B68G, B68E Filter/Regulator

Installation & Maintenance Instructions

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document. (1999 - I&M8093d) © 2015 IMI International s.r.o.

I&M/en 8.260.300.02

7/15

Note

With non-relieving filter/regulators, make

pressure reductions with some air flow in the

system. If made under no flow (dead-end)

conditions, the filter/regulator will trap the

over-pressure in the downstream line.

4. Knob Adjustment. Push knob toward body

to lock pressure setting. Pull knob away from

body to release. Install tamper resistant cover

and wire (see Replacement Items) to make

setting tamper resistant.

5. T-bar Adjustment. Tighten lock nut (8) lock

pressure setting.

Servicing

1. Open manual drain to expel accumulated

liquids. Keep liquids below bae (53).

2. Clean or replace filter element when dirty.

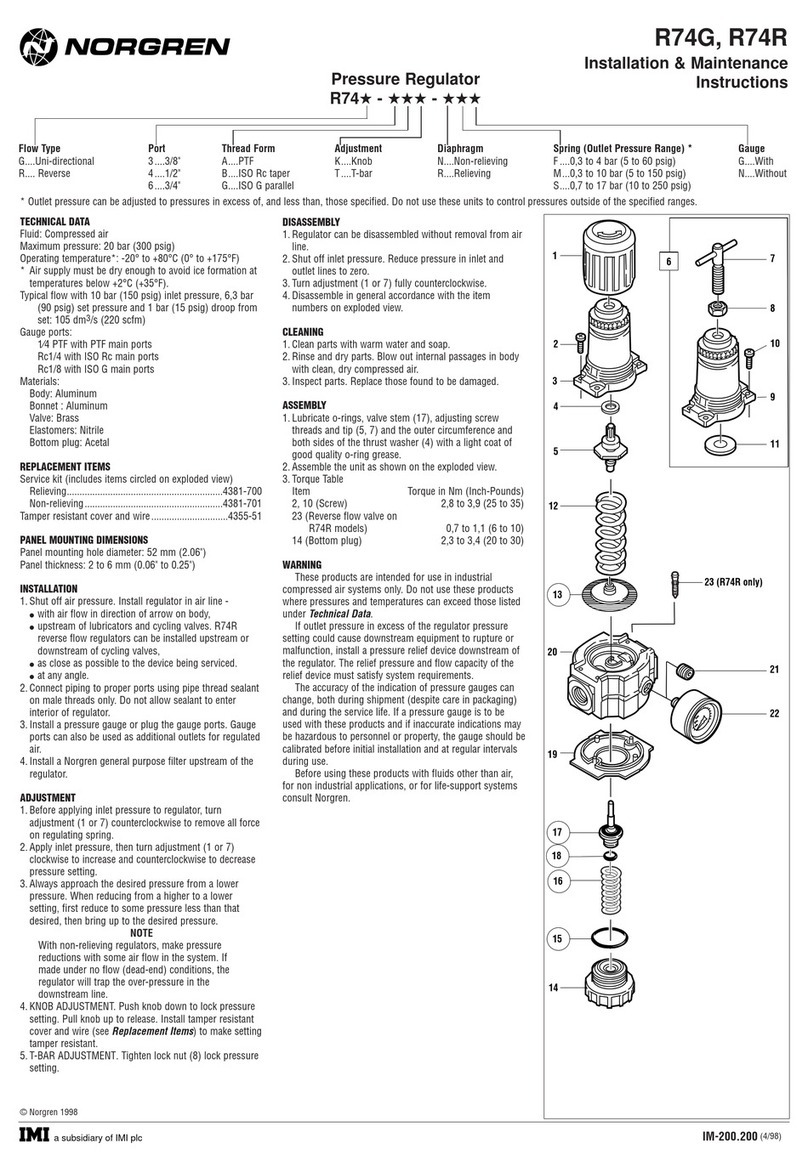

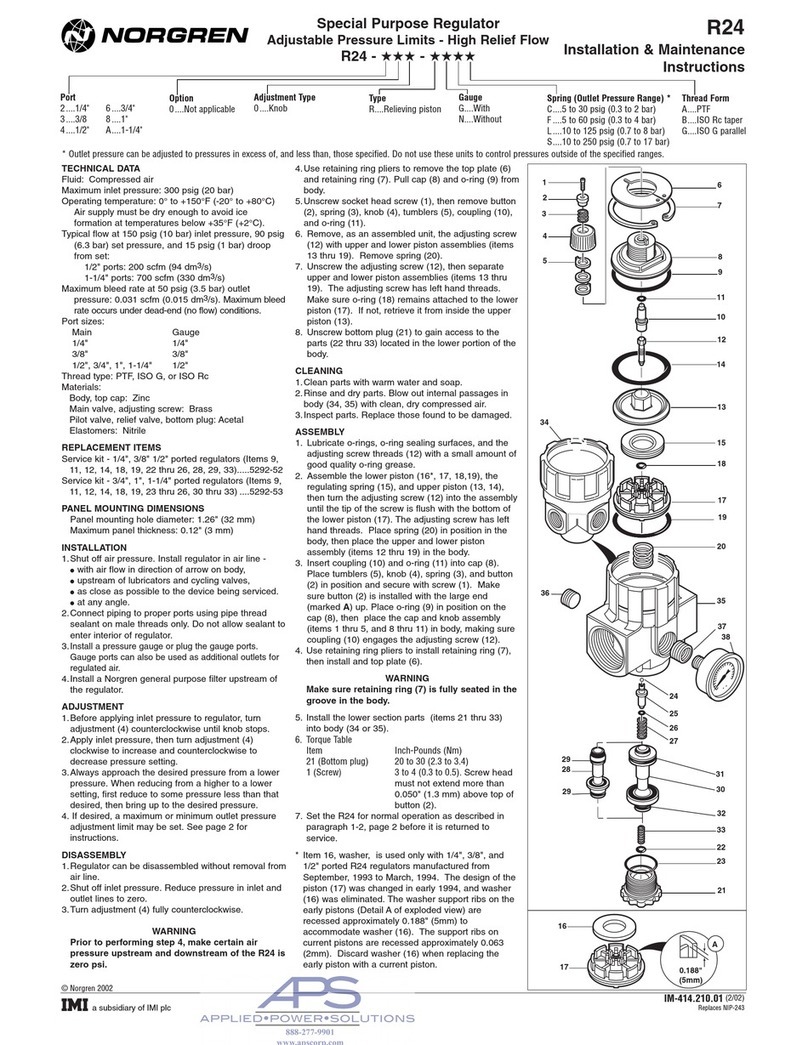

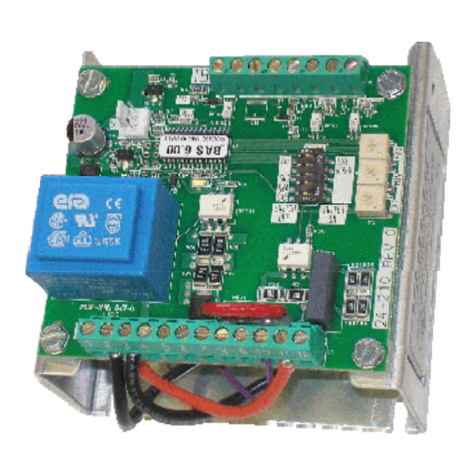

Diassembly

1. Shut o inlet pressure. Reduce pressure in

inlet and outlet lines to zero.

2. Turn adjustment (1 or 7) fully counterclock

wise.

3. Unscrew clamp ring and remove unit from

yoke.

4. Disassemble in general accordance with

the item numbers on exploded view. Do

not remove the drains unless replacement

is necessary. Remove and replace only if they

malfunction.

Cleaning

1. Clean parts with warm water and soap.

2. Rinse and dry parts. Blow out internal

passages in body with clean, dry compressed

air. Blow air through filter element (55) from

inside to outside to remove surface

contaminants.

3. Inspect parts. Replace those found to be

damaged.

Assembly

1. Lubricate o-rings, the portion manual drain

body (43) that contacts the bowl, and the hole

in the manual drain body that accommodates

the stem of drain valve (41) with o-ring grease.

2. Lubricate valve stem (62), adjusting screw

threads and tip (3, 7) and the recess of spring

rest (10) with a light coat of good quality

o-ring grease.

3. Lubricate bonnet threads (2, 9) with a small

amount of anti-seize compound.

4. Assemble the unit as shown on the exploded

view.

5. Assemble the liquid indicator parts (19 thru

26, 30 thru 37) to reservoir. Apply a 0.9 to

1.8 kg (2 to 4 pound) clamping force to upper

and lower sight glass brackets (20, 31).

Tighten screws (19, 30).

6. Torque Table

Item Torque in Nm (Inch-Pounds)

2, 9 (Bonnet) 62 ... 68 (550 ... 600)

16 (Pipe plug) 3,3 ... 5,5 (29 ... 49)

19, 30 (Screw) 1,8 ... 2,3 (16 ... 20)

45, 50 (Nut) 0,8 ... 1,2 (7 ... 10)

53 (Bae) 1,1 ... 1,4 10 ... 12)

.

WARNING

These products are intended for use in industrial

compressed air systems only. Do not use these

products where pressures and temperatures can

exceed those listed under Technical Data.

Polycarbonate plastic bowls can be damaged

and possibly burst if exposed to such

substances as certain solvents, strong

alkalies, compressor oils containing ester-based

additives or synthetic oils. Fumes of these

substances in contact with the polycarbonate

bowl, externally or internally, can also result in

damage. Clean with warm water only.

Use metal bowl in applications where a plastic

bowl might be exposed to substances that are

incompatible with polycarbonate.

If outlet pressure in excess of the

filter/regulator pressure setting could cause

downstream equipment to rupture or

malfunction, install a pressure relief device

downstream of the filter/regulator. The relief

pressure and flow capacity of the relief device

must satisfy system requirements.

The accuracy of the indication of pressure

gauges can change, both during shipment

(despite care in packaging) and during the

service life. If a pressure gauge is to be used

with these products and if inaccurate indications

may be hazardous to personnel or property, the

gauge should be calibrated before initial

installation and at regular intervals during use.

Before using these products with fluids other

than air, for non industrial applications, or for

life-support systems consult Norgren.

Use in potentially explosive atmospheres

Code of device according EC

directive 94/9/EC ExII 2 GD c TX

• Only non-ammable gasese to be used as a

medium.

• Surface temperature dependant on process

fluid temperature and ambient temperature -

must be below the ignition temperature of the

flammable gas or dust.

• Earth unit and/or pipework to avoid

electrostatic discharge.

• Precautions should be taken to prevent hazard

from adiabatic compression.

• Use wet cloth for cleaning.

• Protect the unit from object falling onto it.

• Avoid contact with corrosive environment.

• For servicing the unit it is recommended to

carry out this work outside of the danger zone.

• For details of ignition hazard assessment

contact Norgren.

17

16

11

14

2

1

7

8

9

10

1

5

4

6

3

53

55

57

58

59

60

62

64

63

61

56

54

12

13

15

29

32

32

31

30

36

37

35

31

30

33

39

34

33

38

18

28

19

25

26

24

21

22

19

21

20

20

23

22

27

41

43

42

40

46

45

47

44

48

51

50

49

52