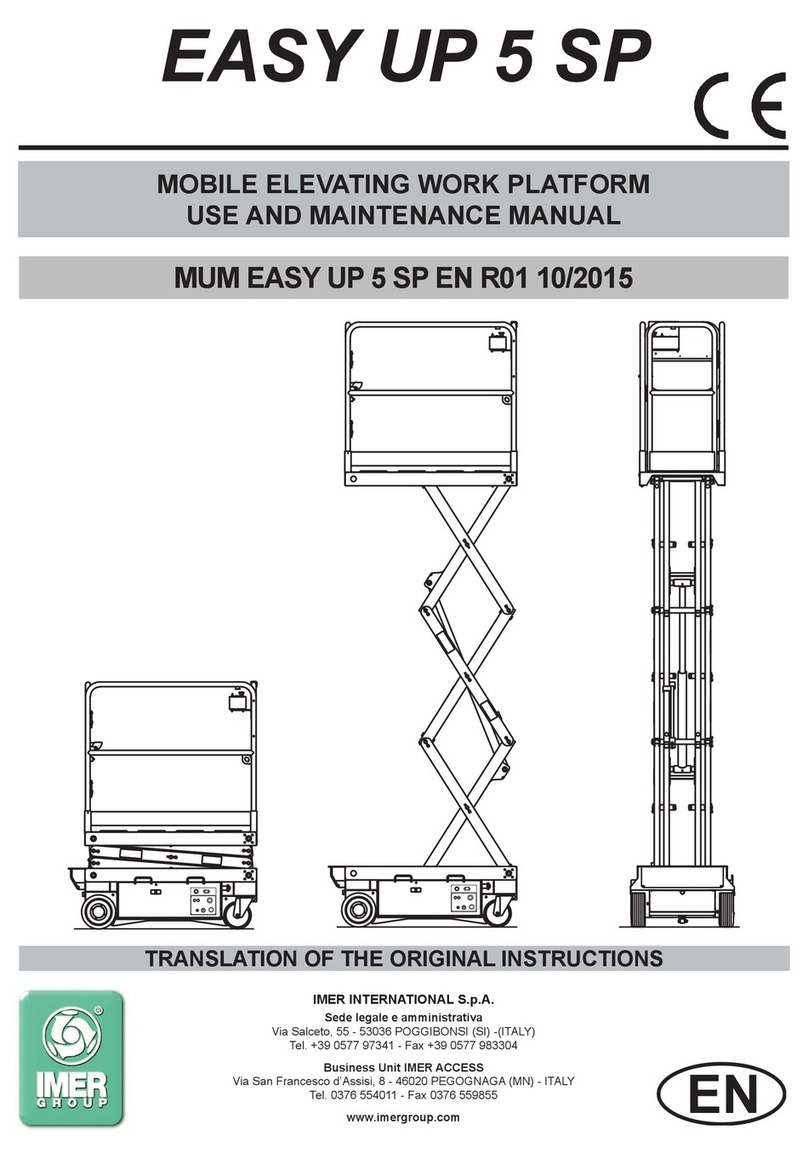

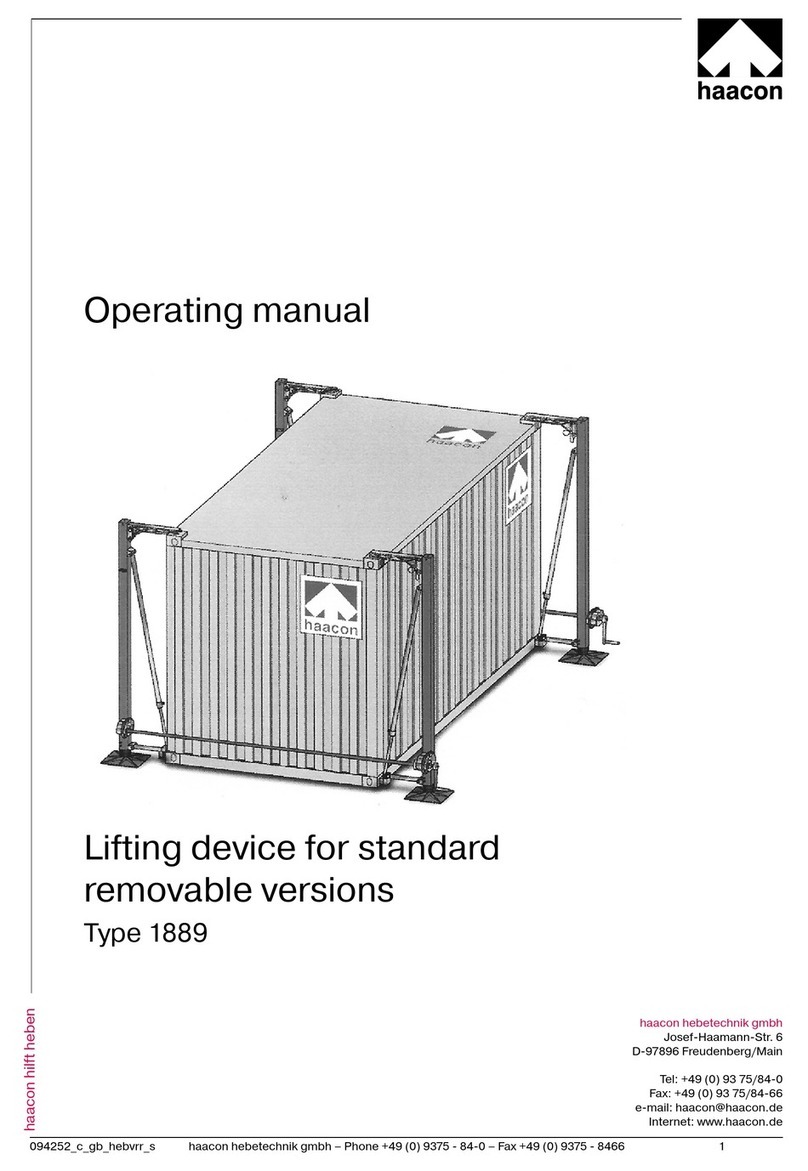

IMER INTERNATIONAL IM R15 User manual

EN

MOBILE ELEVATING WORK PLATFORM

USE AND MAINTENANCE MANUAL

MUM IM R15 EN R00 06/2013

TRANSLATION OF THE ORIGINAL INSTRUCTIONS

IMER INTERNATIONAL S.p.A.

Sede legale e amministrativa

Via Salceto, 55 - 53036 POGGIBONSI (SI) -(ITALY)

Tel. +39 0577 97341 - Fax +39 0577 983304

Business Unit IMER ACCESS

Via San Francesco d’Assisi, 8 - 46020 PEGOGNAGA (MN) - ITALY

Tel. 0376 554011 - Fax 0376 559855

www.imergroup.com

IM R15

USE AND MAINTENANCE MANUAL

Table of contents

Contents of the CE conformity declaration.............................................................. 7

Static and dynamic tests .............................................................................................. 7

Aer-sale service ........................................................................................................... 8

Spare-part service.......................................................................................................... 8

Standard equipment.......................................................................................... 9

Optional............................................................................................................... 9

General instructions - safety..................................................................................... 10

Manual............................................................................................................... 10

Safety systems .................................................................................................. 10

Labels and plates.............................................................................................. 10

Operator’s requirements ................................................................................. 11

Distance from the electric lines ...................................................................... 13

Not allowed operations................................................................................... 14

To minimize hazards ....................................................................................... 16

Risk of folding .......................................................................................... 16

Risk of falling............................................................................................ 17

Electric hazards ........................................................................................ 17

Explosion or burn hazards ..................................................................... 17

Residual risks.................................................................................................... 18

Description of the machine....................................................................................... 19

Presentation ...................................................................................................... 20

Identication..................................................................................................... 21

Main components ............................................................................................ 22

Operation .......................................................................................................... 23

Movement list........................................................................................... 24

Drive and Steering...................................................................................................24

Tracks widening.......................................................................................................24

Stabilization ..............................................................................................................24

Boom liing/lowering.............................................................................................24

Pantograph liing/lowering...................................................................................25

Turret rotation ..........................................................................................................25

Telescopic boom extension/retraction...................................................................25

Jib liing/lowering...................................................................................................25

Cage rotation ............................................................................................................26

Cage levelling...........................................................................................................26

Control proportionality........................................................................... 26

Electronic circuit ...................................................................................... 27

3

IM R15

USE AND MAINTENANCE MANUAL

Remote control and Radio control ........................................................ 27

Remote control .........................................................................................................27

Radio control (optional)..........................................................................................28

The push-buon panel............................................................................................28

Central unit...............................................................................................................28

Push-buon panel baery ......................................................................................29

Baery for wire controlled versions ................................................................29

Baery for versions with radio control............................................................29

Charging the baery (only for radio versions)...............................................30

Control and power instruments position..................................................... 32

Technical specications................................................................................... 34

Overall dimensions.......................................................................................... 35

Diagram work................................................................................................... 37

Plates and labels............................................................................................... 38

Use of the machine...................................................................................................... 39

Checking before use ........................................................................................ 39

Visual checking ........................................................................................ 39

Operating check ....................................................................................... 40

Operation .......................................................................................................... 41

Machine congurations .......................................................................... 42

Aerial part - Ground part .......................................................................................42

Machine status ........................................................................................................43

Machine stowed ..................................................................................................43

Machine in safety transport...............................................................................44

Machine open ......................................................................................................44

Control panels .......................................................................................... 45

Ground control panel..............................................................................................45

Push-buon panel....................................................................................................48

Selectors................................................................................................................50

Switches................................................................................................................52

Joystick controls ..................................................................................................54

Leds Bar ...............................................................................................................55

Display .................................................................................................................56

Safety systems ......................................................................................... 58

Audible alarms.........................................................................................................58

Overturning moment limiter .................................................................................59

Load sensor...............................................................................................................60

Emergency stop .......................................................................................................61

Faults ........................................................................................................................61

Safety belt aachments ...........................................................................................61

Microswitches ..........................................................................................................61

4

IM R15

USE AND MAINTENANCE MANUAL

Microswitch SQ1A-B (machine stowed)..........................................................61

Microswitch SQ8 (boom) ...................................................................................61

Microswitch SQ9 (pantograph).........................................................................62

Microswitch SQ10 (control panel on cage) (for radio versions)...................62

Microswitches SQ3-4-5-6....................................................................................62

Clogged oil lter sensor..........................................................................................63

Temperature sensor (optional)...............................................................................63

Machine stop ........................................................................................... 63

Use of the machine........................................................................................... 64

Starting the machine................................................................................ 65

Motor start-up .......................................................................................... 65

Drive and Steering................................................................................... 65

Stabilization .............................................................................................. 67

Enabling the aerial part........................................................................... 69

Return to stowed machine...................................................................... 70

Levelling outriggers retraction .............................................................. 70

Enabling the movements from ground panel...................................... 71

Turret rotation .........................................................................................................71

Pantograph liing/lowering ..................................................................................71

Boom liing/lowering ............................................................................................71

Telescopic boom extension/retraction ..................................................................71

Jib liing/lowering ..................................................................................................71

Cage rotation ...........................................................................................................71

Cage levelling ..........................................................................................................71

Emergency manual procedures ..................................................................... 72

Manual emergency movements............................................................. 73

Emergency movements with 12V electric pump (optional).............. 79

Manual start of endothermic motor...................................................... 80

Diesel motor .............................................................................................................80

Petrol motor..............................................................................................................81

Baery recharge ............................................................................................... 83

Transport and Liing ...................................................................................... 84

Storage ............................................................................................................... 87

Disposal and scrapping................................................................................... 87

Maintenance................................................................................................................. 88

Machine cleaning ............................................................................................. 88

Maintenance summary table.......................................................................... 89

Check oil level and change............................................................................. 90

Electrolyte level check..................................................................................... 90

Check of baery charge................................................................................... 90

5

IM R15

USE AND MAINTENANCE MANUAL

Check of screw tightening .............................................................................. 91

Grease the mechanisms................................................................................... 91

Safety devices check ........................................................................................ 92

Red emergency stop buon.................................................................... 92

Safety speed.............................................................................................. 92

Load Limiter ............................................................................................. 93

Load sensor............................................................................................... 93

Manual emergency movements check.......................................................... 94

Check brakes..................................................................................................... 94

Good grip .................................................................................................. 94

Braking spaces.......................................................................................... 94

Structure check................................................................................................. 95

Check of wheel reduction gear oil................................................................. 96

Check of hydraulic tubes ................................................................................ 97

Checking performance.................................................................................... 97

Safety speed.............................................................................................. 97

Pantograph liing/lowering................................................................... 97

Boom liing/lowering ............................................................................. 98

Telescopic boom extension/retraction................................................... 98

Turret rotation .......................................................................................... 98

Jib liing/lowering................................................................................... 98

Basket rotation.......................................................................................... 98

Oil lter check .................................................................................................. 99

Wheel reduction gear oil change ................................................................. 100

Check register................................................................................................. 102

6

IM R15

Contents of the CE conformity declaration

We: IMER International S.p.a.

Address: Via Salceto, 53-55 53036 Poggibonsi (SI) - Italy

Declare under our own sole responsibility that the mobile elevating work platform, with internal

combustion engine

IM R15

Conforms to the conditions of the Machine Directive 2006/42/CE•

Conforms also to the provisions of the following Directives:•

2004/108/CE (Electromagnetic Compatibility Directive ) and following amendments and integrations

2006/95/CE (Low Voltage Directive ) and following amendments and integrations

2000/14/CE (environmental acoustic emission of equipment and machines having the aim to work

outdoor) and standards transferring them into every national legislation.

Procedures: annex V

We further certify that the following harmonised rules have been applied:•

EN 60204-1, EN ISO 12100, EN280

The name of the person authorised to compile the technical documentation is Paolo Pianigiani,•

Director of Business Unit IMER ACCESS – Via S.Francesco d’Assisi 8 - 46020 Pegognaga (MN)

– Italy

Measured sound power level

Guaranteed sound power level

Net installed power

Diesel Petrol

Static and dynamic tests

Before commissioning, the static and dynamic tests have been performed according to the

harmonised standard EN 280 section 6.3.

dB 104 102

dB 107 104

kW 6,5 8,2

USE AND MAINTENANCE MANUAL

This edition contains the use and maintenance manual of the tracked

self-propelled aerial platform IM R15.

IM R15 reaches a working height of 15 m.

Designed and manufactured to be hydraulically operated and with

proportional controls, remote-controlled by remote control.

The machine can be used outdoors.

Onlyqualiedandskilledoperatorscanusethesemachines.

Platform manufacturer:

IMER INTERNATIONAL S.p.A.

Via Salceto, 55 - 53036 POGGIBONSI (SI) - (ITALY)

Tel. 0577 97341 - Fax 0577 983304

www.imergroup.it

Business Unit IMER ACCESS

46020 PEGOGNAGA (MN) ITALIA

Via S. Francesco D’Assisi, 8

Tel. +39 0376.554011

Fax +39 0376.559855

After-sale service

For interventions, repairs and revisions, address to authorized

workshops. For information contact our Technical After-Sale

Assistance.

Spare-part service

A good and lasting working guarantee is assured by using original

spare parts only; make reference to the “SPARE PARTS

CATALOGUE”.

Alwaysstatethedatadescribedontheidenticationplateplacedon

the chassis if you need spare parts or assistance.

8

IM R15

USE AND MAINTENANCE MANUAL

Standard equipment

The machine is equipped with the following:

Simultaneous and proportional controls•

Remote control for wire control•

Parking brakes•

Rubber tracks•

Hydraulically widening tracks•

Turret rotation of 355°•

Hydraulic cage balancing•

Hydraulic cage rotation•

Manual stabilization•

Overturning moment limiter•

Load limiter•

Lock valve on lifting cylinders•

Emergency manual lowering•

Dual controls: ground and cage•

Hour-counter•

Audible motion alarms•

Battery isolator•

Plug, socket and circuit breaker for 230V line•

Cable pre-set for 230V line to the cage•

Water/air line to the cage•

EC marking–EN280•

Optional

Wireless radio control kit•

Automatic levelling jacks•

Cage beacon kit•

No marking tracks kit•

12V emergency electric pump•

Preheating kit for diesel motor•

9

IM R15

USE AND MAINTENANCE MANUAL

General instructions - safety

Manual

A suitable working safety is very important in order to avoid serious

injuries for the operator himself and for the other persons, therefore it

is compulsory to carefully read and well-understand this manual to

know the exact and essential instructions for the use of the machine

and the maintenance operations.

This manual is to be considered as an integral part of the machine

and it should always remain on the platform for future reference.

This use manual must be carefully preserved by the user for the whole machine life, even if the

machine is lent, rent or sold.

The gures described in this manual DON’T always exactly reproduce the model described but

these are used for a beer and easier understanding of the text.

Safety systems

The safety systems applied to the machine are inevitably subject to wear and to go out of tune.

Therefore,theymustbecontrolledandkeptinperfectefciency;also,itisnotadvisabletoevaluate

their operational and safety conditions only on the basis of their functioning.

Such systems do not relieve the operator of the responsibility of carrying out an informed and

appropriate use of the machine.

It is absolutely forbidden to remove, modify or tamper with parts of the self-propelled aerial platform,

which are important for safety and stability.

Any tampering whatsoever with the main members of the self-propelled aerial platform and associated

safetydevicesimmediatelynulliesguaranteeconditions.

Labels and plates

Potential dangers and instructions regarding the machine are given

on labels and plates; these should therefore be kept in a clearly

legible, good condition.

10

IM R15

USE AND MAINTENANCE MANUAL

Operator’s requirements

The operator shall:

Rea• d and well understand all the documentation enclosed to the

machine, be properly trained and instructed in the correct use of

the machine and know the safety rules and devices.

Be physically in good conditions and not make use of dope,•

alcohol or drugs that could affect the attention, the reaction, the

sight and the hearing.

Give a great importance to safety and refuse to work if you think•

you are not working under safe conditions.

Well-know the maximum working load.•

Use suitable accident prevention equipment accordingly with the•

working conditions and the local rules in force.

When you are on the cage keep all the parts of the body inside the guard rails and both feet have•

tobermlyrestontheoorsurface.

Make always use of an assistant in areas where the sight is obstructed.•

Always work under highest safe conditions, tidiness and cleaning.•

Before using the machine check daily the controls and safety devices and make sure they are in•

perfect working order.

Check that the working area is free from persons, animals or obstacles before making any•

movement of the machine.

Check that the ground where the machine has to operate is free from holes, bumps, drops,•

uneven level, obstructions, debris and coverings which could hide possible potholes or others

dangers.

Cleantheladder,theoorsurfaceoftheplatformandthehandrailsfromoilandgrease.•

Oncetheworkhasbeennishedandwhenthemachineremainsunattended,takethekeyoffto•

avoid that unauthorized persons can use it.

Commuting platform control panel, always remove the key to avoid an unauthorized use from the•

ground control panel while personnel is present on the platform. The safety manager must hold

a spare key enabling to use the ground control panel as emergency place. (In case of failure it is

possible to lower the machine).

11

IM R15

USE AND MAINTENANCE MANUAL

In particular

Beawarethatthetrackedplatformscanbeusedbyqualied•

personnel only.

Do not give the push-button panel to people who have not been•

thoroughly trained.

Familiarize yourself with the symbols and the positions of the•

levers for the operation of functions and handling.

Always check before starting work, the functionality of the button•

for the emergency stop of the push-button panel

Stay at a proper distance from the machine during its use, in•

ordertomaintainagoodviewoftheworkingeld.Unauthorised

persons must not stand within the working area of the machine.

Release all the levers if the movement of the machine becomes•

uncontrollable and immediately press the emergency stop button

of the push-button panel.

Always press the emergency button of the push-button panel•

when the unit is not in use. This also applies for short breaks, for

example, if the driver wants to move the machine.

Always press the emergency button of the push-button panel at•

the end of the work. The push-button panel must be kept out of

reach of unauthorized persons.

12

IM R15

USE AND MAINTENANCE MANUAL

Distance from the electric lines

The machine is not electrically insulated and does not offer any

protection against active parts, electrical lines and plants which are

notprotectedornotsufcientlyprotected.

Herebelowyoucanndatableconcerningthesafetydistancesto

be compulsory observed according to the Italian law.

In other countries the operator may have dierent limitations

to be observed.

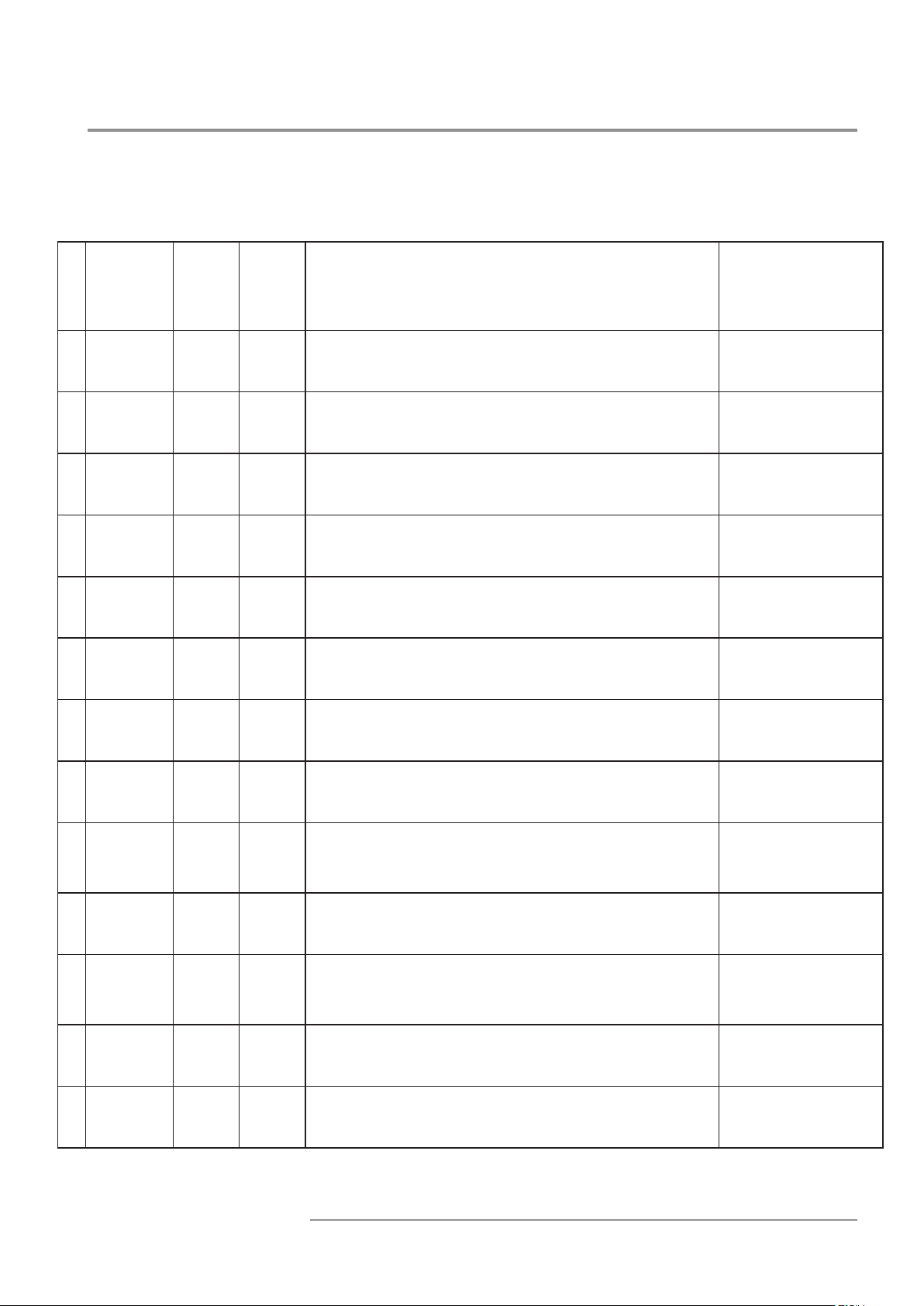

Un (kV) Minimum allowed

distance (m)

Un = nominal voltage

13

IM R15

≤1 3

10 3,5

15 3,5

132 5

220 7

380 7

USE AND MAINTENANCE MANUAL

Not allowed operations

It is strictly forbidden to use the

machine:

On public roads.•

Without an adequate environmental lighting to work or to move•

under safety conditions.

Work in case of strong strom, with or without rain, or with wind•

with speed higher than 12,5 m/s, 6 grade of the Beaufort scale

described below.

Without making sure that the platform gate bar is closed.•

without using the safety belts.•

While moving, with boxes opened.•

If the working area is not free from obstacles which could cause•

dangerous conditions.

While·enteringincontactwithxedormobileobjects.•

Under bad working conditions.•

In a different way from what it has been described in the•

instruction manual.

After modifying or removing the safety devices.•

After fastening it to adjacent structures.•

In addition, it is forbidden to:

Operate or lift the platform when it is placed on the truck loading platform or other vehicle.•

To throw some objects and tools from the top to down and vice versa.•

Use the boom for purposes other than setting the staff, their tools and equipment to work position.•

Control the machine from the ground control panel with a second operator on the cage.•

14

IM R15

USE AND MAINTENANCE MANUAL

Description

Wind

speed

(km/h)

Wind

speed

(km/h)

Sea conditions Land conditions

0 Calm 0 0 Flat Calm. Smoke rises verti-

cally.

1 Light air 1-6 0.3-1.5 Ripples without crests. Wind motion visible in

smoke.

2 Light Breeze 7-11 1.6-3.4 Small wavelets. Crests of glassy appearance, not breaking. Wind felt on exposed

skin. Leaves rustle.

3Gentle

breeze 12-19 3.4-5.4 Large wavelets. Crests begin to break; scattered whitecaps. Leaves and smaller twigs

in constant motion.

4Moderate

breeze 20-29 5.5-7.9 Small waves.

Dust and loose paper

raised. Small branches

begin to move.

5 Fresh breeze 30-39 8.0-10.7 Moderate (1.2 m) longer waves. Some foam and spray. Smaller trees sway.

6Strong

breeze 40-50 10.8-13.8 Large waves with foam crests and some spray.

Large branches in mo-

tion. Whistling heard in

overhead wires. Umbrella

usebecomesdifcult.

7

Near gale

/ Moderate

gale

51-62 13.9-17.1 Sea heaps up and foam begins to streak.

Whole trees in motion.

Effort needed to walk

against the wind.

8 Fresh gale 63-75 17.2-20.7 Moderately high waves with breaking crests forming spindrift.

Streaks of foam.

Some twigs broken from

trees. Cars veer on road.

9 Strong gale 76-87 20.8-24.4 High waves (6-7 m) with dense foam. Wave crests start to roll

over. Considerable spray.

Larger branches break off

trees, construction/tempo-

rary signs and barricades

blown over, damage to

circus tents and canopies.

10 Whole gale /

Storm 88-102 24.5-28.4 Very high waves. The sea surface is white and there is

considerable tumbling. Visibility is reduced.

Trees broken off or

uprooted, saplings bent

and/or deformed, poorly

attached asphalt shingles

and shingles in poor con-

dition peel off roofs.

11 Violent storm 103-117 28.5-32.6 Exceptionally high waves.

Widespread vegetation

damage, minor damage

to most roof shingles/

surfaces, gravel may be

blownfromatroofs.

12 Hurricane > 117 > 32.5 Hugewaves.Airlledwithfoamandspray.Seacompletelywhite

with driving spray. Visibility greatly reduced.

Considerable and wide-

spread damage to vegeta-

tion, a few windows broken,

structural damage to mobile

homes and poorly construct-

ed sheds and barns.

Beaufort Wind Scale

15

IM R15

USE AND MAINTENANCE MANUAL

To minimize hazards

Follow the instructions below:

Risk of folding

Checkthegroundisrmandeven.•

Do not use the machine on slippery, icy, muddy ground and with•

holes, which has a slope higher than the allowed limit.

Keep a distance of at least 2 m from steep unevenness (ditches,•

steep terrain, etc… ).

Check that the ground where the machine has to operate is free•

from holes, bumps, drops, uneven level, obstructions, debris and

coverings which could hide possible potholes or others dangers.

Comply with the maximum load and the allowable number of•

persons.

Distribute the load on the entire platform surface uniformly.•

Avoidthemachineknocksagainstxedormobileobstacles.•

Do not use the machine as a crane with materials suspended to•

the lifting structures or to the basket.

Do not increase the maximum available working height by putting•

ladders or scaffolds on the platform or climbing onto the guard

rails.

Do not place materials on the guard rails.•

Give the best attention during movements with mobile travelling•

platform.

Carry out the movements only if the working area visibility is•

complete.

Do not use an horizontal force above 400N.•

Do not equip the machine with elements (ex. panels) which•

increase the wind exposure.

16

IM R15

USE AND MAINTENANCE MANUAL

Risk of falling

The use of safety belts is compulsory.•

Do not lean out of the safety perimetric guard rails of the platform.•

Do not use guard rails as admittance means to get on or get•

down from the platform.

Do not get on or get down from the platform when it is lifted.•

Electric hazards

As the machine is not electrically insulated, the operator has•

to pay a particular attention to avoid any contact with probably

energized parts.

Do not carry out works near electrical lines at a distance lower•

than the one indicated in the table page 13.

Explosion or burn hazards

Donotusethemachinenearopenamesorheatsources.•

Charge batteries in ventilated environment, far from heat sources•

orexplosiveuids.

Do not use the machine if there are oil leakage.•

Do not use the machine in environments with explosive•

atmosphere.

Shut the engine down during refuelling.•

Make refueling in a well-ventilated area.•

Dry fuel in case it is poured out .•

Do not smoke during refueling.•

17

IM R15

USE AND MAINTENANCE MANUAL

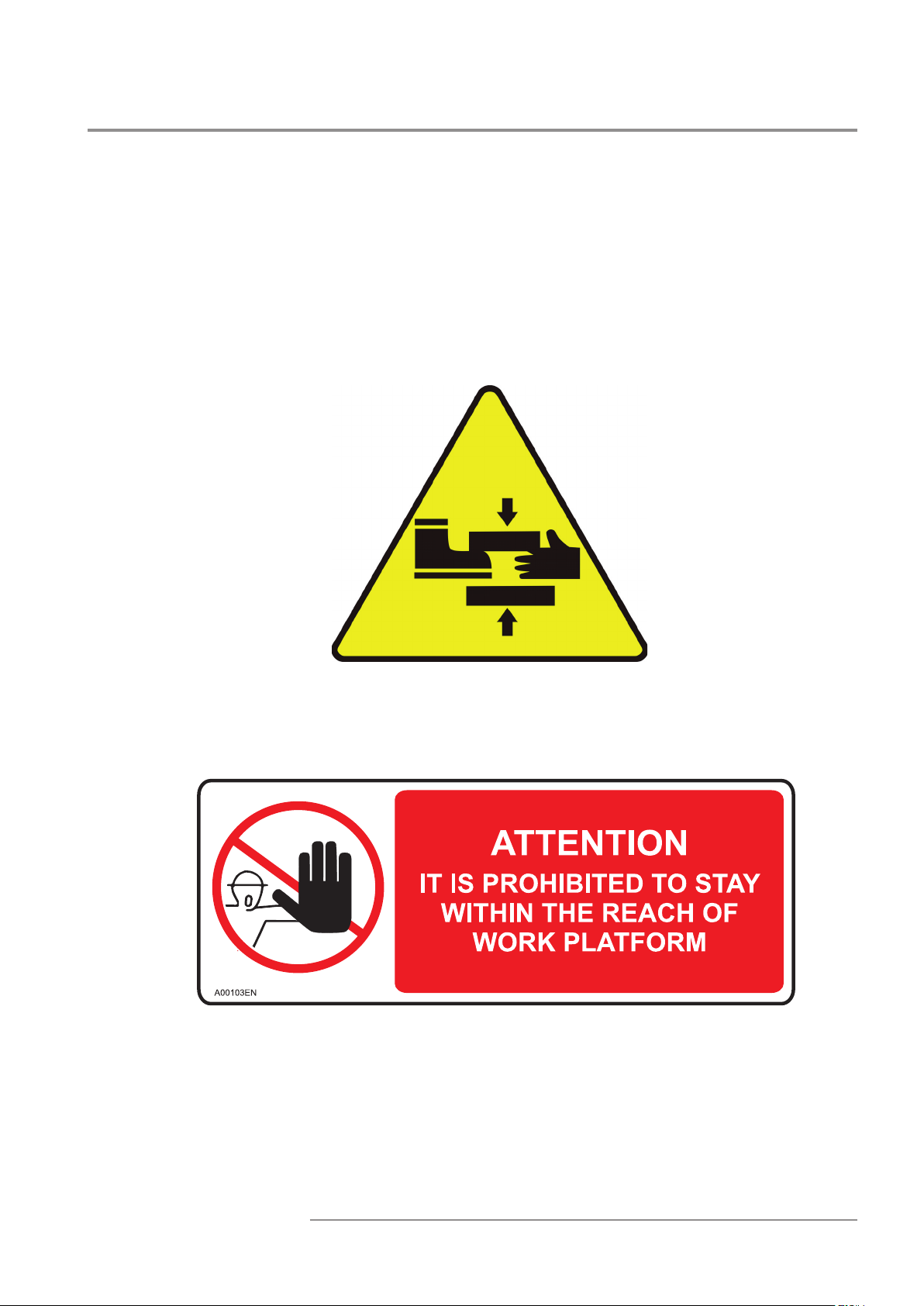

Residual risks

The plates and labels listed below indicate the residual risks that

remain despite there being protective measures incorporated into the

machine's design and regardless of the safety devices adopted.

18

IM R15

USE AND MAINTENANCE MANUAL

Description of the machine

19

IM R15

USE AND MAINTENANCE MANUAL

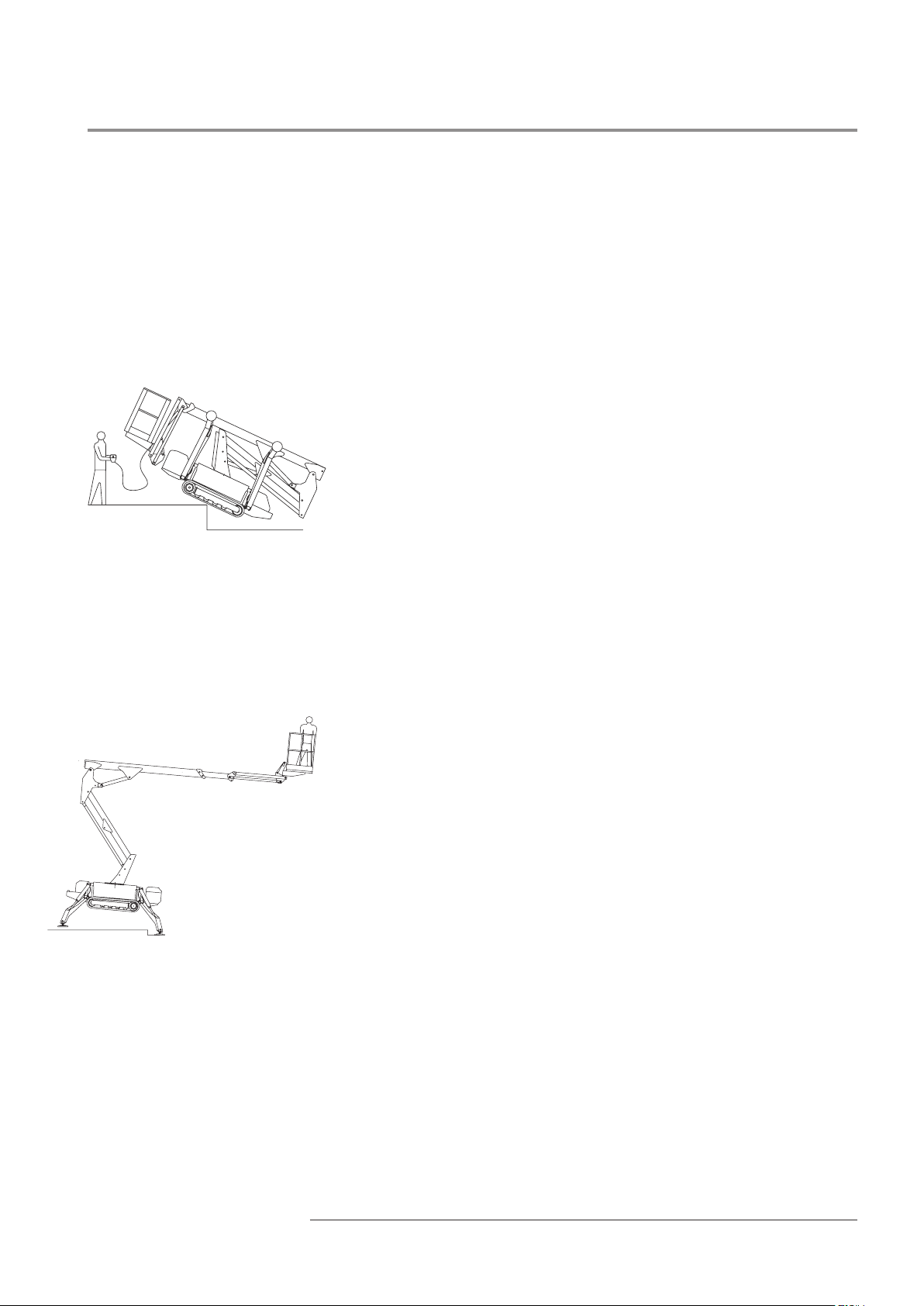

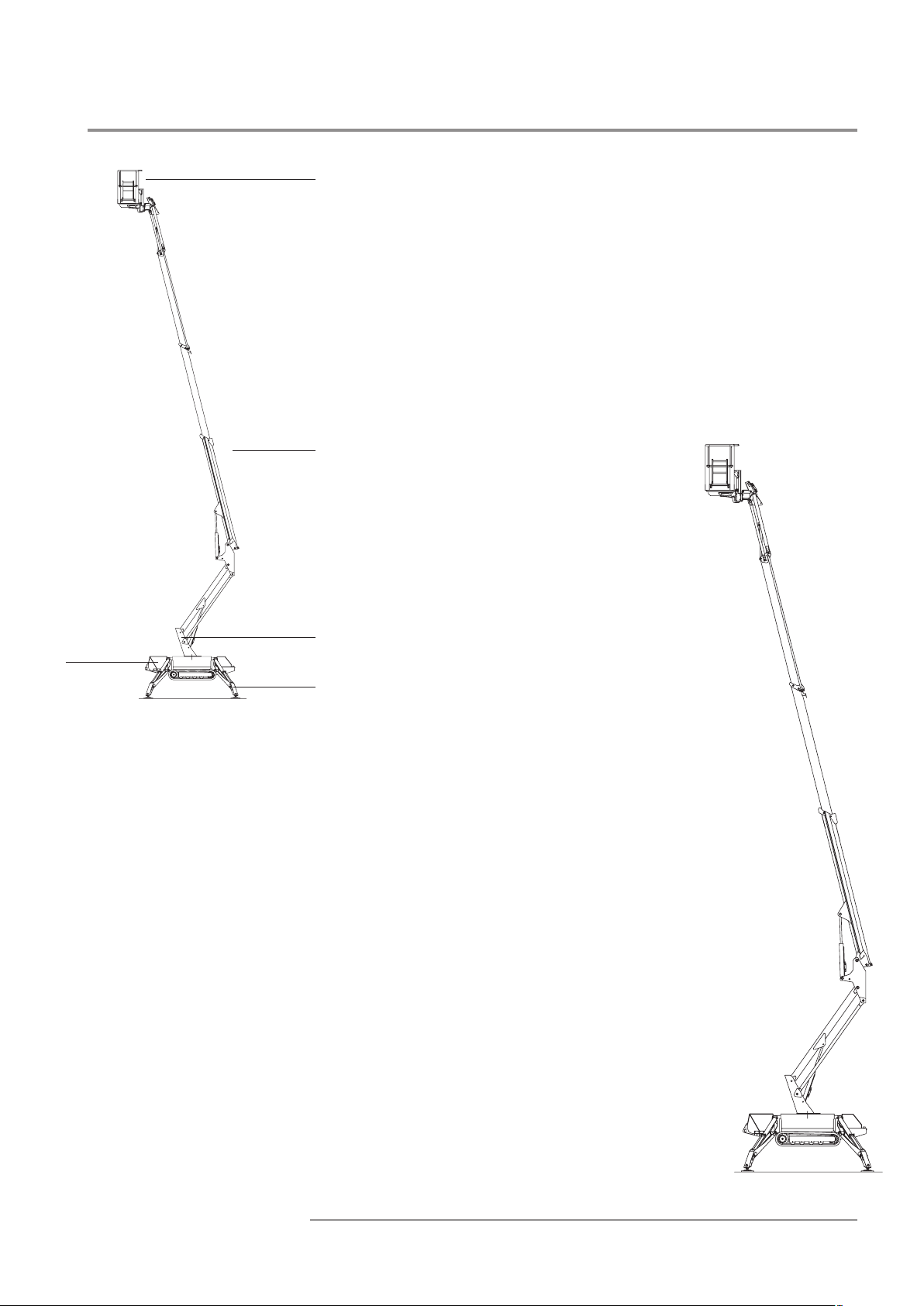

Presentation

The remote-controlled aerial platform IM R15 is used to lift

persons, materials and equipment to enable works to be

performed at certain heights.

It is intended to be used accordingly with the foreseen technical data

described in the suitable sheet, on solid and strong grounds and not

beforeaQualiedOperatorhascheckedtheoperationalsafety.

It is equipped with:

Chassis (• A)

Stabilizers (B)•

Turret (C)•

Lifting structure (D)•

Bearing structure or basket (E)•

The lifting system consists of 3 main structures:

Pantograph•

Telescopic boom•

Jib•

operated by hydraulic cylinders:

pantograph cylinder•

boom cylinder•

telescoping cylinder•

jib cylinder•

PANTOGRAPH

TELESCOPIC

BOOM

JIB

TURRET

20

IM R15

AB

C

D

E

This manual suits for next models

1

Table of contents

Other IMER INTERNATIONAL Lifting System manuals

Popular Lifting System manuals by other brands

Napa

Napa 791-6420 B manual

AmeriGlide

AmeriGlide STRATOS owner's manual

Discount Equipment

Discount Equipment SKYJACK SJ3013 Operation manual

Bishamon

Bishamon ST30EWW Operation and service manual

Novoferm

Novoferm NovoDock L530 Assembly instructions

Lift King

Lift King 243156LK+P04 Installation, operation and maintenance manual