IMO Precision Controls Jaguar VXS User manual

Safety at Work

It is the responsibility of the owner,

installer and user to ensure that the installa-

tion of the equipment and the way in which

it is operated and maintained complies with

the requirements of the Health & Safety at

Work Act in the United Kingdom and other

applicable legislation, regulations and

codes of practice in the UK or elsewhere.

Only qualified personnel should install this

equipment, after first reading and under-

standing the information in this publication.

The installation instructions should be

adhered to. Any question or doubt should

be referred to IMO Precision Controls Ltd.

Operational Safety

Users and operators of the equipment must

take all necessary precautions to prevent

damage to equipment and especially to pre-

vent the risk of injury to personnel working

on or near the motor and the driven equip-

ment.

The stop and start inputs should not be

relied upon alone to ensure the safety of

personnel. If a safety hazard could arise

from the unexpected starting of the motor,

an interlock mechanism should be provided

to prevent the motor from running except

when it is safe for it to do so.

Warnings, Cautions and Notes

‘WARNING’, ‘CAUTION’ and ‘NOTE’

paragraphs appear in the text of this instruc-

tion manual wherever they are applicable as

precautionary reminders to installers and

operators.

NOTE Notes call attention to information

that is especially significant in under-

standing and operating the equipment.

Documentation

Every effort has been made by IMO

Precision Controls Ltd to ensure that this

document accurately and completely repre-

sents the Jaguar VXS range of inverters at

the time of going to press. Information

with respect to installation is necessarily

generalised, and the supplier accepts no lia-

bility for contingencies over which he has

no control in respect of the selection, instal-

lation and/or operation of equipment.

IMPORTANT NOTICE

The software described in this User’s Guide

may not apply to earlier VXS inverters

lacking the suffix ‘-EN’.

WARNING

Denotes operating procedures and prac-

tices which, if not correctly followed and

strictly observed, may result in danger,

personal injury or loss of life.

CAUTION

Denotes operating procedures and prac-

tices which, if not correctly followed and

strictly observed, may result in damage to

or destruction of equipment.

Safety Precautions

In line with IMO’s policy of continuous improvement, the contents of this document are

subject to change without prior notice.

Copyright

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by

any means, electronic or mechanical including photocopying, recording, or by by any information

storage or retrieval system without the prior written permission of IMO Precision Controls Ltd.

© IMO Precision Controls Ltd 1996

Part number VXSMAN. Doc. ref. SWK VXS20-VXS400.

Issue IMO-3 Sept 1998

Safety Precautions Inside front cover

Warranty and Helplines Inside back cover

EMC and LVD Conformity Page 2

1 Inspection, Handling & Storage 2

1.1 Product Enquiries 2

1.2 Inspection 2

1.3 Storage Environment 2

1.4 Storage Precautions 2

1.5 Handling 2

2 Specifications 3

2.1 Output Ratings 3

2.2 Input Ratings 3

2.3 Output Frequency 3

2.4 Braking 3

2.5 General 3

3 Common Specifications 4

3.1 Control 4

3.2 Indication 5

3.3 Protection 5

3.4 Operating Environment 5

4 Mechanical Installation 6

4.1 Handling 6

4.2 Environment 6

4.3 Position and Materials 6

4.4 Cooling and Ventilation 6

4.5 Removable Covers and Keypad 7

4.6 Dimensions 7

5 Electrical Installation 10

5.1 Power Connection Block Diagrams 10

5.2 Power Circuits 11

5.3 Control Circuits 12

5.4 Terminals Functions List 14

5.5 Control Circuits and Terminals 15

6 Keypad Functions 16

6.1 Keypad 16

6.2 Keypad Procedures 16

7 Inverter Functions 21

7.1 Functions Data —Range, Units, 21

Resolution & Default

7.2 Descriptions of Functions 26

8 Troubleshooting 44

8.1 Electronic Protection 44

8.2 Trip Alarm Functions 44

8.3 Trip Alarm Codes 44

8.4 Troubleshooting Flow Diagrams 45

9 Braking 55

9.1 Introduction 55

9.2 Overhauling Loads 55

9.3 Calculations for Braking Resistors 56

9.4 Minimum Braking Resistor Values 56

9.5 Protection Circuits 57

10 EMC, RFI and Filters 58

10.1 Electromagnetic

Compatibility (EMC) 58

10.2 Single Phase RFI-FP Filter 60

10.3 Three Phase RFI-FP Filter 61

10.4 RF Ferrite Physical Data 62

11 Supplementary Data 62

11.1 Insulation Testing 62

11.2 Table of Cable Sizes and Maximum

Lengths 63

11.3 Table of Heat Losses 64

1

Contents

1.1 Product Enquiries

If at any time you have a difficulty or a ques-

tion regarding the inverter, please contact

IMO Precision Controls Ltd at the address

inside the back cover of this Manual. The

following information will be required:

(a) Inverter type (from the rating plate).

(b) Serial number (from the rating plate).

(c) Date of purchase.

(d) The nature of the problem — for instance,

the location and extent of damage, the point

which is unclear or the circumstances under

which a malfunction occurred.

1.2 Inspection

Immediately after unpacking the inverter,

please inspect as follows:

Check the rating plate on the side of the

inverter cover to ensure that the inverter speci-

fication corresponds to the order specification.

Inspect the inverter to determine whether the

unit has been damaged in transit. Look for

loose components and damage to any part of

the cover, side panels, mounting brackets or

other components.

1.3 Storage Environment

• Temperature -20oC to +65oC (-4oF to

+149oF) short-term during transport or

storage.

• Relative humidity 20% to 90% non-con-

densing.

• Avoid places where large variations in

temperature occur, even if the relative

humidity is within the specified limits.

Such places could cause condensation or

freezing and should be avoided.

• The inverter should not be placed in direct

sunlight. The surrounding atmosphere should

ideally be dry, free from dust, corrosive or

inflammable gases or vapours, oil mist,

steam, dripping water and vibration. A salt-

laden atmosphere is especially deleterious.

1.4 Storage Precautions

• Do not place the inverter directly onto the

floor. It should always be placed on a stand

or shelf.

• If the inverter is being stored in a less-than-

ideal environment, cover it with a plastic

sheet for protection.

• If there is a likelihood of humidity affecting

the inverter, place a desiccating agent (such

as silica gel) inside the inverter, and then

cover it with a plastic sheet for protection.

1.5 Handling

Be sure to take a firm grip of the chassis of

the unit when carrying the inverter.

2

CAUTION

Hold and lift the inverter by the

chassis/heatsink, not by the cover. The

cover is a protective shield only, and is not

intended for lifting and carrying. Lifting

the inverter by the cover or other front

parts may result in damage.

1 Inspection, Handling and Storage

EMC and LVD Conformity

IMO Jaguar VXS Inverters carrying the suffix -EN as part of their model number conform to EN 60

947-1:1992, Emissions to EN50081-1 and -2 and Immunity to EN50082-1 and -2, and therefore meet

Directive 89/336/EEC relating to Electromagnetic Compatibility. Additionally, they also comply

with DIN VDE 0160/1988 for Over Voltage Category II, Pollution Degree 2, and hence conform to

the protection requirements of Council Directive 73/23/EEC, Low Voltage Directive. Conformity

requires the VXS inverter to be wired and earthed in accordance with the installation instructions in

this User’s Guide and installed within a steel enclosure which satisfies the requirements of

Pollution Degree 2 and used in conjunction with an AC power supply which is recognised Over

Voltage Category II and has an earthed neutral point. Throughout this manual the -EN suffix has

been omitted for simplicity and for economy of space.

Earth terminals. Jaguar VXS… -EN inverters now carry the standard symbol

instead of the lettering ‘GND(PE)’.

2 Specifications

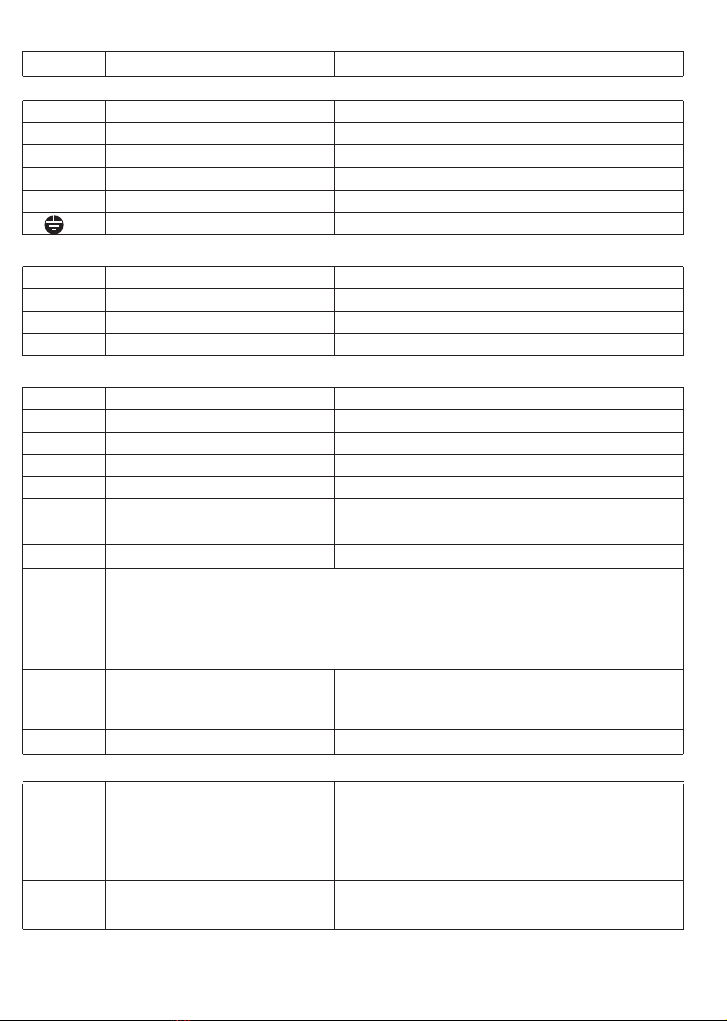

Inverter type VXS… 20-1 40-1 75-1 150-1 220-1 40-3 75-3 150-3 220-3 400-3

2.1 Output Ratings Single-phase Input Three-phase Input

Nominal applied motor kW 0.2 0.4/ 0.75 1.5 2.2 0.4/ 0.75 1.5 2.2 4.0

0.55 0.55

Rated capacity* kVA 0.6 1.2 2.0 3.2 4.4 1.2 1.8 2.7 4.0 6.5

Voltage V 0V to VL

Frequency Hz 0.2Hz to 400Hz

Rated Low PWM freq. A 1.5 3.0 5.0 8.0 11.0 1.6 2.5 3.7 5.5 9.0

current High PWM freq. A 1.3 2.5 4.0 7.0 10.0 1.4 2.1 3.7 5.3 8.7

Overload capability 150% of rated current for 1 minute

200% of rated current for 0.5s

2.2 Input Ratings Single-phase Input Three-phase Input

Rated current (rms) A 2.95 4.1 7.2 14 20 1.3 2.2 4.3 6.0 9.8

Min. supply capacity kVA 0.7 1.2 1.8 3.2 4.5 0.7 1.2 2.2 3.1 5.0

MCB rating with DC reactor A6 6 101020 6 6 6 1010

without DC reactor A 6 10 16 20 32 6 6 10 16 16

Fuse rating with DC reactor A1010203240 6 6 101020

without DC reactor A1010203240 6 6 101020

Phase; Voltage VL; Frequency 1-ph; 200/240V; 50/60Hz 3-ph; 380/415V; 50/60Hz

Voltage +10% to -10% +10% to -15%

Variations Imbalance — Max. 3% of line to line voltage

Frequency +5% to -5%

2.3 Output Frequency Single-phase Input Three-phase Input

Max. frequency Hz 0.2Hz to 400Hz

Base freq. setting range Hz 15Hz to 400Hz

Starting freq. setting range Hz 0.2Hz, 1Hz to 60Hz (minimum unit 1Hz)

Carrier freq. setting range kHz 0.75kHz, 1kHz to 15.6kHz (minimum unit 1kHz)

Accuracy (stability) Analog ±0.2% of Maximum O/P Frequency (25oC ±10oC)

Digital ±0.01% of Maximum O/P Frequency (-10oC to +50oC)

Analog 1/3000 of Max. O/P Frequency

eg 0.2Hz if max. is 60Hz; 0.4Hz if max. is 120Hz, etc

Setting resolution Digital 0.01Hz up to 99.99Hz output frequency and

0.1Hz from 100Hz output frequency upwards

2.4 Braking Single-phase Input Three-phase Input

Braking torque without resistor ≥100% ≥70% ≥40% ≥100% ≥50%

with resistor —≥150% ≥100% ≥150% ≥100%

Starting frequency: 0.2Hz to 60Hz

DC Injection Braking Braking time: 0.01s to 30s

Braking level: 0 to 100% of rated current

2.5 General Single-phase Input Three-phase Input

Heat loss Please refer to data on page 64

Enclosure IP40, all models (side covers in place)

Cooling method Convection Fan-assisted Convection Fan-assisted

Mass kg 1.1 1.6 1.7 2.7 2.8 1.8 1.8 2.7 2.7 3.2

* At 230V single phase or 415V three phase. 3

Control features PWM Sine-weighted PWM output voltage control with dead-time compensation.

Ultra-low acoustic noise realised by high-frequency carrier wave.

Torque Torque Vector control or manual torque boost with slip compensation.

Auto-tune Auto tuning function as standard. Enables automatic calculation of the

total load values of %R and %X.

Operation Key Pad RUN, STOP.

facilities External FWD, REV and coast-to-stop BX. External fault trip THR. Alarm/trip

signal inputs reset RST. Two- or three-wire RUN/STOP control. External selection of

V/f ratio, Accel./Decel., Torque Boost and Thermal Overload for 2nd motor.

Preset speeds Seven preset speeds selection X1, X2, X3; 8 additional preset speeds, X4.

Speed Key Pad Raise and lower speed, ∧and ∨ keys.

reference Potentiometer 1kΩ, 1W external control.

Analog I/P 0 to +5V DC, 0 to +10V DC and 4-20mA DC.

Digital I/P ‘Motorised pot.’, or 7 or 15 preset speeds.

Serial communications RS485 optional.

Voltage-dip ride-through VXS inverters can be operated continuously when the supply voltage is

≥165V (1-ph) or ≥310V (3-ph). Operating time if <165V (1-ph) or

<310V (3-ph) = 15ms. Smooth recovery selectable.

Run status Digital O/P RUN, FDT, FAR, LU, TL, IP (1) selectable outputs at terminal Y1E.

signals Analog O/P At terminal FMA, the following status signals are selectable:

O/P frequency, O/P current, O/P torque %, load factor %.

Pulse O/P At terminal FMP, O/P frequency multiplying factor adjustable from 10

to 100.

Accel/Decel Time 0.01 to 3600s. There are two independently-adjustable sets of accelera-

tion and deceleration times.

Characteristic Choice of linear or two types of S-curve accel/decel pattern.

Voltage/Frequency V/f Automatic AVR control of V/f characteristic at base frequency.

Output voltage at base frequency adjustable from 80V to 240V, 1-ph;

160V to 480V, 3-ph. Base frequency is selectable for two motors.

Frequency Limiter Output frequency can be held within selectable high and low limits.

Bias Analog frequency reference can be biased from -400Hz to +400Hz, in

steps of 1Hz.

Gain An adjustable gain can be applied to the analog frequency reference,

range to 250%.

Skip-frequency Three preset skip (jump) frequencies, 0 to 400Hz in steps of 1Hz.

Bandwidth (hysteresis) for jump frequencies, 0 to 30Hz in steps of 1Hz.

Slip compensation Selectable compensation to maintain speed when load torque changes.

Auto-restart Four selectable modes of operation.

Torque boost Auto Boost adjusts automatically according to the calculated load torque

value.

Manual 31 patterns selectable as follows:

Squared torque characteristic; Proportional torque characteristic;

Weak linear boost… adjustable in 28 steps to… strong linear boost.

4

3 Common Specifications

(1) FDT = Frequency detected; FAR = ‘At speed’ window; LU = Undervoltage protection trip operated; TL =

Inverter at torque limit; IP = Inverter auto-restarted after restoration of I/P power following momentary loss.

3.1 Control

Torque Starting 150%+ at 1Hz. With Torque Vector control, 200%+ at 3Hz.

boost (contin.) Limit When the motor torque reaches a preset level, the torque limit function

automatically controls the output frequency to prevent the inverter from

tripping due to an overload, if selected.

2nd motor operation The following functions are provided for the control of a 2nd motor:

Rated current 2; Base frequency 2; Torque boost 2; Acceleration time

2; Deceleration time 2; Electronic thermal overload relay 2.

3.2 Indication

Operating mode The following operating parameters can be selected to view:

Output frequency; Output current; Output voltage;

Motor synchronous speed (rpm); Line speed (m/min).

Programming mode LED display: Function number and data (refer to pages 18 to 20).

Trip mode LED display: cause of trip. Refer to Function 29, page 32.

3.3 Protection

Supply system surge V Protection to the following level: 1.2 x 50µs, 7kV peak.

Overload trip Selectable electronic thermal overload relay protecting the power output

IGBTs.

Overvoltage trip Detection of overvoltage in the DC bus circuit at the following levels:

Single phase inverters: 400V DC. Three phase inverters: 800V DC.

Undervoltage trip Detection of undervoltage in the DC bus circuit at the following levels:

Single phase inverters: 200V DC. Three phase inverters: 400V DC.

Overtemperature trip Temperature detection of inverter hardware.

Output short circuit trip Inverter output circuit, factory-set short circuit protection.

Earth (ground) fault trip Inverter output circuit, factory-set earth fault protection.

Motor thermal O/L trip Internal electronic thermal overload, user-selectable for application.

The second unit of this function is available for a 2nd motor.

Stall prevention Prevents the inverter tripping on overcurrent when the output current

exceeds a preset limiting level during acceleration, deceleration, or at

steady speed by freezing or reducing the output frequency.

Alarm output Changeover contacts operate when a protective function is activated.

Rating: 48V DC, 0.3A.

Alarm reset Alarm cancelled by either RESET keypad key or terminal RST.

Alarm history The last four alarms are recorded and can be viewed. Refer to

Function 29, page 32.

3.4 Operating Environment

Altitude Derate the inverter if installed above 1000m (3280ft).

Location The inverter is designed for installation in a steel enclosure.

Do not install the inverter in a dusty location or expose to corrosive

gases, oil or water, or direct sunlight.

Ambient temperature -10oC to +50oC (+14oF to +122oF). If ambient temperature exceeds

40oC (104oF), remove inverter side covers.

Ambient humidity 20% to 90% non-condensing.

Vibration 5.9m/s2(0.6G) or less.

5

4.1 Handling

4.2 Environment

• The inverter should be installed in an ade-

quately-ventilated, steel enclosure.

• The inverter is designed to operate at full

rating at an altitude not above 1000m

(3280 ft). Derate if installed above this.

Install the inverter in a location that meets the

following requirements:

• Ambient temperature between -10oC and

+50oC (+14oF to +122oF).

• If the ambient maximum temperature

exceeds 40oC (104oF), remove the venti-

lation covers located one on either side to

allow increased air flow.

For other operating environment specifica-

tions, refer to Section 3.4, page 5.

4.3 Position and Materials

• Position the inverter vertically so that the

inscriptions on the keypad panel are the

right way up.

• Bolt the inverter firmly to a rigid structure.

• The material of the mounting panel should

be able to tolerate the temperature attain-

able by the inverter heatsink, normally

90oC (194oF).

• The fixing bolts should be used with nuts

or washers that will resist vibration.

•Do not overtighten the fixing bolts.

4.4 Cooling and Ventilation

For inverter heat losses refer to page 64.

Observe the minimum clearances shown in the

illustration below.

The inverter should be installed in an enclo-

sure. The minimum clearances to adjacent

equipment must be allowed.

If two or more inverters are to be installed in

6

4 Mechanical Installation

CAUTION

Hold and lift the inverter by the

chassis/heatsink, not by the cover. The

cover is a protective shield only, and is not

intended for lifting and carrying. Lifting

the inverter by the cover or other front

parts may result in damage. 50

Minimum clearances (mm) from the

inverter to any other equipment.

120

120

50

50

50mm

minimum

between

inverters

Inverter(s) mounted on

deflector plate to nullify

the effect of other heat

source(s).

Ventilation should take

account of all other

heat-producing

equipment.

Ventilation should take

account of all other

heat-producing

equipment.

Inverter

the same enclosure, they should ideally be

side by side at a minimum spacing of 50mm.

If an inverter is to be mounted above heat-pro-

ducing equipment of any type, precautions

must be taken to ensure that the heat generated

by the lower unit does not affect the upper. A

deflector plate may be fitted below the invert-

er to nullify the heating effect, as illustrated

on the previous page.

4.5 Removable Covers and Keypad

Front cover

It is not necessary to remove the inverter front

cover for cooling. It should be left in place,

except when wiring up, for safety.

Removable side covers

Removable covers are fitted to the sides of the

inverter. Normally these should be left in

place. If the ambient temperature of the

installation is likely to exceed 40oC, these

covers should be removed.

The temperature within an enclosure should

not exceed 50oC under any circumstances.

Removable keypad

The keypad can be detached from the front

cover and mounted remotely (max. distance

5m).

Two keypad retaining screws can be released

from the back when the front cover is

removed.

A 2m screened connector cable with fitted ter-

minations is available.

7

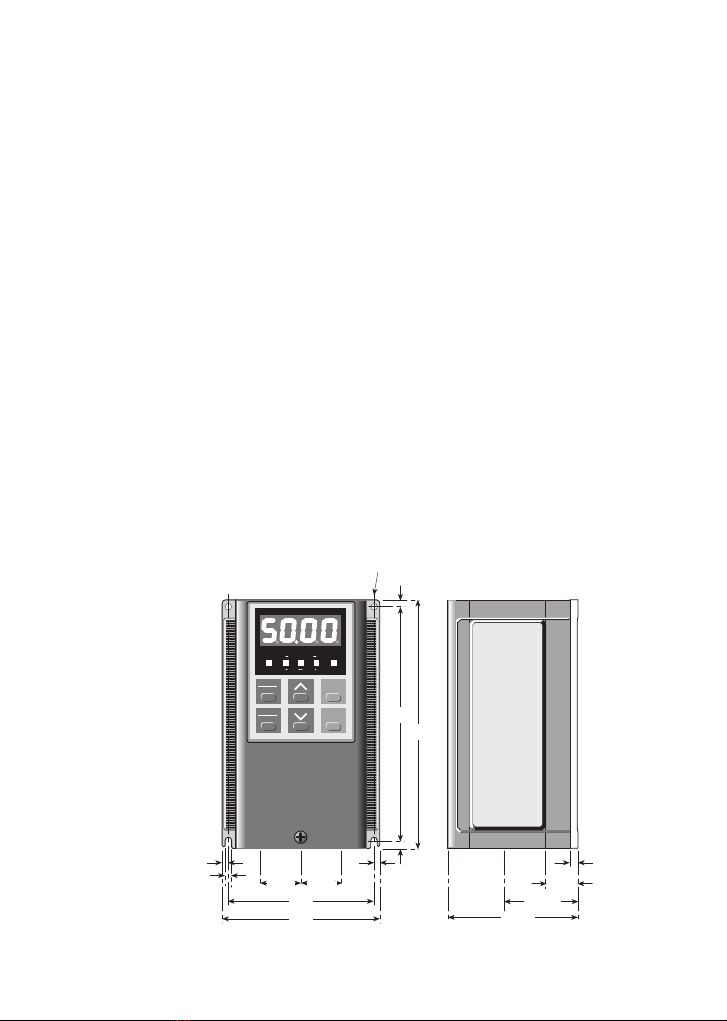

VXS20-1 (Single Phase)

PANEL

CONTROL PRG MODE RUN

Hz A V

r/min m/min

PRG

RESET RUN

FUNC

DATA STOP

*Centrelines of 3 cable entry holes, 18mm dia.

22.5 22.5

93

105

5

666

6

138

150

5

80 45.5

** * *

Removable

side-cover

17

Dimensions in mm

2 holes, 5mm

4.6 Dimensions

8

VXS40-1 and VXS75-1 (Single Phase)

VXS40-3 and VXS75-3 (Three Phase)

PANEL

CONTROL PRG MODE RUN

Hz A V

r/min m/min

PRG

RESET RUN

FUNC

DATA STOP

*Centrelines of 3 cable entry holes, 22mm dia.

30 30

128

140

5

666

6

Dimensions in mm

138

150

2 holes, 5mm

46

6

109 75

*** *

Removable

side-cover

PANEL

CONTROL PRG MODE RUN

Hz A V

r/min m/min

PRG

RESET RUN

FUNC

DATA STOP

30 30

188

200

5

666

6

Dimensions in mm

138

150

71 6

100

134

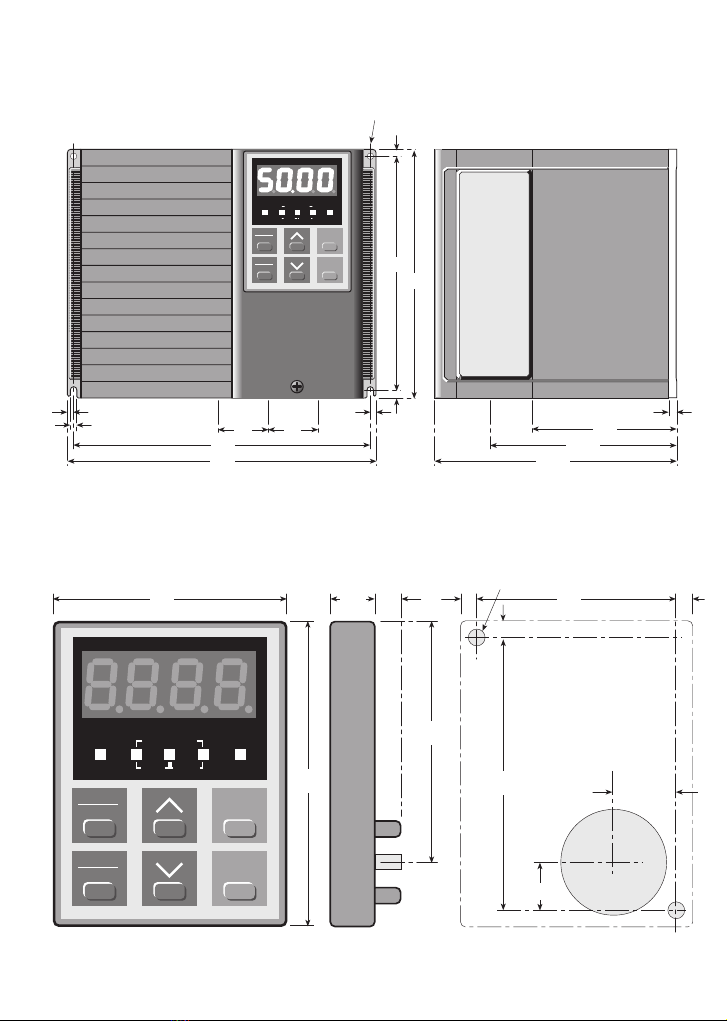

VXS150-1 and VXS220-1 (Single Phase)

VXS150-3 and VXS220-3 (Three Phase)

*Centrelines of 3 cable entry holes, 22mm dia.

*** *

2 holes, 5mm

Removable

side-cover

4.6 Dimensions continued

9

VXS400-3 (Three Phase)

PANEL

CONTROL PRG MODE RUN

Hz A V

r/min m/min

PRG

RESET RUN

FUNC

DATA STOP

30 30

188

200

5

666

6

Dimensions in mm

138

150

86 6

115

149

*Centrelines of 3 cable entry holes, 22mm dia.

*** *

2 holes, 5mm

Removable

side-cover

Keypad and Drilling Pattern for Remote Mounting Dimensions in mm

PANEL

CONTROL PRG MODE RUN

Hz A V

r/min m/min

PRG

RESET RUN

FUNC

DATA STOP

65

85

12.3 7.9

67.5

5 55 5

5

75

12.5 ±0.5

17.5 ±0.5

dia 30

2 holes,

dia 3.5

4.6 Dimensions continued

10

5 Electrical Installation

WARNING

ELECTRICAL SHOCK HAZARD

Do not touch any electrical parts of the

inverter when the power supply is connect-

ed, even if the inverter output is at STOP.

After the power supply has been discon-

nected, the built-in smoothing capacitor

will hold a residual charge. It takes up to

10 minutes for the capacitor to discharge

completely. To avoid danger, wait until the

charge indicator LED is extinguished.

WARNING — SAFETY EARTHING

The inverter chassis, motor base and

equipment enclosure structure should be

earthed in accordance with the national

and local safety specifications in force.

CAUTION

Do not connect any supply voltage that

exceeds the standard voltages and varia-

tions specified on page 3, or the inverter

will be damaged and the Warranty will be

invalidated.

5.1 Power Connection Block Diagrams

These diagrams are not suitable for Electromagnetic Compatibility (EMC), refer to page 58.

For the Table of Cable Sizes and Maximum Lengths, refer to page 63.

L

N

Jaguar

VXS

Inverter

Input

contactor

U

V

W

E

RF

FILTER

(Footprint

type FP)

HRC

Fuse

or MCB

FERRITE

RING

(Two

turns)

Keep distance (and conductors)

between inverter and motor

cable entry as short as possible.

Steel or aluminium Back Plate

Line Load

M

L

N

Link

F

LK

E

Remove paint at

fixing points

Jaguar

VXS

Inverter

Input

contactor

U

V

W

E

RF

FILTER

(Footprint

type FP)

HRC

Fuse

or MCB

FERRITE

RING

(Two

turns)

Keep distance (and conductors)

between inverter and motor

cable entry as short as possible.

Steel or aluminium Back Plate

Line Load

M

L1

Link

E

Remove paint at

fixing points

L2

L3

L1

L2

L3

240V 50/60Hz Single-phase

415V 50/60Hz Three-phase

5.2 Power Circuits

Access to Terminals

Remove the front cover by releasing the single

captive screw near the lower edge of the

cover. Press firmly inwards on the sides of

the cover near the lower edge and lift it away.

Power terminals and control terminals are

now accessible from the front.

Power Input/Output Terminal Blocks

Power Input Circuit

It is essential that the incoming supply cir-

cuit to the inverter is properly protected

against short-circuit and earth faults.

The alternatives are a suitably-rated fused

contactor, MCB or RCD to ensure that the line

and neutral (or all three phases) are operated

simultaneously.

For ratings refer to pages 3 or 63.

Power Output Circuit

Connect a three-phase squirrel-cage motor to

the output terminals U, V, W in the correct

sequence, preferably using screened or

armoured cable. If the operational commands

FWD and REV do not match the desired

direction of motor rotation, interchange any

two of the U, V, W connections. It is not nec-

essary to change the power input connections.

The motor circuit is protected by the inverter

software against overload provided that

Functions 15 & 16 (and Functions 66 & 67 if

applicable) are correctly set. The inverter

automatically protects the power output circuit

against short circuit and earth faults.

The installation of any type of automatic or

semi-automatic switchgear in the inverter out-

put circuit is not recommended (see below)

except for changeover switching when two

motors are supplied from the one inverter.

Power Output Circuit Isolation

An isolator may be installed in the inverter

output circuit for reasons of operational safe-

ty. Auxiliary contacts (early break, late

make), should interface with the inverter con-

trol terminals. On no account should the

isolator be used to control the start/stop

operation of the motor. Consult IMO

Precision Controls Ltd if in any doubt.

11

Single phase inverters VXS40-1 to 220-1

L N P1 (+) DB U V W

L1 L2 L3 P1 (+) DB U V W

Three phase inverters, all sizes

—

Single phase inverter VXS20-1

L N P1 (+) — U V W—

CAUTION

Connect the power supply to the power ter-

minals L, N (1-phase) or L1, L2, L3 (3-

phase), NOT to the output terminals U, V,

W, or to the control terminals.

CAUTION

Do not overtighten terminal screws.

CAUTION

Do not install filter capacitors, power factor

correction capacitors, a surge absorber or

any form of automatic switchgear on the

output side of the inverter.

CAUTION

Motor thermal overload protection is desir-

able. Use either the inverter electronic

overload protection, or a motor thermistor

and thermistor relay.

DC Bus Reactor

NOTE If a reactor is not fitted to the inverter, it

is essential that terminals (+) and P1 remain

linked.

IMO Precision Controls Ltd recommend the

use of a DC reactor to improve the overall

power factor and to reduce the harmonics

reflected into the supply network.

Braking Terminals

Jaguar VXS inverters (except VXS20-1) are

equipped with an internal resistor to apply

dynamic braking as standard. If additional

braking torque is required, an external braking

resistor can be connected to terminals (+) and

DB.

A thermal overload sensor for the resistor is

essential to protect the inverter. The ther-

mal protection should be arranged to trip

the main power supply switch and/or termi-

nal THR, page 15. For further information,

refer to Chapter 9.

5.3 Control Circuits

FWD/REV Input Terminals

At the time of shipment, terminals FWD-P24

are connected by a solid link and Function 02

is set to the default value 0. This puts the

inverter in keypad operating mode, in which

the inverter is operated by the RUN and STOP

keys.

NOTE Whilst terminal FWD or REV is

connected to terminal P24, Function 02

cannot be changed.

To reverse the direction of motor rotation in key-

pad mode, link terminal P24 to REV instead of

FWD as shown in the diagram above.

Control Terminal Block — all models

12

30A

30C

30B

CMC

Y1E

FMP

FMA

X1

BX

X2

RST

X3

C1

X4

13

REV

12

FWD

11

THR

CM

P24

CM

P24

Jaguar

VXS

Terminals linked

(as shipped).

Field

Links changed

to reverse motor

rotation.

Jaguar

VXS

REV

Field

FWD

P24

THR

REV

FWD

P24

THR

WARNING

The RUN and STOP inputs, whether at the

keypad or terminals FWD or REV, should

not be relied upon to ensure the safety of

personnel. If a safety hazard could arise

from the unexpected starting of the motor,

an interlock mechanism should be provided

to prevent the motor from starting except

when it is safe for it to do so.

(+) DB

Jaguar VXS

Inverter

Connections for

an external

braking resistor.

External

braking

resistor

WARNING

The STOP pushbutton on the keypad is

effective ONLY when Function 02 = 0. If

Function 02 is set to 1, an external

RUN/STOP control circuit may be required

at terminals FWD or REV for safety. The

factory-fitted link, shown below, should be

replaced by an external control contact.

Jaguar VXS

Inverter

(+) P1

Connections for a

DC bus reactor.

Remove this link

before connecting

the reactor DC reactor

if required

13

Control Circuits

Use 0.75mm2wiring. All control circuits

should be screened as shown in the illustration

in the adjacent column.

NOTE If control signals originate from a

process controller, it is recommended that

the screening should be terminated at the

source end rather than at the inverter as

shown in all illustrations in this manual.

Control wiring should be installed at least

300mm distant from any power system cables,

and if the two types of conductors must cross

they should be arranged as nearly as possible

at right angles to each other.

The function of each control terminal is given

in the table on the following page.

Control Input Circuits

Contactors or switch contacts should be care-

fully selected for high reliability and absence

of closing defects.

Control Output Circuit

Screening of Control Circuits

Control screening should be connected to a

0V common terminal at the inverter end only,

as shown below. If an external process con-

troller or PLC is used, it is recommended that

the screening should be connected at the end

remote from the inverter.

Suppression of Control Circuits

Sudden changes of flux in the operating coils

of relays and magnetic contactors induce high

transient EMFs which may cause ‘noise’ on

the control circuits, resulting in possible mal-

function of internal or external circuits. It is

advisable to suppress these coils in the manner

shown below.

Y1E

Control output circuit Y1E.

CM

CMC

RC

Jaguar

VXS

Field

+24V DC

from internal

source P24,

or external

(PLC etc).

Output from Y1E —

If internal supply from

P24, connect to

Inverter terminal CM.

If external supply (eg

PLC), connect to PLC

common terminal.

P24

FWD etc

General control input circuit.

24V to 27V DC

power supply

6mA max

CM

Jaguar

VXS

Field

FWD

P24

Screening of external control circuits.

13

12

11

Potentiometer

1kΩ, 1W

Field

contact

CM

C1

Surge suppression for relay and

contactor operating coils.

+

RC

-

CC

C

R

D

D = flywheel diode

RC = relay coil

R = 100Ω, C= 0.1µf

CC = contactor coil

C= capacitor

R= resistor

Typically,

ñ

14

Terminal Terminal Function Description

Power Circuits

L, N Power supply input to inverter Single phase AC power supply.

L1, L2, L3 Power supply input to inverter Three phase AC power supply.

U, V, W Power output to 3-phase motor

(+), P1 DC reactor Optional. Improves p.f. and reduces harmonics.

(+), DB External dynamic braking resistor Optional (DB not available for VXS20-1).

Earth terminal WARNING! Inverter must be earthed.

Frequency Input Reference

11 Common 0V For terminals 12, 13, C1 and FMA.

12 Reference input voltage 0 to +10V DC = 0Hz to max. freq. Z = 22kΩ.

13 Pot. (1kΩ, 1W) power supply +10V DC power supply; max output 10mA.

C1 Reference input current 4 to 20mA DC = 0Hz to max. freq. Z = 250Ω.

Control Inputs

FWD RUN/STOP command — forward -P24 closed = RUN forward; open = decel. & stop.

REV RUN/STOP command — reverse -P24 closed = RUN reverse; open = decel. & stop.

BX Coast-to-stop command -P24 closed = coast to stop.

THR External fault/alarm trip command -P24 open = OH2 trip and coast.

RST Reset inverter after protective trip -P24 closed momentarily (>0.1s) = reset.

X1, X2 ‘Motorised pot.’ X1-P24 closed = accel. time 1 (Function 06).

X2-P24 open = decel. time 1 (Function 07).

X1, X2, X3 Preset frequency select Terminals enable 7 different frequencies to be preset.

X4 Auxiliary control input Four functions according to data set in Function 43:

When F43 = 0, X4-P24 closed selects accel/decel time 2 (Functions 63 and 64).

When F43 = 1, X4 functions as a fourth signal, allowing 15 preset frequencies.

When F43 = 2, X4-P24 closed selects base frequency 2 (Function 62).

When F43 = 3, X4 functions as a ‘hold’ (HLD) signal for 3-wire operation.

Control power supply (two) Internal 24V DC supply. Capacity is adequate to

P24 CAUTION Do not short circuit support all input control circuits plus Y1E output

to either terminal 11 or CM . provided that the load at Y1E is not >50mA.

CM* Common terminals (two) Common for FMP, Y1E and external control contacts.

Monitor Outputs 0 to 10V DC 1mA max. output, proportional to

the value of four parameters (refer to Functions

FMA Analog monitor 09, 40 and 41):

Output frequency; output current;

calculated torque %; load factor %.

FMP Output frequency monitor (pulse) O/P pulse rate = O/P frequency x Function 42.

O/P voltage = 15V peak-to-peak.

* The two terminals CM are at the same potential as terminal 11.

5.4 Terminals Functions List

15

5.5 Control Circuits and Terminals

13

12

11

FWD

REV

THR

CM

X1

X2

X3

X4

BX

RST

P24

CMC

Y1E

30C

30B

30A

Trip

relay

Open collector O/P

P24

CM

FMP

FMA

Pulse O/P

0-10V analog O/P

Keypad Operation Terminal Operation

Analog voltage

freq. ref. input

0V to 10V

(Pot. 1kΩ, 1W)

Programmable

digital

output

+

-

Analog current

freq. ref. input

(4-20mA)

Programmable

analog

output

to terminal 11

(+)

N/C

C1

DB

P1

V

W

U

[L2]

[L3]

[L1]

(+)

DB

P1

V

W

U

Trip

relay

NOTE 2

Open emitter O/P

Refer to Control

O/P Circuit, p.13

Blank

L

N[L2]

[L3]

[L1]Blank

L

N

NOTE 1

13

12

11

FWD

REV

THR

CM

X1

X2

X3

X4

BX

RST

P24

CMC

Y1E

30C

30B

30A

P24

CM

FMA

FMP

C1

NOTE 1

Data in […] applies

to 3-phase inverters

CAUTION

Do not short-circuit terminal P24 to either 11

or CM. Damage may result.

NOTES

1 Terminal DB not available for VXS20-1.

2 Input to terminal THR, (N/C contact)

from external protection relay.

TRIP/ALARM RELAY

Relay is shown with the inverter in either the

power-off or power-on state, condition

‘healthy’.

5.4 Terminals Functions List continued

Terminal Terminal Function Description

Control Outputs

Y1E Open emitter output; 50mA max. Six different functions are available according to

preset selection; refer to Function 54.

CMC Reserved for Y1E output only Refer to the illustration on page 13.

30A, 30B, When no trip, N/O circuit 30A-30C; N/C circuit

30C Alarm output, all trips 30B-30C. When inverter trips, 30A-30C closes.

Rating 48V DC, 0.3A.

16

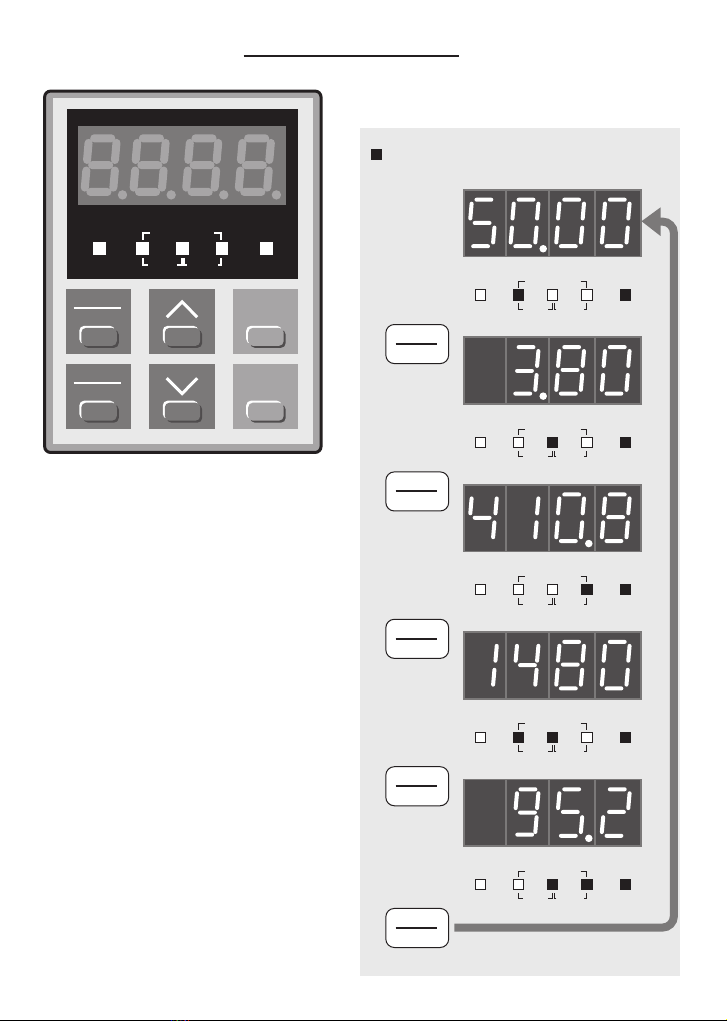

At Power-on

When power is switched on, the 7-segment

LEDs display flashes together with the (red)

‘Hz’ LED below it if the inverter is in the as-

delivered condition, and the (green) Panel

Control LED also illuminates, not flashing.

The 7-segment LEDs display normally shows

the value set in Function 03 (max. output fre-

quency). The frequency output can be

changed to current, voltage, speed (rpm) or

line speed (m/min). Refer to ‘Changing the

Inverter Output Display’ in the next column.

When one of these has been selected and the

inverter switched off, that same output will

appear at the next power-on.

Keypad Mode

The inverter is factory-set in Keypad Mode

(Functions 01 = 0 and 02 = 0) and is locked

into that mode by the standard link applied to

terminal P24-FWD. If it is desired to oper-

ate the inverter in Terminal Mode, this link

must first be removed before either

Function 01 or Function 02 can be changed.

Functions 01 and 02 can be changed indepen-

dently of each other.

Changing the Inverter Output Display

6 Keypad Functions

6.1 Keypad 6.2 Keypad Procedures

PANEL

CONTROL PRG MODE RUN

Hz A V

r/min m/min

PRG

RESET RUN

FUNC

DATA STOP

PANEL

CONTROL PRG MODE RUN

Hz A V

r/min m/min

PANEL

CONTROL PRG MODE RUN

Hz A V

r/min m/min

Motor

current

PANEL

CONTROL PRG MODE RUN

Hz A V

r/min m/min

Output

voltage

PANEL

CONTROL PRG MODE RUN

Hz A V

r/min m/min

Motor

speed

PANEL

CONTROL PRG MODE RUN

Hz A V

r/min m/min

Line

speed

FUNC

DATA

PRESS

FUNC

DATA

PRESS

FUNC

DATA

PRESS

FUNC

DATA

PRESS

FUNC

DATA

PRESS

Illuminated in RUN mode

Flashing in STOP mode

Illuminated

(not flashing)

in RUN mode

17

STOP Mode Display

7-segment LEDs display flashing. Three out-

put data LEDs flashing.

The 7-segment LEDs display normally shows

the maximum output frequency data set in

Function 03 or whichever other inverter output

value has been selected for display (refer to

Changing the Inverter Output Display, page 16).

When a keypad or a terminal STOP command

is given, the following will be observed:

The RUN (green) LED is extinguished;

The motor decelerates;

The 7-segment LEDs display shows the

decreasing speed (or other output, as

selected);

When the output stops, the LEDs flash;

The 7-segment LEDs display shows

whichever output value has been selected.

RUN Mode Display

7-segment LEDs display and three output data

LEDs are illuminated, not flashing.

The 7-segment LEDs display normally shows

the actual output frequency, or whichever

other inverter output value has been selected

for display (refer to Changing the Inverter

Output Display, page 16).

When a keypad or a terminal RUN command

is given, the following will be observed:

The LEDs stop flashing, become steady;

The RUN (green) LED illuminates;

The motor accelerates;

The 7-segment LEDs display shows the

increasing frequency (or other output, as

selected).

RUN/STOP keys

• Keypad Mode (Function 02 = 0)

‘Panel Control’ LED ON

Start and stop commands. Inverter will accel-

erate and decelerate in the time set in

Functions 06 and 07. It will decelerate when

the STOP key is pressed whether it has

reached full speed or not, and re-accelerate

when the RUN key is pressed, whether it has

reached zero speed or not.

• Terminal Mode (Function 02 = 1)

‘Panel Control’ LED OFF

No effect. Use terminals FWD/REV-P24.

UP and DOWN keys (∧and ∨)

• Keypad Mode (Function 01 = 0)

Change the maximum output frequency data

value set in Function 03.

• Terminal Mode (Function 01 = 1)

No effect. Use terminals 12/C1-11.

• Programming Mode

Refer to the following page.

RUN/STOP terminals FWD/REV-P24

• Keypad Mode (Function 02 = 0)

‘Panel Control’ LED ON

Terminal control is disabled.

• Terminal Mode (Function 02 = 1)

‘Panel Control’ LED OFF

RUN Mode

Close the external contact in the control circuit

connecting P24-FWD or P24-REV.

STOP Mode

Open the external contact in the control circuit

connecting P24-FWD or P24-REV. Refer also

to Function 43 = 3.

INPUT REFERENCE terminals 12-11

and/or C1-11

• Keypad Mode (Function 01 = 0)

Terminal control is disabled.

• Terminal Mode (Function 01 = 1)

Analog frequency control inputs. If both

inputs 12-11 and C1-11 are used, the result-

ing reference is the sum of the two.

WARNING

If a RESET is performed while a RUN

command is present, the inverter will start.

To avoid danger, check that a RUN signal

is not present before performing a RESET.

WARNING

The STOP pushbutton on the keypad is

effective ONLY when Function 02 = 0. If

Function 02 is set to 1, an external

RUN/STOP control circuit may be required

at terminals FWD and REV for safety.

PRG/RESET key

• RUN mode or STOP mode

In either keypad mode or terminal mode, and

provided that the inverter is not in a TRIP

condition, the PRG/RESET key sets the

inverter into PROGRAM mode, allowing the

operator to select the menu of Inverter

Functions (Chapter 7).

When PRG mode is selected, the LED display

shows the Function available, eg F 00, and all

three red LEDs below it illuminate in RUN

mode or flash in STOP mode.

For the explanation of procedures and the use

of the ∧and ∨ keys, refer to the diagrams on

the following pages.

• TRIP Mode

In TRIP mode, the PRG/RESET key resets the

inverter. Refer to Chapter 8.

FUNC/DATA key

• RUN mode or STOP mode

The Function/Data key calls up the Data of the

Function selected in PROGRAM mode.

For the explanation of procedures and the use

of the ∧and ∨ keys, refer to the diagrams on

the following pages.

• STOP Mode

The FUNC/DATA key permits the selection

of one of the 5 different inverter output para-

meters for display on the 7-segment LEDs.

Refer to Changing the Inverter Output

Display, page 16.

NOTES

1 All Functions can be read in both RUN

and STOP modes, and all Functions can

be adjusted in STOP mode. In RUN

mode, some Functions are ‘read only’.

Refer to Chapter 7.

2 If Function Data is protected, adjustment

is not possible. Refer to Function 00

page 26, and Function 57 page 37.

18

This manual suits for next models

4

Table of contents

Popular Inverter manuals by other brands

HQ Power

HQ Power PSIC75 Series user manual

Western Co

Western Co Leonardo Off-Grid 8kW-8000-48 MG user manual

Badger Power Electronics

Badger Power Electronics BPE-HI-3.6K user manual

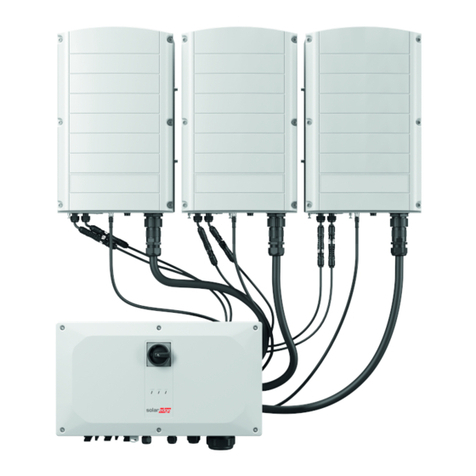

SolarEdge

SolarEdge SE K Series installation guide

RCT

RCT Power Storage DC 4.0 Setup & installation

Defort

Defort DCI-600 user manual

SMA

SMA Sunny Central 500CP-JP installation manual

Islandaire

Islandaire EZ Series Engineering manual

York

York RVHC-09 Service manual

Samil Power

Samil Power SolarRiver 1100TL-S manual

Power One

Power One AURORA PVI-OUTD-US Series Installation and operator's manual

TECO-Westinghouse

TECO-Westinghouse E510-201-H-U Installation and start-up manual