IMER USA WHEELMAN 1105422 User manual

INSTRUCTION MANUAL

U.S.A. inc.

WHEELMAN CONCRETE MIXER

( 1105422 )

Machine serial N°

Part. number 3210884 - 03/2003

IMER U.S.A. Inc.

221WesthamptonPlace

CapitolHeights,MD

20743

Ph/800.275.5463

R

R

Thank you for purchasing a Mixer from an IMER U.S.A. dealer. Your decision is an

intelligent one. No other mixer in the world today offers the features and value of the

Mixer.

At IMER U.S.A. we continually search for ways to better serve our customers. Should you have an idea

or thought to share with us regarding this Product we would appreciate hearing from you. Our motto is

"Tools and Services for the 21st Century". We look forward to delivering the goods.

Thank you again for your purchase,

* After the initial set-up the Mixer can be knocked down or reassembled in

just minutes.

* Direct drive drum rotation, efficient and safe.

* Portable, the large 14" wheels make moving the a breeze around the

home or job site.

* Compact, the clever design allows the to fit into the trunk or hatchback

area of almost all cars and trucks.

*Finish,thehighqualityof paintandconstructioncomponentsensureapieceofequipment

that you will be proud to own for years.

Mace T. Coleman, Jr.

President, IMER U.S.A. Inc.

221WesthamptonPlace

CapitolHeights,MD

20743

Ph/800.275.5463

S/N:

®

WHEELMAN

®

WHEELMAN

®

WHEELMAN

®

WHEELMAN

®

WHEELMAN

IMER U.S.A. Inc.

3

®

WHEELMAN

TABLE OF CONTENTS

TECHNICALDATA.....................................................................................................page 4

NOISELEVEL ...........................................................................................................page 5

WIRINGDIAGRAM....................................................................................................page 5

SAFETYNOTES ........................................................................................................ page 6

ASSEMBLYOF THEWHEELMANWITHELECTRIC MOTOR ..................................page 7

MOVING THE WHEELMAN.................................................................................. page 9

OPERATING THE WHEELMAN ........................................................................... page10

MAINTENANCE AND CLEANING......................................................................... page10

ORDERINGSPAREPARTS....................................................................................... page10

SPAREPARTSDIAGRAMS ...................................................................................... page11

ACCESSORY WORK STAND................................................................................page15

WARRANTY .......................................................................................................page16

IMER U.S.A. Inc.

4

®

WHEELMAN

Product development and improvement is an ongoing process, therefore, specifications may change

without notice.

* Capacities based on usable volume.

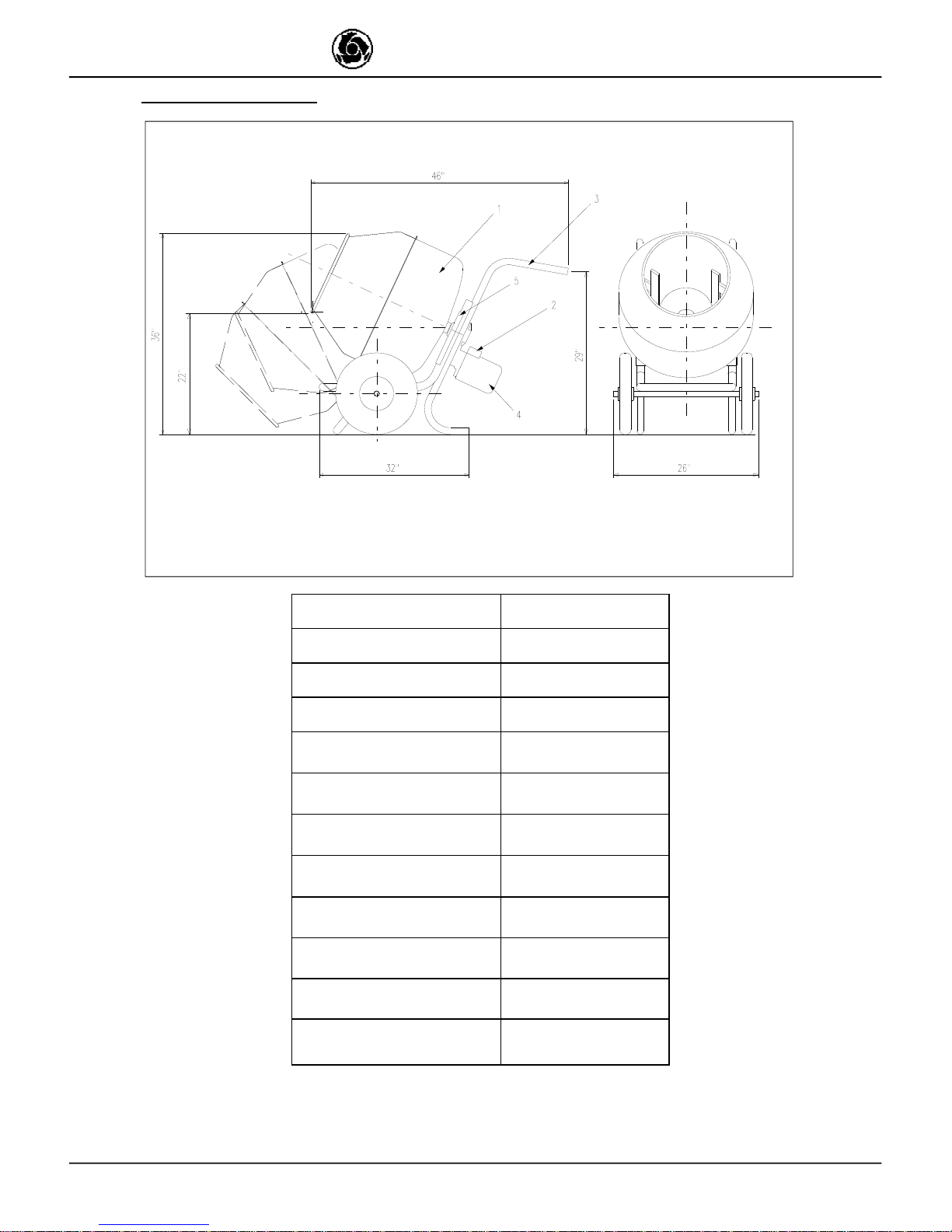

TECHNICALDATA

1 MIXINGDRUM

2 ON/OFFSWITCH

3 DUMP HANDLES

Drum capacity 5 cubic feet

Batch Output 2.5 cubic feet, 225 lbs. *

Drum Diameter 24 inches

Wheels 14.5" x 2.5"

Single Phase electric motor 0.5 H.P.

Hertz 60

Voltage 110 / 115 V

Motor R.P.M. 3350

Nominal current 6.2 Amp

Operating dimensions 46" x 26" x36"

Storage dimensions 29" x 26" x 28"

Weight : electric model 105 pounds

4 MOTORANDGEARBOXDRIVE

5 GEARBOXMOUNTINGFRAME

IMER U.S.A. Inc.

5

®

WHEELMAN

The with electric motor has a noise level of 65 decibels. It's very quiet, operate it anywhere.

NOISE LEVEL

WIRING DIAGRAM

WARNING.

Any type of electrical repair or trouble-shooting should only be performed

by an IMER dealer or a properly qualified electrical repair shop. For

assistance with any electrical difficulty, IMER U.S.A. is always directly

available @ 800.275.5463.

®

WHEELMAN

The concrete mixer WHEELMAN is equipped with a safety device to

prevent accidental electrical contacts, with class II Double Insulation type

of all live components ( ). For this reason it is not required to be

grounded.

CAUTION: when carrying outrepairs, classII Double Insulation,protection

will only be maintained if the original insulating materials are used and

provided thatthe tolerances andinsulating materials remain unmodified.

R

N

L1

S1

F2

C1

M1

AM

AA

Neutral wire

Phase wire

Stop and start button

Thermal protection for electric motor

Capacitor

Single phase motor

Motor winding

Motor winding

IMER U.S.A. Inc.

6

®

WHEELMAN

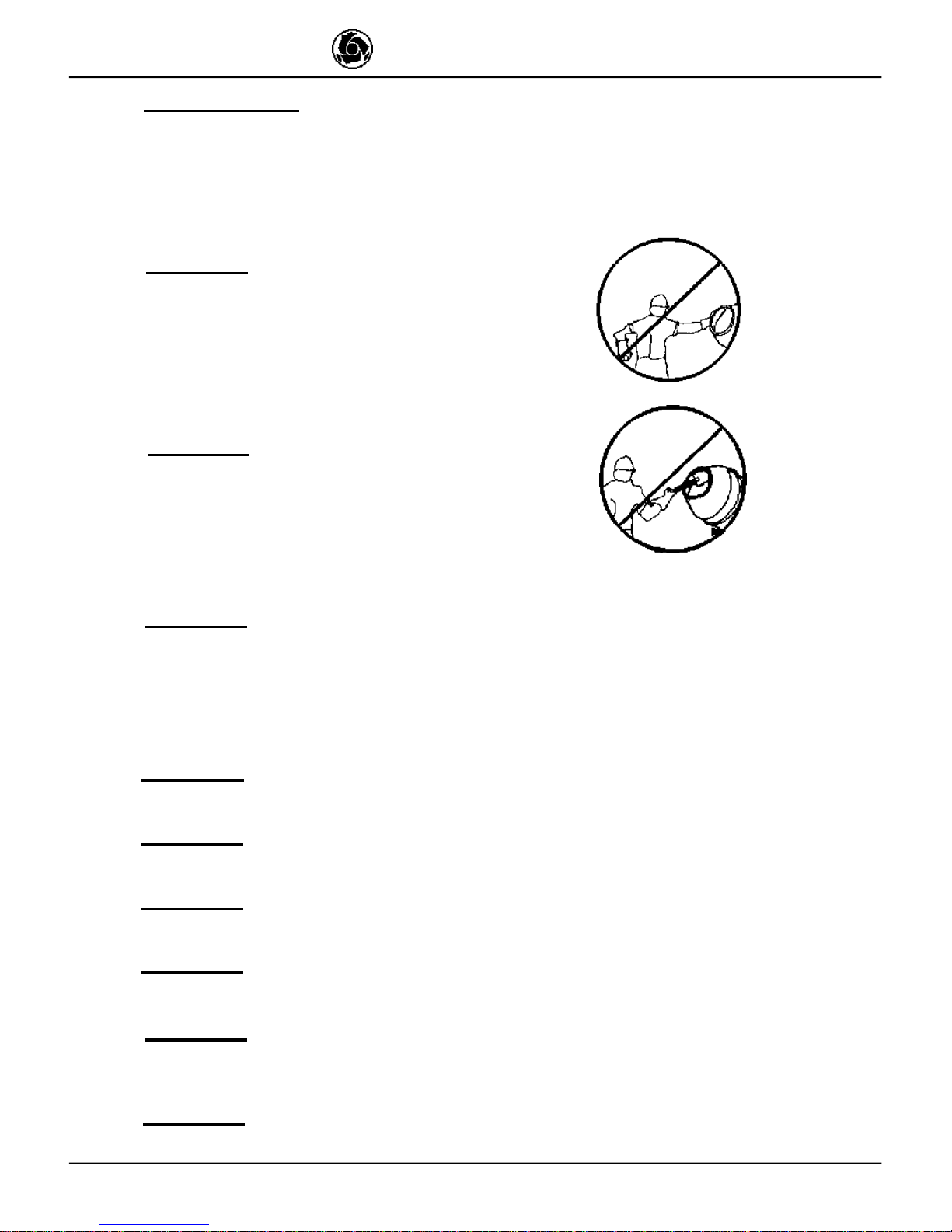

Your mixer has been designed with safety in mind. However, as with any type of

machinery, some basic DO'S and DONT'S apply:

IMPORTANT !

READ THIS SECTION CAREFULLY !

Place your hand or hands in or around any part of

the drum while it is operating !

DO NOT

Place any tools or instruments in or around the drum

while it is operating !

DO NOT

DO NOT

Clean, assemble or work on the unit while it is plugged in !

Allow water to contact the motor or electrical connections at any time !

DO NOT

DO NOT

DO NOT

Operate the unit in or around water puddles.

DO NOT

Leave the machine unattended !

DO NOT

Operate the mixer on a surface that is not flat or is

uneven !

Always operate the on a level surface,

if placed on an incline the machine will fall over.

Allow other persons around the mixer while it is operating ! Keep children away from

your work area !

SAFETY NOTES

DO NOT

Operate the mixer while under the influence of alcohol or drugs !

®

WHEELMAN

®

WHEELMAN

IMER U.S.A. Inc.

7

®

WHEELMAN

SAFETY NOTES

DO

Read all the instructions before operating the mixer.

DO

Usecautionwhen assembling and transporting themixer. Tieit downgood inyour vehicle.

DO

Keep the mixer clean and free of debris and mix build-up. After using, fill the drum with

water and run the WHEELMAN for 10 minutes or so, most of the cement will break

loose from the drum.

DO

Keep all themoving partslightlylubricated,WD-40maybesprayedallaroundthemachine.

DO

Periodically inspect your mixer for abnormal wear or damage. If something does not

seem right call your dealer or IMER USA direct @ 800.275.5463.

DO

Wear the appropiate safety gear; hard hat, gloves, goggles, ear protection and wear

snug clothing around the mixer. Loose clothing can cause injury should it become

entangled with the mixer.

Do not start and stop the mixer with material in the drum, this will damage the motor and is

not the best way to mix.

Always have the drum rotating when filling or discharging the mixer, this produces the

highest quality concrete.

DO NOT

R

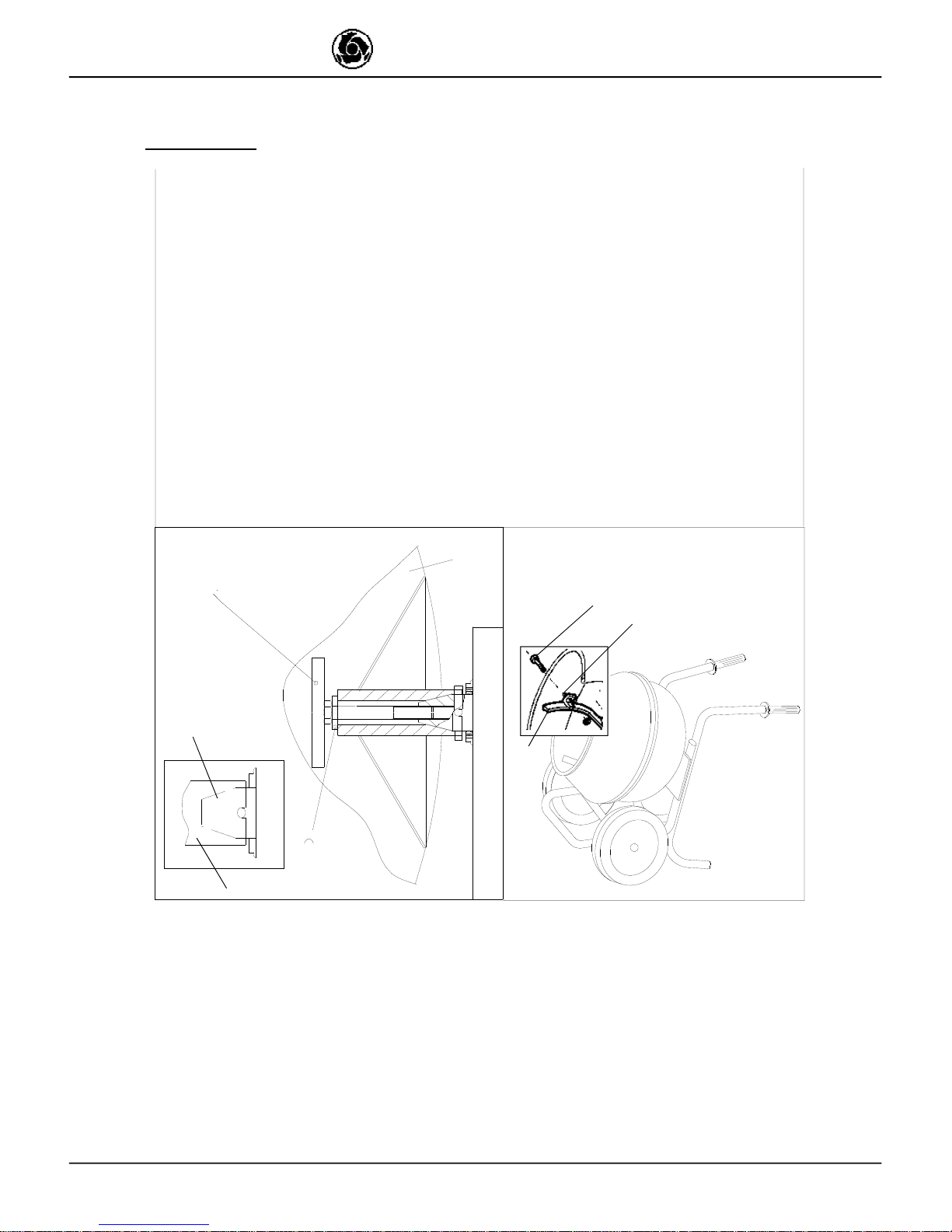

ASSEMBLY OF THE WHEELMAN WITH ELECTRIC MOTOR

- Follow drawings 1 thru 4 -

R

Slide the motor gearbox assembly #1onto the

motor gearbox frame #2 and anchor it in place

by using the 4 qty. 6mm locknuts provided #3.

2

1Attachthemotorgearboxframe#2,tothedump

handles #1 using the nuts,bolts,and washers

provided.Slide the wheels onto the axle and

keeptheminplacewiththesplitpinsprovided.

4

5

2

3

1

IMER U.S.A. Inc.

8

®

WHEELMAN

ASSEMBLY

3 4

Next slide the drum onto the driveshaft #3,make

sure the notched area on the drum #4 lines up

with the shear pin.Then anchor the drum in

place with the T-Bolt #1 and T-Bolt #2 washer.

Push the drum up onto the driveshaft while at

the same time tightening the T-Bolt by hand.

Once the T-Bolt is tightened as much as

possible by hand,give it a whack or two with a

hammer-no more,no less.

Anchor the mixing paddles #2,with the large

flat head screws #1 and nuts #3 provided.

It is best to place the flat head of the screw on

the outside of the drum.

This keeps the external contour of the drum

smoother and less likely to catch or pinch

objects as the drum is rotating.

13

2

1

2

4

3

DRUM

DRIVE

SHAFT

IMER U.S.A. Inc.

9

®

WHEELMAN

Drawing 8

Drawing 7

Lift handles here

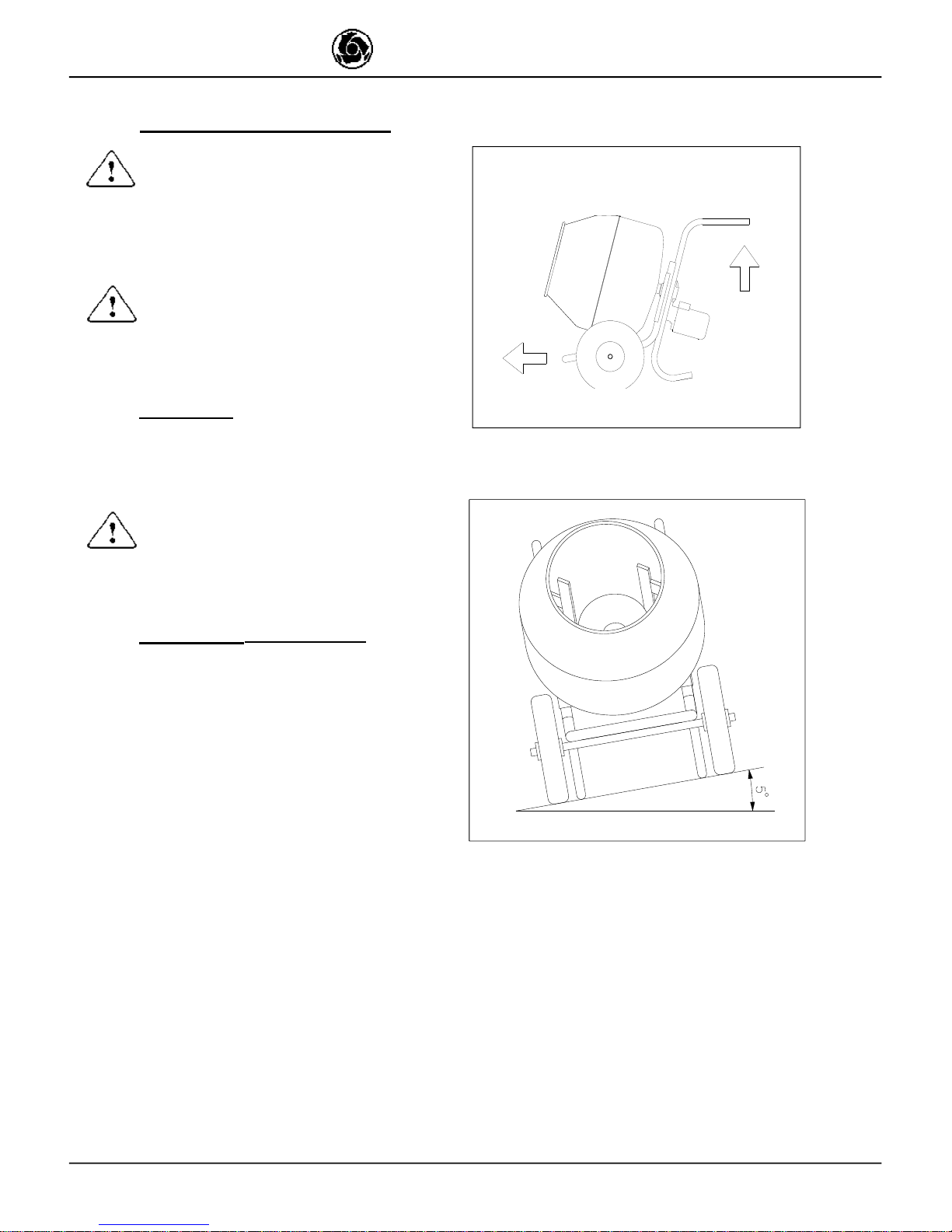

MOVING THE WHEELMAN®

WARNING

Always disconnect the power source

before rolling the mixer.

To roll the machine, grasp the two dump handles

#7 and gently lift upwards.

Lift gently,for if you lift the machine up too

quickly and too far, it will begin to

discharge the loaded material.

Whenmovingthemixeraround,whetherloadedor

unloaded,clearapathwaysothattheWHEELMAN

will be under control at all times.

Remember - the batch capacity of the

WHEELMAN is 225 lbs,do not attempt to roll it

fullyloadedacrossunevensurfacesordown steep

slopes. Thiscouldleadto yourlosingcontrolofthe

machineandconcretegoingeverywhere.

When in doubt, roll the machine empty to

where you want to pour the concrete,and

mix in that spot.

CAUTION -Set Up Properly !

Clearasuitableworkareaaroundthemixer.Position

theWHEELMAN onlevelground.

DONOTEXCEEDMORETHAN5°ofgroundslope

or the mixer can fall over and cause bodily harm

and a big mess.

®

®

®

IMER U.S.A. Inc.

10

®

WHEELMAN

MAINTENANCE AND CLEANING

The WHEELMAN Mixer requires very low maintenance.However, a few basic maintenance procedures

shouldbefollowed.

NOTE: Always unplug the mixer from its power source before cleaning or maintenance

functions are performed.

1) Clean the mixer after each use and do not allowany concrete to build up on anyportion of the mixer.

2) Essentially the gearbox is sealed for life. The quality of the gears and the lubricant are such that

changing the oil is not necessary. Should you want to change the oil, see your dealer or call IMER

U.S.A. @ 800.275.5463.

3) Keep all moving parts lightly lubricated with WD-40.

4) Keep the electric motor cooling fins clean and free of debris build-up.

5)BeforestoringtheWHEELMAN afteraprojectis completed,sprayn'wipetheentiremachinewithWD-

40, and store it inside.

NOTE: When cleaning the mixer with water, do not spray the water onto the motor or the

ON/OFF switch assembly.

SPARE PARTS

All orders forspare parts must include the following:

1) Type of machine.(Example: concrete mixer)

2) Part number and drawing referencesof each part,see the parts list.

3) Serial numberand year of manufacturerecorded on the machine's identification plate.

OPERATION

WHEELMAN WITH ELECTRIC MOTOR

1) Use a2 prong, grounded, 110/115 Volt powerconnection for safe operation. The line should be at least

12 gauge.

2) To mix concrete, add water, concrete, and aggregate while the drum is rotating.

3) Discharge the mixed concrete by lifting up the dump handle Drawings #7 page 9 while the drum is

rotating.

NOTE: When tilting the drum to discharge the concrete, do so slowly. It is important to

perform the discharge smoothly, this keeps the machine balanced and upright.

4)TheON/OFFswitchonthe motoroftheWHEELMAN mixerprovidesthermalprotectionto the motorin

the event of overheating. Should your motor shut off automatically, turn off the unit and unplug it for 15

minutes. This allows the motor to cool. After the cooling period, plug in the motor and press the start

switch. If the motor does not restart and continue to run, contact your local IMER products distributor, or

call IMER direct @ 800.275.5463.

®

®

®

WHEELMAN

®

®

IMER U.S.A. Inc.

11

®

WHEELMAN

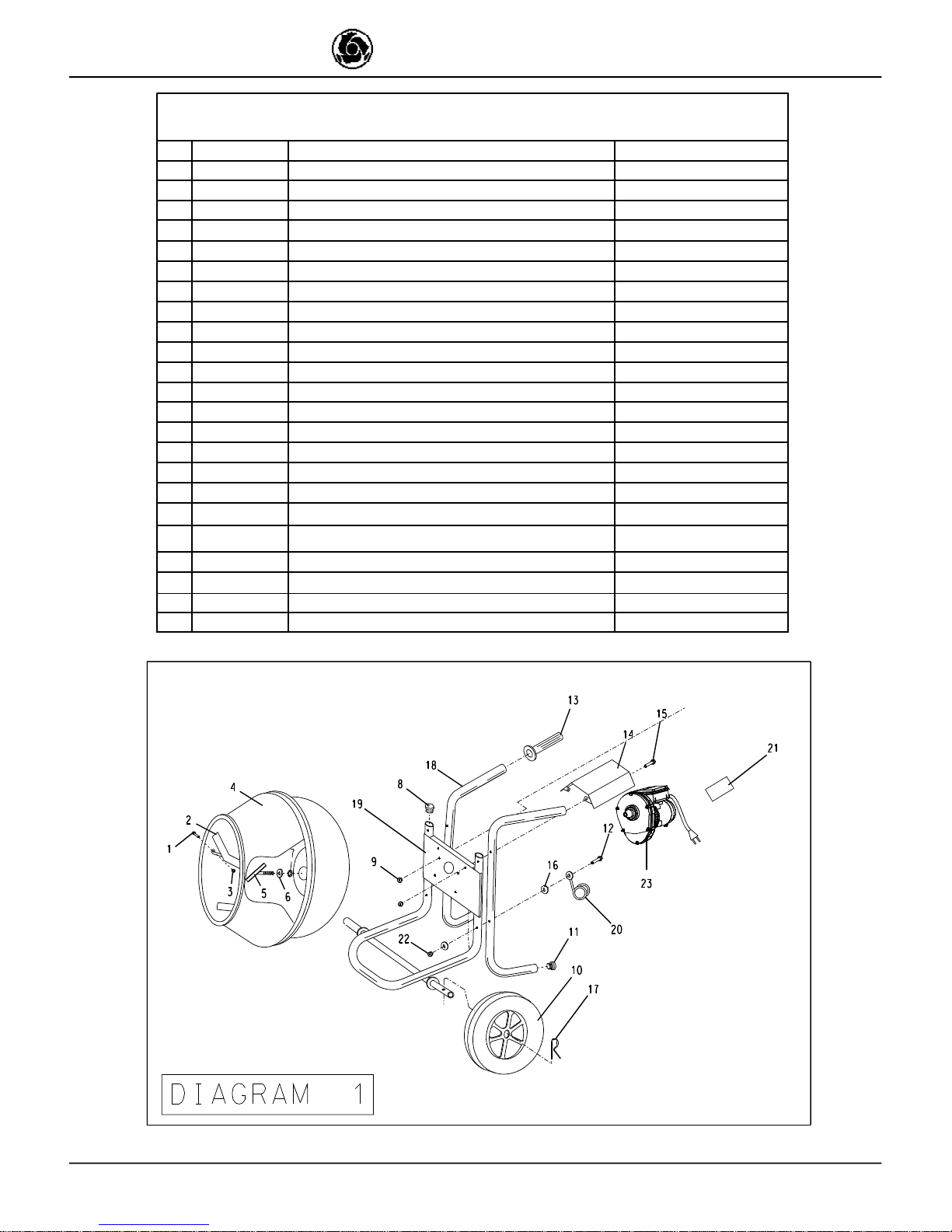

DIAGRAM #1 FRAME AND DRUM ASSEMBLY

COD.1105422 - WHEELMAN ( 110 / 115V - 60 Hz)

Rif. P.n. Description Note

1 2222193 SCREW TB M12 x 25

2 2250155 PADDLE

3 2223700 NUT 5588 M12z

4 2250719 DRUM

5 2222982 T-BOLT

6 2224428 T-BOLT WASHER 14X36X6

7 3206800 STOP RING M1455 ZA Ø14

8 2235457 PLASTIC PLUG

9 2223924 NUT 5588 M6z

10 3208129 WHEEL

11 3208452 PLASTIC PLUG

12 2222110 BOLT TE M8 x80 z

13 3208139 HANDLE GRIP D.30

14 3208397 MOTOR GUARD

15 2222002 BOLT TE M6 x 16 z

16 3208181 WASHER

17 2226700 SPLIT PIN

18 3208177 DUMP HANDLE

19 3210879 MOTOR GEARBOX FRAME

20 3208182 CORD KEEPER

21 3210883 ID PLATE

22 2223923 SELF-LOCKING NUT M8

23 3210492 MOTOR GEARBOX COMPLETE 110 / 115V - 60Hz

IMER U.S.A. Inc.

12

®

WHEELMAN

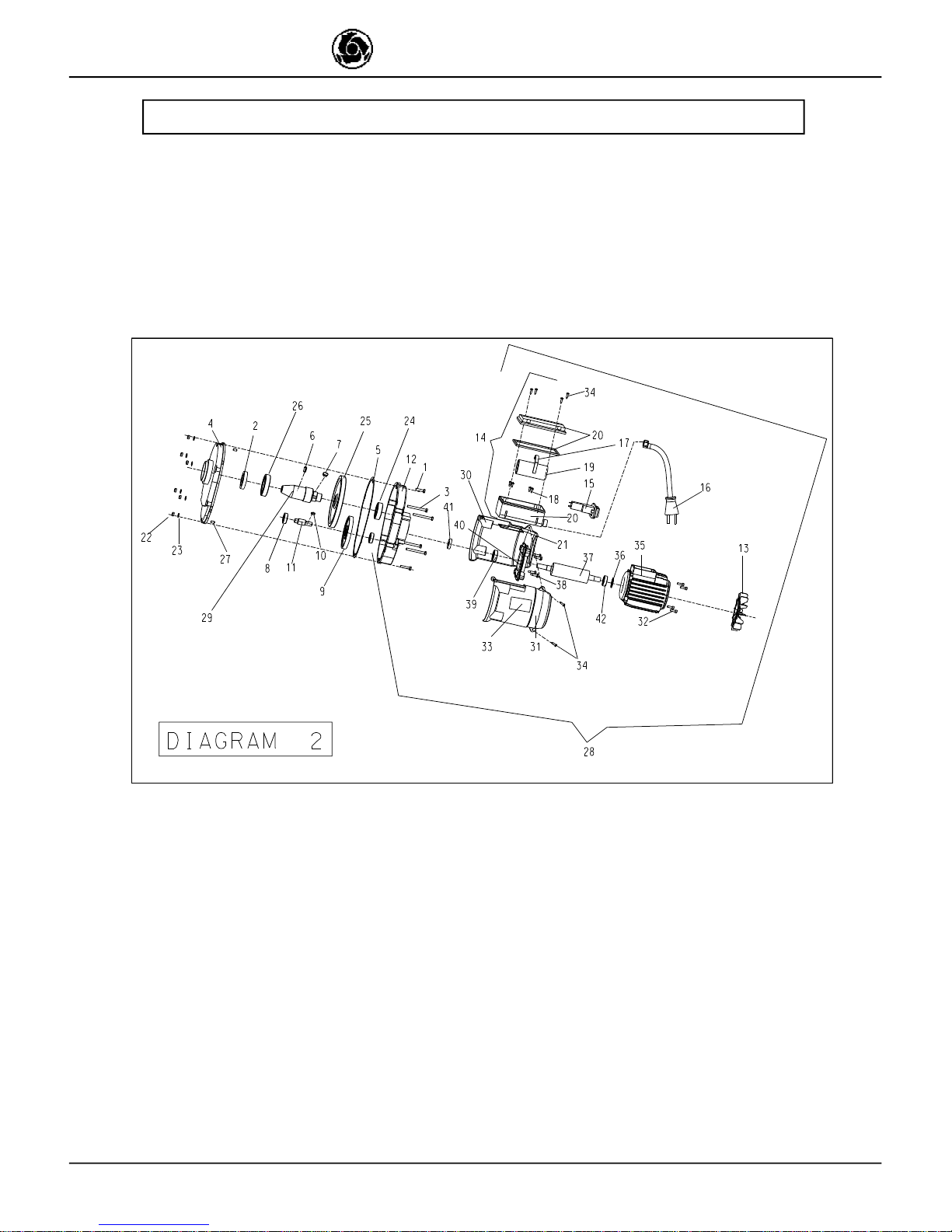

DIAGRAM #2 MOTOR AND GEARBOX ASSEMBLY (110/115V - 60Hz)

IMER U.S.A. Inc.

13

®

WHEELMAN

DIAGRAM #2 MOTOR AND GEARBOX ASSEMBLY

COD. 3210492 (110 / 115 V - 60 Hz)

RIF. P.n. Description Note

1 2222010 BOLT M6x25

2 2207405 OIL SEAL 55x40x10

3 2222012 BOLT M6x60

4 3210485 GEARBOX CASE-HALF

5 3210482 GEARBOX GASKET

6 2228360 SHEAR PIN Ø8x16

7 2229500 KEY 8x7x15

8 2204420 BEARING 6201

9 3210487 GEAR Z 81

10 2229249 KEY 5x5x12

11 3210483 PINION GEAR Z 9

12 3210486 GEARBOX CASE-HALF

13 3210904 FAN

14 3210911 ELECTRIC BOX COMPLETE (ALL COMPONENTS)

15 3209539 SWITCH

16 3210955 ELECTRICAL PLUG

17 3209541 CLAMP

18 2222460 SCREW

19 3210923 CAPACITOR 50µF 250 V

20 3209217 ELECTRIC BOX ASS'Y + SCREW + GASKET ONLY

21 3209214 GASKET

22 2223260 NUT M6

23 2224530 WASHER Ø6x12.5

24 2204550 BEARING 6205

25 3210479 GEAR Z 104

26 2204504 BEARING 6008

27 2228819 LOCATING PIN Ø6x12

28 3210494 MOTOR ASS'Y WITH CASE HALF

29 3210481 DRIVE SHAFT SPINDLE

30 3210496 RIGHT SIDE MOTOR COVER

31 3210495 LEFT SIDE MOTOR COVER

32 3210036 SCREW M5x16

33 3210587 RATING PLATE

34 3210903 SCREW 3,9x19

35 3210906 STATOR

36 3210898 SPACER WASHER

37 3210486 ROTOR

38 3210901 SCREW M5x22

39 3208982 BEARING 6202

40 3210488 INSULATING FLANGE

41 2207350 OIL SEAL 12x32x7

42 3210902 BEARING 6002

IMER U.S.A. Inc.

14

®

WHEELMAN

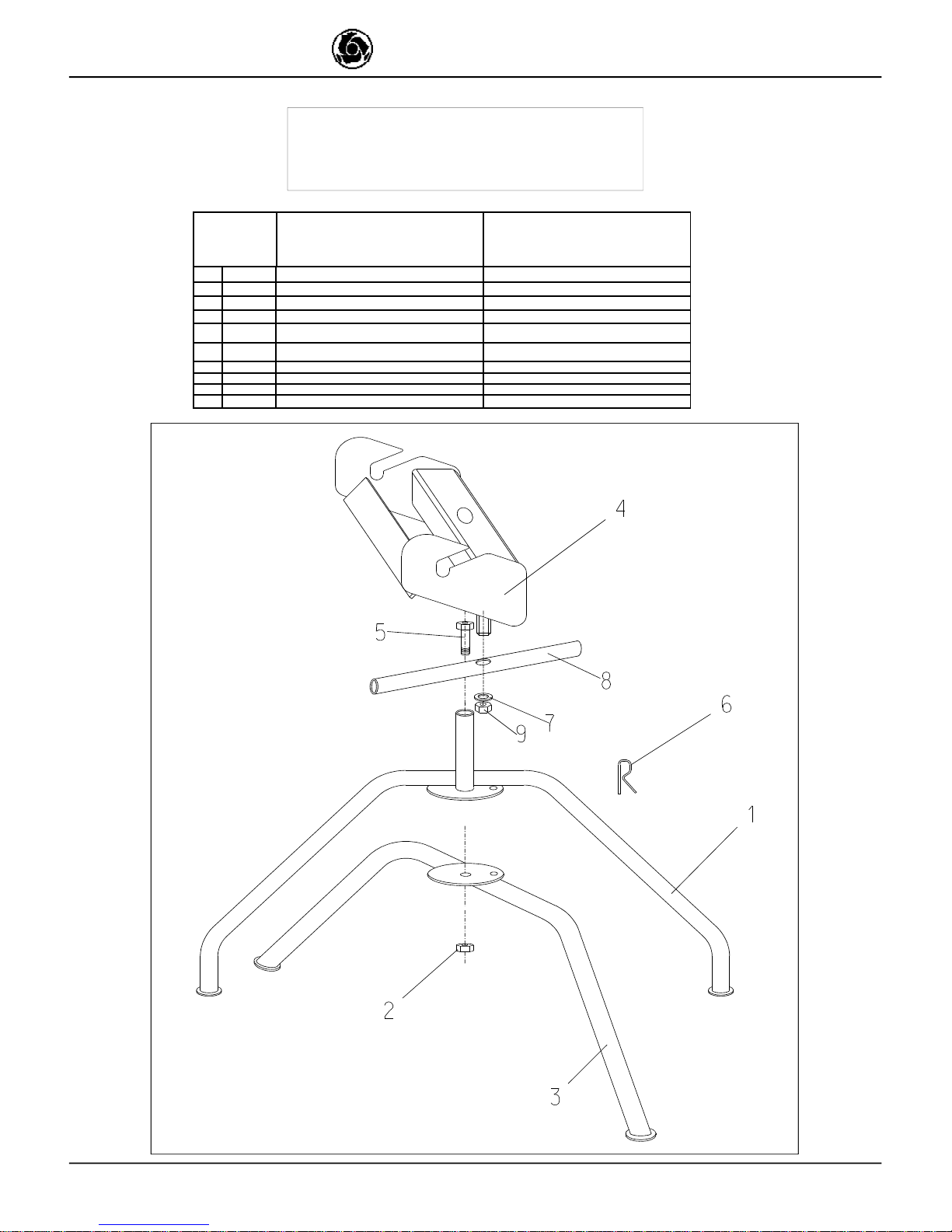

ACCESSORY WORK STAND

FOR THE WHEELMAN MIXER

(1105490)

®

TAV. 3 STATIONARY WORK

PLATFORM 1105490

Ref. Pn. Description Note

1 3208203 EXTERNAL LEG

2 2223929 LOCK NUT M.14

3 3208198 INTERNAL LEG

4 3208191 SWIVEL BRACKET

5 2224430 BOLT 14X36 z

6 2226700 SPLIT PIN

7 2224380 WASHER 12x25 z

8 3210656 LOCKING LEVER

9 2223929 LOCK NUT M.12

IMER U.S.A. Inc.

15

®

WHEELMAN

ACCESSORY WORK STAND

FOR THE WHEELMAN MIXER (1105490)

®

IMER U.S.A. Inc.

16

®

WHEELMAN

221WesthamptonPlace

CapitolHeights,MD

20743

Ph/ 800.275.5463

U.S.A. INC.

IMER

EQUIPMENT WARRANTY

R

U.S.A. INC.

We warrant to the original purchaser that the IMER equipment described herein (the "equipment") shall be

free from defects in material and workmanship under normal use and service for which it was intended for

period of one (1) year from the date of purchase by the original purchaser.

Our obligation under this warranty is expressly limited to replacing or repairing, free of charge, F. O.B. our

designated service facility, such part of the equipment as our inspection shall disclose to be defective.

Parts such as engines,motors, pumps, valves, electric motors, etc. furnished byus, but not manufactured

by us, will carry only the warranty of the manufacturer. Transportation charges or duties shall be borne by

purchaser. This shall be the limit of our liability with respect to the quality of the equipment.

This warranty shall not apply to any equipment, or parts thereof, which has been damaged by reason of

accident, negligence, unreasonable use, faulty repairs, or which has not been maintained and operated in

accordance with our printed instructions for the equipment. Further, this warranty is void if the equipment,

or any of its components, is altered or modified in any way.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

We make no other warranty, representation or guarantee, nor is anyone authorized to make one on our

behalf. We shall not be liable for consequential damage of any kind, including loss or damage resulting,

directly or indirectly, from the use or loss of use of the machine. Without limiting the generality of the

foregoing, this exclusion from liability embraces the purchaser's expenses for downtime, damages for

which the purchaser may be liable to other person, damages to property, and injury or death of any

persons.

This warranty shall not be deemed to cover maintenance parts, including but not limited to blades, belts,

hoses, hydraulic oil, or filters, for which we shall have no responsability or liability whatsoever.

HEADQUARTERS

Table of contents

Other IMER USA Construction Equipment manuals