3

INDEX

How to use the instruction book.................................................................4

Foreword ..................................................................................................4

General recommendations...........................................................................4

Case cleaning .................................................................................................5

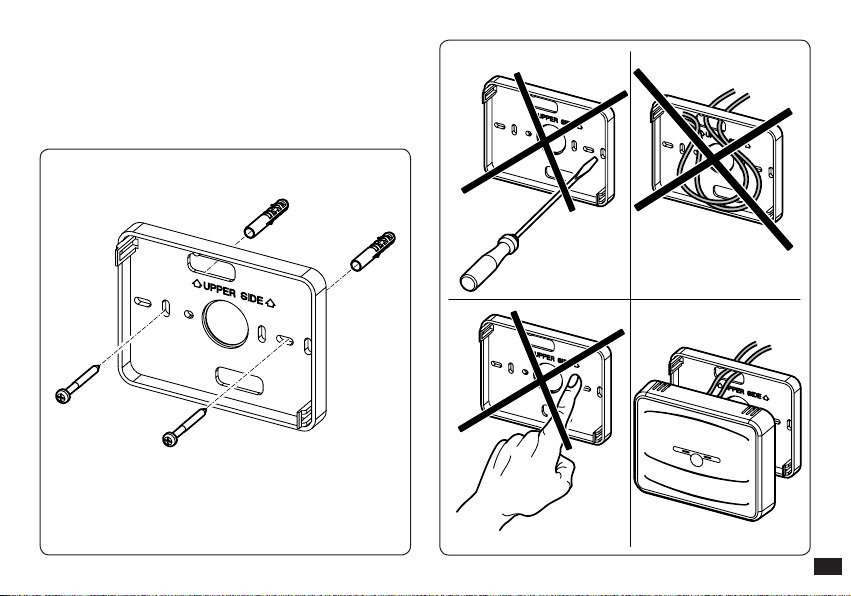

1. Installation..............................................................................................6

1.1 Installation recommendations.................................................6

1.2 Installation operations..............................................................6

2. Description of Controls......................................................................11

2.1 Description of reception Base in radio frequency...............11

2.2 Base Signals. .............................................................................11

2.3 No communication between the Base and CARV2..............12

2.4 CARV2 description. ..................................................................13

3. Description of display.........................................................................14

3.1 Back-lighting............................................................................15

4. Start-up.................................................................................................16

4.1 Programming current day and time. ....................................16

4.2 Selection of functioning mode ..............................................16

5. Summer mode functions....................................................................19

5.1 DHW temperature setting......................................................19

5.2 DHW timer (for storage tank unit). .....................................19

6. Winter mode functions ......................................................................20

6.1 Manual functioning. ...............................................................20

6.2 Automatic functioning. ..........................................................21

6.3 Forced automatic functioning. ..............................................21

6.4 Boiler ow temperature..........................................................22

6.5 Room anti-freeze function.....................................................22

6.6 Functioning in winter mode with external temperature pro-

be. ..............................................................................................22

7. Cooling mode functions.....................................................................23

7.1 Manual functioning. ...............................................................23

7.2 Automatic functioning. ..........................................................24

7.3 Forced automatic functioning. ..............................................24

8. Information .........................................................................................25

9. Programming THE CARV2 .................................................................26

9.1 Setting comfort and economy room temperature...............26

9.2 Programming functioning time. ...........................................27

10. Diagnostics and errors........................................................................29

10.1 Diagnostics...............................................................................29

10.2 Reset errors...............................................................................29

10.3 Reset CARV2 remote control...................................................29

11. Special functions..................................................................................30

11.1 LANGUAGE (language selection). .......................................30

11.2 REGOLAZ (Management of regulation parameter). .........30

11.3 VACANZ (holiday program).................................................31

11.4 LEGION (anti-legionella function ). ....................................31

11.5 REMOTO (telephone control). .............................................31

11.6 CODE........................................................................................31

12. Functions protected by code (CODE)..............................................32

12.1 AMB (room probe - On / O or Modulating functioning

mode)........................................................................................32

12.2 RIDOTT (functioning in reduced mode)............................32

12.3 ANTIGL (anti-freeze level)....................................................33

12.4 ZONA (function not present on this model). .....................33

12.5 MANUTZ (programmed maintenance)..............................33

12.6

Association procedure in RF

....................................................33

12.7 RF disassociation procedure. .................................................33

12.8 Check the RF signal. ...............................................................34

13. CARV2 Base test procedure.................................................................34

14. Disabling the chrono-thermostat......................................................35

15. Replace the batteries ...........................................................................35

16. Technical characteristics.....................................................................36

16.1 Base CAR V2.............................................................................36

16.2 CAR

V2.......................................................................................36

16.3 Product specications.............................................................37

17. Factory setting .....................................................................................38

Page