR AND

LOCAL SWITCH

DISPLAY MODE SWITCHES

AND

INDICATORS

TEMPERATURE LOCK MODE

SWITCH AND INDICATOR

MAIN CONTROL KNOB

LIMITCURRENT

DISPLAY INDICATOR

THERMISTOR CONSTANTS

DISPLAY INDICATORS

OUTPUT

OFFION

SWITCH

PARAMETER SET

SELECTOR SWITCH

PARAMETER DISPLAY

SELECTOR SWITCH

FEEDBACK LOOP GAIN

DISPLAY INDICATOR

FIGURE

2-1

LDT-5910 FRONT PANEL LAYOUT

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2.7

Power

With the LDT-5910 connected to an

AC

power source, pressing the Power off/on

switch will supply power to the instrument and start the power-up sequence.

All

the front panel LEDs will light. After approximately threc scconds the display

will read the actual temperature in degrees centigrade and the instrument

will

bc

in Auto mode.

2.8

Main Control Knob

The main control knob is a precision ten turn potentiometer that adjusts the

instrument set temperature. This knob is also used to change the instrument sct

point temperature setup parameters. Turning this knob to the right increases

the value on the display.

2.9 Auto

When in Auto mode the display shows the actual thermistor temperature until

you turn the main control knob. The LDT-5910 senses that you have turned thc

knob and "knows" that you want to input a new set temperature. The instrument

displays the new set point temperature for three seconds and then rcturns to

displaying the actual temperature. The Auto mode allows you to accurately change

the set point temperature and quickly see how your device is responding. The

Auto button has a toggling action; press it to enter auto mode and press it again

to exit auto mode.

2.10 Actual Temp

When this button is pressed the LDT-5910 displays the actual thermistor temperature

and the LED on the button lights to indicate that the actual temperature is dis-

played.

2.11 Set Temp

This button, when pressed, displays the temperature set point and the LED on

the button lights to indicate that the set tempcrature is

displayed.

Turn the

main control knob to enter a new set point.

2.12 Lock

When you press the front panel LOCK button the LDT-5910 stores the current

set temperature in memory and disables the main control knob. The LED lights

to show that the unit is in lock mode. The value stays in memory even if the

LDT-5910 is shut off. If you use the same set point temperature day after day

you will appreciate the LDT-5910 LOCK feature. To release the LDT-5910 from

lock mode, press the lock button again.

Caution

Turn the output off before releasing the unit from lock mode.

If the main control knob position has changed the LDT-5910 will

read the new knob position and try to control the temperature

to that setting.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2.13

Output On

This button switches the output of the LDT-5910 on. The off/on button has a

toggling action. If the output is off, pressing it will turn the output on and vice

versa. The LED above the indicator button lights when the output is active.

When the output is off it is safe to connect or remove sensitive devices from

the LDT-5910 even though power is on. The output is off when power is first

applied to the instrument.

The output off/on button also indicates when a thermal limit condition occurs.

In

the rare event that excessive heating occurs in the LDT-5910 output stage (or in

an attached booster module) the output of the LDT-5910 is turned off and thc

output off/on LED flashes. The output automatically turns back on when the

output stage cools down.

2.14

GPIB Remote/Local Switch

This button returns the instrument to local control when it is in remote mode with

the optional Model 1227 GPIB/IEEE-488 interface installed. Any command sent

to the LDT-5910 via the GPIB bus automatically places the instrument in remote

mode and the REMOTE LED lights. All the front panel controls, except power

and GPIB REMOTE/LOCAL, are disabled and will only operate remotely. Pressing

the LOCAL button will return the instrument to local mode and all the front

panel controls will operate.

If no command has been sent over the GPIB bus, the LDT-5910 is in LOCAL mode

and its address will be displayed when you press this button. If the instrument

is in remote mode and a local lockout (LLO) mcssage has bccn sent, the host has

complete control of the LDT-5910 and the LOCAL button has no effect. For

more information on GPIB programming, read chapter

3.

2.15

Parameter Set-Up

2.16

Select

The select function displays the setup parameters so you can review or change

their values to configure the LDT-5910 for your thermistor and TE cooler. Press

the SELECT button and the limit will be displayed until you release the button.

The value will show for three seconds before the LDT-5910 returns its previous

state. Press the Select button again to sequence the display through GAIN, C1,

C2 and C3. The sections below describe each of these values and how to change

them.

2.17

Set

This button, along with the main control knob, is used to change the setup par-

ameters: LIMIT, GAIN, C1, C2 and C3. Sequence to the setup parameter you

wish to change and hold the SELECT button in to continuously display this value.

Simultaneously press and hold in the SET button. Now turn the main control

knob until the new value is displayed. Release the Set button to store the par-

ameter in non-volatile memory. The instrument will automatically go into lock

mode to save the present set point when the SET button is pushed.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2.18

Limit

The limit function limits the output current so that the LDT-5910 does not provide

more current than your device can safely handle. To rcad the limit, press the

select button until the LED by the LIMIT is lit and the display will show the

value of the

LIMIT

(in mA). To change the limit, sequence

to

thc LIMIT value

and hold in the SELECT and the SET button. Turn the main control knob until

the new value is on the display and then release the SET button. The LIMIT

should be entered in milliamperes, e.g., 1 amp would be entercd as 1000 mA.

The LDT-5910 will supply as much current as it can, up to a current limit set

point of 4600 mA, to control the temperature as quickly as possible. The LDT-5910

can supply up to 10 A with the optional power booster module installed.

The LIMIT LED also indicates two special conditions, current and voltage limiting.

If the output is current limited, as when the output is first turned on, the LIMIT

LED will flash slowly

(2

times/second). If the output is voltage limited, if for

instance no load is connected, the LIMIT LED will flash faster (4 times/second).

2.19 Gain

The gain function sets the analog feedback gain which determines how fast the

actual temperature reaches and settles to the set point temperature. If the gain

is set too low the TE cooler will take longer to reach the temperature set-point.

If it is set too high the actual temperature will overshoot and may cycle around

the set temperature. The gain setting depends on the type of TE cooler that

you are using, but we can give guidelines for selecting the proper gain. Set the

gain to its lowest value and increase it until the actual tempcrature oscillates

around the set temperature. Then reduce the gain one increment. To set the gain,

sequence to the GAIN value and hold in the SELECT and the SET button. Turn

the main control knob until the new value is displayed and then release the SET

button. The feedback loop gain can be selected in increments of

1,

3, 10, 30,

100 and 300.

2.20 Calibration Constants

-

C1, C2 and C3

These are the constants of Steinhart-Hart equation that you enter to calibrate

the LDT-5910 for different thermistors. Appendix A contains an explanation of

the Steinhart-Hart equation, the values of these constants for some common ther-

mistors and a computer program to determine these values for any thermistor.

To read a constant press the SELECT button until it sequences to C1, C2 or C3.

The LED next to the constant will light. To change the value, press the SELECT

and the SET buttons and turn the main control knob until the correct number is

displayed. Release the SET button to store the new value in non-volatile memory.

2.21 Back Panel

The back panel contains the thermistor input,

TE

module output, AC power entry

connector, fuse, and a thermistor source current set switch. When the optional

model 1227 GPIBIIEEE-488 interface is installed, the back panel additionally contains

the standard GPIB bus connector and the GPIB address selector switch. The

back panel is shown in figure 2-2.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

THERMISTUR

INPUT

GPIB

BUS

CONNECTOR

TE MODULE THERMISTOR

OUTPUT SOURCE CURRENT

SET SWITCH

GPIB

ADDRESS

SELECTOR SWITCH

AUXILIARY

INPUT/UUTPUT

CUNNECTOR

FUSE

POWER

ENTRY

CONNECTOR

I

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2.25

Operating Instructions

2.26

Warm

Up

and Environmental Considerations

Operate the LDT-5910 at an ambient temperature between 0 and 50 degrees centi-

grade. Storage temperatures should be in the range

-40

to

70

C.

To

achieve

the rated accuracy let the LDT-5910 warm up for about

1

hour before use.

2.27

General Operating Procedure

You can operate the LDT-5910 in several modes. The following operating procedure

is applicable for most common use.

a. Plug the LDT-5910 into an AC power source supplying the correct voltage

and frequency for your unit (refer to the rear panel for the correct

ratings).

b. Turn on the LDT-5910. The output stage will be off at power-up.

c. Check the setting of the GAIN, LIMIT and C1, C2, and C3 to insure that

they are compatible with the equipment you are using. Refer to sections

2.15 to 2.20 if you need to change them.

d. Press the Set Temp button and check the set point temperature. If it

requires changing refer to the section above.

e. Turn the output on by pressing the output on button

f.

The LDT-5910 will automatically control the temperature to the set point.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

CHAPTER

3

GPIBIIEEE-488 BUS

CONTROL

3.1

Introduction

When the model 1227 GPIB/IEEE-488 intcrface is installed and the instrumcnt

is

connected to a host computer, the LDT-5910 can be used as an automated tcmper-

ature controller and temperature recorder for test measurement applications.

3.2

Capabilities

The model 1227 GPIB/IEEE-488 interface allows GPIB/IEEE-488 bus control of the

LDT-5910. All of the features accessible from the front panel and some advanced

features can be accessed via the interface bus. Information can also be read by

the host computer and printed or stored. Other features include:

A concise and simple command set

Full talk/listen capability

Full serial poll capability, with bit-maskable SRQ

Selectable output terminators

Full local/remote capability including LOCAL LOCKOUT

Resistance Control Mode controls to a set

resistance

Support for the following interface messages: REN, DCL,LLO, GTL and

SDC

3.2

Preparation

for

Bus Control

To use the LDT-5910 remotely, you will need to install an IEEE-488 interface

adapter in your host computer. These adapters and support software are avail-

able from several manufacturers and can be installed in most computers. This

manual assumes that you have a basic knowledge of the GPIB/IEEE-488 interface

bus and how to use it for instrument control. This section also assumes that

you are familiar with the controls on the LDT-5910. Read Chapter

2

again if

you need more details on how to operate the LDT-5910.

Install the 1227 interface using the procedure outlined in Chapter

6.

Prepare the

LDT-5910 for bus control using the following procedure:

1.

Turn off the power to the LDT-5910/1227 and set the GPIB/IEEE-488

interface address with the DIP switches on the back panel. The switch

settings are shown in figure 3-1. You can choose any address for the

LDT-591011227 but this address should be unique, i.e., different than any

other instrument connected to the bus.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Switch Positions

Address

1

2

3

4

5

Switch Positions

Address

1

2

3

4

5

00001

10001

01001

11001

00101

10101

01101

11101

00011

10011

01011

11011

00111

10111

01111

-Not Allowed-

FIGURE

3-1

ADDRESS SELECTION SWITCH SETTINGS

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2.

Plug

the

GPIBIIEEE-488

bus cable into the LDT-5910/1227 rear panel

connector and secure it with the plug-mounted screws.

3. Turn on the LDT-591011227 and press the local button to display the

selected IEEE-488 instrument address on the front panel display.

3.3

An Overview of Remote Programming

The block diagram, figure 3-2 shows the flow of data from the LDT-5910/1227 to

the host computer (the controller). Each block represents a register, buffer etc,

contained in the LDT-5910. The input buffer receives data from the IEEE-488

bus. The output buffer receives data from the blocks to its left and sends data

to the IEEE-488 bus. The serial poll register is a separate buffer that gets the

attention of the controller in special conditions.

Information is transferred between blocks by device dependant commands. For

example, a Put command takes a number from the input buffer and stores it in

the internal memory of the LDT-5910. Likewise the Get command gets the con-

tents of the LDT-5910 internal memory and copies it into the output buffer.

Programming commands, like print and read in BASIC or FORTRAN, transfer the

information from the input or output buffers to the controller. The following

simple program provides an example of how the LDT-5910 is controlled by the

host computer. The exact programming statements you will need to use will depend

-

on the programming language and IEEE-488 interface card that you are using. This

program instructs the LDT-5910 to display actual thermistor temperatures and

then reads out the current display. The LDT-5910 is assumed to be at GPIB

-

address

1.

100 Print @1:"D2"

110 Input @l:A$

120 Print

A$

130 End

-

3.4

Command Set

There are two types of commands that you can use with the LDT-5910/1227 and

-

the GPIB bus. Messages that only the LDT-5910/1227 understands are called

device dependant commands. Messages that are common to any instrument on

the GPIB bus are called interface messages. The device dependant commands are

summarized in Table

3.1

and described in sections 3.7 to 3.17. The LDT-5910/1227

-

also responds to a number of interface messages to participate in IEEE-488 bus

communication. The interface messages are summarized in Table 3.5.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

MICROPRUCESSOR MEMORY

SET POINT Tnnnmnn

TEMPERATURE

v

A

Rnnnmnn

RESISTANCE

--

A

GO

-

e

3

SRQ

REGISTER

SET-UP PERAMETERS

G1

,

P1

I

DISPLAY

CURRENT LIMIT

G2

,

P2

GAIN

G3

,

P3

C1

7

A

G4

,

P4

C2

V

G5

,

P5

INSTRUMENT MUDE

CUNTROL

INPUT

BUFFER

--

-

-

DO

,

01 OUTPUT CONTROL

LO

,

L1 LOCK CUNTROL

DO

-

D5

DISPLAY MODE

WO

-

W5

OUTPUT TERMINATOR CUNTRUL

ZO

,

n

SELF TEST

,

CLEAR

YO

-

Y2 REMOTE/LOCAL MODE CUNTRUL

FIGURE

3-2

GPlB REMOTE OPERATION DIAGRAM

C3

CALIBRATION PERAMETERS G6

,

P6

CAL-RlO

w

A

G7

,

P7

CAL-R100

3,

CAL-CL OUTPUT

BUFFER

G9

,

P9

USER DEFINED MESSAGE

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Table of contents

Other ILX Lightwave Temperature Controllers manuals

ILX Lightwave

ILX Lightwave LDT-5412 User manual

ILX Lightwave

ILX Lightwave LDT-5412B User manual

ILX Lightwave

ILX Lightwave LDT-5525 User manual

ILX Lightwave

ILX Lightwave LDT-5900 Series User manual

ILX Lightwave

ILX Lightwave LDT-5500B Series User manual

ILX Lightwave

ILX Lightwave LDT-5416 User manual

ILX Lightwave

ILX Lightwave LDT-5525 User manual