Perform the periodic inspections for safe operation.

1. Ensue that tha chain is not rusted, broken, cracked, or missing links (Monthly)

2. Ensure that battery terminal cover is without abnormality (Monthly)

3. Check the sliding portion of roller inside post, grease fitting of the chain

bracket portion, and grease up the chain. (Every 6 months)

4. Ensure that the density of each battery cell is 1,270 (at 20°) or greater

after charging. (Every 6 months)

5. Change the motor oil (Every 12 months)

■ Types of Hydraulic Oil ■ Replacing Battery

Viscosity classification ISO VG32 abrasion Battery used for this stacker is

resistant hydraulic fluid oil; JIS standard battery. Make sure to

Fluid volume : 1.6 liters replace with same standard spec.

Oil Brand Product Name Applicable Model No. JIS Spec.

Esso Nuto H32, HP32, Unipower SQ32 STL38E, ST38E GR-55B24R

Idemitsu Super Hydraulic Fluid 32 STL50E, ST50E, ST50EWN,

Showa Shell Terasu Oil 32, K32 ST30EWW, STL65E, ST65E, ST80E,

Mobile Mobile DTE24 ST80EWW, ST100E, ST100EWN,

Cosmo Cosmo Hydro AW32 STW38E

Kygnus Unit Oil WR32 STW50E, STW65E GX-130E41R

The below show how to deal with relatively minor malfunctions. For other further issues,

please contact your supplier of this stacker.

・Wiring defects

・Battery Socket is loose Fix the socket firmly

Check battery and charge

Readjust Relief Valve

・Power Unit(Pump) defects Replace Power Unit (Pump)

・Hydraulic Oil is not full Fill the oil

Replace Lowering Valve

・Piping defects Repair location of leak

・Piping defects

・Defective Lowering Valve Replace Lowering Valve

At Cylinder ・Defective Seals Replace Cylinder seales

At Pipe or Joint ・Improper fastening Check and Fasten

At Air Breather ・Excessive Oil Adjust fluid to appropriate level

When disposing of this stacker, dispose of the metal, non-metal, plastic, and hydraulic oil

components separately. There are regulations for disposing of the hydraulic oil, so make

sure to sourt and follow the local rules. If you have any questions regarding disposal,

please check with your supplier of the stacker.

- 6 -

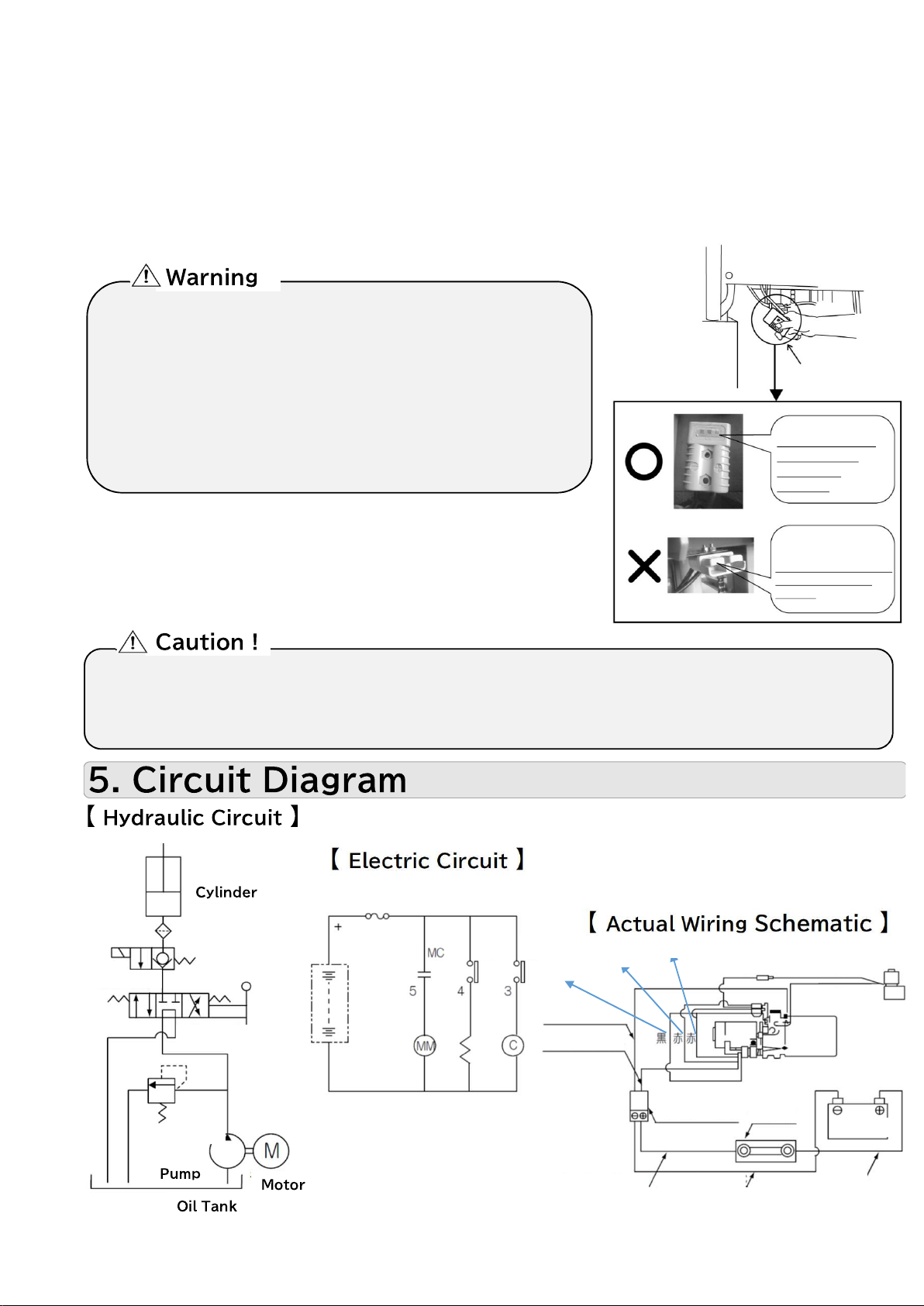

Check through 【Actual Wiring

Schematic】

Do not lower

Oil Leak

・Defective seating of

Lowering Valve

Lowers natually

・Battery is not fully charged

Motor does not run

・Relief Valve is not

adjusted Properly

Motor is running

GR-95D31R

Symptoms of malfunction Possible Cause Action

Check through 【Actual Wiring

Schematic】

Does not

rise

・Make sure to remove the battery socket before work.

・Always be cautious of a short circuit.

・DO NOT mistake the (+) and (-) terminals.

・Make sure to cover the (+) terminal.

・Make sure to secure the battery with a battery clamp to prevent vibrating etc.