Imada DSW Series User manual

TORQUE MEASUREMENT

01/07

DIMENSIONS

INSTRUCTION MANUAL

Digital Torque

Tester/Wrenches

Models: DSW-15, -20, -75, -120

with continuous RS-232 output

2 YEAR WARRANTY (RESTRICTIONS APPLY)

Imada, Inc. warrants its products to the original purchaser to be free

from defects in workmanship and material under normal use and

proper maintenance for two years (one year for adapters, attachments

and cables) from original purchase. This warranty shall not be effective

if the product has been subject to overload, shock load, misuse,

negligence, accident or repairs attempted by others than Imada, Inc.

During the warranty period, we will, at our option, either repair or

replace defective products. Please call our customer service department

for a return authorization number and return the defective product to us with freight prepaid.

The foregoing warranty constitutes the SOLE AND EXCLUSIVE WARRANTY, and we hereby disclaim all

other warranties, express, statutory or implied, applicable to the products and/or software, including but

not limited to all implied warranties of merchantability, fitness, non-infringement, results, accuracy,

security and freedom from computer virus. In no event shall Imada, Inc. and/or its affiliated companies

be liable for any incidental, consequential or punitive damages in connection with the use of its products

and/or software.

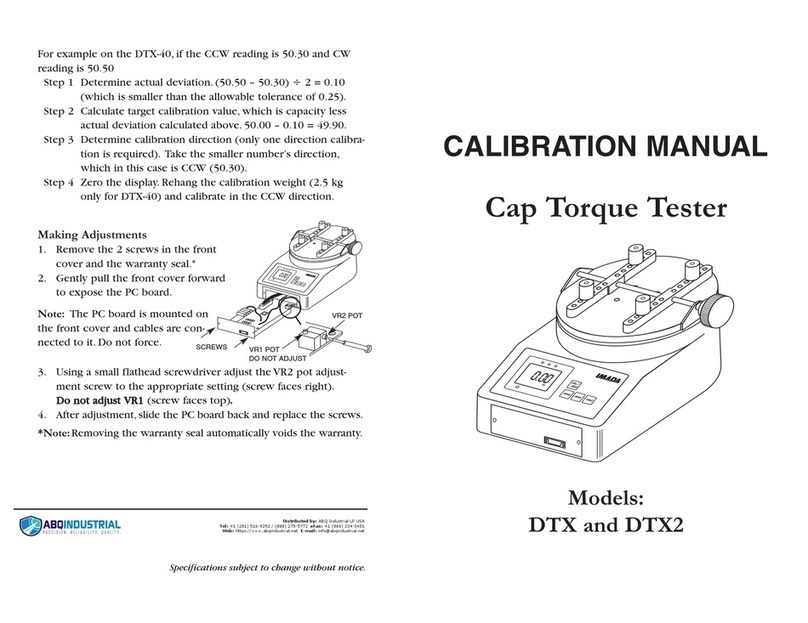

Models: DSW-15&20

Model: DSW-75

Model: DSW-120

page 7page 2

TORQUE MEASUREMENTTORQUE MEASUREMENT

RS-232C Serial Output

Output is available in PD, PP and C modes. In PD and PP modes peak

data is output when ZERO is pressed or activated by the AUTO ZERO

function. In C mode, the gauge outputs data continuously.

RS-232C Signal: 8 data, 2 stop, no parity. Baud Rate: 9600 bps.

Peak Data Output Format

[CAN] _ _ _ [SO] [value] _ [SI] [unit] [CR]

[CAN]: ASCII control code 24

_: Space (code 32)

[SO]: ASCII control code 14

[value]: Output data with sign and decimal point. Plus sign

represents for CW torque and minus sign for CCW.

[Value] always occupy six locations and empty

locations will be filled with spaces.

[SI]: ASCII control code 15

[unit]: N*m _ _ _=N.m

kgf*cm = kg.cm

lb*in _ = lb.in

[CR]: ASCII control code 13 (Carriage Return)

Continuous Output Data Format

[CAN] [value] [CR]

IMPORTANT!Use the provided AC adapter/charger exclu-

sively and plug into the correct AC output. It takes 8 hours to fully

recharge. Do not recharge for more than 12 hours. When fully

charged, disconnect the AC adapter/charger to avoid overcharging.

In order to avoid high heat, explosion or toxic fumes, please note

the following precautions:

1. Be sure to use only the provided AC charger exclusively.

2. Do not plug the charger into unspecified higher voltage.

3. Do not recharge until LOBAT icon appears.

System Reset

When battery power is completely depleted, the tester may not

work even though it has been recharged. In this case, press the

System Reset Button.

Read First: Safety Information

For safety, and for damage avoidance, be sure to read this manual

thoroughly. The warranty is only valid when the product is used fol-

lowing the instructions provided within this manual.

●Do not use tester in high temperature, high humidity, or in

damp or wet areas.

●Recommended operating temp. is between 0-42ºC (32-100ºF).

●Do not apply torque exceeding the rated capacity (180 lbf-in),

regardless of whether the unit is On or Off. Avoid shock load.

Do not use with impact wrenches.

●When charging the battery, be sure to use the provided AC

adapter/charger exclusively.

●Do not use lacquer thinner or any solvent to clean the unit.

●Do not disassemble or modify the unit.

●Recommended re-calibration cycle is one (1) year.

Digital Torque Tester/Wrench Ranges Accuracy ± 0.5% F.S., ±1 LSD

Digital Torque Tester/Wrenches

Models: DSW-15, -20, -75, -120

List of Equipment

Torque Tester

CW one-way clutch

(available but not included

with DSW-75 or DSW-120)

AC adapter/charger

Carrying case

Model Capacity Drive

DSW-15 3.0 – 130.0 lbf-in 1/4"

DSW-15kg 3.0 – 150.0 kgf-cm 1/4"

DSW-15N 0.30 – 15.00 N-m 1/4"

DSW-20 3.0 – 180.0 lbf-in 3/8"

DSW-20kg 3.0 – 200.0 kgf-cm 3/8"

DSW-20N 0.30 – 20.00 N-m 3/8"

Model Capacity Drive

DSW-75 3.0 – 660.0 lbf-in 3/8"

DSW-75F 0.30 – 55.00 lbf-ft 3/8"

DSW-75kg 3.0 – 750.0 kgf-cm 3/8"

DSW-75N 0.30 – 75.00 N-m 3/8"

DSW-120 30 – 1040 lbf-in 1/2"

DSW-120F 3.0 – 87.0 lbf-ft 1/2"

DSW-120kg 30 – 1200 kgf-cm 1/2"

DSW-120N 3.0 – 120.0 N-m 1/2"

3

4

2

3

1

2

4

1

page 3page 6

TORQUE MEASUREMENTTORQUE MEASUREMENT

5

ON/OFF Switch Press to turn on, press again to turn off (click

once, do not hold). After 10 minutes of non-use the unit shuts off.

CLR/PRG Switch To reset display to zero and to store data.

LCD Display Displays torque value and battery icon (LOBAT).

AC charger/adapter receptacle If LOBAT icon appears, 8-

hour battery recharge required.

System reset button When the battery has been depleted

completely and a recharge has been executed, the system may

not yet operate. In this case, press the System Reset Button.

RS-232 output

Wrench head swivels 300° to allow the display to be positioned

for the most convenient torque reading.

1

3

4

6

1

2

3

4

5

6

7

2

Models: DSW-15, -20, -75, -120

Consistent readings no matter where the wrench is gripped because

the torque sensor is centered on the drive.

Storing and Recalling Data from Memory

Memory functions work in PP, PD and C modes. Store up to 300

values in memory.Values are simultaneously output as RS-232

even after memory is full.

1. Measure in PP or PD mode, press CLR/PRG to store peak values.

In C mode, the tester outputs data continuously (80 data/sec).

2. To recall a value, press UP or DOWN to select a memory loca-

tion, the display cycles between location and torque value (i.e.

.0.0.1 for first location).

Note: Selecting an invalid location, defaults to measurement mode.

Clearing Data from Memory

1. Single Clear: When a memory value is displayed, press CLR/PRG,

then “CLR” displays and blinks 3 times. Press CLR/PRG switch

again before “CLR” stops blinking and the memory value is erased.

2. All Clear: Press CLR/PRG and DOWN simultaneously until “ALL”

is displayed.While “ALL” is blinking, press CLR/PRG again. Display

changes to “CLR” and blinks 3 times. Press CLR/PRG again before

“CLR” stops blinking and all memory data is erased.

Downloading Memory Data

1. Press ON/OFF to turn on.

2. Press UP and DOWN switches simultaneously. The display blinks

"FA" twice and then displays numbers with decimal points in

between (.0.0.1 for first memory location).

3. Press UP or DOWN switch to select the desired beginning mem-

ory location and press CLR/PRG to enter. The displays blinks

"LA" for the ending memory location.

4. Press UP switch or DOWN switch to select the desired ending

memory location and press CLR/PRG to enter.

5. Press CLR/PRG switch to download the data.While downloading

the data, the display shows "-P-".

Note: By pressing DOWN switch for more than 1 sec, the download

function can be terminated.

Auto Power Off

To maximize the life of the battery, power automatically shuts off

after 10 minutes of non-use.

GENERAL OPERATION

1. Place the appropriate size socket onto the drive.

2. Rotate the wrench head so the display may be viewed while

measuring and position the socket securely over the bolt (not at

an angle) and turn to measure.

3. After taking measurement, press CLR/PRG switch to zero display

for the next test.

SELECTING MEASURING MODES

Press ON/OFF to turn on. Hold CLR/PRG for more than 4 seconds.

Display cycles GO, PP, PD or C. Select desired measuring mode,

which becomes the default mode. Press CLR/PRG to display the mea-

suring mode.

GO (Real Time) Display torque transient (no output).

PP (Peak) Capture peak torque (peak data output).

PD (Peak Down) Capture peak down value (peak data output).

C(continuous RS-232 output, 80 data/sec) Display torque tran-

sients.

PROGRAMMING (to exit programming at any time press OFF)

Press ON/OFF to turn on. Press CLR/PRG and UP switches simulta-

neously and hold for more than 4 seconds.The Green LED lights

and one beep sounds, "HI" is displayed and then the High setpoint

value. This confirms the tester is ready for the following program-

ming steps.

1. High Setpoint (HI)

After "HI" is displayed and then the High setpoint value. Press UP

or DOWN switch to select the High setpoint value i.e. 50.0 for

50.0 lbf-in (for lb-in gauge), then press CLR/PRG to enter.

2. Low Setpoint (LO)

After High value is entered, "LO" is displayed and then the Low

setpoint value. Press UP or DOWN switch to select the Low set-

point value, then press CLR/PRG to enter.

3. Peak Down Minimum and Trigger Point (PdLO)

After Low value is entered, "PdLO" is displayed and then the PdLO

value. Press UP or DOWN switch to select, then press SET to enter.

page 5page 4

TORQUE MEASUREMENTTORQUE MEASUREMENT

PdLO sets a minimum torque value for Peak Down mode. For

example, if "PdLO" value is set at 5.0 lbf-in, only a reading over

5.0 lbf-in will be measured in Peak Down mode.

PdLO also sets the start and stop trigger points for Continuous

data output.When torque reaches the PdLO value, the gauge

starts to output data and stops if torque falls below the value.

4. Batch Counter (CO)

After "PdLO" value is entered, "CO" is displayed and then the

batch count number. Press UP or DOWN switch to select (0 to

99), then press CLR/PRG to enter.

Batch counter retains the number of properly torqued fasten-

ers counted in memory even if the tester is turned OFF. Press

and hold ON/OFF for more than 1 second to reset.

5. Beeper (bp)

After the batch count number is entered, "bp" is displayed and the

display shows "On" for beeper set ON, "Off" for beeper set OFF or

"FF" for no beep unless over high setpoint. Press UP or DOWN

switch to select, then press CLR/PRG to enter.

6. Auto Zero Reset (AC)

After Beeper selection is entered, "AC" is displayed and then Auto

Zero Reset duration value. Press UP or DOWN to select 0.0C -

0.5C - 1.0C - 1.5C - 2.0C - 2.5C - 3.0C, and press CLR/PRG to

enter (0.5C for 0.5 second and 0.0C for MANUAL RESET).

After measuring, Auto Zero automatically resets the tester to "0.0".

7. Time (In)

After Auto Zero Reset is entered "In" is displayed and then the

Time duration.Press UP or DOWN switch to select (0 to 24 sec-

onds), then press CLR/PRG to enter.

After "In" is entered, "S-" is displayed to confirm programming com-

pletion and 0.0 is shown.

After High and Low setpoints and batch counter are set, the tester

counts the number of correctly torqued fasteners (between High

and Low setpoint). When completed, tester flashes the Green LED

and beeps three times. If the "Time" duration ("In" value) elapses

before reaching the batch count number, the Red LED flashes and

beep sounds to alert to possible mis-tightening or stripped thread.

This manual suits for next models

13

Table of contents

Other Imada Test Equipment manuals

Popular Test Equipment manuals by other brands

Dräger

Dräger Alcotest 9510 Standard IR Instructions for use

Gossen MetraWatt

Gossen MetraWatt PROFITEST PVSUN operating instructions

Dantel

Dantel 05615 Installation & operation manual

Rohde & Schwarz

Rohde & Schwarz RTE user manual

YOKOGAWA

YOKOGAWA DL7440 user manual

Teledyne

Teledyne T3DSO3000 quick start guide