Impakt i1 System User manual

Impakt Tools

Pocket Hole Jig

Model I1 System

Instruction Manual

1

Introduction

Congratulations on your purchase of the Impakt Tools I1 Pocket-Hole Jig. Many

people will not use anything but 3/4-inch material. For that reason, the I1

Pocket-Hole Jig was designed, simple and economical. Please check the section

at the end that will give you some guidelines for using other thicknesses of

material.

You will be able to find other helpful information online at:

Safety Guidelines

GENERAL POWER TOOL SAFETY WARNINGS

Read all safety warnings and instructions. Failure to follow the warnings and

instructions may result in electrical shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your main-operated (corded)

power tool or battery operated (cordless) power tool.

impakttools.com

2

GENERAL SAFETY RULES

You will become very familiar with I1 System. Do not let that familiarity

with the tool make you become careless and forget the safety rules. A

careless moment can easily inflict severe injury.

For your own safety, read this instruction manual entirely before

operating the I1 Pocket Hole Joinery System. Learning the I1 Pocket

Hole Joinery System’s application, limitations, and specific hazards will

greatly minimize the possibility of accidents and injury.

When operating a power tool, wear proper apparel. Do not wear loose

clothing, gloves, neckties, rings, bracelets, or other jewelry which may

get caught in moving parts. Nonslip protective footwear is

recommended. Wear protective hair covering to contain long hair. Air

vents may cover moving parts and should also be avoided.

Do not use the I1 Pocket Hole Joinery System in a dangerous

environment. The use of power tools in damp or wet locations or in rain

can cause shock or electrocution.

Keep your work area well-lit to prevent tripping or placing arms, hands

and fingers in danger.

Before using the jig, check for proper settings, tightened knobs,

condition of the drill bit and secure setup.

Keep the work area clean. Cluttered areas and benches invite accidents.

Keep children away. All visitors should be kept at a safe distance from

work area. Your shop is a potentially dangerous environment.

Make workshops childproof with padlocks, master switches, or by

removing starter keys. The unauthorized start-up of a machine by a

child or visitor may result in injury.

Reduce the risk of unintentional starting. Make sure that the switch on

your drill is in the “off” position before connecting to the power

sources. In the event of a power failure, move the switch to the “off”

position. An accidental start-up can cause injury. Do not touch the

plug’s metal prongs when unplugging or plugging in the cord.

Remove adjusting keys and wrenches. Form a habit of checking to see

that keys and adjusting wrenches are removed from spindle before

turning tool on. Tools, scrap pieces and other debris can be thrown at

high speed, causing injury.

3

General Safety Rules cont.

Use the right drill. Don’t force the drill, damage to the drill and/or injury

may result. Make sure drill is turning the right direction before inserting

into the drill bushings.

Use recommended accessories. The use of accessories and attachments

not recommended by Impakt Tools may cause damage to the jig or

injury to the user.

Do not overreach while operating the power tool. Maintain a balanced

working stance at all times. When necessary, use only properly

positioned, safe platforms and scaffolding. WORK SAFE.

Turn the drill “off”, and disconnect the drill from the power source

before installing or removing accessories, changing bits, adjusting or

changing set-ups. When making repairs, unplug the tool / remove

battery and be sure to keep the start switch in the “off” position. An

accidental start-up can cause injury.

ALWAYS USE SAFETY GLASSES (ANSI Z87.1) and (CAN/CSA Z94.3).

Everyday eyeglasses are NOT safety glasses. Also use face or dust mask

if airborne dust is present. ALWAYS WEAR CERTIFIED SAFETY

EQUIPMENT:

oANSI Z87.1 eye protection (CAN/CSA Z94.3);

oANSI S12.6 (S3.19) hearing protection;

oNIOSH/OSHA/MSHA respiratory protection.

4

DRILL SAFETY RULES

WARNING: To reduce the risk of serious personal injury:

Read and understand the drill’s instruction manual before operating the

I1 Pocket Hole Joinery System.

Hold tool by insulated gripping surfaces when performing an operation

where the cutting tools may contact hidden wiring or its own cord.

Contact with a “live” wire will make exposed metal parts of the tool

“live” and shock the operator.

Maintain all drills and drill bits to be used in the jig in good working

condition. Keep tools sharp and clean for best and safest performance.

Poorly maintained tools and machines can further damage the jig

and/or cause injury.

Keep handles dry, clean and free from oil and grease.

Care should be taken if the jig is operated for long periods of time.

Vibration caused by the operating action of this tool may cause

permanent injury to fingers, hands, and arms. Use gloves to provide

extra cushion, take frequent rest periods, and limit daily time of use.

Use the proper extension cord. Make sure your extension cord is in

good condition. When using an extension cord, be sure to use one

heavy enough to carry the current your product will draw. An

undersized cord will cause a drop in line voltage, resulting in loss of

power and overheating. See the extension cord chart in your drill’s

owner manual for the correct size depending on the cord length and

nameplate ampere rating. If in doubt, use the next heavier gauge. The

smaller the gauge number, the heavier the cord.

5

I1 POCKET HOLE JOINERY SYSTEM SAFETY RULES

Clamp the I1 Pocket Hole Jig to a secure work surface or mount the jig

to a board that is then clamped to a secure work surface.

Turn the drill off, remove the drill from the I1 Pocket Hole Joinery

System and disconnect the drill from the power source before installing

and removing accessories, before adjusting or changing set-ups or

when making repairs. An accidental start-up can cause injury.

Handle drill bits by the smooth shaft only. The drill bit flutes are

extremely sharp.

Do not lock the drill on during drilling.

Always use the side handle supplied with the tool, if supplied. Keep a

firm grip on the drill at all times. Do not attempt to operate the drill

without holding it with both hands. Operating this tool with one hand

could result in loss of control.

Be sure the I1 Pocket Hole Joinery System is clamped or screwed

securely to a sturdy workbench or table before use.

Be sure the workpiece is free of nails and staples.

Secure the workpiece. Use clamps or a vise to hold long workpieces

when practical. Loss of control of a workpiece can cause injury.

Only use the included bit and drill bit depth collar or a proper IMPAKT

TOOLS replacement bit or collar sold for use with the I1 Pocket Hole

Joinery System.

NOTICE: To reduce the risk of tool or workpiece damage:

Verify the collar on your drill bit is calibrated properly according to

instructions and be sure it is tightened fully onto the bit’s shaft.

Be sure your drill is at full speed before drill bit contacts the workpiece

and a hole is drilled.

Only power drills should be used to drill holes. Do not use a router or

other similar tool.

The length of the workpiece should be at least as tall as the drill guide

bushings.

6

WARNING: Some dust created by power sanding, sawing, grinding, drilling,

and other construction activities could contain chemicals known to the State of

California to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

lead from lead-based paint.

crystalline silica from bricks and cement and other masonry products.

arsenic and chromium from chemically-treated lumber (CCA).

Your risk from exposure to these chemicals varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals: work in a well

ventilated area with approved safety equipment, such as dust masks that are

specially designed to filter out microscopic particles.

WARNING: Avoid prolonged contact with dust from power sanding, sawing,

grinding, drilling, and other construction activities. Wear protective clothing

and wash exposed areas with soap and water. Allowing dust to get into your

mouth, eyes, or lay on the skin may promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust, which may

cause serious and permanent respiratory damage or other injury. Always use

NIOSH/OSHA/MSHA approved respiratory protection appropriate for the dust

exposure. Direct particles away from face and body.

7

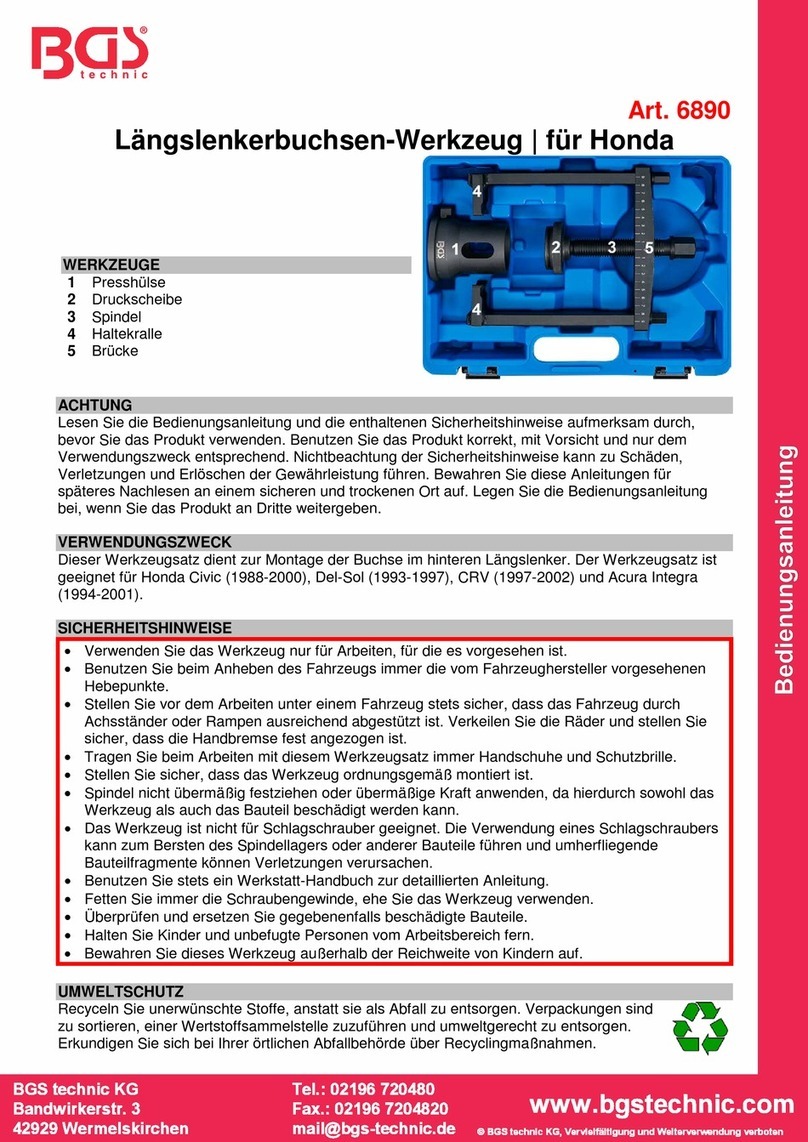

What’s in the Box

POCKET HOLE ACCESSORY PACK

8

Setup and Usage

Step #1

Mount your I1 Pocket-Hole Jig to a board or clamp it to you work surface with

the supplied 6-inch Face Clamp. For added support when working with larger

panels use short sections of 2x4’s.

Step #2

What is your material thickness? The I1 Pocket-Hole jig can drill 1/2 and 3/4

material. You can drill pocket-holes in other sizes but the screw will not exit the

center of the workpiece. Working with other thicknesses will be discussed later.

Step #3

Set the Depth Collar. There is an area under the toggle clamp that is used to set

the depth collar for use with 3/4 material.

Slide the depth collar onto the shank of the drill bit.

Insert the drill bit and depth collar into the area in the back and under

the toggle clamp.

Push the drill bit in until it stops.

Push the depth collar up to the stop surface in the back of the base of

the jig and tighten the depth collar with the supplied 1/8”hex key.

9

Step #4

Setting the toggle clamp.

Put the toggle clamp in the forward most position.

Place your work piece between the Clamp Pad and the Drill Guide. If the

workpiece will not fit, turn the screw in until the workpiece fits. You

may have to back off the nut until you can accomplish this.

With the workpiece in place turn the Clamp Pad until it touches the

workpiece.

Pull the handle of the toggle clamp backwards.

Give the Clamp Pad screw a turn outwards between 1/2 and 1 full turn.

This will give you the pressure necessary to hold the workpiece in place.

Put the toggle clamp in the forward most position. You should feel

resistance when doing this. If there is too much resistance, turn the

Clamp Pad screw in a little at a time until the clamp closes.

Test the clamp pressure by trying to move the workpiece. It should take

considerable effort to move the workpiece. If there is too much

pressure, the task of clamping, drilling and unclamping will get

tiresome. After some practice, you will determine the correct pressure

to hold the workpiece in place and secure. Tighten the hex nut.

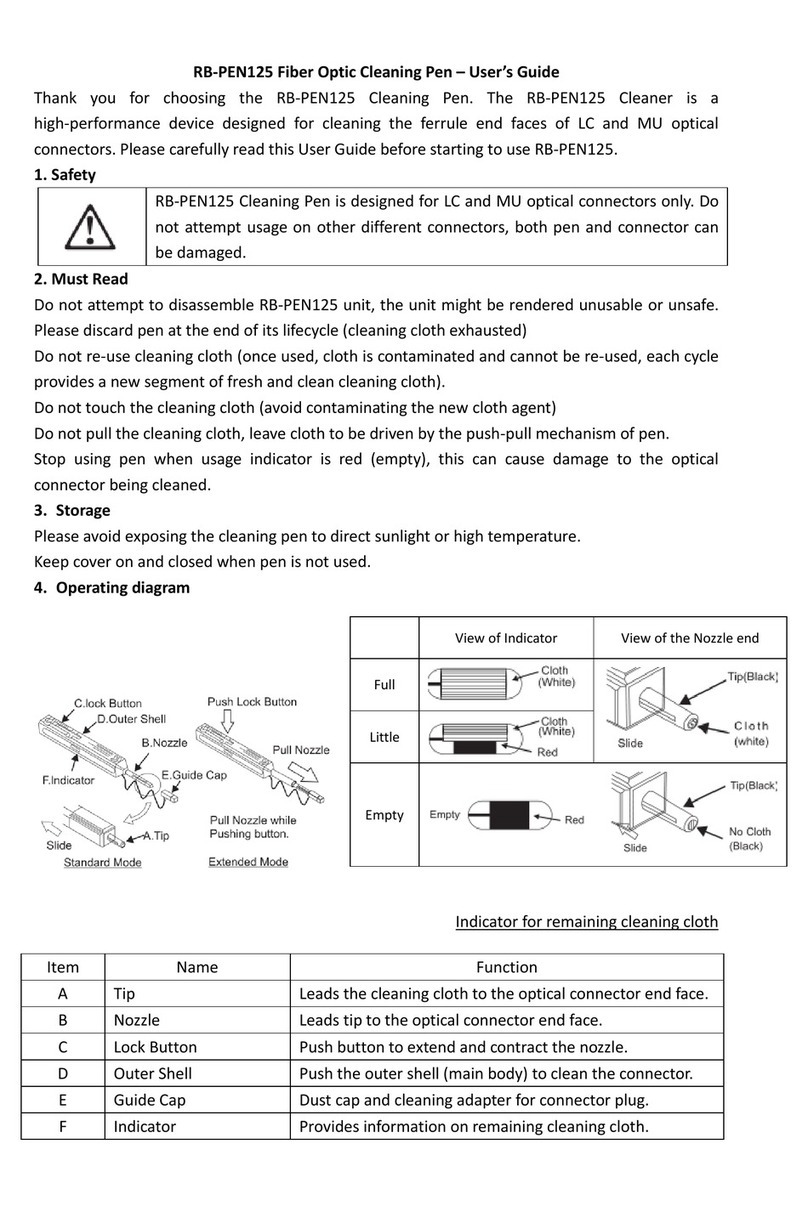

This figure shows the I1

Pocket Hole Jig setup

properly.

Step #5

Drilling

Attach the stepped drill to a corded or cordless drill and tighten the

chuck securely

Insert the drill bit into the drill guide and feel for where the edge of

the workpiece is and back it up slightly

Turn the drill on to high speed and drill completely until the depth

collar stops on the top of the drill guide.

Repeat for both holes if required

10

Pocket-Hole Screws

When choosing a screw, there are a couple of things to consider.

What is the material that the threads will be going into?

oIs it hardwood or softwood/plywood?

Examples of common hardwoods are: Oak,

Maple, Cherry, Walnut.

Examples of common softwoods are: Pine, Cedar,

Douglas Fir, Redwood.

What is the thickness of both pieces you are joining?

If you are using hardwoods, you will want to use a fine thread screw.

If you are using softwoods or plywood, you will want to use a coarse thread

screw.

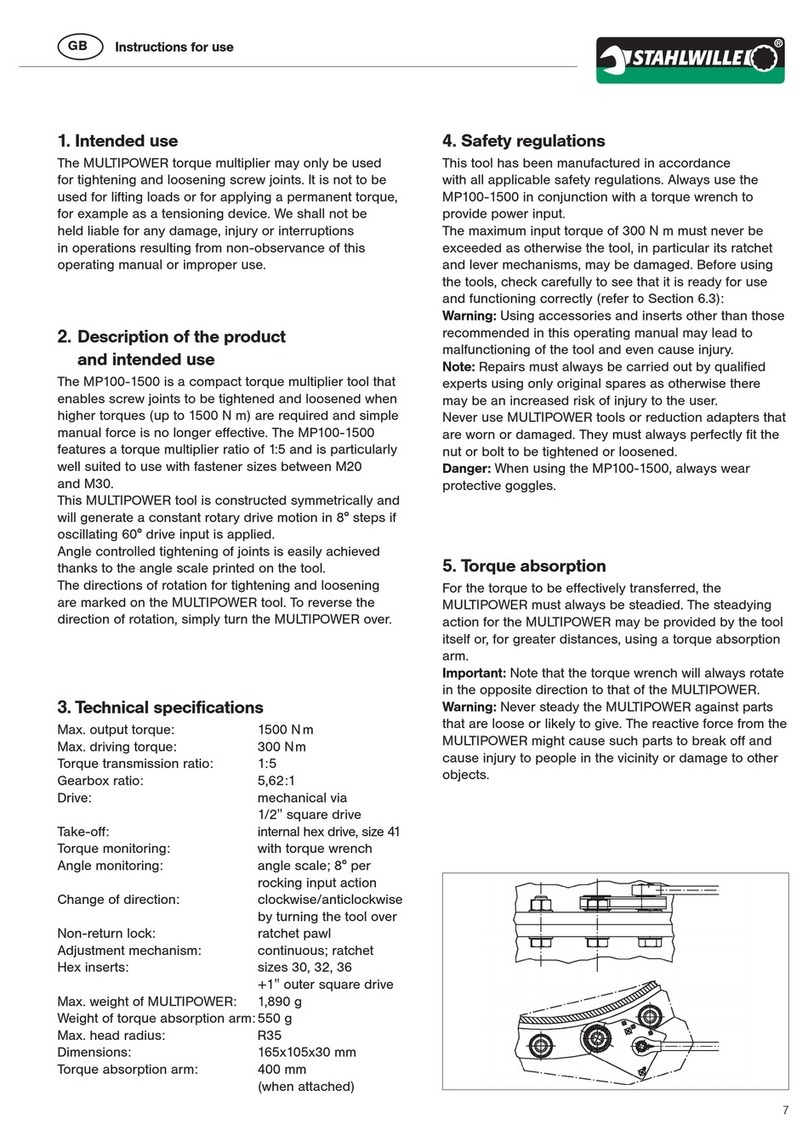

For material thicknesses, the next 2 figures are guidelines for you to use.

11

Pocket Hole Joinery Uses and Applications

Pocket hole joinery is fast, strong and the simplest type of joinery that can be

used in modern woodworking. That is why a novice to building wood projects

can have incredible success in a short time. It involves drilling an angled “pocket

hole” in just one of the pieces being joined.

Use an Impakt Tools Face Clamp that has the capacity to clamp across the joint

to hold it flush while driving the screws. A minimum of two screws per joint is

recommended. Although if the workpiece is very narrow, one screw can be used.

For a workpiece that is wide, more than 2 screws should be used. In the case of

a cabinet side for a bookcase, space the pocket holes 4-8 inches apart.

12

Use of all thicknesses with I1 Pocket-Hole Jig

The figures on the previous page can all be done with the I1 Pocket-Hole Jig.

Sizes from 3/4 to 1-1/2 are all done without any changes to the setup.

The applications showing a pocket-hole being drilled slightly off center.

These joints will still be very strong with the screw being off center.

The 5/8-inch thick workpieces are drilled with a change in the depth

collar position. Loosen the depth collar and insert the stepped drill bit

in the drill guide. Allow the tip of the drill bit to rest on the top of the

base and tighten the depth collar. This will make the screw head sit a

little deeper in the pocket-hole.

The 1/2-inch workpieces are drilled with a change in the depth collar

position and adding a spacer under the workpiece as you are drilling.

The spacer that can be used is a simple wood pencil.

To set the depth collar, lay the pencil on top of the base. Loosen the

depth collar and insert the stepped drill bit in the drill guide. Allow the

tip of the drill bit to rest on the top of the pencil. Pull the drill bit up so

there is about 1/16-inch gap between the tip of the bit and the pencil.

You can also use a penny to check this gap, a penny is 1/16-inch thick.

Tighten the depth collar.

13

Assembly

Now that you have drilled all your workpieces, you are ready to assemble them

by using a cordless drill / driver to drive your screws.

You need to be able to position the parts to be assembled in a way to get your

Face Clamp positioned across the joint. There are several ways to accomplish

this. Here are 2 ways to position your parts.

Method #1: Just hang the joint to be assembled over the edge of your work

surface and center the clamp pad on the joint. Make sure the large pad is on the

side opposite the drilled pocket holes. This will aid in keeping the joint flush.

Method #2: Similar to Method #1 but make yourself some risers to lift all of your

parts off the bench top and tall enough to clear the face clamp.

14

Common Applications

Here are just some typical applications and some that are a little bit more

advanced. Uses of pocket-hole joinery are only limited by your imagination.

Standard Face Frame

Attach Cabinet side to Face Frame

Picture Frame

Table Apron

Beveled Corner

Edge Joining

Edge Banding

Leg Rails

Stairs

15

Proposition 65

WARNING: This product contains chemicals known to the State of California

to cause cancer and birth defects or other reproductive harm.

WARNING: Some dust created by power sanding, sawing, grinding, drilling,

and other construction activities may contain chemicals known to the State

of California to cause cancer and birth defects or other reproductive harm.

Some examples of these chemicals are: lead from lead-based paints,

crystalline silica from bricks and cement and other masonry products, and

arsenic and chromium from chemically treated lumber. Your risk from

exposure to these chemicals varies, depending on how often you do this type

of work. To reduce your exposure, work in a well-ventilated area and with

approved safety equipment, such as dust masks that are specially designed

to filter out microscopic particles.

Warranty

Three Year Limited Warranty –Impakt Tools will repair or replace without

charge, any defects due to faulty materials or workmanship for three years from

the date of purchase.

Lifetime Warranty –Impakt Tools will replace any worn-out drill bushing for

the life of the product.

For further information visit –Impakttools.com

Impakttools.com

Table of contents