R64G Regulator

Installation & Maintenance Instructions

7/15

I&M/en 8.240.200.01

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document. (1999 - I&M8078d) © 2015 IMI International s.r.o.

Fluid: Compressed air

Maximum pressure: 17 bar (250 psig)

Operating temperature*:

–20° ... +80°C (0° ... +175°F)

* Air supply must be dry enough to avoid ice

formation at temperatures below +2°C (+35°F).

Typical flow with 10 bar (150 psig) inlet pressure,

6,3 bar (90 psig) set pressure and 1 bar

(15 psig) droop from set: 120 dm3/s (254 scfm)

Gauge ports:

1/8“ PTF with PTF main ports

1/8“ ISO Rc with ISO Rc main ports

1/8“ ISO Rc with ISO G main ports

Materials:

Body: Zinc

Bonnet: Aluminium

Valve: Brass

Elastomers: Synthetic rubber

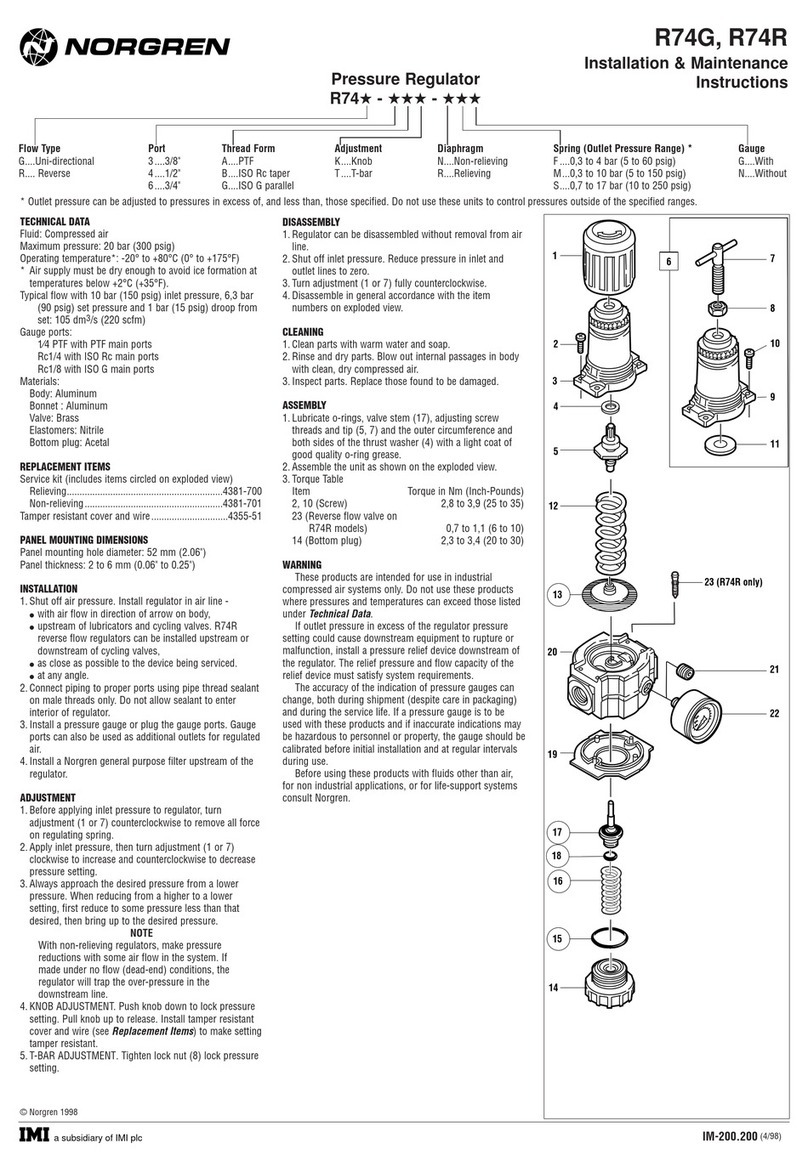

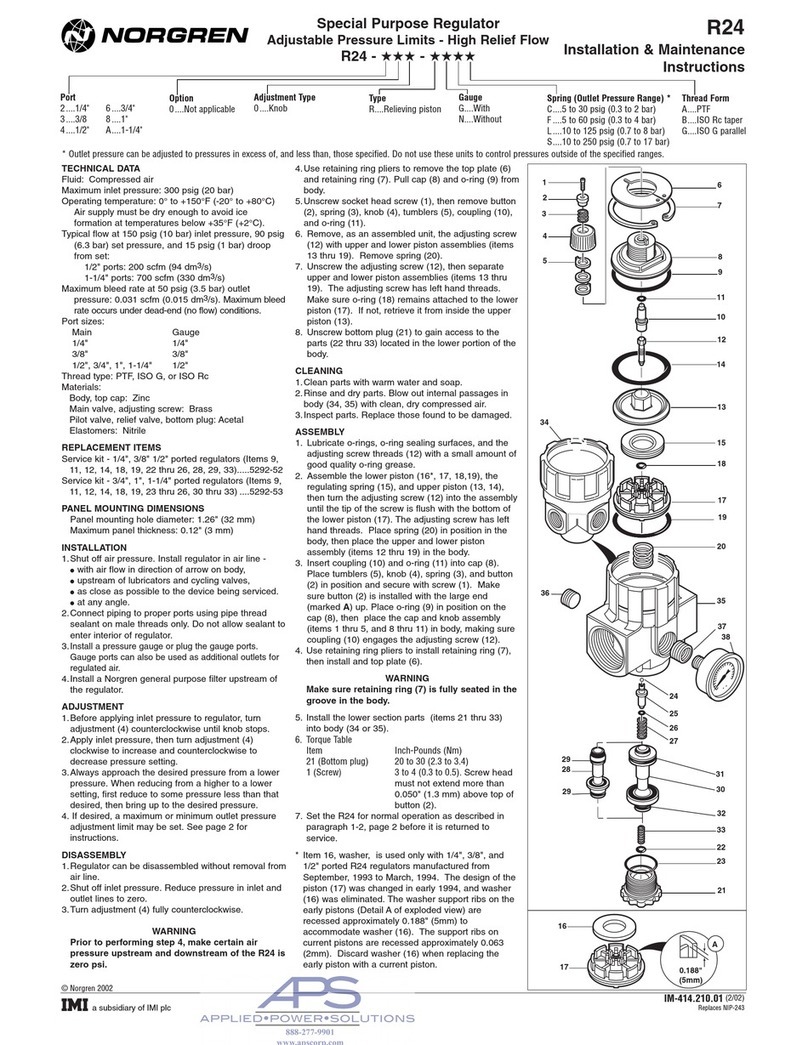

Replacement Items

Service kit, contains required items circled:

Relieving 4381-200

Non relieving 4381-201

Panel Mounting Dimensions

Panel mounting hole diameter: 52 mm (2.06“)

Panel thickness: 6 mm (0.25“) max.

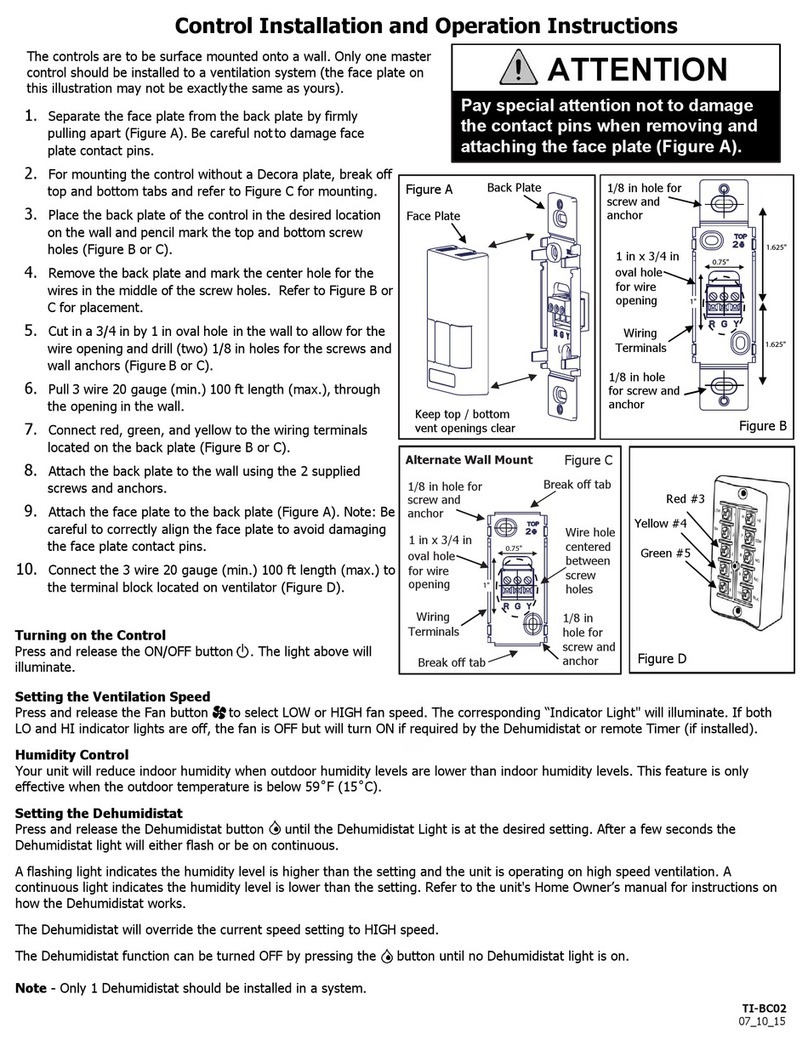

Installation

1. Install unit vertically in air line -

• upstream of lubricators and cycling valves,

• with air ow in direction of arrow on body,

• as close as possible to the device being

serviced.

2. Before assembling the basic unit into the yoke

the port seal o-rings should be lightly smeared

with o-ring grease.

3. Locate clamp ring under lugs on top of yoke,

oer basic unit into yoke with directional

arrows correctly aligned (an interference fit

prevents assembly if misaligned) before

engaging and fully tightening the clamp ring.

4. Install a pressure gauge or plug the gauge

ports. Gauge ports can also be used as

additional outlets for regulated air.

A B C

Adjustment

1. Before applying inlet pressure to regulator,

turn adjustment (1 or 6) counterclockwise to

remove all force on regulating spring (11).

2. Apply inlet pressure, then turn adjustment

(1 or 6) clockwise to increase and

counterclockwise to decrease pressure

setting.

3. Always approach the desired pressure from

a lower pressure. When reducing from a

higher to a lower setting, first reduce to some

pressure less than that desired, then bring up

to the desired pressure.

Note

With non-relieving regulators, make pressure

reductions with some air flow in the system.

If made under no flow (dead-end) conditions,

the regulator will trap the over-pressure in the

downstream line.

4. Knob adjustment. Push knob down to lock

pressure setting. Pull knob up to release.

Install tamper resistant cover (see

Replacement Items) to make setting tamper

resistant.

5. T-BAR adjustment. Tighten lock nut (7) to lock

pressure setting.

Disassembly

1. Shut o inlet pressure. Reduce pressure in

inlet and outlet lines to zero. Turn adjustment

(1 or 6) fully counterclockwise.

2. For ease of maintenance the unit can be

removed from the yoke by unscrewing the

clamp ring, which will jack the unit out

downwards.

3. Disassemble in general accordance with the

item numbers on exploded view.

4. To disassemble turn the adjuster (1 or 6)

counter-clockwise to relieve compression on

the adjusting spring (11). Remove 4 screws

(2 or 8) to disassemble the bonnet (3 or 9)

from the body. Remove the adjusting spring

(11) and diaphragm (12). Inspect all

components for damage, foreign matter

and cleanliness and reassemble using service

replacement parts where necessary.

Cleaning

1. Clean parts with warm water and soap.

2. Rinse and dry parts. Blow out internal pas

sages in body with clean, dry compressed

air.

3. Inspect parts. Replace those found to be

damaged.

Assembly

1. Lubricate o-rings with o-ring grease.

2. Check valve for free movement in the valve

guide.

3. Assemble the unit as shown on the exploded

view.

4. Torque Table

Torque in

Item N-m (Inch-Pounds)

3, 9 (Bonnet) 61 ... 68 (555 ... 618)

Technical features

Option selector

Port

2 1/4”

3 3/8“

4 1/2“

6 3/4

Gauge

G With

N Without

Thread

A PTF (1/8 PTF gauge ports)

B ISO Rc taper (1/8 ISO Rc gauge ports)

G ISO G parallel (1/8 ISO Rc gauge ports)

R64G – ˙˙˙ – ˙˙˙

Diaphragm

R Relieving

N Non relieving

Adjustment

K Knob

T T-bar Spring (Outlet pressure range) *

F 0,3 ... 4 bar (3 ... 60 psig)

M 0,3 ... 10 bar (3 ... 150 psig)

S *1) 0,7 ... 17 bar (10 ... 250 psig)

* Outlet pressure can be adjusted to pressures in excess of, and less than, those specified. Do not use these units to control pressures outside of the specified ranges.

*1) Units with 17 bar (250 psig) adjustment range are available only with the T-bar adjustment, therefore substitute T at the 7th digit and S at the 12th position.

7

1

2

6

9

10

11

12

14

16

13

19

17

18

4

3

5

8

20

15