Imlab IKA ULTRA-TURRAX T 10 basic User manual

12

T 10 basic_092012

Contents

EN

Page

EC-declaration of conformity 12

Explanation of symbols 12

Safety instructions 13

Correct use 14

Unpacking 14

Useful information 15

Drive unit 15

Assembly of clamp and stand 15

Working with the unit 16

Error correction 16

Maintenance and cleaning 16

Note to the flat key and shaft key 17

Accessories 17

Permitted dispersing tools 17

Speed table 18

Technical data 18

Warranty 19

EC-Declaration of conformity

We declare under our sole responsibility that this product

corrosponds to the regulations 89/336EC, 98/37EC and 2006/95EC

and conforms with the standards or standardized documents DIN

EN IEC 61010-1, DIN EN IEC 61326-1, DIN EN ISO 12100-1, -2 and

EN 60204-1.

Explanation of symbols

General hazard

This symbol identifies information that is of vital

importance for safeguarding your health

and safety. Disregarding this information can

lead to health impairment and injuries.

This symbol identifies information that is of

importance for the technically correct

functioning of the system. Disregarding this

information can result in damage to the instru-

ment or to system components.

This symbol indicates information which is im-

portant for ensuring that the operations of

the appliance are performed eciently and

for using the instrument. Failure to observe

this information can result in inaccurate results.

Source language: German

DANGER

WARNING

ATTENTION

13

T 10 basic_092012

ō

Read the operating instructions in full before starting up

and follow the safety instructions.

ō

Keep the operating instructions in a place where they can be

accessed by everyone.

ō (QVXUHWKDWRQO\WUDLQHGVWDIIZRUNZLWKWKHLQVWUXPHQW

ō )ROORZWKHVDIHW\LQVWUXFWLRQVJXLGHOLQHVRFFXSDWLRQDOKHDOWK

safety and accident prevention regulations.

Wear your personal protective equipment in ac-

cordance with the hazard category of the medi-

um to be processed. Otherwise there is a risk of:

- splashing liquids

- body parts, hair, clothing and jewelry getting

caught.

Please pay attention to the dangerous

points of the equipment marked in Fig. 1.

ō

Check the instrument and accessories beforehand for damage each

time when you use them. Do not use damaged components.

ōDo not operate the instrument in explosive atmospheres, with

hazardous substances or under water.

ō

There may be electrostatic discharges between the medium and

the dispersing instrument shaft which could cause a direct danger.

ō 7KHLQVWUXPHQWLVDOVRVXLWDEOHIRUPDQXDORSHUDWLRQ

ō 6HWXSWKHVWDQGLQDVSDFLRXVDUHDRQDQHYHQVWDEOHFOHDQ

non-slip, dry and fireproof surface.

ō (QVXUHWKDWWKHVWDQGGRHVQRWVWDUWWRPRYH

ō

The agitated vessels used for dispersing have to be secured.

Consider on a good stability of the entire structure.

ō 6HFXUHWKHGLVSHUVLQJYHVVHODJDLQVWWZLVWLQJ

ō *ODVVYHVVHOVPXVWDOZD\VEHVHFXUHGZLWKDFODPSWRSUHYHQW

them spinning. When working with glass vessels, the dispersing

tool must not come into contact with the glass.

ō

Note the operating instructions of the dispersing tool and accessories.

ō 2QO\GLVSHUVLQJHOHPHQWVDSSURYHGE\IKA®can be used.

ō $VVHPEOHH[DFWO\WKHGLVSHUVLRQWRROIROORZLQJWKHLQVWUXFWLRQV

ō 'RQRWXVHWKHLQVWUXPHQWZLWKRXWDGLVSHUVLQJHOHPHQW

ō 8VHWKHGLVSHUVLQJWRRODOZD\VLQVLGHWKHGLVSHUVLQJYHVVHO

ō

Check that the turning handles are secure and tighten if necessary.

ō

Make certain that the unit is set at the lowest speed before com-

missioning; otherwise, the unit will begin running at the set

speed in last operation. Gradually increase the speed.

ō

Reduce the speed if the medium splashes out of the vessel because

the speed is too high.

ō %HIRUHVZLWFKLQJRQWKHGLVSHUVLQJLQVWUXPHQWPDNHVXUHWKDW

its shaft is immersed min. 20 mm in the medium to prevent the

medium from splashing out.

The distance between the dispersing tool and

the vessel bottom should not be less than 10

mm (Fig. 1).

ō

In the event of unbalance or unusual noises, switch off the instru-

ment immediately. Replace the dispersing element. If there is no

difference after the change of the dispersing tool, return it to the

dealer or the manufacturer along with a description of the fault.

Do not touch rotating parts during operation!

ō3lease note that the dispersing element and the journal bearings

may become extremely hot during use.

ō

Only process media that will not react dangerously to the extra en-

ergy produced through processing. This also applies to any extra

energy produced in other ways, e.g. through light irradiation.

ō 'RQRWSURFHVVDQ\ĠDPPDEOHRUFRPEXVWLEOHPDWHULDOV

ō

Process pathogenic materials only in closed vessels under a suit-

able fume hood. Please contact IKA

®

if you have any questions.

ō$EUDVLRQRIWKHGLVSHUVLRQHTXLSPHQWRUWKHURWDWLQJDFFHVVRULHV

may get into the medium you are working on.

Safety instructions

DANGER

DANGER

DANGER

WARNING

14

T 10 basic_092012

Correct use

ōUse

When used in combination with one of our recommended dispersing

elements, the drive unit is a high-speed dispersing and emulsifying

unit capable of handling free-flowing and liquid media in batches.

- Production of: Emulsions

Dispersions

Wet crushing

- Operating modes: Manual mode

On stand

ōRange of use (indoor use only)

- Laboratories - Schools

- Pharmacies

- Universities

This instrument is suitable for use in all areas except:

- Residential areas

-

Areas that are connected directly to a low-voltage supply network

that also supplies residential areas.

The safety of the user cannot be guaranteed:

- If the instrument is operated with accessories that are not supplied

or recommended by the manufacturer

- If the instrument is operated improperly or contrary to the manu-

facture’s specifications

- If the instrument or the printed circuit board are modified by the

third parties.

ō3RZGHUFDQQRWEHWRRFORVHWRWKHĠDQJH,WFDQEHEORZQDZD\

by air turbulences of the drive.

ō

The instrument starts up again following a cut in the power sup-

ply. Please note that the instrument must be switched off at the

ON/OFF switch in this case before the power supply is recon-

nected.

ō7KHLQVWUXPHQWFDQRQO\EHGLVFRQQHFWHGIURPWKHPDLQVVXSSO\

by pulling out the mains plug or the connector plug.

ō 7KHVRFNHWIRUWKHPDLQVFRUGPXVWEHHDVLO\DFFHVVLEOH

ō $OZD\VGLVFRQQHFWWKHSOXJEHIRUHğWWLQJDFFHVVRULHV

ō6DIHRSHUDWLRQLVRQO\JXDUDQWHHGZLWKWKHDFFHVVRULHVGHVFULEHG

in the ”Accessories” chapter.

Never run dispersion tools dry, as the gasket

and bearings will be destroyed if the tools are

not cooled by the medium.

ō

The voltage stated on the nameplate must correspond to the

mains voltage.

ō3URWHFWWKHLQVWUXPHQWDQGDFFHVVRULHVIURPEXPSVDQGLPSDFWV

ō 7KHLQVWUXPHQWFDQRQO\EHRSHQHGE\H[SHUWV

ō

Removable parts must be refitted to the instrument to prevent

the infiltration of foreign objects, liquids etc.

ō'RQRWFRYHUWKHYHQWLODWLRQVORWVRQWKHGULYHLQRUGHUWRHQVXUH

adequate cooling of the drive.

ō

The gasket and bearings are made of PTFE and rustproof steel; the

following points should therefore be noted: Chemical reactions of

PTFE occur in contact with molten or solute alkali metals and alka-

line earth metals, as well as with fine powders of metals in groups

2 and 3 of the periodic system at temperatures above 300 °C - 400

°C. Only elementary fluorine, chlorotrifluoride and alkali metals at-

tack it; halogenated hydrocarbons have a reversible swelling effect.

(Source: Römpps Chemie-Lexikon and ”Ulmann”, Volume 19)

WARNING

15

T 10 basic_092012

Unpacking

ōUnpacking

- Please unpack the device carefully

- In the case of any damage a fact report must be sent immediately

(post, rail or forwarder).

ōDelivery scope

One

T 10 basic ULTRA-TURRAX

®

dispersion equipment accord-

ing to the ordered type, one clamp R 200, a shaft key, a flat key,

an operating instructions,

a warranty card

and a decontamination

clearance certificate, all stored in a suitcase.

Useful information

Dispersion refers to the dissipation and scattering of a solid, liquid or

gaseous phase in a liquid which cannot be fully mixed with this phase.

The rotor/stator principle:

Due to the high rotation speed of the rotor, the medium to be pro-

cessed is automatically drawn axially into the dispersing head and

then forced radially through the slots in the rotor/stator arrangement.

The high accelerations acting on the material produce extremely

strong shear and thrust forces. In addition, high turbulence occurs

in the shear gap between rotor and stator, which provides optimum

mixing of the suspension.

The dispersion effectiveness is heavily dependent on the product of

the shear gradient and the time the particles spend in the shear zone.

The optimum range for the circumferential velocity of the rotor/stator

arrangement is 6-20 m/s.

A processing time of a few minutes is usually sucient to produce

the desired fineness. Long processing times bring only insignificant

improvements in the obtainable fineness; the energy expended serves

merely to increase the temperature of the medium.

Assembly of clamp and stand

Assembly (see Fig. 1 and Fig. 2)

ō

Push the clamp (6) as shown in Fig. 1 over the dispersion

in-

strument, until it engages in the position planned for it audibly.

ō7LJKWHQWKHWXUQLQJKDQGOHE\KDQGXQWLOWRVWRS

ō6FUHZWKHFODPSE\PHDQVRIFURVVVOHHYHRQWRWKHVWDQG

For safe working the drive units should be fastened by means of

a cross sleeve to the plate stand. Pay attention when assembling

the dispersion instrument to the stand to a perfect and firm seat

of the cross sleeve.

In order to increase the stability of the mechanical structure, the drive

unit must be installed as closely as possible to the stand support rod.

Drive

The open up a wide range of possibilities for dispersion technology in

the conventional laboratory with a respective performance output of

approximately 75 watts at 30.000 rpm.

The speed of the T 10 basic ULTRA-TURRAX

®

dispersion unit set by

using the speed adjusting wheel.

RO

TO

R

ST

AT

OR

Fig. 5

16

T 10 basic_092012

Working with the unit

Check that the voltage listed on the designation plate matches the

mains voltage. Also pay attention to the ambient conditions listed

in the technical data.

Assembly of the dispersing tool (see Fig. 1 and Fig. 3)

- Open the shaft lock (3) by turning to the left as far as the stop.

- Insert the dispersing element into the collet as far as the stop.

-

Lock the shaft lock (3) by turning it to the right until it noticeably

clicks into place. The marks (A) on the shaft lock (3) and mark (B)

on the casing should be over each other when closed.

The distance between the dispersion tool and the vessel bottom

should not be less than 10 mm.

Please observe also the operating instructions of the dispersion

tool to ensure a safe usage.

The entire unit may also be arranged somewhat off centre in order

to avoid any undesired air admission caused by the strong rota-

tional turbulence.

Set the adjusting wheel (1) to the minimum speed before switch-

ing on the instrument. You can read the set speed by comparing

the numbers on the adjusting wheel (1) and the speed table (see

chapter: Speed Table).

By using the adjusting wheel (1) the speed may be infinitely adjusted

to meet the requirements of the medium to be processed. The no-

load speed of the T 10 basic ULTRA-TURRAX

®

driving unit may

be set between 8.000 and 30.000 rpm.

Error correction

The instrument is appropriate for short-time duty (10 minutes

ON/5 minutes OFF), i.e. the OFF time must be noted. Failure to

observe the ON/OFF time, the instrument can switch off depend-

ing upon load by temperature rise during the dispersing, since the

drive is equipped with an overload safety device, which switches

the instrument off with overload or temperature rise. If the instru-

ment switched off at the ON/OFF switch, after an appropriate

cooling time the equipment can be restartet.

Note: The instrument does not restart it after responding the

overload safety device automatically, must for cooling at the rocker

switch (2) be switched off.

Maintenance and cleaning

Maintenance and Cleaning

Drive unit:

The drive unit is maintenance-free but not immune from wear. The

carbon brushes of the motor wear down over the time.

For cleaning disconnect the main plug.

Only use cleansing agents which have been recommended by IKA

®

.

Disassembly (see Fig. 1 and Fig. 2)

ōFor the disassembly of the dispersion instrument from the clamp (6),

turn handle (5) firstly to loosen the clamp.

ō

Hold the dispersion instrument with a hand, with the other hand

to pressure on the locking lever (Fig. 2). Now, the dispersing in-

strument could be disassemble from the clamp.

The unit is ready for service when the mains

plug has been plugged in.

The driving unit is switched on by pressing the rocker switch (2)

in "I" position.

17

T 10 basic_092012

Dirt Cleaning agent

Dye isopropyl alcohol

Construction material

water containing tenside/ isopropyl alcohol

Cosmetics

water containing tenside/ isopropyl alcohol

Foodstuffs

water containing tenside

Fuel

water containing tenside

For materials which are not listed, please request information from

IKA®application support.

Wear protective gloves during cleaning the instruments.

Electrical instruments may not be placed in the cleansing agent for

the purpose of cleaning.

Do not allow moisture to get into the instrument when cleaning.

Before using another than the recommended method for cleaning

or decontamination, the user must ascertain with IKA®that this

method does not destroy the instrument.

Dispersion tools:

Please refer to the manuals associated to the dispersion tools.

Spare parts order

When ordering spare parts, please give:

- machine type

- manufacturing number, see type plate

- item and designation of the spare part, see www.ika.com,

spare parts diagram and spare parts list.

Repair

In case of repair the device has to be cleaned and free from

any materials which may constitute a health hazard.

For repair, please fill up the “Decontamination Clearance Certificate”

form supplied with instrument or printed copy on the IKA® website:

www.ika.com.

Note to the flat key and shaft key

The provided assembly tools (flat key and shaft key, Fig. 4) can

be used to disassemble and assemble the dispersing elements for

cleaning and maintenance. Take the information about the exactly

use of the operating instructions of the dispersion tools.

Accessories

ō 5 Stand

ō 5 Plate stand

ō 5 Plate stand

ō 5 Plate stand

ō 5 Cross sleeve

ō + Cross sleeve

If you require servicing, return the appliance in its original packag-

ing. Storage packaging is not sucient. Please also use suitable

transport packaging.

18

T 10 basic_092012

Speed table

Note: The speed table was calculated on the basis of a dispersion

volume of 5 ml water using the dispersing tool S 10 N - 5 G.

With other combinations (dispersion tools; medium quantity and

medium viscosity) can result other number of revolutions values.

Adjusting wheel

scale

123456

No-load speed 8.000 9.500 11.500 14.500 20.500 30.000

Speed with

5 ml water

7.900 9.400 11.400 14.450 20.450 29.900

The speeds depend on the dispersing element used as well as the

viscosity and quantity of the medium. Therefore it may change

over the course of a dispersing process if the viscosity of the liquid

changes.

Permitted dispersion tools

Designation Material of shank

S 10 N - 5 G

Stainless steel

S 10 N - 8 G

Stainless steel

S 10 N - 10 G

Stainless steel

S 10 D - 7 G - KS - 65

Synthetic material

S 10 D - 7 G - KS - 110

Synthetic material

Only use the dispersing tools listed in the table and note

the according operating instructions of the dispersion tool.

19

T 10 basic_092012

Technical data

Speed range rpm 8.000 - 30.000

(at nominal designed voltage and

50 Hz)

Speed display Scale (see speed table)

Speed variation on load change

%< 6

Perm. ambient temperature °C 5 – 40

Perm. relative humidity %80

Perm. on time (drive unit) min max. 10 ON/min. 5 OFF

Overload protection/blocking

protected

locking bimetallic switch;

temperature and power sensitively

Protection to DIN EN 60529

IP 30

Power consumption W125

Power output W75

Voltage

or

VAC

220 – 240

(nominal design voltage 230V)

100 – 120

(nominal design voltage 115V)

Frequency Hz 50/60

Noise (without dispersing element)

dB (A) 65

Drive dimension (W x D x H) mm 56 x 66 x 178

Clamp arm dimension (Ø x L) mm 8 x 100

Weight kg 0,5

Contamination level 2

Protection class II

Overvoltage categorie II

Operation at a terrestrial altitude

m

max. 2000 above sea level

Subject to technical changes!

Warranty

In accordance with IKA

®

warranty conditions, the warranty period

is 24 months. For claims under the warranty please contact your

local dealer. You may also send the machine direct to our works,

enclosing the delivery invoice and giving reasons for the claim. You

will be liable for freight costs.

The warranty does not cover wearing parts, nor does it apply to

faults resulting from improper use or insucient care and mainte-

nance contrary to the instructions in this operating manual.

Table of contents

Other Imlab Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

cytiva

cytiva FineLINE Pilot 35 column operating instructions

PASCO

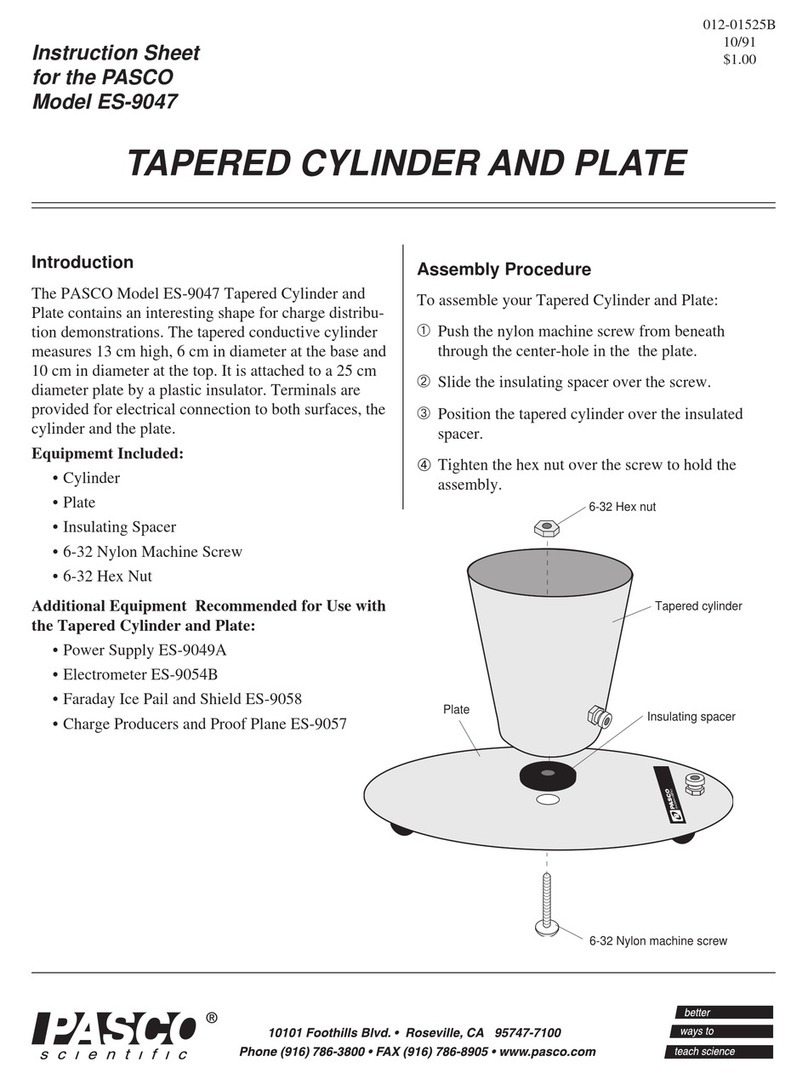

PASCO ES-9047 instruction sheet

Thermo Scientific

Thermo Scientific 88881-003 user manual

Biohit

Biohit eLINE Lite instruction manual

Thermo Scientific

Thermo Scientific A 40B manual

Drucker Diagnostics

Drucker Diagnostics Horizon 6 Flex Operator's manual