Imaje 4040 User manual

Technical File Manual

High definition for

customizing cases

Imaje 4040

101075

101075

Imaje 4040

1. Introduction

1

Technical Manual Imaje 4040.doc

1. Introduction ......................................................................................... 4

1. Introduction.............................................................................................. 4

2. Safety ................................................................................................... 5

Safety Requirements................................................................................... 5

Certification and Approvals ......................................................................... 7

CE Standards & Directives.......................................................................... 7

3. System Specification .......................................................................... 8

Technical Specifications (Hardware)........................................................... 8

4. Controller .................................................................... 10

Maintenance.............................................................................................. 10

Service/Troubleshooting:........................................................................... 10

Troubleshooting......................................................................................... 14

Wiring Diagram.......................................................................................... 16

Power Entry............................................................................................... 17

Power Supply 1 ......................................................................................... 18

Power Supply 2 ......................................................................................... 19

USB........................................................................................................... 20

Product Detect, Encoder ........................................................................... 21

Mouse to Panel Support............................................................................22

Panel Support to CPU............................................................................... 23

Photocell.................................................................................................... 24

Encoder..................................................................................................... 25

Inverter to Panel Support .......................................................................... 26

Controller to Print Module.......................................................................... 27

Schematic, I/O, Driver Board..................................................................... 28

Panel Support Board Schematic, I/O, Overview........................................ 29

Ethernet 10/100Base-T Connector (CN15)............................................... 30

Audio Connector (CN14)........................................................................... 30

Main Power Connector (CN9) ................................................................... 30

Keyboard and PS/2 Mouse Connector (CN12) ......................................... 30

Floppy Disk Drive Connector (CN20)........................................................ 31

Parallel Port Connector (CN19)................................................................. 31

IDE Hard Drive Connector (CN13)............................................................ 32

Power and HDD LED Connector (CN11) .................................................. 32

USB Connector (CN17)............................................................................. 32

COM2 RS-232/422/485 Series Port (CN16).............................................. 33

Imaje 4040

1. Introduction

2

Technical Manual Imaje 4040.doc

Flat Panel Connector (CN2)...................................................................... 33

External Flat Panel Display Connector (CN4)........................................... 34

Compact Flash Card Connector (CN21) ................................................... 34

Peripheral Power Connector (CN10)......................................................... 35

COM1 RS-232 Serial Port (CN8)............................................................... 35

LCD Inverter Backlight Connector (CN1) .................................................. 35

CRT Display Connector (CN5).................................................................. 35

LCD Signal Mapping ................................................................................. 36

PC20000301 (PCM-9372) CPU Board Specifications............................... 38

Award BIOS Setup .................................................................................... 41

Imaje 4040 BIOS Settings......................................................................... 45

Standard CMOS Features......................................................................... 46

Advanced BIOS setup............................................................................... 47

Advanced Chipset Features...................................................................... 48

Intergraded Peripherals............................................................................. 49

PnP/PCI Configuration .............................................................................. 50

Set Password ............................................................................................ 51

Cleaning the vent screens and fan inside the 4040................................... 52

5. XJ500 Print Module ...................................................... 54

Maintenance.............................................................................................. 54

Theory of Operations................................................................................. 56

Trouble Shooting....................................................................................... 57

Vacuum Priming the Printhead.................................................................. 59

Vacuum Priming the XJ500 Head .............................................................60

Pressure Priming the XJ500 Printhead ..................................................... 61

Removing/Installing the XJ500 Printhead.................................................. 62

Flushing the XJ500 Printhead................................................................... 65

XJ-500 Head Solvent Based Notes:.......................................................... 66

IDS2-500 Ink System Circuit Board Schematic, I/O.................................. 67

Drawing, Ink Level Sensor Assembly, IDS2/500 revision.......................... 68

Wiring Diagram, IDS2/500 Print Module, Old............................................ 69

Plumbing Diagram, IDS2/500....................................................................70

6. XJ128 Print Module ...................................................... 71

Maintenance.............................................................................................. 71

Trouble Shooting....................................................................................... 71

Priming the XJ128 Printhead..................................................................... 73

Procedures for Cleaning a Clogged Printhead (XJ128) ............................ 76

Cleaning a Severe Clog: ........................................................................... 77

Removing/Installing the XJ128 Printhead.................................................. 78

Schematic, I/O PCB, IDS-128 Ink System................................................. 80

Imaje 4040

1. Introduction

3

Technical Manual Imaje 4040.doc

Electrical Diagram, IDS2/128 ....................................................................81

Drawing, Replacement Printhead, XJ128.................................................. 82

7. Table of Figures................................................................................. 83

Imaje 4040

1. Introduction

4

Technical Manual Imaje 4040.doc

1. Introduction

1. Introduction

Disconnect the machine from the mains before any operations requiring modules or components

to be removed or exchanged.

Liability

Imaje cannot be held responsible if safety instructions and basic safety rules for using and

servicing the products are not followed.

Any modification or intervention is the responsibility of the user as far as its possible

consequences are concerned.

The same applies to any use of the product that fails to comply with Imaje specifications.

Any modification carried out may be counter to product compliance and the relevant safety

standards.

Therefore, Imaje cannot be held liable for any malfunction or damage caused by any

modification of the use as recommended by Imaje, or for any incident arising from use of the

product for any purposes other than those for which it is designed. It is the sole responsibility of

the user to take the precautions required by any use to which he or she puts the product.

Use

Only use Imaje original spare parts and consumables (ink, cleaning products, and other servicing

products).

Other types of consumables should not be used without Imaje’s written approval, and any

consequences shall be under the entire responsibility of the user.

Servicing

Disconnect the Imaje 4040 Large Character Ink Jet Printing System from the mains before any

operations requiring components to be removed or exchanged.

Use appropriate tools for any work on the electrical and ink circuits.

We recommend that the interventions be carried out by persons who have been given the

appropriate technical training proposed by Imaje.

Conditions

Imaje AB reserves the right to change specifications in both the text and illustrations without

prior notice. The contents of the publication may not be copied, either wholly or in part, without

permission from Imaje AB.

First published: 2005

Art number: 101075-01

Version: 00

Imaje 4040

2. Safety

2. S

afet y

5

Technical Manual Imaje 4040.doc

Safety Requirements

Imaje disclaims all responsibility regarding the CE directive if the printer is used,

altered or installed in any way other than described in this manual.

This symbol is used to indicate circumstances that may be dangerous to the user

or that cause damage to the equipment.

This symbol is used to draw your attention to important information that will

facilitate work or operations.

Please Note the Following Warnings:

■Never use sharp or pointed tools when cleaning or replacing the print head.

■The nozzle plate on the printer head is sensitive to handling. Contact with this

surface must be minimized to prevent damage to the nozzle plate. Damage to the

nozzle plate surface can cause a reduction in the performance of the print head.

■If the XJ-500/ XJ-128 nozzle plate requires cleaning – flood the nozzle plate

with the appropriate cleaner (see chapter 4 – Priming the print head).

Use only Imaje authorized cleaners. Never clean the nozzle plate with tools.

Never wipe the nozzle plate.

■Never point the nozzle end of a print head at yourself or another person.

Imaje 4040

2. Safety

6

Technical Manual Imaje 4040.doc

■Please read all instructions before using the printer for the first time.

■The printer should be connected to the power supply indicated on the voltage

plate. If you are unsure of the type of power supply available, please contact Imaje

service personnel.

■The printer should be connected to a grounded socket.

■The printer is equipped with a plug suitable for grounded sockets. This is a

safety measure. If the plug does not fit the power socket, a qualified electrician

must replace it.

■We do not recommend the use of extension cables.

■The power cable must not be subjected to pressure. Ensure that the printer is

not placed anywhere where the cable can be put under pressure.

■Check that the power switch is off (in the ‘0’ position) before connecting the

power cable.

■Do not attempt to open the electronic unit or other sealed parts! The user

cannot service these parts.

■Never expose the unit to high humidity or liquids.

■Ensure that the lighting at the installation site is in accordance with local

regulations.

■All chemicals, even ink, may present unknown health hazards, and should be

treated with caution.

Disconnect the power to the printer and call in qualified personnel under

the following conditions:

■The power cable or plug is damaged or worn.

■Liquid has been spilled on the printer.

■Rain or water has leaked into the printer.

■The printer is not functioning correctly although the user has followed the

instructions.

■The printer has been dropped or the casing has been damaged.

■The printer is not functioning correctly and requires service.

Imaje 4040

2. Safety

7

Technical Manual Imaje 4040.doc

Certification and Approvals

The Imaje 4040 printers are certified in

accordance with the requirements for CE

marking.

CE = European Commission

The Imaje 4040 printers are certified in

accordance with the requirements for ETL

marking.

ETL = Electrical Testning Labs

The Imaje 4040 printers are certified in accordance

with the requirements for the FCC.

FCC = Federal Communications Commission

CE Standards & Directives

Imaje 4040 printers are in accordance with the following

European directives applicable to the products:

■The electromagnetic compatibility directive, EMC

Directive 89/336/CEE, and its corresponding European

standards.

■The Low Voltage Directive 93/68/CEE, and its

corresponding European standards.

■The Machine Directive AFS 1994:48 (98/37/EC), and its

corresponding European standards.

■ETL listed: Conforms to ANSI/UL STD 60950.

CERTIFIED TO CAN/CSA C22.2 STD NO.60950-00.

The above referenced product bears the CE mark.

Imaje 4040

3. System Specifications

8

Technical Manual Imaje 4040.doc

3. System Specific ation

Technical Specifications (Hardware)

General Description

The 4040 controller is a high-resolution ink jet printing system. This ink jet printer utilizes state of the art

Impulse Piezo printhead technology capable of utilizing a wide variety of inks to print onto a wide variety of

media at very high resolution.

Controller:

Pentium class processor based PC-104 industrial computer. Running the Windows XP operating system.

Printhead Expansion:

Up to four printheads per controller. Field expandable, add a printhead driver card in 10 minutes. No need to

send into factory or pay for a technician’s visit. Mix and match printhead types with easy “plug and play”

technology.

User Interface:

10.4” TFT Color flat panel display with 800x600 resolution.

Integrated, rubberized, waterproof industrial mouse.

Industrial membrane QWERTY keyboard.

WYSIWYG (what you see is what you get) software. See Software specifications.

Input/Output (I/O):

Printhead Ports: 4

Product Detector Port: 2. Can be used independently or linked together.

Encoder Port: 2. Can be used independently or linked together.

Serial Ports : 1-RS232, 1-RS232,422,485 (Configurable)

Parallel Port : 1

USB Port: 1 *Allows easy upload of messages created off line, database files, graphics or software updates via

any type of USB device. And with Windows XP technology there are no worries about drivers.

Ethernet (LAN) Port: 1 (10/100 base T). For networking using Net-Jet

™

software.

PS2 Port: 1. For use with external keyboard, PS2 Wedge scanner, etc.

Video Port: 1. For use with external monitor.

Processor:

Via-Eden Pentium class 400MHZ and 800 MHZ standard.

Memory:

Operating Memory: 256mb PC100 D-RAM

Image Memory: 8MB, capable of printing an image up to 500 nozzles tall at 360 DPI up to 8 feet in length.

Storage:

20GB Hard Drive (minimum) Message storage is virtually unlimited.

Electrical Requirements:

120VAC/60HZ, 240VAC/50HZ

Environmental Ratings:

Operating temperature 0-50 deg. C, 32-122 Deg. F. to 90% RH, non-condensing

Cabinet Construction:

Stainless Steel, splash proof design features gasket seal protection.

Safety Agency Compliance:

UL, CE, TUV, GS, CSA

Imaje 4040

3. System Specifications

9

Technical Manual Imaje 4040.doc

Printheads:

XJ128-200:

• Nozzle Count: 128 nozzles (all points addressable)

• Horizontal Resolution: 200 DPI

• Vertical Resolution: 185 DPI, Capable of printing razor sharp graphics and reliable bar codes.

• Print Speed: 140 Feet per minute (FPM) at 200 DPI.

• Maximum Print Height: 0.7 inches (17mm)

• Ink: Oil, Solvent, UV (UV types are limited in this head due to lack of temperature compensation).

• Throw distance: Optimal-1mm, Maximum-5mm

• Shock resistance: Since the Xaar printheads were originally designed for desktop and wide area format printers;

they are designed to be able to be moved very rapidly. Thus, these printheads are extremely robust, tolerate

shock and resist depriming far better than most other industrial printheads such as Trident printheads.

• Operating temperature: 35 deg. F (2C) to 105 deg. F (41C). These temperatures are designated for optimal

performance and are conservative. The printhead can actually perform fairly up to 115 Deg. F (46C).

XJ500-180

• Nozzle Count: 500 nozzles (all points addressable)

• Horizontal Resolution: 200 DPI

• Vertical Resolution: 180 DPI, Capable of printing razor sharp graphics and reliable bar codes.

• Print Speed: 150 Feet per minute (FPM) at 200 DPI.

• Maximum Print Height: 2.8 inches (70mm)

• Ink: Oil, Solvent, UV

• Throw distance: Optimal-1mm, Maximum-5mm

• Shock resistance: Since the Xaar printheads were originally designed for desktop and wide area format printers;

they are designed to be able to be moved very rapidly. Thus, these printheads are extremely robust, tolerate

shock and resist depriming far better than most other industrial printheads such as Trident printheads.

• Operating temperature: 35 deg. F (2C) to 105 deg. F (41C). These temperatures are designated for optimal

performance and are conservative. The printhead can actually perform fair at up to 115 Deg. F (46C).

Ink Delivery System:

• The IDS-128 ink delivery system utilizes a 500ml disposable bag in box ink cartridge. This IDS is currently

used in conjunction with the XJ128 and XJ126 printheads. It is made of Stainless Steel and chemically inert

materials to be compatible with solvent, oil, UV, and aqueous based inks. Using this IDS, the XJ126 and XJ128

may be set up to print at almost any angle.

• Flashing red Ink Low LED.

• The IDS2-500 ink delivery system utilizes a 500ml disposable bag in box ink cartridge. The IDS2-500 can also

be fitted with a bulk feed ink delivery system called “Ultra-Tank™”. This IDS is currently used in conjunction

with the XJ500 printhead. It is made of Stainless Steel and chemically inert materials to be compatible with

solvent, oil, UV, and aqueous based inks. Using this ID, the XJ500 may be set up to print horizontally,

vertically or at 45 a degree angle.

• Flashing red Ink Low LED.

Print Module:

• The Print Module consists of the printhead, ink delivery system and printhead bracket assemble as one

assembly, ready to install. This is available in several variations.

Inks:

Types: Oil base, Solvent Base, UV Curable, Security (invisible), USDA, IR readable.

Colors: Cyan, Magenta, Yellow, Black, Red, Blue, Green, White Opaque, Yellow Opaque, Orange

Opaque, Powder Blue Opaque.

Imaje 4040

4. Controller

10

Technical Manual Imaje 4040.doc

4. Controll er

• The controller is a Windows XP Professional based industrial computer.

Maintenance

The controller requires very little maintenance.

Monthly: Check the fan filters on the bottom of the controller for excessive build up. If clogged up, they

need to be removed and either washed with water, or blown off with air.

Service/Troubleshooting:

Adding or Replacing a Driver Board

You many need to add a driver board for driving additional print heads

Tools Required

1. One Philips Screw Driver (Small

tip).

2. One 5mm nut driver.

Figure 1: Tools Required to Add/Replace a Driver Board

Step 1 Remove Jack Screws

3. With power off, set the Controller

onto a firm flat workspace.

4. Rotate Controller onto its side.

5. Remove the Jackscrews from any

currently installed Driver Boards

(indicated by H1-H4).

Figure 2: Removing Jack Screws

Imaje 4040

4. Controller

11

Technical Manual Imaje 4040.doc

Step 2 Removing Cover Plate.

6. If expanding a controller (adding

printheads) remove the Driver

Board Cover Plate(s).

7. Remove H2-H4 depending on how

many boards you are adding.

Figure 3: Removing Cover Plate

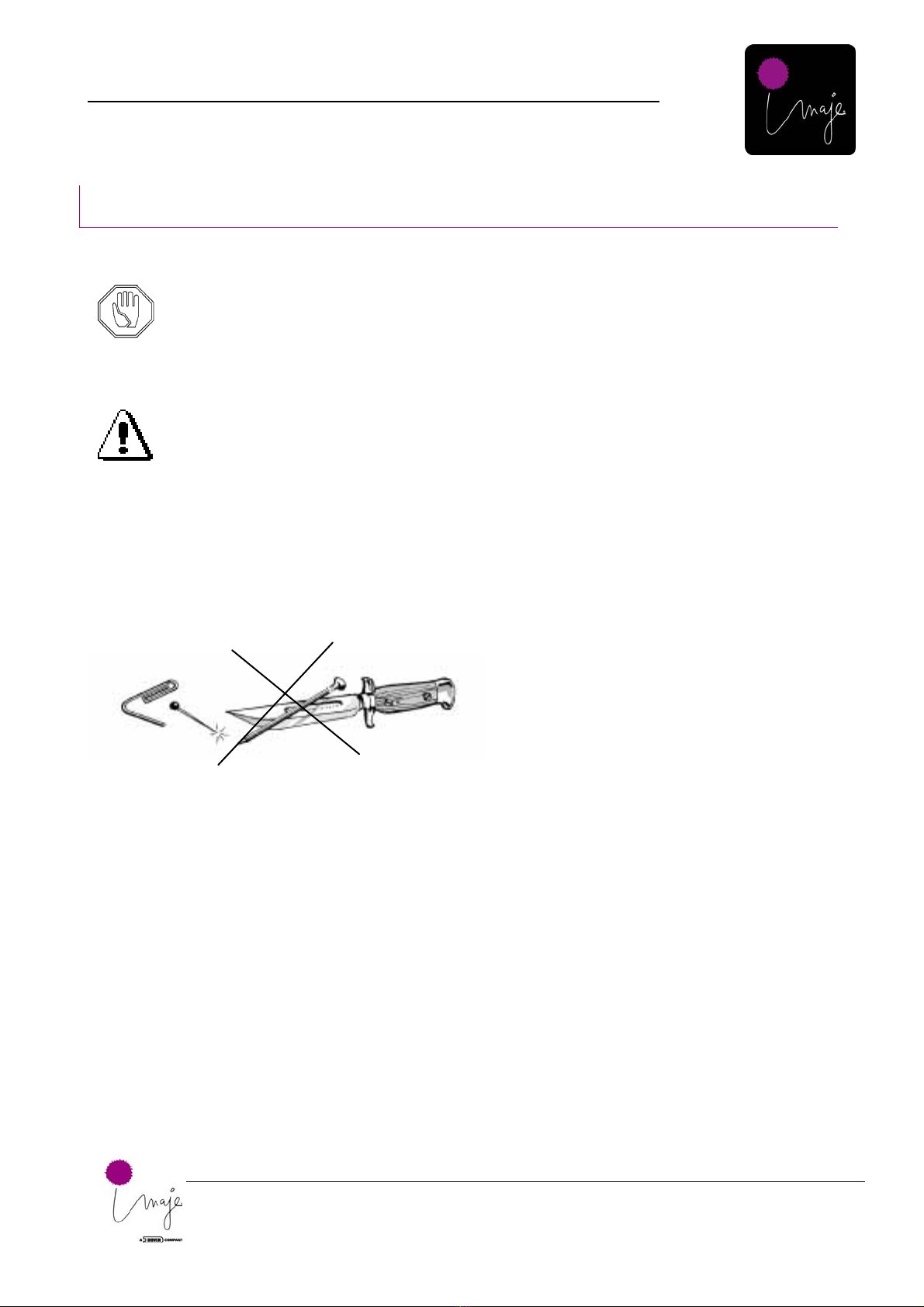

Step 3 Attaching Anti-Static Wrist Strap.

8. Attach Anti-Static strap to wrist and

9. Connect the clip to the case for

proper ground. Make sure that the

Mains (AC) cable is connected to

power, but power turned off

Figure 4: Attaching Anti-Static Wrist Strap

Step 4 Loosen PCB Mounting Plate

10. Using a Philips Screw Driver,

loosen (do not remove) all four

screws in the slotted holes on the

PCB mounting plate.

Figure 5: Loosening PCB Mounting Plate

Imaje 4040

4. Controller

12

Technical Manual Imaje 4040.doc

Step 5 Lifting the PCB Plate

11. Once all four screws are loose, lift

the plate as shown until the plate

moves to the top of the screw slots

shown in previous Figure.

Figure 6: Lifting the PCB Plate

Step 6. Tightening the PCB plate screws.

12. Upon lifting the PCB mounting

plate, re-tighten at least one screw to

hold the plate into place so that the

drive boards may be removed or

installed.

Figure 7: Tightening the PCB Plate Screws

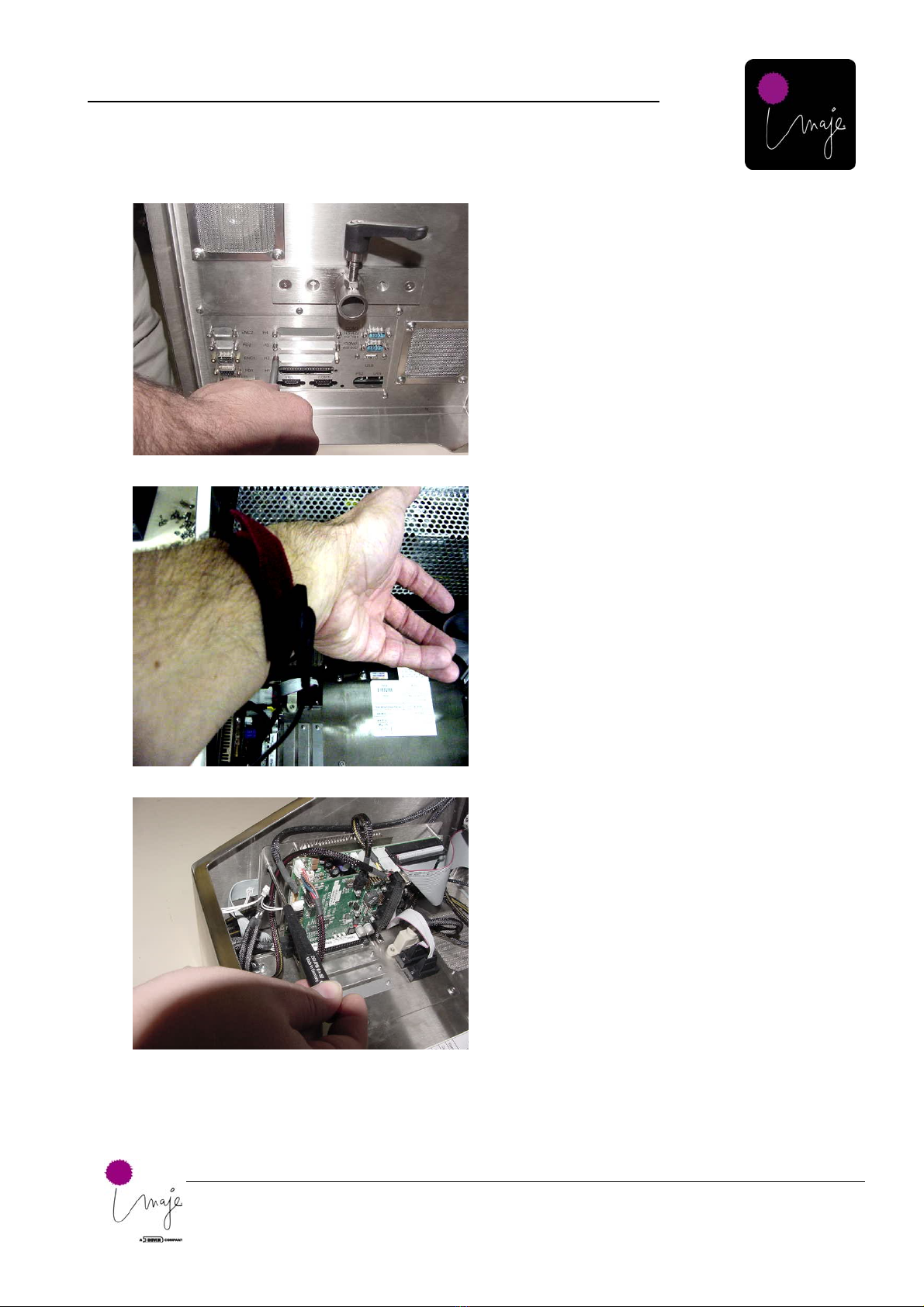

Step 7. Installing the Driver Board

13. Line up the pins on the PC140 bus

and push the driver board onto the

board beneath it.

Figure 8: Installing the Driver Board

Imaje 4040

4. Controller

13

Technical Manual Imaje 4040.doc

Step 8. Securing Driver Board

14. Using the standoffs supplied with

the driver board expansion kit,

fasten each one loosely, and then

tighten them once each screw has

threaded in smoothly.

Figure 9: Securing Driver Board

Step 9. Driver board Installed with

Standoffs attached.

15. Your new driver board is now

installed

Figure 10: Driver Board Installed

Step 10, 11, 12. Securing PCB Plate

16. Repeat in reverse steps 6 then 5 then

4.

Imaje 4040

4. Controller

14

Technical Manual Imaje 4040.doc

Troubleshooting Symptom: No power upon startup

Possible cause Possible solution

• Poor AC connection Check AC connections

• Blown AC fuse Check fuse

• UPS (Uninterruptible Power

Supply) or Line conditioner

not turned or defective

Check line conditioner power and connection if using a line

conditioner. Try plugging printer directly into AC power to

be sure UPS or line conditioner is OK.

• Problem at AC power source

(wall outlet). Check AC voltage at source, or try another source.

Symptom: Upon Power up, Fan comes on, but the display does not illuminate

Possible cause Possible solution

• The Inverter cable is

loose or

disconnected.

Shine a flashlight onto the display to view if Windows can be seen on

the display. If so, open the controller door and check the inverter

cable connection at both ends. See wiring section.

• Display cable loose

or disconnected.

Shine the flashlight onto the display. If Windows cannot be viewed,

then the display is not functioning. Open the controller door and

check the connection on the display cable at both the display side

and the CPU board side.

• Inverter Bad

If inverter cables are connected ok, the inverter may need to be

replaced.

• Display bad If cable connections are all ok, replace the display.

• Bios Re-set (this can

happen when the C-

MOS battery dies)

If the BIOS becomes re-set, this is usually caused by a dead C-MOS

battery. The CMOS battery has a life of about 5 years replace the

battery, then attach an external CRT monitor to the video port,

because the system has defaulted back to factory settings. You will

need to re-set the bios settings so that your panel display will work.

There is a BIOS Flash utility saved on the hard drive of the system

for convenient re-load. If the re-load does not work, see the BIOS

section of this manual for making BIOS adjustments.

Imaje 4040

4. Controller

15

Technical Manual Imaje 4040.doc

Symptom: Photocell lights up but no print

Possible cause Possible solution

• The Print Speed

and or Margin

are set

incorrectly

Run a piece of paper in front of the print head with one hand, and with

the other hand trigger the photocell. If the printer prints, then you can

determine if the printer is printing to early or too late. Adjust Margin

and or print speed accordingly.

• Product

detect/encoder

settings

incorrect

Check that these settings match the hardware configuration. Ex. If using

a PD but no Enc. Only PD should be enabled. Check that the

linked/independent mode settings are correct according to hardware set

up.

• PD/Enc.

Connector loose

at Driver Board

input

Open door and check that the connector is connected to driver board.

See wiring diagram.

To ensure PD signal, check that LED on driver board lights when PD is

tripped. Also, check the Encoder LED. It should light when the encoder

is connected and moving or at a resting state on a pulse. If both LED’s

light, connectivity is secure.

If this symptom occurs on any head other than head 1, check that the

linking cable is connected. See wiring diagram.

Symptom: In NJ Processor the Printhead Icon has an “X” through it.

Possible cause Possible solution

• DIP Switch on one of the

Driver Boards set

incorrectly

Check the dipswitch settings on the corresponding board(s) that

are X’d out. If switch setting ok, board could be faulty.

• Driver board not seated

properly Check that the Driver Board(s) is seated fully and that the pins

are properly lined up. If correct, driver board could be faulty.

• Defective Driver Board Replace Driver Board

Symptom: Boot Failure/Boot Errors

Possible cause Possible solution

• Hard drive cable

disconnected. *Often when a driver board is added, the technician disconnects the

HD cable and then forgets to re-connect it. Re-connect it.

• Hard Drive crashed Replace hard drive

• Memory Failure Replace memory (RAM) module on CPU board

• CPU Board Failure Replace CPU board

• BIOS Problem See Technical Bulletin

Imaje 4040

4. Controller

16

Technical Manual Imaje 4040.doc

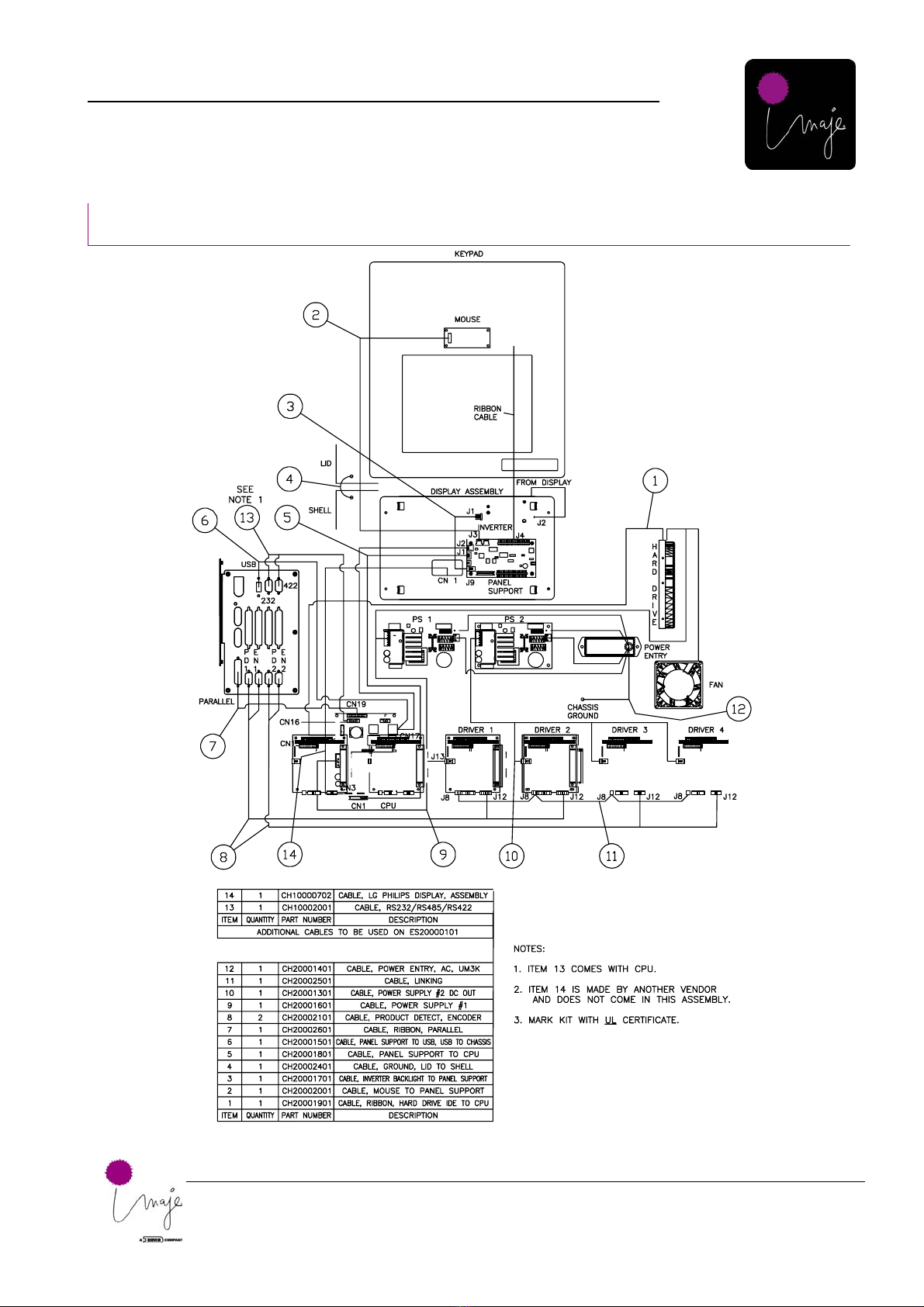

Wiring Diagram

Figure 11: Wiring Diagram (ES20000101)

Imaje 4040

4. Controller

17

Technical Manual Imaje 4040.doc

Power Entry

Figure 12: Power Entry (CH20001401)

Imaje 4040

4. Controller

18

Technical Manual Imaje 4040.doc

Power Supply 1

Figure 13: Power Supply 1 (CH20001601)

Imaje 4040

4. Controller

19

Technical Manual Imaje 4040.doc

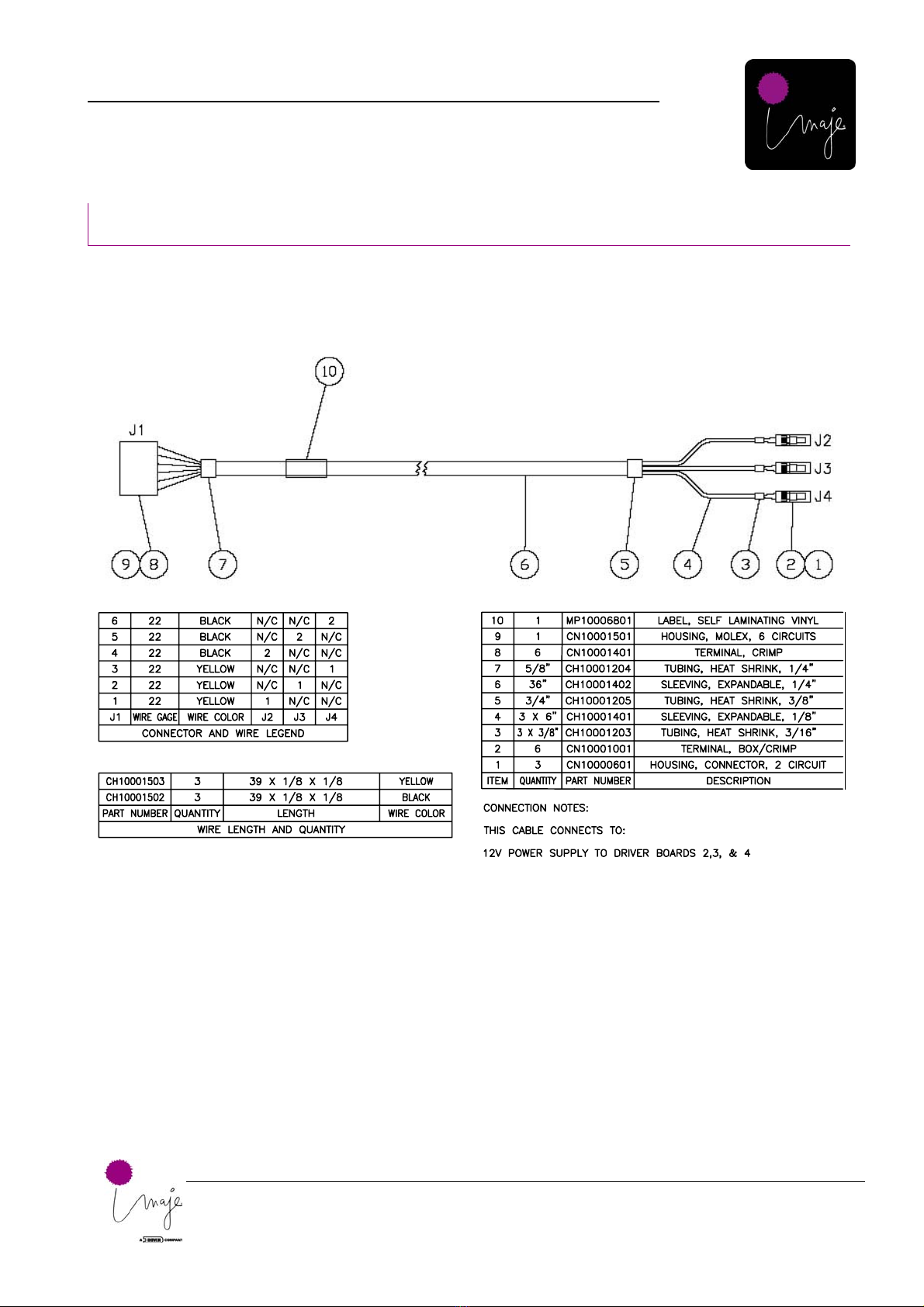

Power Supply 2

Figure 14: Power Supply 2 (CH20001301)

Table of contents

Other Imaje Printer manuals