7

45

31

58

INSTALLERUSER

MAINTENANCE TECHNICIAN

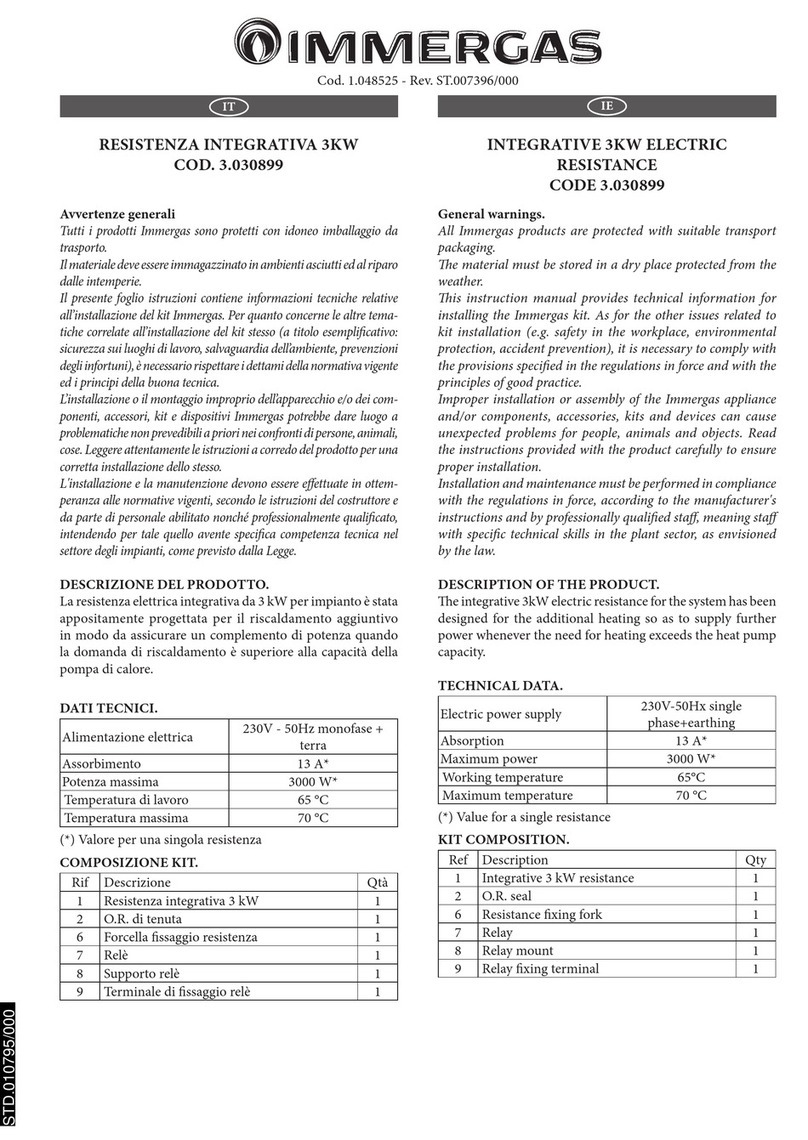

1.5 EXTERNAL PROBE OPTIONAL.

e boiler is designed for the application of the

Room ermostat (Fig. 1-5) which is available as

an optional kit. Refer to the relative instruction

sheet for positioning of the external probe.

e probe can be connected directly to the boiler

electrical system and allows the max. system

ow temperature to be automatically decreased

when the external temperature increases, in

order to adjust the heat supplied to the system

according to the change in external temperature.

e external probe always acts when connected

independently from the presence or type of room

thermostat used. e correlation between system

flow temperature and outdoor temperature

is determined by the position of the selector

switch on the boiler control panel according to

the curves shown in the diagram (Fig. 1-6). e

electric connection of the external probe must be

made on clamps 38 and 39 on the boiler P.C.B.

(Fig. 3-2).

1.6 VENTILATION OF THE ROOMS.

In the room in which the boiler is installed it is

necessary that at least as much air ows as that

requested for by normal combustion of the gas

and ventilation of the room. Natural air ow must

take place directly through:

- permanent openings in the walls of the room

to be ventilated that lead towards the outside;

- ventilation pipes, individual or branched type.

e air used for ventilation must be withdrawn

directly from outside, in an area away from

sources of pollution. Natural air flow is also

allowed indirectly by air intake from adjoining

rooms. For further information relative to

ventilation of the rooms follow that indicated

by the standards in force and the following

modications and integrations.

Evacuation of foul air. In the rooms where

the gas appliances are installed it may also be

necessary, as well as the intake of combustion

agent air, to evacuate foul air, with consequent

intake of a further equal amount of clean air. is

must be realised respecting the provisions of the

technical regulations in force.

1.7 FLUE DUCTS.

e gas appliances with attachment for the ue

gas discharge pipe must have direct connection

to chimneys or safely ecient ues.

The combustion products can be discharged

directly outside only if these are missing, as long

as the standard regulations for the ue terminal

are respected as well as the existing laws.

Connection to chimneys or flues. The

connection of the appliances to a chimney or

ue takes place by means of ue ducts.

In the event of ttings with pre-existing ues, these

must be perfectly clean because the detachment

of any waste from the walls during functioning,

could block the passage of ue gases, thus causing

extremely dangerous situations for the user.

e ue ducts must be connected to the chimney

or ue in the same room in which the appliance

is installed or, at most, in the adjoining room and

must comply with the requirements indicated by

the regulation.

1.8 FLUES/CHIMNEYS.

For the appliances with natural draught

individual chimneys and branched flues can

be used.

Individual chimneys. e individual ues must

be dimensioned with respect to the standard

in force.

Branched ues. In buildings with lots of oors,

branched flues can be used for the natural

draught evacuation of combustion products. New

ues must be designed following the calculation

method and provisions of the regulation.

Chimney caps. e chimney cap is a device

positioned on the top of an individual chimney

or branched collective ue. is device promotes

the dispersion of combustion products, even in

adverse weather conditions, and prevents the

deposit of foreign bodies.

It must satisfy the requisites set forth in the

relative regulation.

e outlet quota, corresponding to the top of the

chimney/ue, independently of any caps, must

be out of the “backow area”, in order to prevent

the formation of counter-pressures that impede

the free discharge of the combustion products

into the atmosphere. It is therefore necessary

to use the minimum heights indicated in the

gures stated in the regulation, depending on

the slope of the roof.

Direct exhaust outside. e natural draught

appliances, envisioned to be connected to a

chimney or a ue, can discharge the combustion

products directly to the outside, through a

pipe passing through the perimeter walls of

the building. In this case discharge takes place

through an exhaust ue, which is connected to

a draught terminal at the outside.

Exhaust flue. The exhaust flue must be in

compliance with the same requisites listed for

the ue ducts, with further provisions stated in

the regulation in force.

Positioning the draught terminals. e draught

terminals must:

- be installed on external perimeter walls of the

building;

- be positioned according to the minimum

distances specified in current technical

standards.

Fume exhaust of forced draught appliances

in closed open-top environments. In spaces

closed on all sides with open tops (ventilation

pits, courtyards etc.), direct flue gas exhaust

is allowed for natural or forced draught gas

appliances with a heating power range from 4 to

35 kW, provided the conditions as per the current

technical standards are respected.

Important: it is prohibited to put the fumes

exhaust control device out of order voluntarily.

Every piece of this device must be replaced using

original spare parts if they have deteriorated. In

the case of repeated interventions of the fumes

exhaust control device, check the fumes exhaust

ue and the ventilation of the room in which the

boiler is located.

Fig. 1-5 Fig. 1-6

Position of the central heating

temperature user adjustment