Imlab IKA Series User manual

13

Page

Declaration of conformity 13

Explication of warning symbols 13

Safety instructions 14

Correct use 14

Unpacking 15

Useful information 15

Interfaces and outputs 16

Commissioning 17

Switching on the instrument 17

Factory setting 18

Setting menu parameters 18

Setting working parameters 19

Warning messages 20

Error codes 20

Using the coupling extractor 21

Maintenance and cleaning 21

Accessories 21

Technical data 22

Warranty 22

Contents

EN

Declaration of conformity

Explication of warning symbols

Source language: German

General hazard

This symbol identifies information that is of vital importance for protecting your health

and safety. Disregarding this information may lead to health impairment and injuries.

This symbol identifies information that is of importance for the technically correct func-

tioning of the system. Disregarding this information can result in damage to the instrument or

to system components.

This symbol indicates information which is important for proper use and ensuring that the

operations of the instrument

are performed eciently and for using the instrument.

Failure to observe this information may result in inaccurate results.

Danger - Risk of hand injury.

Danger - Risk of injury by high temperature.

DANGER

DANGER

We declare under our sole responsibility that this product corresponds to the regulations 2014/35/EU, 2006/42/EC,

2014/30/EU and 2011/65/EU

and conforms with the standards or normative: EN 61010-1, EN 6010-2-051

,

EN 61326-1,

EN 60529 and EN ISO 12100.

DANGER

CAUTION

WARNING

14

• The milling tube must only be attached and removed

while the motor is stationary.

Always open the milling tube care-

fully after use, as the material in

the tube may be hot due to trans-

fer of energy during operation. Wear gloves if necessary

or wait for the tube and material cool down.

• The IKA®milling tubes must always be closed during

operation. Switch off the instrument immediately if any

material leaks from the tube. Clean the instrument.

•

Observe the operating instructions of the milling tube.

• The temperature of the material for milling must not ex-

ceed 40 °C.

•

Only use tubes approved by IKA.

• Only process samples that will not react dangerously to

the extra energy produced through processing. This also

applies to any extra energy produced in other ways, e.g.

through light irradiation.

• Beware of the risk of flammable materials.

• Do not operate the instrument in explosive atmo-

spheres, with hazardous substances or under water.

• The instrument doesn’t start up again automatically fol-

lowing a cut in the power supply.

•

Safe operation is only guaranteed with the accessories

described in the ”Accessories” chapter.

• Socket must be earthed (protective ground contact).

• The instrument could only be disconnected from the

mains supply by pulling out the mains plug or the con-

nector plug.

• The socket for the mains cord must be easily accessible.

• The voltage stated on the name plate must correspond

to the mains voltage.

•

Protect the instrument and accessories from bumps

and impacts.

• The instrument can only be opened by experts.

Only process dry solid sample with

the device. Never use it for pro-

cessing liquid samples.

•

Read the operating instructions completely before

starting up and follow the safety instructions.

•

Keep the operating instructions in a place where they

can be accessed by everyone.

• Ensure that only trained staff work with the instrument.

• Follow the safety instructions, guidelines, occupational

health and safety and accident prevention regulations.

• The instrument must be supervised at all times when in

operation.

• Hearing protection must be worn when working with

the instrument in high speed.

Wear your personal protective

equipment in accordance with the

hazard category of the medium to

be processed. There may be:

- projectile parts

-

body parts, hair, clothing and jewelry getting caught.

•

Set up the instrument in a spacious area on an even,

stable, clean, non-slip, dry and fireproof surface.

• The feet of the instrument must be clean and undamaged.

• The instrument is not suitable for hand held operation.

• The instrument may heat up when in use.

•

Check the instrument and accessories for damage be-

fore each use. Do not use damaged components.

Please pay attention to avoiding

hand injury when operate the in-

strument.

•

Ensure that the milling tube is tightly closed.

•

Ensure that the milling tube is firmly attached to the

coupling connector on the drive unit prior to operating

the device.

• The instrument must only be operated with a milling

tube attached; without a milling tube the instrument

can’t be started.

• Before starting operation, the protective hood of the

device must be closed, otherwise the instrument can

not be started.

Safety Instructions

DANGER

DANGER

WARNING

DANGER

•

Use:

The Tube Mill control is a batch mill that allows for

both impact milling and cutting milling.

The milling tube closes airtight. This means that the loss

of ground material is equivalent to practically zero.

Impact milling:

For use with hard, brittle material, dried material or ma-

terial that is brittle because of cold (for example grain,

coffee, etc.). The granularity of the final product is de-

termined by the duration of the grinding, the level to

which the container is filled and the physical property of

the material being processed.

Correct use

Cutting milling:

For usage with soft, fibrous grinding material (for ex-

ample hay, paper, etc.).

In this case as well, the granularity of the final product is

determined by the duration of the grinding, the level to

which the container is filled and the physical property of

the material being processed.

Intended use: Tabletop device

15

The Tube Mill control is not suit-

able for grinding wet materials

with too much water. Otherwise,

the water may leak from the grinding tube and damage

the drive unit.

• Range of use (indoor use only):

- Laboratories - Schools

- Pharmacies - Universities

This equipment is suitable for use in all areas except:

- Residential areas

-

Areas that are connected directly to a low-voltage supply

network that also supplies residential areas.

• Unpacking:

- Please unpack the device carefully

- In the case of any damage a detailed report must be sent

immediately (post, rail or forwarder).

• Delivery scope:

IKA

®

Tube Mill control

:

-

IKA

®

Tube Mill control drive

- One MT 40 milling tube

- One MMT 40.1 multi-use milling tube package

- Coupling extractor

- Mains cable

- USB cable

- Operating instructions

- Warranty card.

Unpacking

IKA

®

Tube Mill 100 control

:

-

IKA

®

Tube Mill 100 control drive

- One MT 100 milling tube

- One MT 40 milling tube

- One MMT 40.1 multi-use milling tube package

- Coupling extractor

- Mains cable

- USB cable

- Operating instructions

- Warranty card.

WARNING

The safety of the user cannot be guaranteed:

- If the instrument is operated with accessories that are not

supplied or recommended by the manufacturer

- If the instrument is operated improperly contrary to the

manufacture’s specifications

- If the instrument or the printed circuit board are modified

by third parties.

Useful information

The Tube Mill control device can be used for a wide

range of applications. The list of grinding materials given

below is not complete. It is possible to expand the range

of applications further by means of grinding experiments

with corresponding grinding procedures and sample prep-

arations.

Impact milling:

The milling tube for the Tube Mill control instrument

with a beater can reduces soft, medium hard and brittle

materials with a Mohs’ hardness of up to 5. For greater

levels of hardness, the wear and tear on the pulverization

tool is very high and the plastic coupling can break.

Everything that is brittle, dry, and does not have a high fat

content can be ground. Following is a list of substances

that can be ground dry:

Wheat, barley, corn, malt, pectin, roasted coffee, nut-

shells, bones, ergot, compressed materials, peat, cellulose,

pharmaceutical, fertilizers, feed materials, spices, resin,

potash, seeds, salts, cinders, tablets.

The grinding material must be initially broken down into

pieces with max. diameter of 1 cm (feed granularity 10

mm, the size of a grain of corn is ideal). The total volume

of grinding material should not more than 40 ml.

Cutting milling:

The milling tube for the device can also crush bulky, elastic

fibrous and soft materials with high cellulose content. Fol-

lowing is a list of some materials that can be crushed:

Leaves, fibers, hops, cardboard, paper, hay, plastics, to-

bacco and roots.

The feed granularity should be no greater than 10 mm.

Note: Materials that are not listed should only be ground

in the Tube Mill control after consult IKA®application

support, especially if there is uncertainty about the dan-

ger of explosion (dust explosion as a result of electrostatic

charge).

Working with coolants:

Please follow the safety instructions.

Crushing causes the mill feed to heat up. This may not al-

ways be desirable as the mill feed can change when heat-

ed (e.g. increased oxidation, loss of moisture, evaporation

of volatile components, etc.).

It can be possible to dry crush mill feed which is viscous or

has a high fat content by embrittling using coolants.

16

The following table summarize the (NAMUR) commands.

Abbreviation used:

m = Numbering parameter (integer)

X = 4 Speed

NAMUR Commands Function Remark

IN_NAME Request designation.

Start the Remote control function.

After this command is sent to device,

“Remote” symbol is displayed, device

Keypad is not available except mains switch

is pressed.

RESET Switch to normal operation

Device Keypad is available again, and

"Remote" symbol disappear.

IN_PV_X

X=4

Read actual speed value

IN_SP_X

X=4

Read target value input

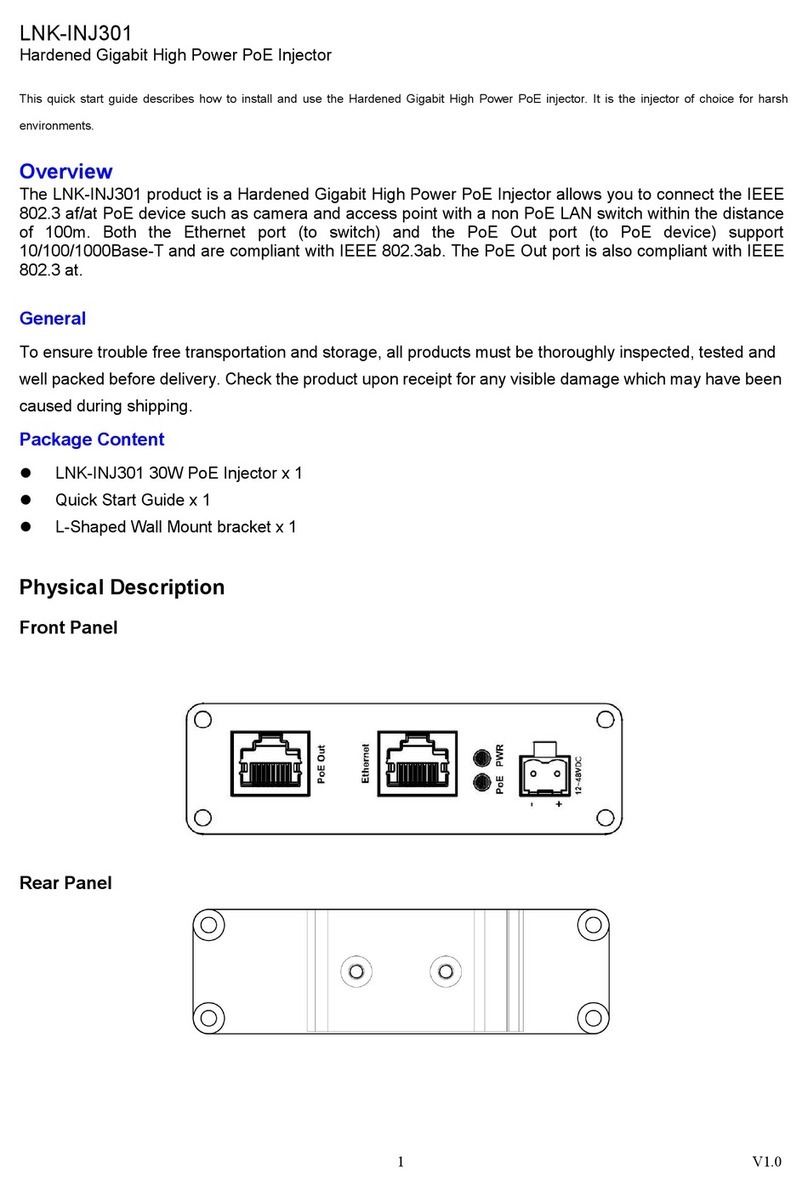

Remote control:

The instrument can be operated in “Remote” mode via

USB interface using labworldsoft

®

laboratory software. The

USB interface is located on the right side on the device and

can be connected to a PC using the supplied USB cable.

Note: Please note the system requirements as well as the

operating instructions and help section included within

the software.

USB interface:

The Universal Serial Bus (USB) is a serial bus for connect-

ing the device to the PC. Equipped with USB devices can

be connected to a PC during operation (hot plugging).

Connected devices and their properties are automatically

recognized. The USB interface can also be used to update

firmware.

USB device drivers:

First, download the latest driver for IKA®devices with USB

interface from:

http://www.ika.com/ika/lws/download/usb-driver.zip.

Install the driver by running the setup file. Then connect the

IKA

®

device through the USB data cable to the PC.

The data communication is via a virtual COM port.

Interfaces and outputs

Command syntax and format:

The following applies to the command set:

- Commands are generally sent from the computer (Mas-

ter) to the device (Slave).

-

The instrument sends only at the computer’s request.

Even fault indications cannot be sent spontaneously from

the instrument to the computer (automation system).

- Commands are transmitted in capital letters.

- Commands and parameters including successive parame-

ters are separated by at least one space (Code: hex 0x20).

- Each individual command (incl. parameters and data)

and each response are terminated with Blank CR LF

(Code: hex 0x20 hex 0x0d hex 0x20 hex 0x0A) and have

a maximum length of 80 characters.

- The decimal separator in a number is a dot (Code: hex 0x2E).

The above details correspond as far as possible to the rec-

ommendations of the NAMUR working party (NAMUR

recommendations for the design of electrical plug con-

nections for analogue and digital signal transmission on

individual items of laboratory control equipment, rev. 1.1).

The NAMUR commands and the additional specific IKA®

commands commissioning serve only as low level com-

mands for communication between the tube driver and

the PC. With a suitable terminal or communications pro-

gram these commands can be transmitted directly to the

tube driver. The IKA®software package, Labworldsoft®,

provides a convenient tool for controlling tube driver and

collecting data under MS Windows, and includes graphi-

cal entry features, for motor speed ramps for example.

Dry ice cooling (CO2):

First put the feed product into the milling tube and then

add about half a teaspoon of dry ice snow. Thoroughly

mix the dry ice with the mill feed.

Please note that the mill feed heats up again extremely

quickly during crushing (it may reach room temperature

again after approximate 30 seconds of grinding). You may

have to repeat the process several times if the product is

not adequately crushed after one cooling process.

17

OUT_SP_X m

X=4

Set target speed value, input: rpm

START_X

X=4

Switch on appliance remote function.

Start value function with setting.

IN_SOFTWARE

Request software ID, number, date and version

Commissioning

Pay attention to the ambient conditions listed in the

“Technical Data”.

Check whether the voltage given on the type plate cor-

responds to the available mains voltage.

The socket used must be earthed

(fitted with earth contact)

If these conditions are met, the unit is ready for operating

when the mains plug has been plugged in.

If these conditions are not met, safe operation is not guar-

anteed and the machine can be damaged.

Attach the milling tube by twisting it clockwise on to the

bayonet coupling of the drive. The tube is correctly at-

tached after a “click“. Then close the protective hood.

If above procedures are not followed, the tube mill will not

start.

Note: remove the milling tube by twisting it counterclock-

wise. After a “click”, the milling tube can be removed from

the bayonet coupling.

Switching on the instrument

)

Switch on the instrument with mains switch (A).

Ö

The device enter the standby status.

)

Press the power key (D).

ÖThe start-up screen will be displayed for several sec-

onds. This screen shows the unit designation and the

software version.

Standby

c

g

d

e

f

h

Symbols are shown on the screen, including the working

mode setting, the target speed, the maximum rotation

speed (rpm) and timer maximum value etc. of the instru-

ment.

Symbols Explanation:

c

Maximum speed value

dRotation symbol

eRotation speed setting

fOperation mode

g“Timer” maximum value of the device

h“Timer” symbol

Ö

Then, the system check screen will be displayed for few

seconds.

CLICK

18

The device is supplied with following factory setting:

Menu Settings:

mode A

max rpm 25000

timer max 03:00

language english

Working Setting:

target rpm 5000

timer sec off

int sec off

Factory setting

Resetting parameters to factory setting:

To reset the parameters to the factory settings, proceed

as following:

• Switch off the instrument with the mains switch (A).

• Press down the “Menu/Back” key (G) and “Timer” key

(E) simultaneously and re-start the instrument again.

• The unit is now reset to the factory settings.

Note: Above figures show specified values corresponding

to the default settings at delivery.

Setting menu parameters

Menu

Maximum rotation speed (max rpm) ……………………………………....

Timer maximum value (timer max) …………………………………….......

Operation mode mode A …………………………....

mode B ………………………........

program saved P1…………………

...

program saved P9…………………

Language english ………….………………....

ˎ……………………………....

deutsch …………………………...

français …………………………....

español …………………………....

italiano …………………………....

ࣜ 穢剳檺………………………….....

日本語………………………….....

25000 rpm

03:00 [mm:ss]

activated

-

-

-

-

activated

-

-

-

-

-

-

-

Factory setting

• Menu system:

ÖAfter the system check screen, the working screen appears

and the instrument is ready for operation.

19

• Basic guide to using the menu system:

Selecting a menu

)

Press the “Menu/Back” key (G) in working screen to

enter menu system.

)

Turn the Rotating/Pressing knob (B) to select the desired

menu option.

Editing a value in menu

)

Press the Rotating/Pressing knob

(B)

on selected

menu option.

ÖA markindicates that the selected menu option

could be editing.

)Turn the Rotating/Pressing knob

(B)

to edit the value.

)Press the Rotating/Pressing knob

(B)

again to finish

the editing.

)Press the “Menu/Back” key

(G)

again after editing a

menu option and back to working screen.

Note: The selected menu option is shown with a yellow

background on the display.

• Maximum rotation speed (max rpm):

The default setting “max rpm” is 25000 rpm in the in-

strument. User can change the setting in the range from

5000 rpm to 25000 rpm in the menu option.

The “max rpm” setting will be stored automatically

when operation is over or the device is switched off.

Note: During setting the “max rpm“ by rotating the “

Ro-

tating/Pressing” knob

(B)

, the setting magnitude is 100

rpm. In remote control mode via computer, setting mag-

nitude is 1 rpm.

• Timer maximum value (timer max):

The default “timer max” is 3 minutes in the instrument.

User could change the setting in the range from 5 sec-

onds to 3 minutes in menu option.

The “timer max” setting will be stored automatically

when operation is over or the device is switched off.

Note: During setting the “timer max“ by rotating the

“

Rotating/Pressing” knob

(B)

, the setting magnitude is

5 second. In remote control mode via computer, setting

magnitude is 1 second.

• Operation mode:

The instrument can be operated in mode A, B and P1 to

P9. The mode setting will be stored automatically when op-

eration is over or the instrument is switched off. User may

change the mode setting in the main menu if necessary.

Operation mode A:

In this mode, when current operation is over or the device is

switched off, all working settings will not be stored.

Operation mode B:

In this mode, when current operation is over or the device is

switched off, all menu and working settings will be stored.

Operation mode P1-P9:

In mode P1-P9, the user can set and save required param-

eters, (target speed, timer value and interval value) in pro-

gram. The parameter settings can only be changed in the

menu program. These settings can be used directly when

necessary.

• Language Preference:

The language can be set to: English, German, Chinese...

The languages setting will be stored automatically when

operation is over or the device is switched off. User can

change the language setting in the main menu if necessary.

Setting working parameters

•

Target speed (target rpm):

Set “target rpm” within “rpm max” range in the wor-

king screen by rotating the

Rotating/Pressing knob

(B)

.

Adjustment magnitude is 100 rpm. In remote control

mode via computer, adjusting magnitude is 1 rpm.

Setting “target rpm” in working screen

)Turn the “Rotating/Pressing” knob (B) to change the

value.

)Press “Rotating/Pressing” knob (B) to start working.

ÖRotation symbol ( ) indicates running.

•Timer function:

Set “Timer” within “timer max” range in the working screen

by rotating the “Rotating/Pressing”

knob (B)

. Adjustment

magnitude is 5 seconds. In remote control mode via com-

puter, adjusting magnitude is 1 second.

If the “Timer” is deactivated when the instrument is started,

the instrument will automatically count from 0 second to 3

minutes and then the unit will stop running.

Note: After the device runs 9 minutes (3 cycles when

the “Timer“ is deactivated), we recommend that the de-

vice to rest at least 1 minute for cooling. Otherwise, error

message may occur (see “Error codes“ section).

20

Warning messages

Warning 1: The protective hood is not closed.

Warning 2: The milling tube is not properly adapted.

Corrective action: Adapt the milling tube properly and close the protective hood, then start the test.

Error codes

The fault is shown by an error code on the display (C) as following if the error occurs.

Proceed as follows in such cases:

)

Switch the device off with mains switch (A).

)

Carry out corrective measures.

)

Restart the device.

Error code Cause Effect Solution

Error 3 • Inside temperature is too hot motor off

- Switch off the instrument and allow it to cool down.

- Restart the instrument.

Error 4 • Motor can’t running normal (can’t

start or not reach the target speed)

• Overload

motor off - Switch off the instrument.

- Check and reduce the grinding material.

- Reduce the grinding speed at the beginning.

- Restart the instrument.

Error 25

Error 26

Error 70

Error 71

• Electronic hardware failure motor off - Send the instrument for repair.

Error 86 • Voltage for electronically

commutated motors is too low

motor off - Switch off the instrument.

-

Check if voltage give on the type plate corresponds

to the mains voltage.

If the actions described fails to resolve the fault or another error code is displayed then take one of the following steps:

- Contact the service department.

- Send the instrument for repair, including a short description of the fault.

Setting “Timer” value (timer sec) in working screen:

)Press “Timer” key (E) to activate the timer setting in

the working screen.

)Turn the “Rotating/Pressing” knob (B) to change the

value.

)Press “Timer” key (E) again to complete the setting.

ÖCurrent values are stored.

•Interval function:

When set “Int” value with the “

Rotating/Pressing” knob

(B)

, the value can be set from 5 to 60 seconds where ad-

justment magnitude is 5 second.

Note: If both “Int” function and “Timer” function are

activated, the “Int” value should be less than “Timer”

value. Otherwise, the interval function will not work.

Setting “Int” timer (int sec) in working screen:

)

Press “Int” key (F) to activate the interval setting in the

working screen.

)Turn the “Rotating/Pressing” knob (B) to change the

value.

)Press “Int” key (F) again to complete the setting.

ÖCurrent values are stored.

21

Using the coupling extractor

Milling tube coupling broken:

The milling tube coupling may be broken when the

grinding material is too much or too hard.

Pull the broken coupling out from the drive unit:

cFit the coupling extractor in clockwise direction. The

coupling puller is properly attached to the coupling af-

ter a “click“.

d

Turn the coupling extractor in counterclockwise direction.

The broken coupling will be extracted out after a “click“.

CLICK

I

II

CLICK

III

c

d

Maintenance and cleaning

The instrument is maintenance-free. It is only subject to

the natural wear and tear of components and their statisti-

cal failure rate.

Cleaning:

Disconnect mains plug prior to

cleaning!

- Wear protective gloves when cleaning the devices.

-

Do not place electrical appliances into the cleaning

agents for cleaning purposes.

- Do not allow moisture to get into the appliance when

cleaning.

- Please consult IKA®before using any cleaning or decon-

tamination methods, other than those recommended here.

- The device must not be washed in a dishwasher.

- The protective hood is of polycarbonate and can be treat-

ed using commercially-available disinfectants. Avoid prod-

ucts that contain aldehydes, phenols, acetone or alcohol.

- It should be cleaned only by hand using a liquid disinfectant.

- The only cleaners or disinfectants that may be used are

those that:

- lie in the pH range 5 - 8,

- contain no corrosive alkalis, peroxides, chlorine com-

pounds, acids or brine.

- If rotator becomes contaminated with milled material,

clean it thoroughly with vacuum cleaner.

Only clean IKA®appliances using these IKA®approved

cleaning agents. To remove use:

Dirt Cleaning agent

Dyes isopropyl alcohol

(do not use for the protective hood)

Building materials

water containing detergent, Isopropanol

(do not use for the protective hood)

Cosmetics

Water containing detergent, Isopropa-

nol (do not use for the protective hood)

Food

Water containing detergent

Fuels

Water containing detergent

Other materials

Please consult IKA

®

After the device is used some time, the screw cap should

be cleaned as following:

cUnscrew the screw cap.

d

Disassemble the screw cap.

e

Clean the parts of the screw cap, e.g.

with vacuum

cleaner

.

After cleaning, the screw cap can be installed back to the

device in the reverse sequence.

Spare parts order:

When ordering spare parts, please give:

- Machine type.

- Serial number, see type plate.

- Item and designation of the spare part,

see www.ika.com, spare parts diagram and spare parts list.

-

software version.

Repair:

Please send instrument for repair only after it has

been cleaned and is free from any materials which

may constitute a health hazard.

For this you should request the “Decontamination Cer-

tificate” from IKA®, or use the download printout of it

from the IKA®website www.ika.com.

Return the instrument in its original packaging. Storage

packaging is not sucient. Also, please use suitable ship-

ping package material.

4

c

d

22

Technical data

Warranty

In accordance with IKA®warranty conditions, the war-

ranty period is 24 months. For claims under the warranty

please contact your local dealer. You may also send the

machine direct to our factory, enclosing the delivery in-

voice and giving reasons for the claim. You will be liable

for freight costs.

Tube Mill control Tube Mill 100 control

Operating voltage VAC 220–240

100–120

Frequency Hz 50 / 60

Power consumption, normal operation

W100

Power consumption, standby operation

W2

Power output

W80

Drive EC (Electronically Commutated) motor

Speed range rpm 5000–25000 ± 2 %

(infinitely adjustable, adjustment resolution 100 rpm)

Speed setting rotating / pressing knob

Speed display digital

Timer

5 seconds–3 minutes

Interval timer 5–60 Seconds

Timer display digital

Permissible ambient temperature °C + 5 to + 40

Permissible relative humidity %80

Protection to DIN EN 60529 IP 30

Contamination level 2

Overvoltage category II

Operation at a terrestrial altitude level

mmax. 2000

Dimensions (W x D x H)

mm 180 x 300 x 170 180 x 300 x 212

Dimensions (W x D x H) (Opening status)

mm 180 x 370 x 210 180 x 404 x 236

Weight kg 2.7 2.8

Subject to technical changes!

The warranty does not cover worn out parts, nor does

it apply to faults resulting from improper use, insucient

care or maintenance not carried out in accordance with

the instructions in this operating manual.

Accessories

Tube mill control

:

•

MT 40 Milling tube

•

MMT 40 Multi-use milling tube

• Labworldsoft

®

Tube mill 100 control

:

•

MT 100 Milling tube

•

MT 40 Milling tube

•

MMT 40 Multi-use milling tube

• Labworldsoft

®

See more accessories on www.ika.com.

This manual suits for next models

2

Table of contents

Other Imlab Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Beckman Coulter

Beckman Coulter Spinchron DLX instruction manual

CORNING

CORNING LSE 6709 instruction manual

Leica

Leica EM TXP operating manual

Hardy Diagnostics

Hardy Diagnostics QuickSlide AFB-PRO User's operation manual

PlexBio

PlexBio IntelliPlex IW100 user manual

MingTai

MingTai SUN18-III Operation manual