Stahlwille multipower MP100-1500 User manual

7

GB Instructions for use

1. Intended use

The MULTIPOWER torque multiplier may only be used

for tightening and loosening screw joints. It is not to be

used for lifting loads or for applying a permanent torque,

for example as a tensioning device. We shall not be

held liable for any damage, injury or interruptions

in operations resulting from non-observance of this

operating manual or improper use.

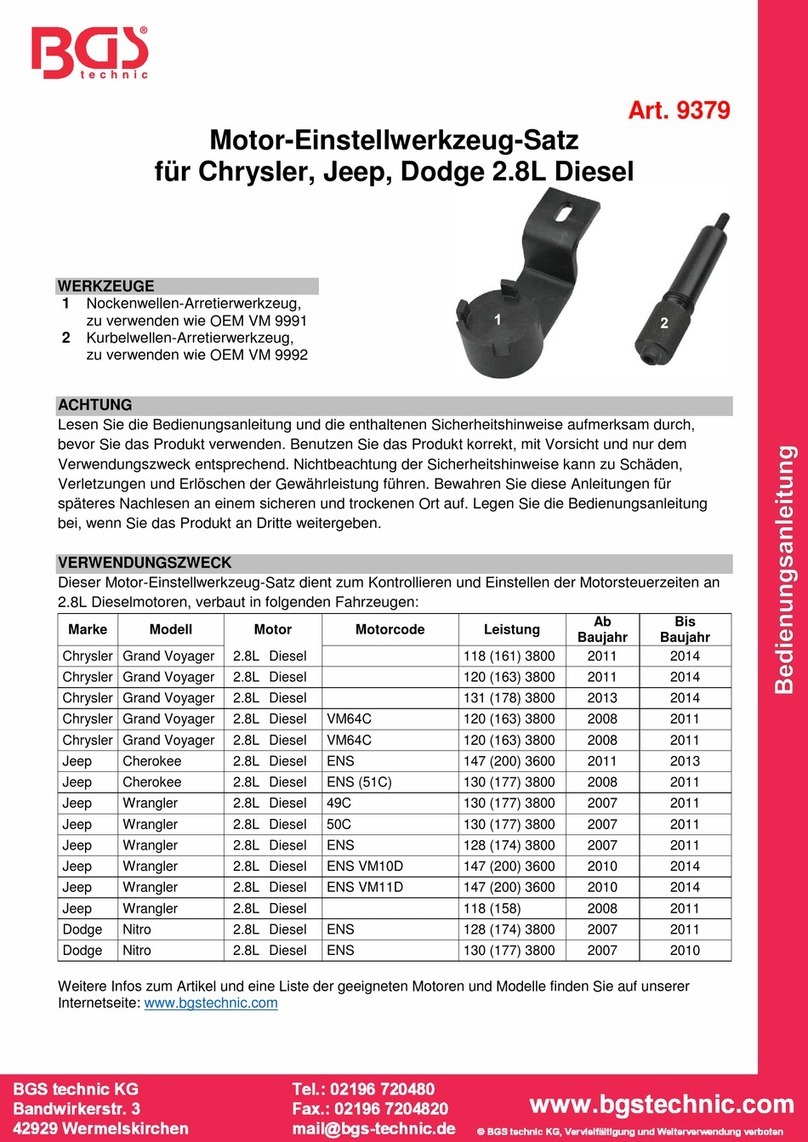

2. Description of the product

and intended use

The MP100-1500 is a compact torque multiplier tool that

enables screw joints to be tightened and loosened when

higher torques (up to 1500 N m) are required and simple

manual force is no longer effective. The MP100-1500

features a torque multiplier ratio of 1:5 and is particularly

well suited to use with fastener sizes between M20

and M30.

This MULTIPOWER tool is constructed symmetrically and

will generate a constant rotary drive motion in 8° steps if

oscillating 60° drive input is applied.

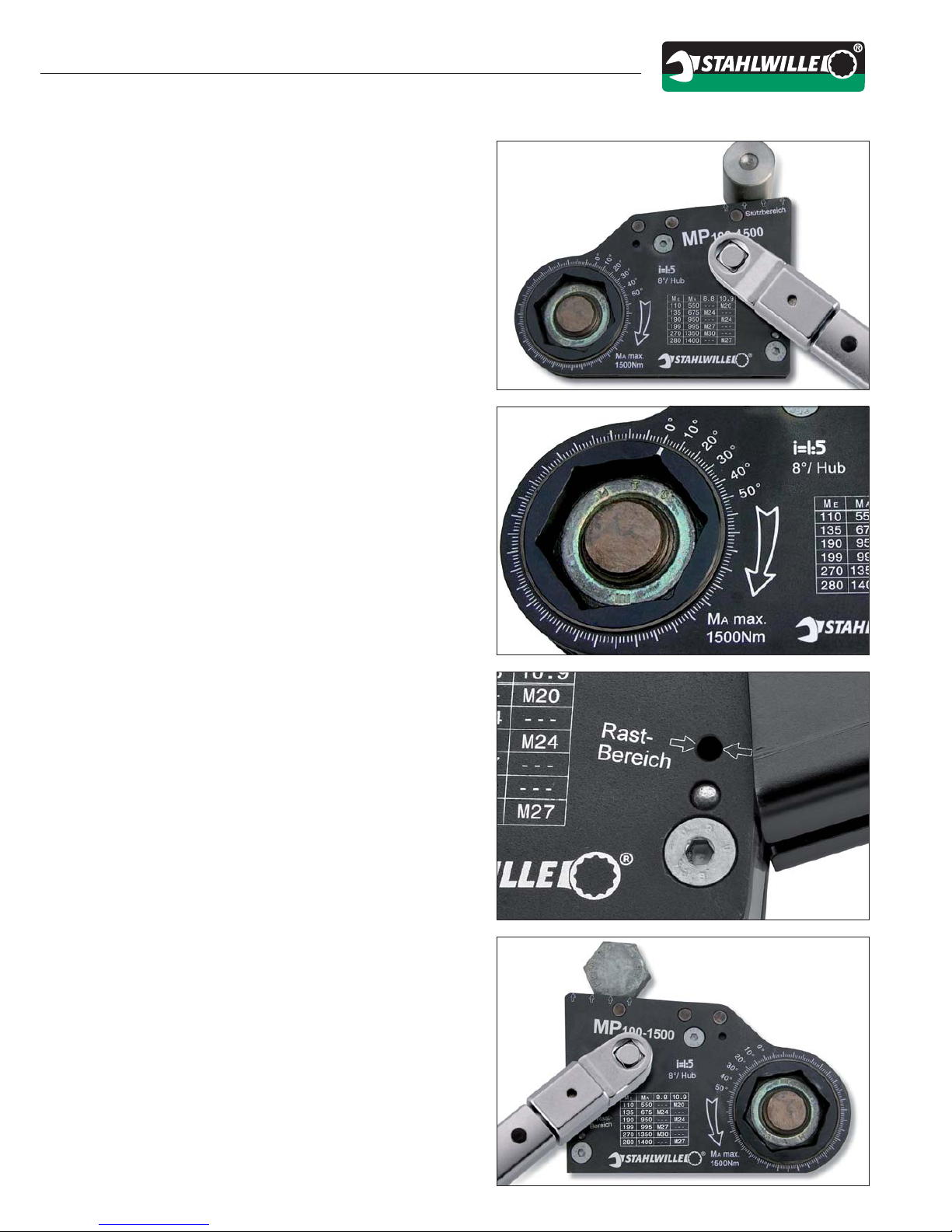

Angle controlled tightening of joints is easily achieved

thanks to the angle scale printed on the tool.

The directions of rotation for tightening and loosening

are marked on the MULTIPOWER tool. To reverse the

direction of rotation, simply turn the MULTIPOWER over.

3. Technical specifications

Max. output torque: 1500 N m

Max. driving torque: 300 Nm

Torque transmission ratio: 1:5

Gearbox ratio: 5,62:1

Drive: mechanical via

1/2" square drive

Take-off: internal hex drive, size 41

Torque monitoring: with torque wrench

Angle monitoring: angle scale; 8° per

rocking input action

Change of direction: clockwise/anticlockwise

by turning the tool over

Non-return lock: ratchet pawl

Adjustment mechanism: continuous; ratchet

Hex inserts: sizes 30, 32, 36

+1" outer square drive

Max. weight of MULTIPOWER: 1,890 g

Weight of torque absorption arm: 550 g

Max. head radius: R35

Dimensions: 165x105x30 mm

Torque absorption arm: 400 mm

(when attached)

4. Safety regulations

This tool has been manufactured in accordance

with all applicable safety regulations. Always use the

MP100-1500 in conjunction with a torque wrench to

provide power input.

The maximum input torque of 300 N m must never be

exceeded as otherwise the tool, in particular its ratchet

and lever mechanisms, may be damaged. Before using

the tools, check carefully to see that it is ready for use

and functioning correctly (refer to Section 6.3):

Warning: Using accessories and inserts other than those

recommended in this operating manual may lead to

malfunctioning of the tool and even cause injury.

Note: Repairs must always be carried out by qualified

experts using only original spares as otherwise there

may be an increased risk of injury to the user.

Never use MULTIPOWER tools or reduction adapters that

are worn or damaged. They must always perfectly fit the

nut or bolt to be tightened or loosened.

Danger: When using the MP100-1500, always wear

protective goggles.

5. Torque absorption

For the torque to be effectively transferred, the

MULTIPOWER must always be steadied. The steadying

action for the MULTIPOWER may be provided by the tool

itself or, for greater distances, using a torque absorption

arm.

Important: Note that the torque wrench will always rotate

in the opposite direction to that of the MULTIPOWER.

Warning: Never steady the MULTIPOWER against parts

that are loose or likely to give. The reactive force from the

MULTIPOWER might cause such parts to break off and

cause injury to people in the vicinity or damage to other

objects.

6. Using the MULTIPOWER

6.1 Analysing the tightening job:

•Tighten or loosen the joint?

•Clockwise or anticlockwise?

•What size is the fastener (M...)?

•What size spanner or insert is needed?

•Is there a suitable steady point for the torque

absorption arm?

•Measure the length of the arm required

6.2 Get the required accessories together:

•Torque wrench with permanent 1/2" square drive

•Reduction adapter, if size < 41.

•O-ring to secure the adapter

•Torque absorption arm, if steady distance

exceeds 140 mm.

•If necessary, additional spanner or wrench.

for the other end of a two-ended fastener.

6.3 Functional check of the MP100-1500:

•Check general state of the MP100-1500 torque

multiplier

➩Any cracks, deformations, wear are not permitted.

•Using a torque wrench, move the drive back and

fore between the endstops (approx. 70°).

➩Check that take-off wheel action and steps are

smooth.

➩Oscillating, clearly audible pawl and ratchet

action.

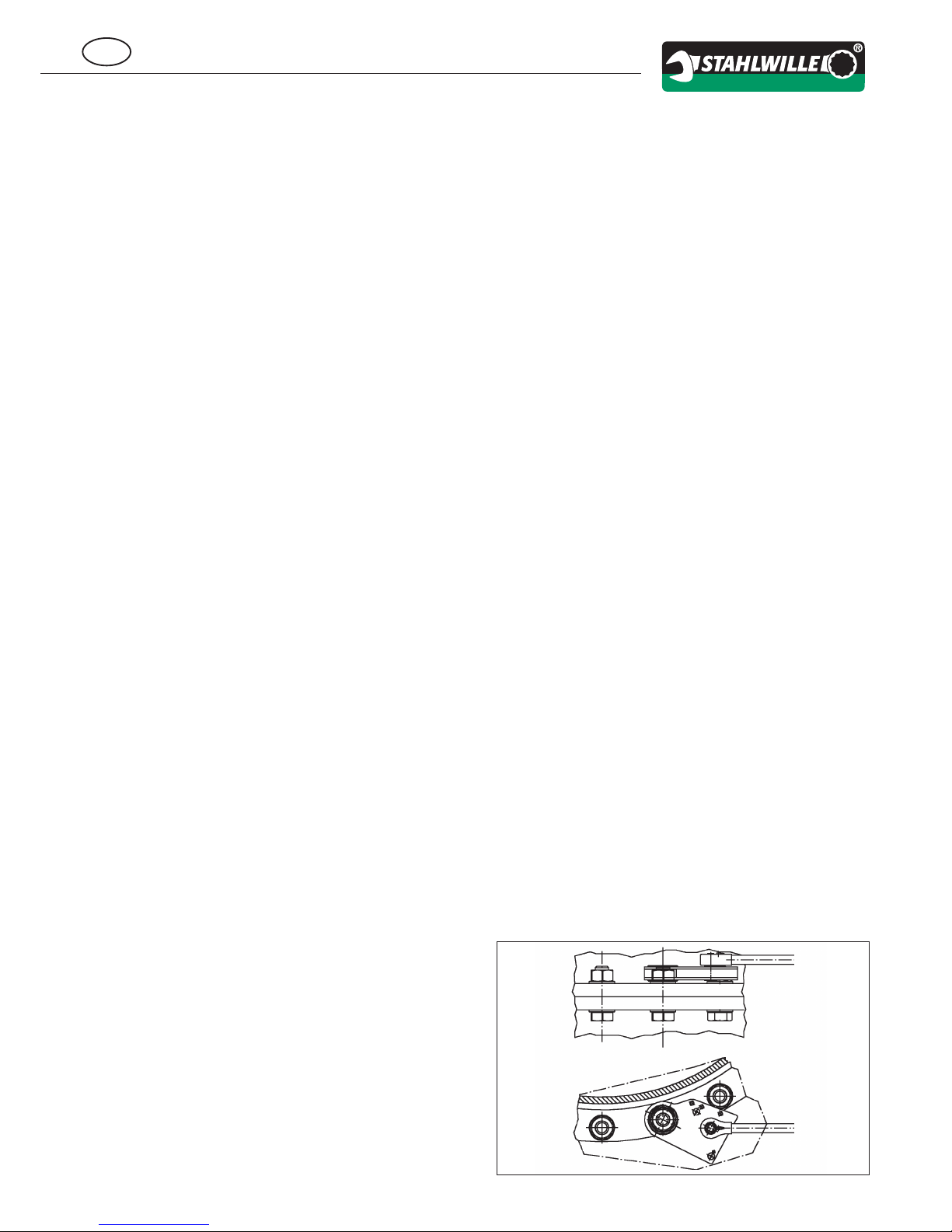

6.4 Fitting the torque absorption arm:

•The arm is only necessary if the steady point is

more than 140 mm from the fulcrum.

➩Put the torque absorption arm on as shown

and secure with the two M6 screws.

6.5 Positioning the MP100-1500 for

tightening/loosening:

•Place the MULTIPOWER on the fastener the right

way round for the required direction of rotation

(see arrows on housing).

•Swing the MULTIPOWER as far as the absorption arm

endstop (audible click as the ratchet re-engages).

•Set the cut-out value for the torque wrench in

accordance with the printed scale on the MP or the

table in Section 9.

➩Input torque must be ≤300 N m.

•Fit the torque wrench into the input square drive and

fix it in the required position.

Fastener can be

tightened/loosened without

torque absorption arm

Fastener can be

tightened/ loosened without

torque absorption arm

8

GB Instructions for use

6.6 Torquing the fastener:

•Using the torque wrench, move the input lever back

and fore between the endstops (approx. 70°).

➩Ensure you always move the tool through the

entire pivot range.

➩Apply oscillating motion and listen for the clearly

audible pawl and ratchet action.

•As soon as the torque wrench cuts out, the required

torque level has been reached.

➩Do not continue to move the drive after the wrench

has cut out.

➩Input torque must be ≤300 N m.

6.7 Tightening a fastener by angle:

•Mark the starting position of the hexagonal socket

opposite the mark.

➩Use a strip of adhesive tape or a light coloured

marker.

•Using the torque wrench, move the input lever back

and fore between the endstops (approx. 70°).

➩Ensure you always move the tool through the

entire pivot range.

➩Apply oscillating motion and listen for the clearly

audible pawl and ratchet action.

•Apply oscillating movements to the wrench until the

required angle has been reached as seen on the

scale.

➩Alternatively, it is possible to count the number

of oscillating motions (8° angle).

➩Input torque must be ≤300 N m.

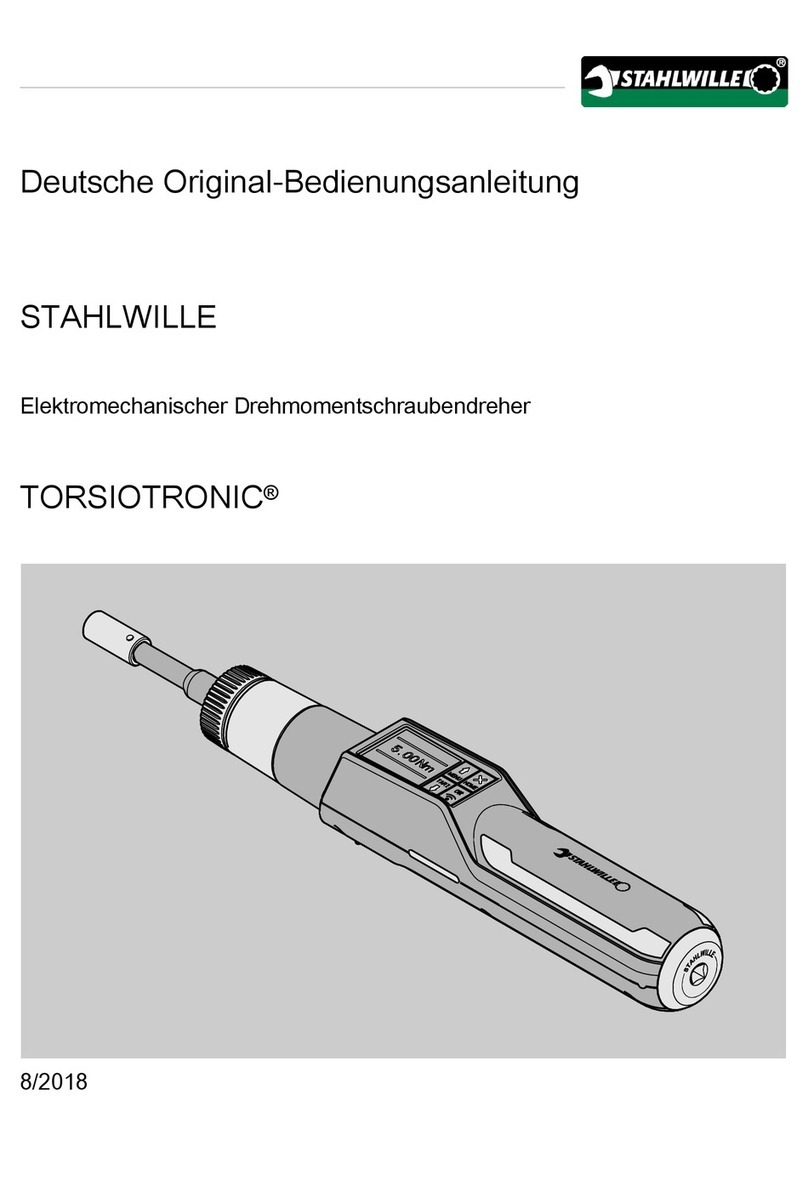

6.8 Releasing tension after completing the tightening

action:

•After the torque wrench has cut out, it is possible that

the MULTIPOWER will remain in the tensioned state

between the joint and the absorption arm endstop.

To enable the MULTIPOWER to be removed from the

fastener, it is necessary to move the drive through

approx. half a stroke, however not further than the

lock position (marked on the tool as “Rast-Bereich”),

and then release it.

➩The edge of the lever must only be visible as far

as the tips of the arrows to prevent the pawls from

re-engaging.

6.9 Loosening a joint:

•Set the torque wrench to the maximum permitted

input torque of 300 N m.

•Insert the torque wrench and gently apply ratcheting

motion until the fastener has been released.

•If the torque wrench cuts out before the fastener has

broken free, the maximum permissible release torque

has been reached.

➩Continuing to torque the fastener will damage the

MULTIPOWER.

•Put the MP100-1500 to one side and use some other

suitable means to release the fastener.

➩A more powerful driver or heavy duty, striking

face spanner will be needed.

9

10

GB Instructions for use

7. Maintenance and service

The rod bearing is equipped with special, low-

maintenance plain bearing bushes that guarantee con-

stant, low coefficients of friction. All the remaining moving

parts in the MP100-1500 are greased before delivery to

the customer with an MoS2 paste. Under normal working

conditions, this lubrication will last for several years of

use without failing. If the tool is used very intensively

or if the functional check in accordance with

Section 6.3 indicates that lubrication is insufficient,

8. Malfunctions and their rectification

Note: Malfunctions in the MULTIPOWER can result in consequential damage that may seriously limit the tools lifetime and

accuracy. If you are unsure, please contact STAHLWILLE staff, who will be pleased to assist.

9. Tightening torques and setting torques

The following table shows the tightening torques (MA) for standard metric threads and the corresponding setting torques (ME) for the

torque wrench for use with the MP100-1500 MULTIPOWER torque multiplier.

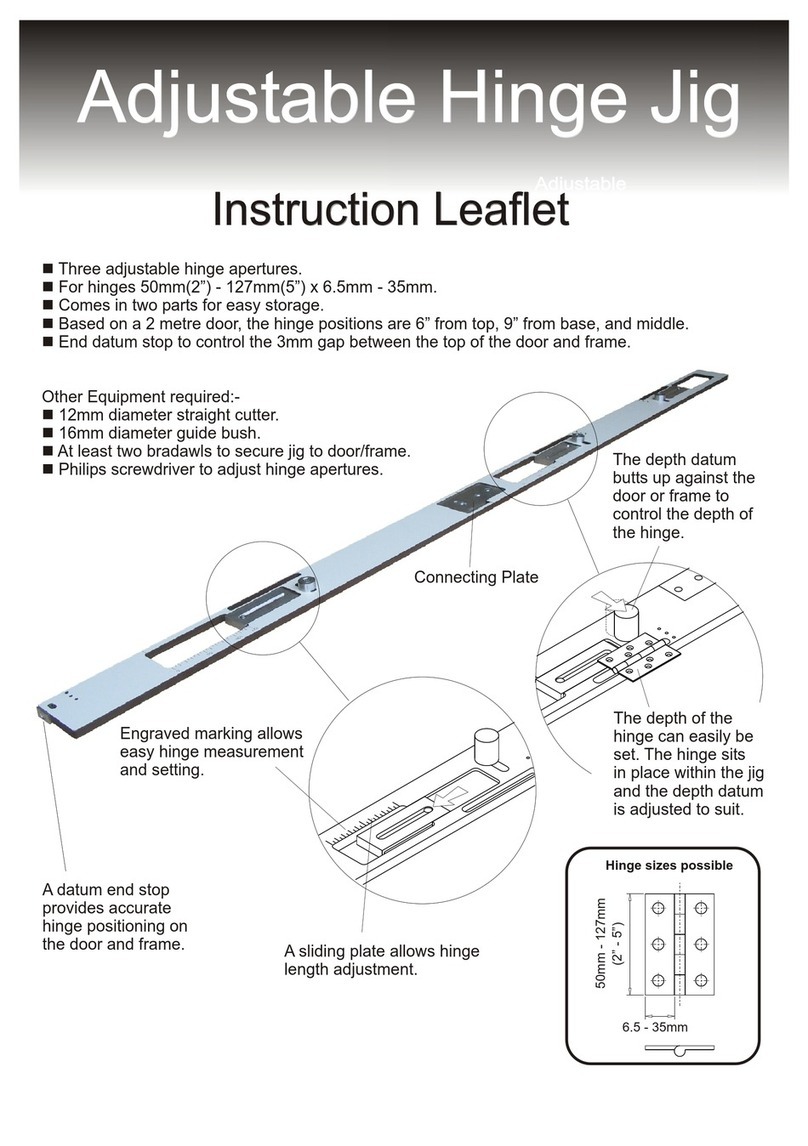

Weight Weight Weight Weight incl. Head Length Breadth Height Steady Breadth Width Height

Output Input Output Input MP100-1500 Torque absorption arm Radius RK L0 B0 H0 LR BR WR HR

Nm Nm SW AK kg kg mm mm mm mm mm mm mm mm

1500 300 41-hex. 1/2"sq. 1.89 2.44 35 160 105 32 400 143 87 20

10. Specifications and dimensions of the MP100-1500

Strength category 8.8 Strength category 10.9 Strength category 12.9

MA Nm ME Nm MA Nm ME Nm MA Nm ME Nm

M18 275 55 390 78 470 96

M20 390 78 550 110 660 132

M22 530 106 745 149 890 178

M24 675 135 950 190 1140 228

M27 995 199 1400 280 1680 –

M30 1350 270 1900 – 2280 –

Fault

Not possible to turn the take-off

(pawl wheel) continuously.

No audible signal when the pawl

ratchet engages.

The eccentric lever is stiff or jammed.

When torque is applied, it

suddenly drops off (before the end-

stop is reached).

Check

Run a function check as given in Section 6.3.

Is there an audible signal when the pawl / ratchet

pairs engage with no working load?

Measure driving torque ME with no working load

⇨should be less than 20 N m.

Run a function check as given in Section 6.3.

Check the toothing of the pawl wheel and ratchets to

see if there are any oil or grease residues there.

Remedy

Have the tool serviced as described in

Section 7.

Check the pawls, ratchets and leaf springs and

have them replaced if necessary.

Lubricate the bearing surfaces of the ratchet

wheel and eccentric lever in both parts of the

housing with MoS2 paste.

Have the tool serviced as described in

Section 7.

Have the toothing of the ratchet wheel, pawls

and ratchets degreased.

or if the pawl/ratchet mechanism fails, the tool will need

servicing. We recommend returning the tool to STAHL-

WILLE for servicing. This will ensure the highest standard

of service at a reasonable price and guarantees that

only original spare parts are used. In addition, every

reconditioned MULTIPOWER is subjected to intensive

checks on a specially designed torque measuring device

before being returned to the customer.

The values assume 90 % exploitation of

the yield point and a total friction

of μ = 0.125.

⇨The maximum permitted input torque

MEmax. must not exceed 300 N m under

any circumstances!

LR

B0

L0

RK

SW

AK

BR

WR

H0

HR

Other manuals for multipower MP100-1500

1

Other Stahlwille Tools manuals

Stahlwille

Stahlwille SENSOTORK 712R/6 User manual

Stahlwille

Stahlwille perfectControl 7794-2 User manual

Stahlwille

Stahlwille TORSIOTRONIC TT 120 User manual

Stahlwille

Stahlwille multipower MP100-1500 User manual

Stahlwille

Stahlwille MULTIPOWER MP300 User manual

Stahlwille

Stahlwille MANOSKOP 755R/1 Manual

Stahlwille

Stahlwille Sensotork 713 User manual

Stahlwille

Stahlwille MANOSKOP 730D User manual

Stahlwille

Stahlwille SMARTCHECK USB/DAPTIQ User manual

Stahlwille

Stahlwille Manoskop 730N User manual