IMI NORGREN VS18G Installation and operating instructions

Operation & Service

Manual

Valve island VS18/VS26

with EtherNet/IP Interface

2

Operation & Service Manual

Valve islands VS18/VS26 EtherNet/IP

09/2018

Construction & Design is subject to change © 2018 Norgren GmbH

Change history:

The Change history reflects all changes of the Operation & Service Manual, which were done after

the initial release.

Index

Chapters

Change description

Date

Name

001

All

Set up initial version

07/03/2017

002

All

Some corrections were made

21/03/2017

003

2

Chapter „Important hints“ added.

20/07/2017

004

All

Changes in IP Address set up, I/O data,

solenoid object, …

31/07/2017

005

All

ISEM description added, valve island

extension added, minor comments

07/11/2017

006

2, 4.4, 10.1,

10.11, 12.2, 12.3

Power-up description updated, ATEX

Note added, Mounting kit added, FW

version and serial number added, New 2

station SPI board added, soft start valve

rules added, technical data corrected

07/09/2018

This Operation & Service Manual makes no claims of being complete as it does not cover all

variants of the VS18/VS26 valve islands series at the moment.

Therefore this document is subject to extensions or changes.

3

Operation & Service Manual

Valve islands VS18/VS26 EtherNet/IP

09/2018

Construction & Design is subject to change © 2018 Norgren GmbH

Content

1. About this documentation..........................................................................................................................5

2. Important hints...........................................................................................................................................6

2.1 Grounding and equipotential bonding ................................................................................................6

2.2 Intermediate supply/exhaust module (ISEM) .....................................................................................6

2.3 ATEX Note..........................................................................................................................................6

2.4 Power-up and initialization phase of the VS18/VS26 valve island.....................................................7

2.4.1 Firmware release V1.001 and lower...........................................................................................7

2.4.2 Firmware release V1.002 and higher .........................................................................................7

2.5 Mounting kit 2-in-1..............................................................................................................................8

2.5.1 DIN-rail assembly without mounting bracket..............................................................................8

2.5.2 Mounting panel assembly without mounting bracket..................................................................9

2.5.3 DIN-rail assembly using the mounting bracket...........................................................................9

2.5.4 Mounting panel assembly using the mounting bracket ............................................................10

3. Electrical Connections of the VS18/VS26 valve islands.........................................................................11

3.1 EtherNet/IP Bus connectors Port 1 & Port 2 ....................................................................................12

3.2 POWER supply connector................................................................................................................12

4. Commisioning..........................................................................................................................................13

4.1 EDS File Installation .........................................................................................................................13

4.2 Hardware configuration: Select valve island ....................................................................................14

4.3 Set up IP Address.............................................................................................................................17

4.3.1 Using a DHCP Server...............................................................................................................17

4.3.2 Static IP Address assignment using TCP/IP Interface Object..................................................17

4.4 Firmware version and serial number................................................................................................19

5. I/O connection via Assembly Object .......................................................................................................21

5.1 Bit allocation valve stations ..............................................................................................................21

5.2 Input data (Assembly Object Instance: 101d) ..................................................................................22

5.3 Output data (Assembly Object Instance: 100d)................................................................................24

6. Solenoid Object.......................................................................................................................................25

7. Diagnostics and LEDs.............................................................................................................................26

7.1 Status LEDs......................................................................................................................................26

7.1.1 Status LEDs description ...........................................................................................................26

7.1.2 Link states for Port P1 and Port P2..........................................................................................26

7.1.3 Network Status LED (NS)........................................................................................................26

7.1.4 Module Status LED (MS).........................................................................................................26

7.1.5 Electronics Power Supply Status, LED (VB) ............................................................................27

7.1.6 Valve Power Supply Status, LED (VA).....................................................................................27

7.2 Valve slice Status LEDs ...................................................................................................................27

8. Output behavior in fault condition (Idle mode/Fault mode).....................................................................28

9. Properties EtherNet/IP Interface .............................................................................................................29

10. Valve island extension..........................................................................................................................30

10.1 Overview –possible combinations...................................................................................................30

10.2 Valve island with 4 stations ..............................................................................................................31

10.3 Valve island with 6 stations ..............................................................................................................31

10.4 Valve island with 8 stations ..............................................................................................................32

10.5 Valve island with 10 stations ............................................................................................................32

10.6 Valve island with 12 stations ............................................................................................................33

10.7 Valve island with 14 stations ............................................................................................................33

10.8 Valve island with 16 stations ............................................................................................................34

10.9 Valve island with 18 stations ............................................................................................................34

10.10 Valve island with 20 stations ............................................................................................................34

10.11 Usage of Soft-start valves ................................................................................................................35

11. Electrical data.......................................................................................................................................36

12. Technical data ......................................................................................................................................37

12.1 Technical data VS18 and VS26........................................................................................................37

12.2 Technical data VS18 ........................................................................................................................38

12.3 Technical data VS26 ........................................................................................................................38

4

Operation & Service Manual

Valve islands VS18/VS26 EtherNet/IP

09/2018

Construction & Design is subject to change © 2018 Norgren GmbH

Contact information

Norgren GmbH

Site Fellbach

Stuttgarter Straße 120

70736 Fellbach

Tel: +49 711 5209-0

5

Operation & Service Manual

Valve islands VS18/VS26 EtherNet/IP

09/2018

Construction & Design is subject to change © 2018 Norgren GmbH

1. About this documentation

This Operation & Service Manual contains the information to set up and operate the VS18/VS26

valve islands with EtherNet/IP interface and to detect and resolve problems.

Note:

In addition to the specific information for the EtherNet/IP variants, all data sheets for the

VS18/VS26 valve island series are applicable and remain valid. The difference between the both

variants consists of the sizes of valves and the resulting maximum flow rate. All electrical

connections and parameterization are the same for both variants.

Refer also to the datasheets on the following weblinks:

http://cdn.norgren.com/pdf/en_5_1_250_VS18.pdf

http://cdn.norgren.com/pdf/en_5_1_350_VS26.pdf

Refer also to the installation video on the following web link:

https://player.vimeo.com/video/256919223

6

Operation & Service Manual

Valve islands VS18/VS26 EtherNet/IP

09/2018

Construction & Design is subject to change © 2018 Norgren GmbH

2. Important hints

2.1 Grounding and equipotential bonding

Proper grounding and equipotential bonding are very important to protect against electromagnetic

interferences in Ethernet networks. In order to reduce potential impact, grounding of the Ethernet

cable screen should be done at both ends of every cable (i.e. at each device). Equipotential

bonding ensures that the ground potential is identical throughout the entire Ethernet network and is

essential to avoid equipotential bonding currents, which could otherwise flow through the Ethernet

cable screen.

Ground connection needs to be established using the M4 thread on the rear of the connection

module. Its location shows the red arrow on the following picture.

2.2 Intermediate supply/exhaust module (ISEM)

In cases where the channel diagnostics is activated on the valve island, the channel diagnostics

setting should be disabled at the position of each ISEM. This needs to be done in order to avoid

any misleading failure indication due to missing electronic components in the ISEM.

2.3 ATEX Note

Please refer to the corresponding ATEX installation instructions and the maximum permissible

operating conditions for valve islands in an ATEX zone.

The maximum allowed power consumption is 20W. This corresponds to 16 simultaneously

energized pilot valves. If a configuration consists of more than 16 pilot valves the user must

undertake external actions (e.g. power-limited power supplies) to make sure that the power

consumption of 20W is not exceeded.

For further details, please refer to the corresponding ATEX installation instructions or contact your

Technical Support.

7

Operation & Service Manual

Valve islands VS18/VS26 EtherNet/IP

09/2018

Construction & Design is subject to change © 2018 Norgren GmbH

2.4 Power-up and initialization phase of the VS18/VS26 valve island

It is possible to read the actual installed firmware release using the Logix-Designer from Allen-

Bradley. Please refer to chapter 4.4 for more details.

2.4.1 Firmware release V1.001 and lower

The valve island initializes automatically after power-up. During initialization the number of

available valve stations is also evaluated, which requires that at this point also the power supply for

the valves (VA) is already available during initialization start. Otherwise not all valve stations might

be detected and initialization of the valve island fails. This failure case is indicated by the following

permanent Status LED states:

P1 –off

P2 –off

NS –off

MS –red

VB –green

VA –green

2.4.2 Firmware release V1.002 and higher

The requirement as described in chapter 2.4.1 is not applicable for the firmware release V1.002

and higher.

The initialization of the valve island is performed during the testing in production before delivery.

Note:

In case any changes are made on the hardware of the valve islands (i.e. adding or removing valve

stations), the power supply must be completely disconnected by unplugging the power supply

connector.

After the hardware change is completed, the new configuration must be initialized.

During initialization the number of available valve stations is evaluated, it is therefore required to

have both the power supply for electronics (VB) and power supply for the valves (VA) available.

Furthermore it is required to adjust the valve island size in the PLC / Hardware configuration for

proper functioning and diagnosis.

8

Operation & Service Manual

Valve islands VS18/VS26 EtherNet/IP

09/2018

Construction & Design is subject to change © 2018 Norgren GmbH

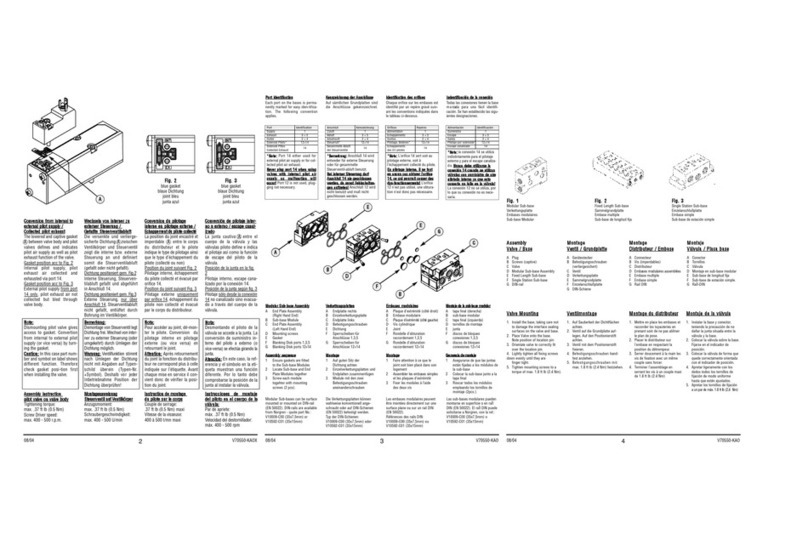

2.5 Mounting kit 2-in-1

Every valve island delivery contains the mounting kit 2-in-1 (part number VS2672971-KG00) as

shown in the below figure. This mounting kit can be used to mount the valve island either to the

DIN rail or directly to the mounting panel.

1. Mounting nut DIN rail

2. Cylinder screw M4 x 8

3. Mounting bracket

4. Cylinder screw M4 x 25

5. Cylinder screw M4 x 36

2.5.1 DIN-rail assembly without mounting bracket

Insert screw M4 x 25 (4) into the left end plate (bus node) and position below the mounting

nut (1)

Insert screw M4 x 36 (5) into the right end plate and position below the mounting nut (1)

Place the valve island on the DIN-rail

Orientate straight flange of the mounting nuts towards the DIN rail

Push the valve island on the DIN-rail and tighten screws with the torque of 1.0 –1.1 Nm

Check the fit of the valve island

DIN-rail assembly without mounting bracket

1

4

3

5

2

1

9

Operation & Service Manual

Valve islands VS18/VS26 EtherNet/IP

09/2018

Construction & Design is subject to change © 2018 Norgren GmbH

2.5.2 Mounting panel assembly without mounting bracket

Insert screw M4 x 25 (4) into the left end plate (bus node)

Insert screw M4 x 36 (5) into the right end plate

Place the valve island on the panel/ wall

Tighten screws with the torque of 1.0 –1.1 Nm

Check the fit of the valve island

Mounting panel assembly without mounting bracket

2.5.3 DIN-rail assembly using the mounting bracket

Hook the mounting bracket (3) into the left end plate (bus node)

Insert screw M4 x 8 (2) into the mounting bracket (3) and position below the mounting nut (1)

Insert screw M4 x 36 (5) on the right end plate and position below the mounting nut (1)

Place the valve island on the DIN-rail

Orientate straight flange of the mounting nuts (1) towards the DIN rail

Push the valve island on the DIN-rail and tighten screws with the torque of 1.0 –1.1 Nm

Check the fit of the valve island

DIN-rail assembly using the mounting bracket

10

Operation & Service Manual

Valve islands VS18/VS26 EtherNet/IP

09/2018

Construction & Design is subject to change © 2018 Norgren GmbH

2.5.4 Mounting panel assembly using the mounting bracket

Hook the mounting bracket (3) into the left end plate (bus node)

Insert screw M4 x 8 (2) into the mounting bracket (3)

Insert screw M4 x 36 (5) on the right end plate

Place the valve island on the mounting panel/ wall

Tighten screws with the torque of 1.0 –1.1 Nm

Check the fit of the valve island

Mounting panel assembly using the mounting bracket

11

Operation & Service Manual

Valve islands VS18/VS26 EtherNet/IP

09/2018

Construction & Design is subject to change © 2018 Norgren GmbH

3. Electrical Connections of the VS18/VS26 valve islands

Top view VS18 with 8 stations

1. Port 1 bus connector for EtherNet/IP

(4 pins M12 D-coded female connector)

2. Port 2 bus connector for EtherNet/IP

(4 pins M12 D-coded female connector)

3. Power supply connector

(5-pins M12 A-coded male connector)

4. Status LEDs

5. Valve status LEDs

1

2

5

4

3

12

Operation & Service Manual

Valve islands VS18/VS26 EtherNet/IP

09/2018

Construction & Design is subject to change © 2018 Norgren GmbH

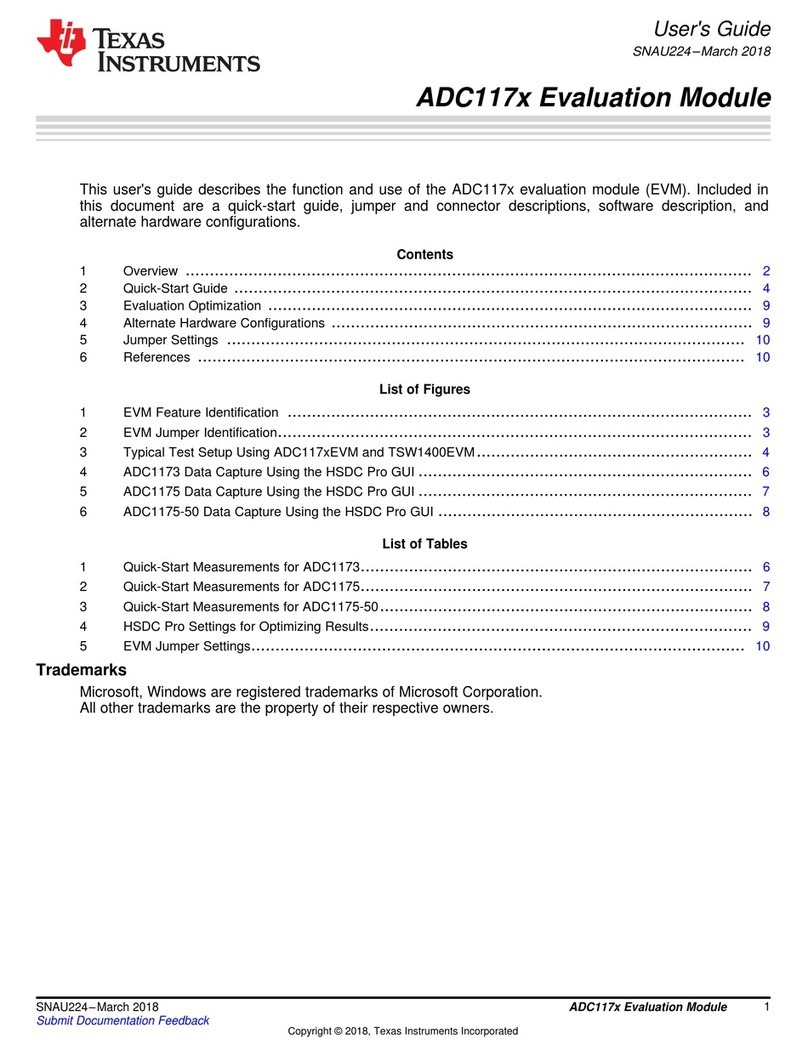

3.1 EtherNet/IP Bus connectors Port 1 & Port 2

M12 / 4 pins / female / D-coded

Pin no.

Function

1

Transmission Data + (TD+)

2

Receive Data + (RD+)

3

Transmission Data - (TD -)

4

Receive Data - (RD -)

Housing

FE (functional earth)

3.2 POWER supply connector

M12 / 5 pins / male / A-coded

Pin no.

Function

1

L1 (VB+) 24V electronics power supply

2

N2 (VA-) 0V valves power supply

3

N1 (VB-) 0V electronics power supply

4

L2 (VA+) 24V valves power supply

5

FE (functional earth)

13

Operation & Service Manual

Valve islands VS18/VS26 EtherNet/IP

09/2018

Construction & Design is subject to change © 2018 Norgren GmbH

4. Commisioning

The configuration of the EtherNet/IP valve island is done via inclusion of the device description file

(EDS file) „002A002Bxxxx0100.EDS“. The device description file is required to be included for the

configuration of the corresponding EtherNet/IP - Controller.

Note:

xxxx = ‘2000’ -> VS18/26 with 4 Stations

`2100` -> VS18/26 with 6 –8 Stations

`2200` -> VS18/26 with 10 –12 Stations

`2300` -> VS18/26 with 14 –16 Stations

`2400` -> VS18/26 with 18 –20 Stations

Note: All explanations in this manual are based on Rockwell Automations “Studio 5000”.

The following steps are necessary.

4.1 EDS File Installation

The EDS file is required to configure the VS18/VS26 valve island. A symbol file is necessary to

display an icon in the engineering tool.

EDS files are provided by the module vendor and can be downloaded from:

https://www.imi-precision.com/uk/en/technical-support/software

Note: The method of module installation strongly depends on the configuration software. Please refer to

the configuration software manual.

The following picture shows Startup image of Rockwell Automations “Logix Designer”.

14

Operation & Service Manual

Valve islands VS18/VS26 EtherNet/IP

09/2018

Construction & Design is subject to change © 2018 Norgren GmbH

In menu “Tool -> EDS Hardware Installation Tool” start the Installation Wizard. Follow the

installation steps described in the wizard.

After the installation the new module is shown in the catalogue.

4.2 Hardware configuration: Select valve island

After the successful installation of the EDS file, the module configuration is needed. In context

menu choose “New Module” after right-clicking on “Ethernet”.

15

Operation & Service Manual

Valve islands VS18/VS26 EtherNet/IP

09/2018

Construction & Design is subject to change © 2018 Norgren GmbH

In the module catalog choose the corresponding VS18/VS26 valve island and click on „Create“.

The picture below shows “Select Module Type” – Dialog

In the following dialogue tab “General” set the “Name” and the correct “IP Address” of the module.

16

Operation & Service Manual

Valve islands VS18/VS26 EtherNet/IP

09/2018

Construction & Design is subject to change © 2018 Norgren GmbH

In dialogue tab “Connection” change “Requested Packet Interval (RPI)” greater than or equal to 10

ms and click “OK”. The RPI times has a direct impact to the busload.

Note: The lower the cycle times, the higher the busload.

The picture bellow shows module tree with the new added module.

After successful configuration please perform download by clicking „Download“ in the menu item

„Communication“.

17

Operation & Service Manual

Valve islands VS18/VS26 EtherNet/IP

09/2018

Construction & Design is subject to change © 2018 Norgren GmbH

4.3 Set up IP Address

4.3.1 Using a DHCP Server

As default the VS18/VS26 valve island is set up as a DHCP client. In this mode IP Address has to

be assigned using a DHCP server or a similar tool. This has to be repeated after each power cycle.

The following example shows the IP Address assignment using Rockwell Automations

BOOTP_DHCP Tool.

It is important to ensure that the network adapter set up in the “Network Settings” of the tool is the

one, which is connected physically to the VS18/VS26 valve island.

Menu: “Tools” -> “Network Settings”

The VS18/VS26 valve island should then appear in the “Discovery History” list. Double clicking the

MAC Address opens the dialog used to set up the IP Address.

The IP Address settings are transferred into the “Discovery History” if they are valid and confirmed

with the “OK” button. Pushing the “Enable BOOTP/DHCP” Button enables the IP Address

assignment for the chosen entry. The VS18/VS26 valve island will appear with assigned IP

Address in “Discovery History” list if address assignment was successful.

4.3.2 Static IP Address assignment using TCP/IP Interface Object

Configuration method of the IP Address could also to be set up as a static value. The interface

configuration is saved to NV storage. This has to be done once and is valid after a power cycle.

The Read/Write access to the TCP/IP Interface Object is done via the Explicit Messages

communication method.

The configuration method is set up with the bits0-3 in attribute 3. Please use the statically-assigned

IP configuration set up value “0” for those bits.

Attribute 3 of TCP/IP Interface Object: Configuration Method

18

Operation & Service Manual

Valve islands VS18/VS26 EtherNet/IP

09/2018

Construction & Design is subject to change © 2018 Norgren GmbH

Attribute 5 contains the configuration parameters required to operate as a TCP/IP node. At least

network address and network mask needs to be configured.

Attribute 5 of TCP/IP Interface Object: Interface Configuration

Next table shows the structure of the interface configuration attribute

Structure of Attribute 5: Interface Configuration

19

Operation & Service Manual

Valve islands VS18/VS26 EtherNet/IP

09/2018

Construction & Design is subject to change © 2018 Norgren GmbH

4.4 Firmware version and serial number

It is possible to read the actual installed firmware version and serial number of the device using the

Logix-Designer (Allen-Bradley). This information is accessible via the Identity Object (Attribute 3)

as described in this section.

Connect to the PLC by choosing the “Go Online” option in the “Communications” drop-down menu.

As soon as the connection with the PLC is established, select the corresponding Valve Island from

the list of Ethernet modules and open the module “Properties”in the context menu or by double-

click.

20

Operation & Service Manual

Valve islands VS18/VS26 EtherNet/IP

09/2018

Construction & Design is subject to change © 2018 Norgren GmbH

The identification and status data of the selected valve island (such as the software version and

serial number) are shown in the Tab „Module Info“.

This manual suits for next models

3

Table of contents

Other IMI NORGREN Control Unit manuals

Popular Control Unit manuals by other brands

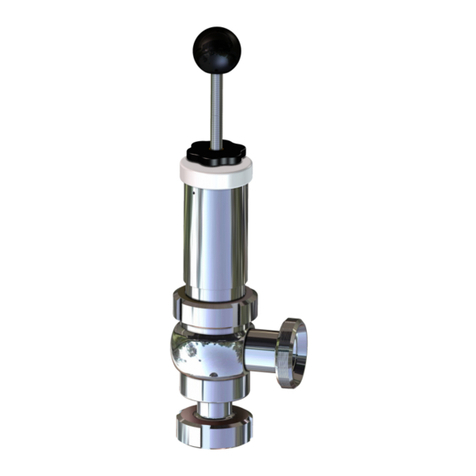

KIESELMANN

KIESELMANN 6268 Translation of the original operating instruction

Yamaha

Yamaha ACD1 Reference manual

New Focus

New Focus 6209 user guide

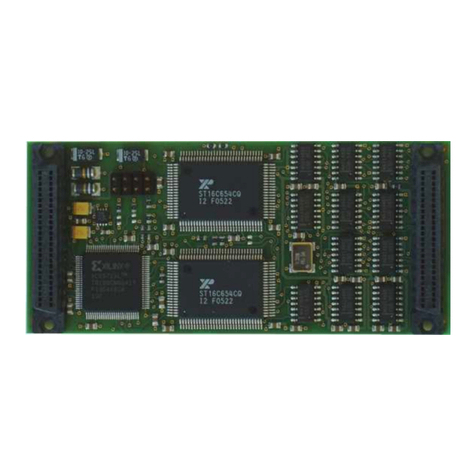

Advantech

Advantech PCL-832 manual

Tews Technologies

Tews Technologies TIP866-TM-10 user manual

VAT

VAT 244 Series Installation, operating, & maintenance instructions

THERMA

THERMA TESC Information booklet

Behringer

Behringer CP35 Attenuators quick start guide

Pego

Pego PLUS300 Expert VD 4 Use and maintenance manual

Festo

Festo CPVSC1-M1H-D-H-M5C Assembly instructions

elsner elektronik

elsner elektronik KNX A3-B2 Installation and adjustment

Softing

Softing FG-200 HSE Quick start up guide