Imesa ES10 User manual

1903KITINE18_02 (E100901B_ENG) 01/02/2016

2

INDICE:

1. INTRODUCTION ..............................................2

2. SAFETY RULES ..............................................2

3. MANUFACTURER’S LIABILITY .....................2

4. KIT COMPOSITION .........................................3

5. MECHANICAL INSTALLATION......................3

6. ELECTRIC INSTALLATION ............................3

7. WORKING TEST..............................................4

1. INTRODUCTION

This document explains all the necessary

steps to make indipendent the drum

rotation from the fan rotation.

This kit is suitable only for tumble dryer

model ES 10/14/18 which are not

equipped with the automatic reversing

drum.

In case of big linen, drying can be difficult

because off the “ball effect” that can

cause a uneven drying of the linen. In

case of a single rotation direction of the

drum, the linen rolled up and stop the

warm air which is not arriving to the

middle.

The double rotation, on the right and on

the left side, avoid the ball effect and

assure an homogenous and rapid drying.

2. SAFETY RULES

Ignoring the following safety precautions

can cause damage either to people, linen,

animals or to the machine.

Installation and maintenance of machines

of this manual must be performed by

authorised and qualified technicians; they

have to know our products and be

acquainted with European standards for

installation of industrial laundry

equipment.

These tumble dryers must be used only

to dry garments and linen exclusively with

water. Any other use is forbidden unless

builder authorises it in writing.

It is forbidden to put anything in the

machine other than the items to be dried.

Do not load the machine with fabrics

contaminated by dangerous substances

such as explosives, inflammables, etc.

Make sure they are rinsed or aired before

washing.

It is forbidden to dry garments soaked in

substances known to be harmful to

persons such as lead, poison or cancer-

producing products

To prevent fire hazard or explosions do

not stand near the machine with

explosive or inflammable products.

Please stick accurately to instructions and

dosages recommended by

manufacturers; Make sure to check and

comply with washing instructions of each

item to be washed.

Use of the machine is forbidden to

children under 14 years of age.

The builder is not responsible for external

connections not duly performed.

These precautions do not

include all possible risks.

Therefore the user must

proceed with caution in the

observance of all safety

specifications.

3. MANUFACTURER’S LIABILITY

These manual instructions are not

intended to substitute, but only to

combine obligations of current legislation

on safety standards.

With reference to information included in

this manual, the manufacturer is not

responsible in case of:

neglect of European safety

standards during machine

utilisation;

incorrect installation of the

machine;

neglect or incorrect observance

of instructions included in this

manual;

faults of voltage or of the feeding

systems;

unauthorised changes on the

machine;

Utilisation of the machine by

unauthorised operators.

1903KITINE18_02 (E100901B_ENG) 01/02/2016

3

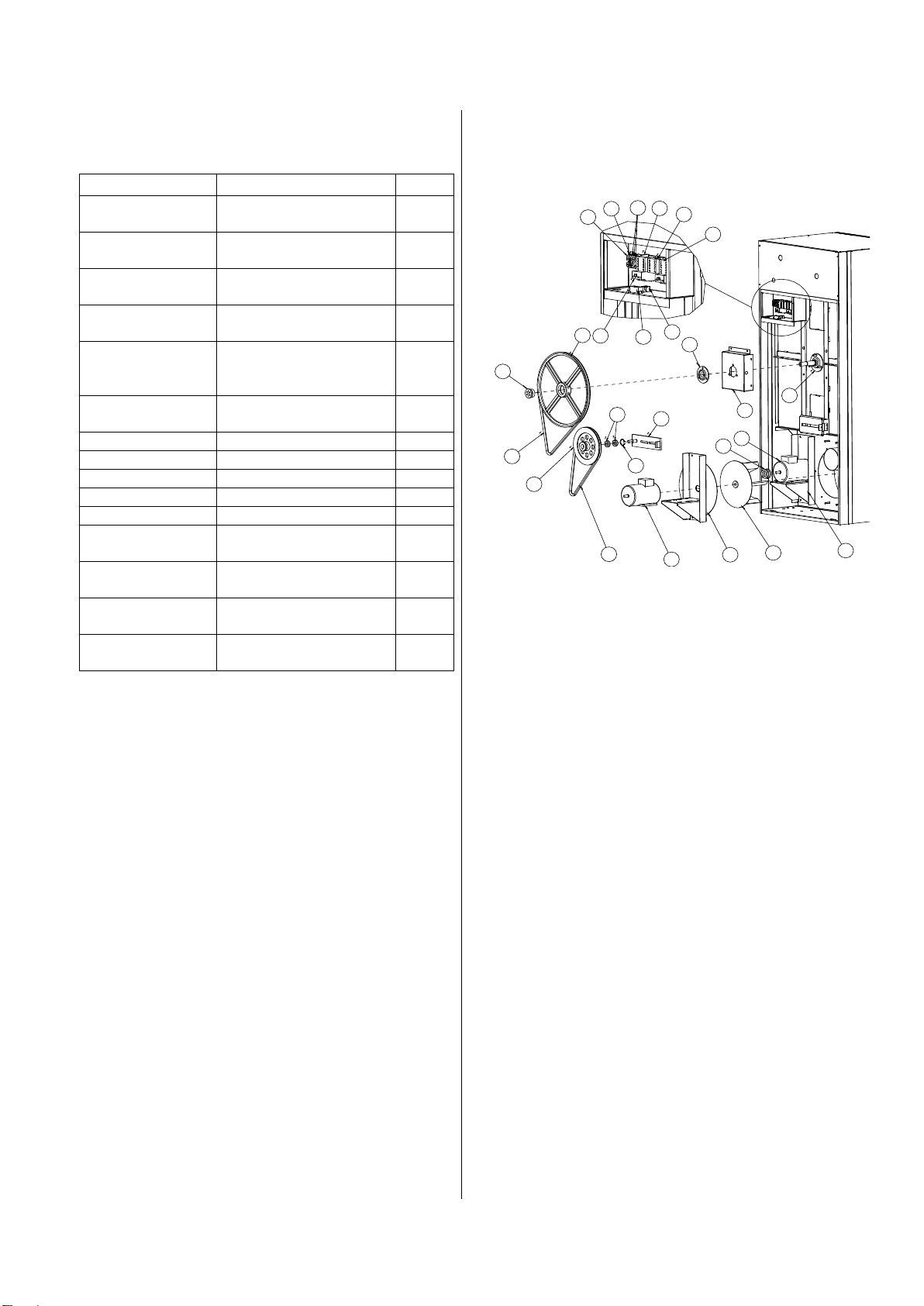

4. KIT COMPOSITION

The kit is made of the following parts:

ARTICOLO

DESCRIZIONE

Q.TA’

2950MINMO408

MINICONTAT. B6-30-

01

2

2950RETT161V3

RELE TERMICO T16

1,7A –2,3A, 1NC+1NA

1

2955MG71MESS

MOTORE 0,37KW - 4P

- 230/400V - 50Hz

1

2080308X

PULEGGIA SPA 67x1

FORO 14 - CAVA 5

1

197848C

SUPPORTO MOTORE

INVERSIONE ES10/34

VERNICIATO

1

0000PRESC1B2

PRESSACAVO 1/2"

NYLON

1

4936DAZ0008M

DADO CL8 M8 ZINB

4

4936BUZ1608M

BULLONE ZN M8X16

4

4936RPZ0008M

ROSETTA Fe 8 ZINB

8

4936DAZ0010M

DADO CL8 M10 ZINB

4

4936BUZ7010M

BULLONE ZN M10X70

4

4936RPZ2410M

RONDELLA ZN

M10X24 PIANA

8

2950CAVSC410

CAVO SCHERMATO

4G10

2mt

2950INBSM589

BARRETTE COL.

INVER. BSM6-30

1

E100901A

LE PRESENTI

ISTRUZIONI

1

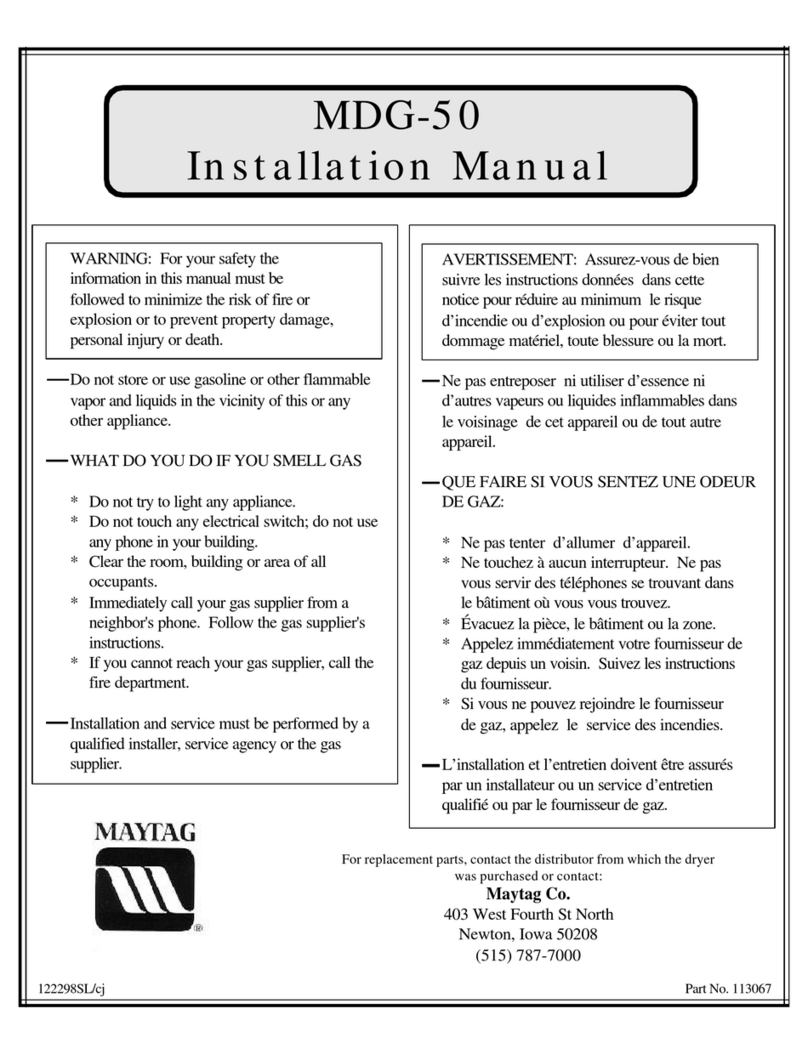

5. MECHANICAL INSTALLATION

Check the exploded view on the right:

a) Unscrew the snub pulley support

(position 8).

b) Unscrew the regulation screw of the

snub pulley support (position 8)

c) Take off the transmission belt

(position 5) which connects the fan

motor (position 26) with the snub

pulley (position 6)

d) Mount the pulley (position 4) on the

motor tree (position 3) and close it

with the apposite dowel.

e) Mount the motor support (position 25)

on the dryer chassis.

f) Fix the motor (position 3) on its

support (position 25).

g) Use the belt (position 5) to connect

the reversing motor pulley (position 3)

to the snub pulley (position 6).

h) Screw the support regulation screw

until the belt is tensioned (position 5)

i) Close the fixing screw of the double

pulley.

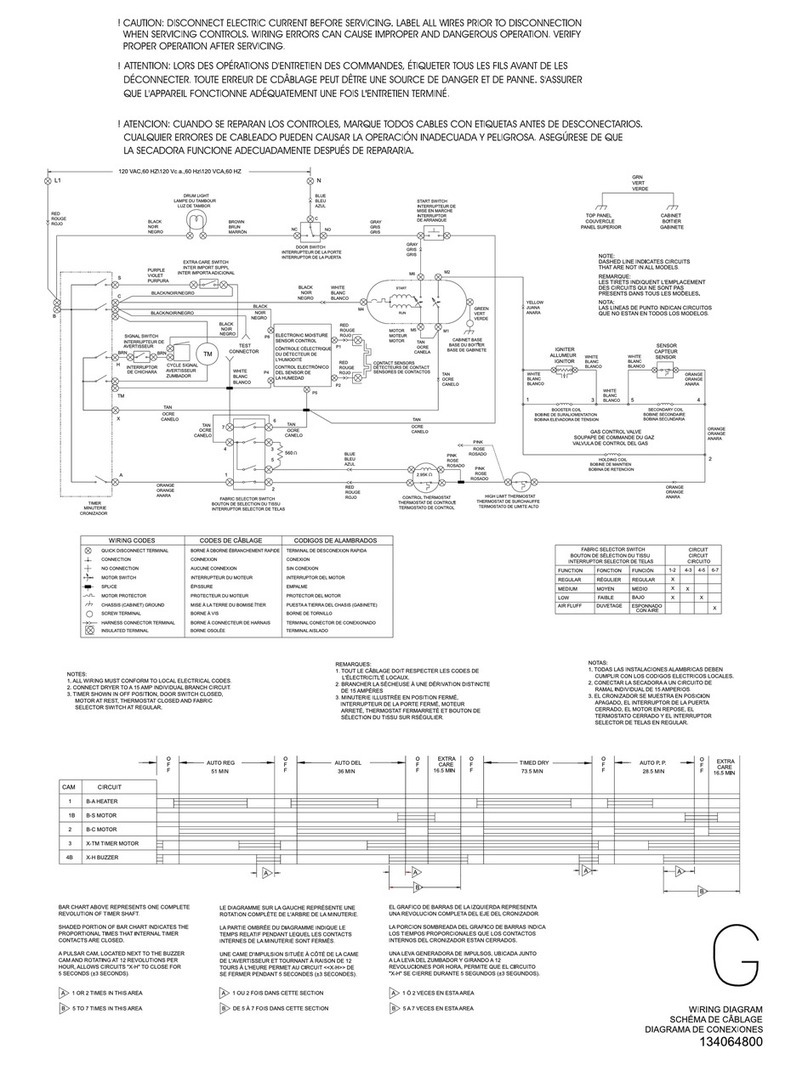

6. ELECTRIC INSTALLATION

1) Fix the two B6 contactors on the

omega bar, which is positioned on the

right of the actual fan contactor (which

will be indicated as VE).

2) Mount the two black bridge on the SX

and DX contactor. Check that the

contact position printed on the bridge

are respected.: 1-L1 to 1-L1 (DX); 3-

L2 to 3-L2 (DX); 5-L3 to 5-L3 (DX); 2-

T1 to 2-T1 (DX); 4-T2 to 4-T2 (DX); 6-

T3 to 6-T3 (DX);

3) Fix the thermal relay on the right

contactor (which will be indicated with

DX), inserting the contacts T1, T2 and

T3.

4) Fix the thermal relay at 2,4 A.

5) Using a 1.5 mm2 cable, make the

following power terminal electric

bridge between the VE fan contactor

and the SX contactor.

a) L1 (VE) –T3 (SX)

b) L2 (VE) –T2 (SX)

c) L3 (VE) –T1 (SX)

1

2

26

4

5

6

78

9

10

11 12

13 14

25

3

24

15 16 17 18 21

22

23

19

20

1903KITINE18_02 (E100901B_ENG) 01/02/2016

4

6) Using a more or less 2mt long 4G1.5

cable connect the motor supply

contacts (passing through the cable

holder) with the magneto thermal relay

contact T1, T2 e T3.

To connect the motor use a Y

connection (supply is 3x400V); ground

must be connected with the whole

ground system.

7) Using a 0.5 mm2cable make the

following control electric connection.

a) Neutral connection (blue cable):

make a bridge between contacts:

A1 (VE), A2 (SX), A1 (DX).

b) From contact A2 (DX) with

insulated fork plug to contact 22

(SX) with insulated fork plug

c) From contact 21 (SX) with male

pin, to the connector (drawing I,

ref. 22). On the connector (position

7) it is already present the female

pin which arrives from contact JP9-

5 of the electronic board and which

control right rotation.

d) With insulated fork plug from

contact A1 (SX) to contact 21 (DX)

with insulated fork plug.

e) With insulated fork plug from

contact 22 (DX) to the connector

poisoned on the below side of the

electric board. On the connector

(position 7) it is already present the

female pin which arrives from

contact JP9-5 of the electronic

board and which control left

rotation.

f) Take of the cable from the

contactor 95 of the fan thermal

relay and connect it to the thermal

relay near the DX contactor.

g) Make a bridge between the contact

96 and the thermal relay next to

VE and the contact 95 of the

thermal relay next to DX contactor.

7. WORKING TEST

Each single contactor can be manually

tested. Using a screwdriver pull the

apposite pin until the contacts are closed.

Check the right rotations sense and, in

case, change the position of the two

phases coming out form the contactor.

VE

SX

DX

Other manuals for ES10

2

This manual suits for next models

2

Other Imesa Dryer manuals

Popular Dryer manuals by other brands

Bosch

Bosch WTW85B49SN Installation and operating instructions

Maytag

Maytag MDG-50 installation manual

Mediclinics

Mediclinics M04A Installation and operating manual

Frigidaire

Frigidaire GLGQ642CAS4 Wiring diagram

Eterna

Eterna HDA-1800 Safety and installation instructions

Hanseatic

Hanseatic HWT8A3GT user manual

Frigidaire

Frigidaire AEQ6000ES - AffinityTM 5.8 cu. Ft. Dryer Factory parts catalog

Alliance Laundry Systems

Alliance Laundry Systems Drying Tumbler 70278501R5EN Installation/operation supplement

Frigidaire

Frigidaire FFQE5000QW Features

Samsung

Samsung DV665JS Owner's instructions

Amica

Amica ACD8WH operating instructions

Frigidaire

Frigidaire 134969400A Service manual